Abstract

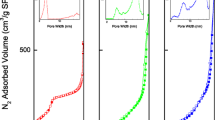

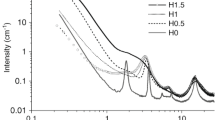

Well-defined spherical particles of silica, containing phenyl group, with the diameter of ca. 2 microns were prepared by the co-condensation of tetraethoxysilane with phenyltriethoxysilane in basic aqueous methanol solutions of hexadecyltrimethylammonium chloride. The products were hydrophobic. The content of phenyl group was controlled by the ratio of tetraethoxysilane and phenyltriethoxysilane in the starting solution. Hexadecyltrimethylammonium was extracted with methanolic HCl to obtain nanoporous silica spherical particle containing phenyl group. The spherical particle possessed pore size of 1.8 nm and the BET surface area of 750 m2 g−1.

Similar content being viewed by others

References

G.J.A.A. Soler-Illia, C. Sanchez, B. Lebeau, J. Patarin, Chemical strategies to design textured materials: from microporous and mesoporous oxides to nanonetworks and hierarchical structures. Chem. Rev. 102, 4093–4120 (2002)

K. Ariga, A. Vinu, Y. Yamauchi, Q.M. Ji, J.P. Hill, Nanoarchitectonics for mesoporous materials. Bull. Chem. Soc. Jpn. 85, 1–32 (2012)

E. Ruiz-Hitzky, P. Aranda, M. Darder, M. Ogawa, Hybrid and biohybrid silicate based materials: molecular versus block-assembling bottom-up processes. Chem. Soc. Rev. 40, 801–828 (2011)

V. Malgras, H. Ataee-Esfahani, H. Wang, H.B. Jiang, H.C. Li, K.C.C. Wu, J.H. Kim, Y. Yamauchi, Nanoarchitectures for mesoporous metals. Adv. Mater. 28, 993–1010 (2016)

G.J. Croissant, X. Cattoën, M. Wong Chi Man, J.-O. Durand, N.M. Khashab, Syntheses and applications of periodic mesoporous organosilica nanoparticles. Nanoscale 7, 20318–20334 (2015)

M. Ogawa, Formation of novel oriented transparent film of layered silica-surfactant nanocomposites. J. Am. Chem. Soc. 116, 7941–7942 (1994)

M. Ogawa, A simple sol–gel route for the preparation of silica-surfactant mesostructured materials. Chem. Commun. 10, 1149–1150 (1996)

M. Ogawa, Preparation of silica-dialkyldimethylammonium salts nanocomposites. Langmuir, 13, 1853–1855 (1997)

M. Ogawa, T. Igarashi, K. Kuroda, Preparation of transparent silica-surfactant nanocomposite films with controlled microstructures. Bull. Chem. Soc. Jpn. 70, 2833–2837 (1997)

M. Ogawa, H. Ishikawa, T. Kikuchi, Preparation of transparent mesoporous silica films by a rapid solvent evaporation method. J. Mater. Chem. 8, 1783–1786 (1998)

P.J. Bruinsma, A.Y. Kim, J. Liu, S. Baskaran, Mesoporous silica synthesized by solvent evaporation: spun fibers and spray-dried hollow spheres. Chem. Mater. 9, 2507–2511 (1997)

M.T. Anderson, J.E. Martin, J.G. Odinek, P.P. Newcomer, J.P. Wilcoxon, Monolithic periodic mesoporous silica gels. Microporous Mesoporous Mater. 10, 13–18 (1997)

P.T. Tanev, Y. Liang, T.J. Pinnavaia, Assembly of mesoporous lamellar silicas with hierarchical particle architectures. J. Am. Chem. Soc. 119, 86–89 (1997)

H.-P. Lin, C.-Y. Mou, Tubules-within-A-tubule hierarchical order of mesoporous molecular sieves in MCM-41. Science 273, 765–768 (1996)

H.-P. Lin, Y.-R. Chen, C.-Y. Mou, Hierarchical order in hollow spheres of mesoporous silicates. Chem. Mater. 10, 3772–3775 (1998)

