Abstract

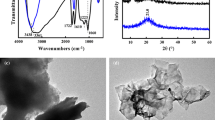

Polymer-based membrane separation technology is gaining popularity due to its cost-effectiveness and operational simplicity. Cellulose acetate (CA) stands out as an attractive biobased polymer for membrane applications due to its remarkable mechanical properties and ease of manufacturing. To improve the selectivity of CA-based membranes for carbon dioxide (CO2) separation, the incorporation of polyethylene glycol methyl ether acrylate (PEGMEA), known for its CO2 absorption properties, has emerged as a promising approach for creating high-performance membrane materials with low operating pressure. This study provides insight into the production of PEGMEA-grafted CA membranes via gamma radiation and their performance for CO2/CH4 gas separation. CO2 permeation of the obtained CA-PEGMEA membranes was successfully improved and achieved the desired selectivity for CO2/CH4 separation. A comprehensive study of the membrane properties was conducted, encompassing structural characterization, surface analysis, permeability, selectivity, thermal analysis, and crystallinity, which are essential for understanding and assessing the membrane’s performance. This work emphasizes gamma radiation graft polymerization and shows its applicability for high-performance gas separation membrane materials.

Similar content being viewed by others

References

Mubashir M, Yeong YF, Lau KK, Chew TL, Norwahyu J (2018) Efficient CO2/N2 and CO2/CH4 separation using NH2-MIL-53(Al)/cellulose acetate (CA) mixed matrix membranes. Sep Purif Technol 199:140–151. https://doi.org/10.1016/j.seppur.2018.01.038

Tanvidkar P, Nayak B, Kuncharam BVR (2023) Study of dual filler mixed matrix membranes with acid-functionalized MWCNTs and metal-organic framework (UiO-66-NH2) in cellulose acetate for CO2 separation. J Polym Environ 31(8):3404–3417. https://doi.org/10.1007/s10924-023-02827-9

Shakeel I, Hussain A, Farrukh S (2019) Effect analysis of nickel ferrite (NiFe2O4) and titanium dioxide (TiO2) nanoparticles on CH4/CO2 gas permeation properties of cellulose acetate based mixed matrix membranes. J Polym Environ 27(7):1449–1464. https://doi.org/10.1007/s10924-019-01442-x

Vatanpour V et al (2022) Cellulose acetate in fabrication of polymeric membranes: a review. Chemosphere 295:133914

Douna I, Farrukh S, Pervaiz E, Hussain A, Fan XF, Salahuddin Z (2023) Blending of ZnO nanorods in cellulose acetate mixed matrix membrane for enhancement of CO2 permeability. J Polym Environ 31(6):2549–2565. https://doi.org/10.1007/s10924-022-02594-z

Abdelwahab NA, Ammar NS, Ibrahim HS (2015) Graft copolymerization of cellulose acetate for removal and recovery of lead ions from wastewater. Int J Biol Macromol 79:913–922

Billy M et al (2010) Cellulose acetate graft copolymers with nano-structured architectures: synthesis and characterization. Eur Polymer J 46(5):944–957

Teramoto Y, Ama S, Higeshiro T, Nishio Y (2004) Cellulose acetate-graft-poly(hydroxyalkanoate)s: synthesis and dependence of the thermal properties on copolymer composition. Macromol Chem Phys 205(14):1904–1915

Alaslai N, Ghanem B, Alghunaimi F, Litwiller E, Pinnau I (2016) Pure-and mixed-gas permeation properties of highly selective and plasticization resistant hydroxyl-diamine-based 6FDA polyimides for CO2/CH4 separation. J Membr Sci 505:100–107

He X (2016) Membranes for natural gas sweetening. Encyclopedia of membranes. Springer, pp 1266–1267

Xu J, Wu H, Wang Z, Qiao Z, Zhao S, Wang J (2018) Recent advances on the membrane processes for CO2 separation. Chin J Chem Eng 26(11):2280–2291

Ji P et al (2009) Preparation of hollow fiber poly(N,N-dimethylaminoethyl methacrylate)–poly(ethylene glycol methyl ether methyl acrylate)/polysulfone composite membranes for CO2/N2 separation. J Membr Sci 342(1–2):190–197

Wang B, Chen J, Peng H, Gai J, Kang J, Cao Y (2016) Investigation on changes in the miscibility, morphology, rheology and mechanical behavior of melt processed cellulose acetate through adding polyethylene glycol as a plasticizer. J Macromol Sci B 55(9):894–907

