Abstract

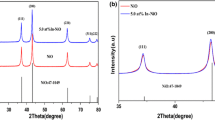

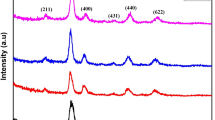

The work outlines the synthesis of mesoporous tin oxide (m-SnO2) with enhanced Nitrogen Dioxide (NO2) gas sensing performance by making use of Cetyl Trimethyl Ammonium Bromide (CTAB) as the soft template. Powder X-ray Diffraction (PXRD), Field Emission Scanning Electron Microscopy (FESEM), Transmission Electron Microscopy (TEM), Fourier Transform Infrared (FTIR) spectroscopy and X-ray Photoelectron Spectroscopy have been used to study the structural characteristics of mesoporous tin oxide. The average crystallite size calculated from the XRD technique was found to be 4.8 nm which is in corroboration with TEM analysis (4.9 nm). The FESEM indicated the porous morphology of the prepared sample which was also confirmed by N2 adsorption–desorption isotherms. The surface area and the average pore size of the sample were calculated from Brunauer–Emmett–Teller (BET) studies and Barrett–Joyner–Halenda (BJH) method and were found to be 154.4 m2 g−1 and 3.2 nm, respectively confirming the mesoporosity of the prepared tin oxide. The sensor was prepared by deposition of m-SnO2 thin film on Inter Digited Electrodes (IDE’s) of platinum decorated on a glass substrate. 10 parts per million concentration of oxidizing gas NO2 was tested on the fabricated sensor in the temperature range, 30 °C to 160 °C. Upon interacting with the gas, the sensor exhibited a response of 8635 with response time of 1s and recovery time of 165 s at 80 °C. The efficient sensor performance at 80 °C as observed in the present study is at much lower temperature in comparison with those reported earlier. The sensor has further shown good repeatability in terms of response and recovery at 80 °C. The sensor also exhibited good reproducibility and selectivity for NO2 gas. The enhanced sensor response of mesoporous tin oxide sensor is mainly because of large surface area (154.4 m2 g−1), mesoporous structure and small crystallite size (4.8 nm). The present study therefore establishes m-SnO2 as a potential candidate for efficient sensing of NO2 gas.

Similar content being viewed by others

Data availability

Data will be made available by corresponding author on reasonable request.

Code availability

Data will be made available by corresponding author on reasonable request.

References

Y.X. Zhen, B.Y. Song, W.X. Liu, J.X. Ye, X.F. Zhang, Z.P. Deng, L.H. Huo, S. Gao, Sens. Actuators B: Chem. (2022). https://doi.org/10.1016/j.snb.2022.13185210

N. Devabharathi, A.M. Umarji, S. Dasgupta, A.C.S. Appl, Mater. Interfaces (2020). https://doi.org/10.1021/ac.sami.0c14704

J.A. Bernstein, N. Alexis, C. Barnes, I.L. Berstein, J.A. Bernstein, A. Nel, D. Peden, D.D. Sanchez, S.M. Tarlo, P.B. Williams, J. Allergy Clin. Immunol. (2004). https://doi.org/10.1016/j.jaci.2004.08.030

K. Luo, R. Li, W. Li, Z. Wang, X. Ma, R. Zhang, X. Fang, Z. Wu, Y. Cao, Q. Xu, Sci. Rep. (2016). https://doi.org/10.1038/srep38328

S. Li, M. Cheng, G. Liu, L. Zhao, B. Zhao, H. Lu, H. Wang, J. Zhao, F. Liu, X. Yan, T. Zhang, G. Lu, J. Colloid Inerface Sci. (2018). https://doi.org/10.1016/j.jcis.2018.04.033

A.M. Ruiz, G. Sakai, A. Cornet, K. Shimanoe, J.R. Morante, N. Yamazoe, Sens. Actuators B: Chem. (2003). https://doi.org/10.1016/S0925-4005(03)00183-7

S. Kumar, V. Pavelyev, P. Mishra, N. Tripathi, P. Sharma, F. Calle, Mater. Sci. Semicond. Process. (2020). https://doi.org/10.1016/j.mssp.2019.104865