H. Imai, N. Takahashi, R. Tamura, H. Hirashima, Formation of whiskers of silicate mesostructures. Langmuir 17, 17–20 (2001)

H. Yang, N. Coombs, G.A. Ozin, Morphogenesis of shapes and surface patterns in mesoporous silica. Nature 386, 692–695 (1997)

S. Che, Z. Liu, T. Ohsuna, K. Sakamoto, O. Terasaki, T. Tatsumi, Synthesis and characterization of chiral mesoporous silica. Nature 429, 281–284 (2004)

Y. Sakamoto, M. Kaneda, O. Terasaki, D.Y. Zhao, J.M. Kim, G.D. Stucky, H.J. Shin, R. Ryoo, Direct imaging of the pores and cages of three-dimensional mesoporous materials. Nature 408, 449–453 (2000)

Q. Huo, J. Feng, F. Schüth, G.D. Stucky, Preparation of hard mesoporous silica spheres. Chem. Mater. 9, 14–17 (1997)

S.M. Yang, N. Coombs, G.A. Ozin, Micromolding in inverted polymer opals (MIPO): synthesis of hexagonal mesoporous silica opals. Adv. Mater. 12, 1940–1943 (2000)

Y. Lu, H. Fan, A. Stump, L.T. Ward, T. Rieker, C.J. Brinker, Aerosol-assisted self-assembly of mesostructured spherical nanoparticles. Nature 398, 223–226 (1999)

W. Stöber, A. Fink, E. Bohn, Controlled growth of monodispersed silica spheres in the micron size range. J. Colloid Interface Sci. 26, 62–69 (1968)

K. Schumacher, M. Grün, K.K. Unger, Novel synthesis of spherical MCM-48. Microporous Mesoporous Mater. 27, 201–206 (1999)

R.I. Nooney, D. Thirunavukkarasu, R. Chen, Y. Josephs, A.E. Ostafin, Synthesis of nanoscale mesoporous silica spheres with controlled particle size. Chem. Mater. 14, 4721–4728 (2002)

K. Yano, N. Suzuki, Y. Akimoto, Y. Fukushima, Synthesis of mono-dispersed mesoporous silica spheres with hexagonal symmetry. Bull. Chem. Soc. Jpn. 75, 1977–1982 (2002)

N. Shimura, M. Ogawa, Growth of nanoporous silica spherical particles by the stober method combined with supermolecular templating approach. Bull. Chem. Soc. Jpn. 78, 1154–1159 (2005)

N. Shimura, M. Ogawa, Preparation of surfactant template nanoporous silica spherical particles by the stober method, effect of solvent composition on the particle size. J. Mater. Sci. 42, 5299–5306 (2007)

K. Kambara, N. Shimura, M. Ogawa, Larger scale syntheses of surfactant-templated nanoporous silica spherical particles by the stöber method. J. Ceram. Soc. Jpn. 115, 315–318 (2007)

S.H. Wu, C.Y. Mou, H.P. Lin, Synthesis of mesoporous silica nanoparticles. Chem. Soc. Rev. 42, 3862–3875 (2013)

K. Shiba, N. Shimura, M. Ogawa, Mesoporous silica spherical particles. J. Nanosci. Nanotech. 13, 2483–2494 (2013)

M. Etienne, A. Lebeau, B. Walcarius, Organically-modified mesoporous silica spheres with MCM-41 architecture. New J. Chem. 26, 384–386 (2002)

S. Huh, J.W. Wiench, J.C. Yoo, M. Pruski, V.S.Y. Lin, Organic functionalization and morphology control of mesoporous silicas via a co-condensation synthesis method. Chem. Mater. 15, 4247–4250 (2003)

S. Sadasivan, D. Khushalani, S. Mann, Synthesis and shape modification of organo-functionalised silica nanoparticles with ordered mesostructured interiors. J. Mater. Chem. 13, 1023–1027 (2003)

C.Y. Lai, B.G. Trewyn, D.M. Jeftinija, K. Jeftinija, S. Xu, S. Jeftinija, V.S.Y. Lin, A mesoporous silica nanosphere-based carrier system with chemically removable CdS nanoparticle caps for stimuli-responsive controlled release of neurotransmitters and drug molecules. J. Am. Chem. Soc. 125, 4451–4459 (2003)