Rodrigues Filho G et al (2007) Water flux, DSC, and cytotoxicity characterization of membranes of cellulose acetate produced from sugar cane bagasse, using PEG 600. Polym Bull 59:73–81

Liu J, Hou X, Park HB, Lin H (2016) High-performance polymers for membrane CO2/N2 separation. Chemistry 22(45):15980–15990

Fan W et al (2021) Multivariate polycrystalline metal–organic framework membranes for CO2/CH4 separation. J Am Chem Soc 143(42):17716–17723

Cao W et al (2017) Hydrophilicity effect on CO2/CH4 separation using carbon nanotube membranes: insights from molecular simulation. Mol Simul 43(7):502–509

Casado-Coterillo C, Garea A, Irabien Á (2020) Effect of water and organic pollutant in CO2/CH4 separation using hydrophilic and hydrophobic composite membranes. Membranes 10(12):405

Shafie SNA, Man Z, Idris A (2017) Development of polycarbonate-silica matrix membrane for CO2/CH4 separation. AIP conference proceedings, vol 1891(1). AIP Publishing

Kim NU, Kim J-H, Park BR, Kim KC, Kim JH (2021) Solid-state facilitated transport membrane for CO/N2 separation based on PHMEP-co-PAA comb-like copolymer: experimental and molecular simulation study. J Membr Sci 620:118939

Wu L-G, Shen J-N, Chen H-L, Gao C-J (2006) CO2 facilitated transport through an acrylamide and maleic anhydride copolymer membrane. Desalination 193(1–3):313–320

Nasef MM, Güven O (2012) Radiation-grafted copolymers for separation and purification purposes: status, challenges and future directions. Prog Polym Sci 37(12):1597–1656

Nasef MM, Hegazy E-SA (2004) Preparation and applications of ion exchange membranes by radiation-induced graft copolymerization of polar monomers onto non-polar films. Prog Polym Sci 29(6):499–561

Febriasari A et al (2021) Gamma irradiation of cellulose acetate-polyethylene glycol 400 composite membrane and its performance test for gas separation. Int J Technol 12(6):1198–1206

Espiritu R, Mamlouk M, Scott K (2016) Study on the effect of the degree of grafting on the performance of polyethylene-based anion exchange membrane for fuel cell application. Int J Hydrogen Energy 41(2):1120–1133

Epp J (2016) X-ray diffraction (XRD) techniques for materials characterization. Materials characterization using nondestructive evaluation (NDE) methods. Elsevier, pp 81–124

Mubashir M et al (2021) Cellulose acetate-based membranes by interfacial engineering and integration of ZIF-62 glass nanoparticles for CO2 separation. J Hazard Mater 415:125639

Park J, Paul D (1997) Correlation and prediction of gas permeability in glassy polymer membrane materials via a modified free volume based group contribution method. J Membr Sci 125(1):23–39

Song C et al (2020) Pebax/MWCNTs-NH2 mixed matrix membranes for enhanced CO2/N2 separation. Greenhouse Gases Sci Technol 10(2):408–420

Ismail AF, Khulbe KC, Matsuura T (2015) Gas separation membranes, vol 10. Springer, Switzerland, pp 973–978

Ghadimi A, Norouzbahari S, Lin H, Rabiee H, Sadatnia B (2018) Geometric restriction of microporous supports on gas permeance efficiency of thin film composite membranes. J Membr Sci 563:643–654

Li Y, Cao C, Chung T-S, Pramoda KP (2004) Fabrication of dual-layer polyethersulfone (PES) hollow fiber membranes with an ultrathin dense-selective layer for gas separation. J Membr Sci 245(1):53–60. https://doi.org/10.1016/j.memsci.2004.08.002

Baracaldo-Santamaría D, Calderon-Ospina CA, Ortiz CP, Cardenas-Torres RE, Martinez F, Delgado DR (2022) Thermodynamic analysis of the solubility of isoniazid in (PEG 200+ water) cosolvent mixtures from 278.15 K to 318.15 K. Int J Mol Sci 23(17):10190

Kono H, Hashimoto H, Shimizu Y (2015) NMR characterization of cellulose acetate: chemical shift assignments, substituent effects, and chemical shift additivity. Carbohyd Polym 118:91–100

Dutta S, Parida S, Maiti C, Banerjee R, Mandal M, Dhara D (2016) Polymer grafted magnetic nanoparticles for delivery of anticancer drug at lower pH and elevated temperature. J Colloid Interface Sci 467:70–80

Yang Z et al (2021) Homoporous hybrid membranes containing metal-organic cages for gas separation. J Membr Sci 636:119564