R.J. Vander, H.J. Eskes, K.F. Boersma, T.P.C. Vannoije, M.V. Roozendael, I.D. Smedt, D.H.M.U. Peters, E.W. Meijer, J. Geophys. Res. Atmos. (2008). https://doi.org/10.1029/2007JD009021

A.V. Agrawal, N. Kumar, M. Kumar, Nano Micro Lett. (2021). https://doi.org/10.1007/s40820-020-00558-3

R. Vasumathi, K.C. Lalithambika, D. Balamurugan, A. Thayumanavan, P. Neelamegam, S. Sriram, J. Comput. Electron. (2018). https://doi.org/10.1007/s10825-017-1091-7

A.K. Vishwakarma, L. Yadav, Environ. Sci. Pollut. Res. (2020). https://doi.org/10.1007/s11356-020-10211-6

T. Lin, X. Lv, Z. Hu, A. Xu, C. Feng, Sensors (2019). https://doi.org/10.3390/s19020233

B. Saruhan, R.L. Fomekong, S. Nahirniak, Front. Sens. (2021). https://doi.org/10.3389/fsens.2021.657931

N.D. Hoa, N.V. Duy, S.A. El-Safty, N.V. Hieu, J. Nanomater. (2015). https://doi.org/10.1155/2015/972025

N.D. Hoa, N.V. Duy, N.V. Hieu, Mater. Res. Bull. (2013). https://doi.org/10.1016/j.materresbull.2012.10.047

H. Wang, Y. Qu, H. Chen, Z. Lin, K. Dai, Sens. Actuators B. Chem. (2014). https://doi.org/10.1016/j.snb.2014.04.049

X. Wang, S. Qiu, J. Liu, C. He, G. Lu, Eur. J. Inorg. Chem. (2014). https://doi.org/10.1002/ejic.201301212

M. Dutt, A. Kaushik, M. Tomar, V. Gupta, V. Singh, J. Porous Mater. (2020). https://doi.org/10.1007/s10934-019-00811-0

Y. Lu, Q. Wang, G. Zhu, Q. Ran, F. Li, M. Guo, G. Wang, H. Zhao, Ceram. Int. (2023). https://doi.org/10.1016/j.ceramint.2023.03.253

A. Dey, Mater. Sci. Eng. B (2018). https://doi.org/10.1016/j.mseb.2017.12.036

G. Eranna, B.C. Joshi, D.P. Runthala, R.P. Gupta, Crit. Rev. Solid State Mater. Sci. (2010). https://doi.org/10.1080/10408430490888977

G. Korotcenkov, Mater. Sci. Eng. B (2007). https://doi.org/10.1016/j.mseb.2007.01.044

J. Xu, J. Han, Y. Zhang, Y. Sun, Sens. Actuators B: Chem. (2008). https://doi.org/10.1016/j.snb.2008.01.062

Y. Xu, C. Lou, L. Zheng, W. Zheng, X. Liu, M. Kumar, J. Zhang, Sens. Actuators B: Chem. (2020). https://doi.org/10.1016/j.snb.2019.127616

J. Wang, Z. Li, S. Zhang, S. Yan, B. Cao, Z. Wang, Y. Fu, Sens. Actuators B: Chem. (2018). https://doi.org/10.1016/j.snb.2017.08.149

X. Xiao, L. Liu, J. Ma, Y. Ren, X. Cheng, Y. Zhu, D. Zhao, A.A. Elzatahry, A. Alghamdi, Y. Deng, A.C.S. Appl, Mater. Interfaces (2018). https://doi.org/10.1021/acsami.7b18830

D. Mardare, N. Cornei, C. Mita, D. Florea, A. Stancu, V. Tiron, A. Manole, C. Adomnitei, Ceram. Int. (2016). https://doi.org/10.1016/j.ceramint.2016.01.137

S. Steinhauer, E. Brunet, T. Maier, G.C. Mutinati, A. Kock, O. Freudenberg, C. Gspan, W. Grogger, A. Neuhold, R. Resel, Sens. Actuators B: Chem (2013). https://doi.org/10.1016/j.snb.2012.09.034