T. Yokoi, H. Yoshitake, T. Yamada, Y. Kubota, T. Tatsumi, Amino-functionalized mesoporous silica synthesized by an anionic surfactant templating route. J. Mater. Chem. 16, 1125–1135 (2006)

D.J. Kim, J.S. Chung, W.S. Ahn, G.W. Kang, W.J. Cheong, Morphology control of organic–inorganic hybrid mesoporous silica by microwave heating. Chem. Lett. 33, 422–423 (2004)

M.P. Kapoor, S. Inagaki, Synthesis of phenylene bridged mesoporous silsesquioxanes with spherical morphology in ammonia solution. Chem. Lett. 33, 88–89 (2004)

J. Wang, F. Li, H. Zhou, P. Sun, D. Ding, T. Chen, Silica hollow spheres with ordered and radially oriented amino-functionalized mesochannels. Chem. Mater. 21, 612–620 (2009)

A. Walcarius, S. Sayen, C. Gérardin, F. Hamdoune, L. Rodehüser, Dipeptide-functionalized mesoporous silica spheres. Colloids Surf. A 234, 145–151 (2004)

S. Brunauer, P.H. Emmett, E. Teller, Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 60, 309–319 (1938)

E.P. Barrett, L.G. Joyner, P.P. Halenda, The determination of pore volume and area distributions in porous substances. I. computations from nitrogen isotherms. J. Am. Chem. Soc. 73, 373 (1951)

M. Ogawa, Photoprocesses in mesoporous silicas prepared by supramolecular templating approaches. J. Photochem. Photobiol. C Photochem. Rev. 3, 129–146 (2002)

M. Ogawa, K. Saito, M. Sohmiya, Possible roles of the spatial distribution of organic guest species in mesoporous silicas to control the properties of the hybrids. Eur. J. Inorg. Chem. 2015, 1126–1136 (2015)

M. Sohmiya, K. Saito, M. Ogawa, Host-guest chemistry of mesoporous silicas; precise design of location and orientation of molecular guests in mesopore. Sci. Tech. Adv. Mater. 16, 054201 (2015)

U. Ciesla, F. Schuth, Ordered mesoporous materials. Micropor. Mesopor. Mater. 27, 131–149 (1999)

B.J. Scott, G. Wirnsberger, G.D. Stucky, Mesoporous and mesostructured materials for optical applications. Chem. Mater. 13, 3140–3150 (2001)

A. Taguchi, F. Schuth, Ordered mesoporous materials in catalysis. Micropor. Mesopor. Mater. 77, 1–45 (2005)

A. Stein, Advances in microporous and mesoporous solids. Adv. Mater. 15, 763–775 (2003)

M. Barboiu, Constitutional hybrid materials—toward selection of functions. Eur. J. Inorg. Chem. 2015, 1112–1125 (2015)

T.H. Tran-Thi, R. Dagnelie, S. Crunaire, L. Nicole, Optical chemical sensors based on hybrid organic–inorganic sol–gel nanoreactors. Chem. Soc. Rev. 40, 621–639 (2011)

B. Lebeau, P. Innocenzi, Hybrid materials for optics and photonics. Chem. Soc. Rev. 40, 886–906 (2011)

G.J. Soler-Illia, O. Azzaroni, Multifunctional hybrids by combining ordered mesoporous materials and macromolecular building blocks. Chem. Soc. Rev. 40, 1107–1150 (2011)

N. Mizoshita, T. Tani, S. Inagaki, Syntheses, properties and applications of periodic mesoporous organosilicas prepared from bridged organosilane precursors. Chem. Soc. Rev. 40, 789–800 (2011)

K. Ariga, Q. Ji, T. Mori, M. Naito, Y. Yamauchi, H. Abe, J.P. Hill, Enzyme nanoarchitectonics: organization and device application. Chem. Soc. Rev. 42, 6322–6345 (2013)

M. Ogawa, N. Shimura, A. Ayral, Deposition of thin nanoporous silica layer on solid surfaces. Chem. Mater. 18, 1715–1718 (2006)

