Abstract

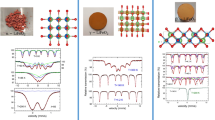

Ni-P alloys were prepared by electrodeposition on a copper substrate at different plating conditions (applied potential and deposition time). The morphology, composition, microstructure, structure, and magnetic properties of the films were investigated by scanning electron microscopy, energy-dispersive spectrometry, X-ray diffraction, and vibrating sample magnetometry, respectively. The phosphorous content is about 8.6–12.2 at.%. The deposits exhibit either a nanocomposite structure where Ni(P)–1 and Ni(P)–2 solid solutions are embedded into an amorphous matrix, or a mixture of Ni2P phosphide and Ni(P)–1 and Ni(P)–2 solid solutions. The coercivity and magnetization are plating condition dependent. All samples exhibit a soft magnetic character with coercivity lower than 58 Oe. The squareness ratio Mr/Ms values that are in the range 0.019–0.123 correspond to a multidomain (<0.1) for all samples except sample B (−1.15 V, 10 min) which falls into a pseudo-single domain (Mr/Ms = 0.123).

Similar content being viewed by others

References

Tebbakh, S., Messaoudi, Y., Azizi, A., Fenineche, N.E., Schmerber, G., Dinia, A.: Trans. IMF 93, 196 (2015)

Kim, D., Park, D.-Y., Yoo, B.Y., Sumodjo, P.T.A., Myung, N.V.: Electrochim. Acta 48, 819 (2003)

Jothi, S., Jianshe, L., Wei, S.: J. Alloys Compds. 571, 183 (2013)

Mallory, G.O., Hajdu, J.: Electroless plating: fundamental and applications. AESF, USA (1990)

Jeong, D.H., Erb, U., Aust, K.T., Palumbo, G.: Scripta Mater. 48, 1067 (2003)

Daly, B.P., Barry, F.J.: Int. Mater. Rev. 48, 326 (2003)

Haidu, J.: Trans. Inst. Met. Finish 75, B7 (1997)

Steplewski, W., Dziedzic, A., Borecki, J., Koziol, G., Serzysko, T.: Circuit World 40, 7 (2014)

Clark, P., Wang, X., Oyama, S.T.: J. Catal. 207, 256 (2002)

Jiaqiang, G., Yating, W., Lei, L., Bin, S., Wenbin, H.: Mater. Lett. 59, 1665 (2005)

Zhang, L., Jin, Y.B., Wang, Z., Yang, Y.X., Jianyu, Q.: Appl. Surf. Sci. 255, 1686 (2008)

Tjong, S.C., Chen, H.: Mat. Sci. Eng. R45, 1 (2004)

Bonino, J.-P.: J. Appl. Elect. 27, 1193 (1997)

Lin, C.S., Lee, C.Y., Chen, F.J., Li, W.C.: J. Electrochem. Soc. 152, C370 (2005)

Kumar, P.S., Nair, P.K. J.: Mater. Process. Technol. 56, 511 (1996)

Martyak, N.M.: Chem. Mater. 6, 1667 (1994)

Brenner, A., Couch, D.E., Williams, E.K.: J. Rees. Nat. Bar. Stand. 44, 109 (1950)

MAUD program, www.ing.unitn.it/~maud/

Rietveld, H.M.: J. Appl. Cryst. 2, 65 (1969)

Chen, B.H., Hong, L., Ma, Y., Ko, T.M.: Ind. Eng. Chem. Res. 41, 2668 (2002)

Sha, W., Murphy, C.J., Quinn, J.: J. Alloys Compd. 287, L7 (1999)

Balaraju, J.N., Millath Jahan, S., Jain, A., Rajam, K.S.: J. Alloys Compd. 436, 319 (2007)

Ashby, M.F., Jones, D.R.H.: Engineering Materials 2: An introduction to microstructure, processing and design, second ed., vol. 17. Butterworth Heinemann, Oxford (1998)

Luborsky, F.E.: Amorphous Metallic Alloys. Butterworths, London (1983)

Mahalingam, T., Raja, M., Thanikaikarasan, S., Sanjeeviraja, C., Velumani, S., Moon, H., Kim, Y.D.: Materials 58, 800 (2007)

Hentschel, T H, Isheim, D., Kirchheim, R., Müller, F., Kreye, H.: Acta Mater. 48, 933 (2000)

Färber, B., Cadel, E., Menand, A., Schmitz, G., Kirchheim, R.: Acta Mater. 48, 789 (2000)

Lu, K., Sui, M.L., Lück, R.: Nano Struct. Mater. 4, 465 (1994)

Fournet, G.: J. Phys. Radium 14, 374 (1953)

Stoner, E.C., Wohlfarth, E.P.: R. Soc. Lond. A 240, 599 (1948)

Fallot, M.: Ann. Phys. 6, 305 (1936)

Acknowledgments

This work was supported by the DGRSDT/PNR project no. 27/53, 2011 (MESRS) Algeria.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alleg, S., Boussaha, A., Tebib, W. et al. Microstructure and Magnetic Properties of NiP Alloys. J Supercond Nov Magn 29, 1001–1011 (2016). https://doi.org/10.1007/s10948-016-3397-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-016-3397-2