I. Hotovy, V. Rehacek, P. Siciliano, S. Capone, L. Spiess, Thin Solid Films (2002). https://doi.org/10.1016/S0040-6090(02)00579-5

J.M. Xu, J.P. Cheng, J. Alloys Compd. (2016). https://doi.org/10.1016/j.jallcom.2016.06.086

K. Schneider, M. Lubecka, A. Czapla, Sens. Actuators B: Chem. (2016). https://doi.org/10.1016/j.snb.2016.04.059

S. Bai, S. Chen, L. Chen, K. Zhang, R. Luo, D. Li, C.C. Liu, Sens. Actuators B: Chem. (2012). https://doi.org/10.1016/j.snb.2012.08.015

I. Boehme, U. Weimar, N. Barsan, Sens. Actuators B: Chem. (2021). https://doi.org/10.1016/j.snb.2020.129004

X. Li, K. Peng, Y. Dou, J. Chen, Y. Zhang, G. An, Nanoscale Res. Lett. (2018). https://doi.org/10.1186/s11671-018-2434-4

S.M. Ingole, S.T. Navale, Y.H. Navale, D.K. Bandgar, F.J. Stadler, R.S. Mane, N.S. Ramgir, S.K. Gupta, D.K. Aswal, V.B. Patil, J. Colloid Interface Sci. (2017). https://doi.org/10.1016/j.jcis.2017.01.025

R. Zhang, X. Liu, T. Zhou, L. Wang, T. Zhang, J. Colloid Interface Sci. (2018). https://doi.org/10.1016/j.jcis.2018.04.015

H.J. Kim, S.B. Jo, J.H. Ahn, B.W. Hwang, H.J. Chae, S.Y. Kim, J.S. Huh, D. Ragupathy, S.C. Lee, J.C. Kim, Adsorption (2019). https://doi.org/10.1007/s10450-019-00105-6

M.G. Masteghin, R.A. Silva, D.C. Cox, D.R.M. Godoi, S.R.P. Silva, M.O. Orlandi, Phys. Chem. Chem. Phys. (2021). https://doi.org/10.1039/D1CP00662B

M. Rieu, M. Camara, G. Tournier, J.P. Viricelle, C. Pijolat, N.F. de Rooij, D. Briand, Sens (Chem, Actuators B, 2016). https://doi.org/10.1016/j.snb.2016.06.042

J. Wang, H. Shen, Y. Xia, S. Komarneni, Ceram. Int. (2021). https://doi.org/10.1016/j.ceramint.2020.11.187

M.A. Andio, P.N. Browning, P.A. Morris, S.A. Akbar, Sens. Actuators: B. Chem. (2012). https://doi.org/10.1016/j.snb.2011.12.045

Y. Liu, J. Goebl, Y. Yin, Chem. Soc. Rev. (2013). https://doi.org/10.1039/C2CS35369E

M.Y. Ahmad, M.Z.A. Bakar, J. Jushila, Am. J. Chem. (2016). https://doi.org/10.5923/j.chemistry.20160605.04

J. Zhao, W. Wang, Y. Liu, J. Ma, X. Li, Y. Du, G. Lu, Sens. Actuators B: Chem. (2011). https://doi.org/10.1016/j.snb.2011.08.035

N.D. Petkovich, A. Stein, Chem. Soc. Rev. (2013). https://doi.org/10.1039/C2CS35308C

R. Daiyan, X. Lu, W.H. Saputera, Y.H. Ng, R. Amal, ACS Sustain. Chem. Eng. (2018). https://doi.org/10.1021/acssuschemeng.7b02913

Y. Wang, C. Liu, L. Wang, J. Liu, B. Zhang, Y. Gao, P. Sun, Y. Sun, T. Zhang, G. Lu, Sens. Actuators B: Chem. (2017). https://doi.org/10.1016/j.snb.2016.07.160

Y. Meng, D. Gu, F. Zhang, Y. Shi, H. Yang, Z. Li, C. Yu, B. Tu, D. Zhao, Angew. Chem. Int. Ed. (2005). https://doi.org/10.1002/anie.200501561