N. Shimura, M. Ogawa, Deposition of thin mesoporous silica films on glass substrates from basic solution. J. Colloid Interface Sci. 303, 250–255 (2006)

R. Hashimoto, Y. Tsuji, M. Ogawa, The syntheses of thin layers of organosilica by the co-condensation of tetraethoxysilane and phenyltriethoxysilane in the presence of cationic surfactant. J. Mater. Sci. 47, 2195–2200 (2012)

R. Kato, N. Shimura, M. Ogawa, Contorolled photocatalytic ability of titanium dioxide particle by coating with nanoporous silica. Chem. Lett. 37, 76–77 (2008)

K.J. Nakamura, Y. Ide, M. Ogawa, Molecular recognitive photocatalytic decomposition on mesoporous silica coated TiO2 particle. Mater. Lett. 65, 24–26 (2011)

Y. Ide, Y. Koike, M. Ogawa, Molecular selective photocatalysis by TiO2/nanoporous silica core/shell particulates. J. Colloid Interface Sci. 358, 245–251 (2011)

M. Ogawa, D. Naito, N. Shimura, Preparation of ZnO–core/nanoporous silica-shell particle and the conversion to hollow nanoporous silica particle. Chem. Lett. 36, 462–463 (2007)

N. Shimura, M. Ogawa, Preparation of hexagonal platy particle of nanoporous silica using hydrotalcite particle as morphology template. J. Colloid Interface Sci. 312, 311–316 (2007)

P.A. Williamson, P.J. Blower, M.A. Green, Synthesis of porous hollow silica nanostructures using hydroxyapatite nanoparticle templates. Chem. Commun. 47, 1568–1570 (2011)

Y. Chen, H. Chen, Y. Sun, Y. Zheng, D. Zeng, F. Li, S. Zhang, X. Wang, K. Zhang, M. Ma, Q. He, L. Zhang, J. Shi, Multifunctional mesoporous composite nanocapsules for highly efficient MRI-guided high-intensity focused ultrasound cancer surgery. Angew. Chem. Int. Ed. 50, 12505–12509 (2011)

J.P. Yang, D.K. Shen, L. Zhou, W. Li, X.M. Li, C. Yao, R. Wang, A.M. El-Toni, F. Zhang, D. Zhao, Spatially confined fabrication of core–shell gold nanocages@mesoporous silica for near-infrared controlled photothermal drug release. Chem. Mater. 25, 3030–3037 (2013)

Z.H. Bai, R. Chen, P. Si, Y.J. Huang, H.D. Sun, D.H. Kim, Fluorescent pH sensor based on Ag@SiO2 core–shell nanoparticle. ACS Appl. Mater. Interfaces 5, 5856–5860 (2013)

Y. Song, X. Cao, Y. Guo, P. Chen, Q. Zhao, G. Shen, Fabrication of mesoporous CdTe/ZnO@SiO2 core/shell nanostructures with tunable dual emission and ultrasensitive fluorescence response to metal ions. Chem. Mater. 21, 68–77 (2009)

G.Q. Wang, Z.P. Chen, L.X. Chen, Mesoporous silica-coated gold nanorods: towards sensitive colorimetric sensing of ascorbic acid via target-induced silver overcoating. Nanoscale 3, 1756–1759 (2011)

L. Zhang, W.C. Geng, S.Z. Qiao, H.J. Zheng, G.Q. Lu, Z.F. Yan, Fabrication and biosensing with CNT/aligned mesostructured silica core–shell nanowires. ACS Appl. Mater. Interface 2, 2767–2772 (2010)

J. Gamonchuang, N. Khaorapapong, M. Ogawa, The effect of alcohol type on the thickness of silica layer of Co3O4@SiO2 core-shell particle. Colloids Surf. A 511, 39–46 (2016)

K. Shiba, M. Ogawa, Mesoporous silica coated silica–titania spherical particles; from impregnation to core–shell formation. Dalton Trans. 45, 18742–18749 (2016)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hashimoto, R., Ogawa, M. Facile syntheses of nanoporous organosilica spherical particles. J Porous Mater 25, 425–431 (2018). https://doi.org/10.1007/s10934-017-0453-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-017-0453-7