W. Li, Z. Wu, J. Wang, A.A. Elzatahr, D. Zhao, Chem. Mater. (2014). https://doi.org/10.1021/cm4014859

A.H. Lu, F. Schuth, C. R. Chim. (2005). https://doi.org/10.1016/j.crci.2004.10.020

A.H. Lu, F. Schuth, Adv. Mater. (2006). https://doi.org/10.1002/adma.200600148

Y. Wang, C. Ma, X. Sun, H. Li, Microporous Mesoporous Mater. (2001). https://doi.org/10.1016/S1387-1811(01)00415-2

D.J. Late, Y.K. Huang, B. Liu, J. Acharya, S.N. Shirodkar, J. Luo, A. Yan, D. Charles, U.V. Waghmare, V.P. Dravid, C.N.R. Rao, ACS Nano (2013). https://doi.org/10.1021/nn400026u

Y. Li, N. Chen, D. Deng, X. Xing, X. Xiao, Y. Wang, Sens. Actuators B: Chem. (2017). https://doi.org/10.1016/j.snb.2016.07.051

A. Khoudro, Chem. Mater. Res. (2020). https://doi.org/10.7176/CMR/10-5-02

Z.M. Jarzebski, J.P. Marton, J. Electrochem. Soc. (1976). https://doi.org/10.1149/1.2133010

T.T. Li, L. Xia, H. Yu, X.X. Huang, J. Mater. Sci. (2020). https://doi.org/10.1007/s10853-020-04892-0

P. Sudarsanam, P.R. Selvakannan, S.K. Soni, S.K. Bhargava, B.M. Reddy, RSC Adv. (2014). https://doi.org/10.1039/C4RA07450E

P. Manjunathan, V.S. Marakatti, P. Chandra, A.B. Kulal, S.B. Umbarkar, R. Ravishankar, G.V. Shanbhag, Catal. Today (2018). https://doi.org/10.1016/j.cattod.2017.10.009

D. Bahati, M. Prasanna, P.V.K. Rao, Open Sci. J. (2020). https://doi.org/10.23954/osj.v5i3.2444

S. Yang, L. Gao, J. Am. Ceram. Soc. (2006). https://doi.org/10.1111/j.1551-2916.2006.00947.x

Y.D. Wang, C.L. Ma, X.H. Wu, X.D. Sun, H.D. Li, Sens. Actuators B: Chem. (2002). https://doi.org/10.1016/S0925-4005(02)00131-4

C. Zhang, J. Wang, R. Hu, Q. Qiao, X. Li, Sens. Actuators B: Chem. (2016). https://doi.org/10.1016/j.snb.2015.08.016

G. Xi, Y. He, Q. Zhang, H. Xiao, X. Wang, C. Wang, J. Phys. Chem. C (2008). https://doi.org/10.1021/jp802180z

J. Huang, L. Wang, C. Gu, Z. Wang, Y. Sun, J.J. Shim, Sens. Actuators: B. Chem. (2015). https://doi.org/10.1016/j.snb.2014.10.128

B. Bhangre, N.S. Ramgir, S. Jagtap, A.K. Debnath, K.P. Muthe, C. Terashima, D.K. Aswal, S.W. Gosavi, A. Fujishima, Appl. Surf. Sci. (2019). https://doi.org/10.1016/j.apsusc.2019.05.176

Y. Tao, Q. Gao, J. Di, X. Wu, J. Nanosci. Nanotechnol. (2013). https://doi.org/10.1166/jnn.2013.7559

D. Li, B. Zhang, J. Xu, Y. Han, H. Jin, D. Jin, X. Peng, H. Ge, X. Wang, Nanotechnology (2016). https://doi.org/10.1088/0957-4484/27/18/185702

M. Dutt, A. Ratan, M. Tomar, V. Gupta, V. Singh, J. Phys. Chem. Solids (2020). https://doi.org/10.1016/j.jpcs.2020.109536

S. Seal, S. Shukla, JOM (2002). https://doi.org/10.1007/BF02709091

C. Xu, J. Tamaki, N. Miura, N. Yamazoe, J. Electrochem. Soc. Jap. (1990). https://doi.org/10.5796/kogyobutsurikagaku.58.1143

H. Ogawa, M. Nishikawa, A. Abe, J. Appl. Phys. (1982). https://doi.org/10.1063/1.331230

L. Zhou, Z. Hu, H.Y. Li, J. Liu, Y. Zheng, J. Wang, Y. Huang, L. Miao, G. Zhang, Y. Huang, J. Jiang, S. Jiang, H. Liu, A.C.S. Appl, Mater. Interfaces (2021). https://doi.org/10.1021/acsami.1c04651

D.L. Kamble, N.S. Harale, V.L. Patil, P.S. Patil, L.D. Kadam, J. Anal. Appl. Pyrolysis (2017). https://doi.org/10.1016/j.jaap.2017.09.004

H. Zhang, M. Zhuo, Y. Luo, Y. Chen, J. Semicond. (2017). https://doi.org/10.1088/1674-4926/38/2/023003

W. Du, N. Wu, Z. Wang, J. Liu, D. Xu, W. Liu, Sens. Actuators B: Chem. (2018). https://doi.org/10.1016/j.snb.2017.10.130

M.K. Sohal, A. Mahajan, S. Gasso, R.K. Bedi, R.C. Singh, A.K. Debnath, D.K. Aswal, Sens. Actuators B: Chem. (2021). https://doi.org/10.1016/j.snb.2020.129169

A. Sharma, M. Tomar, V. Gupta, Sens. Actuators B: Chem. (2011). https://doi.org/10.1016/j.snb.2011.02.033

A. Sharma, M. Tomar, V. Gupta, J. Mater. Chem. (2012). https://doi.org/10.1039/C2JM35172B

W. Li, K. Kan, L. He, L. Ma, X. Zhang, J. Si, M. Ikram, M. Ullah, M. Khan, Appl. Surf. Sci. (2020). https://doi.org/10.1016/j.apsusc.2020.145657

H. Liu, J. Wan, Q. Fu, M. Li, W. Luo, Z. Zheng, H. Cao, Y. Hu, D. Zhou, Sens. Actuators B: Chem. (2013). https://doi.org/10.1016/j.snb.2012.11.051

X. Zhao, W. Shi, H. Mu, H. Xie, J. Alloys Compd. (2016). https://doi.org/10.1016/j.jallcom.2015.11.015

C. Zhang, A. Boudiba, P.D. Marco, R. Snyders, M.G. Olivier, M. Debliquy, Sens. Actuators B: Chem. (2013). https://doi.org/10.1016/j.snb.2013.01.082

C. Xu, J. Tamaki, M. Norio, Y. Noboru, Chem. Lett. (1990). https://doi.org/10.1246/cl.1990.441

Acknowledgements

The authors acknowledge the support and facilities of Guru Gobind Singh Indraprastha University, New Delhi. The authors acknowledge USIC, University of Delhi for FTIR and FESEM characterization, AIRF, JNU for XRD characterization, MARC Bengaluru for N2 sorption studies and XPS studies, SAIF AIIMS for TEM characterization, Miranda House, University of Delhi for providing gas sensing facilities. Vaishali Singh is thankful to GGSIPU for providing financial assistance under the FRGS grant (File No-GGSIPU/DRC/FRGS/2022/1223/12). Alka Singh acknowledges the fellowship support in the form of Indraprastha research fellowship (IPRF) from Guru Gobind Singh Indraprastha University.

Author information

Authors and Affiliations

Contributions

AS: Conceptualization, Methodology, Formal analysis, Investigation, Data curation, Writing-original draft, Writing-review & editing, Visualization. MV: Writing-review & editing. SM: Methodology, Formal analysis, Writing-review & editing. MT: Resources, Writing-review & editing. AC: Resources, Writing-review & editing. VS: Conceptualization, Methodology, Formal analysis, Writing-original draft, Writing-review & editing, Supervision, Funding acquisition.

Corresponding author

Ethics declarations

Competing interests

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethical approval

Not Applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Singh, A., Vats, M., Mohapatra, S. et al. Template-assisted mesoporous SnO2 based gas sensor for NO2 detection at low temperature. J Porous Mater 31, 545–555 (2024). https://doi.org/10.1007/s10934-023-01528-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-023-01528-x