Seong MS, Yu HJ, Ha SY, Chang WS, Kim H-J, Lee JS (2022) Poly(poly(ethylene glycol)methyl ether acrylate) micelles for highly CO2 permeable membranes. J Membr Sci 662:120917

Gu L et al (2009) PPEGMEA-g-PDEAEMA: double hydrophilic double-grafted copolymer stimuli-responsive to both pH and salinity. J Polym Sci A Polym Chem 47(12):3142–3153

Etemadi H, Yegani R, Seyfollahi M (2017) The effect of amino functionalized and polyethylene glycol grafted nanodiamond on anti-biofouling properties of cellulose acetate membrane in membrane bioreactor systems. Sep Purif Technol 177:350–362

Luo S, Wiegand JR, Gao P, Doherty CM, Hill AJ, Guo R (2016) Molecular origins of fast and selective gas transport in pentiptycene-containing polyimide membranes and their physical aging behavior. J Membr Sci 518:100–109

Sen BO, Cetin S, Yahşi U, Soykan U (2021) Role of free volume in mechanical behaviors of side chain LCP grafted products of high density polyethylene. J Polym Res 28:1–18

Li H-L, Ujihira Y, Tanaka S, Yamashita T, Horie K (1996) Variation of free volume parameters of polyalkylmethacrylate derivatives in the range from 15 to 300 K probed by positron annihilation lifetime measurement. J Radioanal Nucl Chem 210:543–553

Kanehashi S et al (2015) Enhancing gas permeability in mixed matrix membranes through tuning the nanoparticle properties. J Membr Sci 482:49–55

Gu Y, Kar T, Scheiner S (1999) Fundamental properties of the CH···O interaction: is it a true hydrogen bond? J Am Chem Soc 121(40):9411–9422

de Freitas RRM, Senna AM, Botaro VR (2017) Influence of degree of substitution on thermal dynamic mechanical and physicochemical properties of cellulose acetate. Ind Crops Products 109:452–458. https://doi.org/10.1016/j.indcrop.2017.08.062

Wang S et al (2014) Pebax–PEG–MWCNT hybrid membranes with enhanced CO2 capture properties. J Membr Sci 460:62–70

Zhao J, Wang Z, Wang J, Wang S (2006) Influence of heat-treatment on CO2 separation performance of novel fixed carrier composite membranes prepared by interfacial polymerization. J Membr Sci 283(1–2):346–356

Hoek EM, Bhattacharjee S, Elimelech M (2003) Effect of membrane surface roughness on colloid-membrane DLVO interactions. Langmuir 19(11):4836–4847

Lalia BS, Kochkodan V, Hashaikeh R, Hilal N (2013) A review on membrane fabrication: structure, properties and performance relationship. Desalination 326:77–95

Bilchak CR et al (2020) Tuning selectivities in gas separation membranes based on polymer-grafted nanoparticles. ACS Nano 14(12):17174–17183

Xing R, Ho WW (2009) Synthesis and characterization of crosslinked polyvinylalcohol/polyethyleneglycol blend membranes for CO2/CH4 separation. J Taiwan Inst Chem Eng 40(6):654–662

Loloei M, Moghadassi A, Omidkhah M, Amooghin AE (2015) Improved CO2 separation performance of Matrimid® 5218 membrane by addition of low molecular weight polyethylene glycol. Greenhouse Gases Sci Technol 5(5):530–544

Rayer AV, Henni A, Tontiwachwuthikul P (2012) High-pressure solubility of methane (CH4) and ethane (C2H6) in mixed polyethylene glycol dimethyl ethers (Genosorb 1753) and its selectivity in natural gas sweetening operations. J Chem Eng Data 57(3):764–775

Wang X, Chen H, Zhang L, Yu R, Qu R, Yang L (2014) Effects of coexistent gaseous components and fine particles in the flue gas on CO2 separation by flat-sheet polysulfone membranes. J Membr Sci 470:237–245. https://doi.org/10.1016/j.memsci.2014.07.040

Ahmad A, Adewole J, Leo C, Ismail S, Sultan A, Olatunji S (2015) Prediction of plasticization pressure of polymeric membranes for CO2 removal from natural gas. J Membr Sci 480:39–46

Balçık M, Ahunbay MG (2018) Prediction of CO2-induced plasticization pressure in polyimides via atomistic simulations. J Membr Sci 547:146–155

Karimi S, Firouzfar E, Khoshchehreh MR (2019) Assessment of gas separation properties and CO2 plasticization of polysulfone/polyethylene glycol membranes. J Petrol Sci Eng 173:13–19

Mosén K, Bäckström K, Thalberg K, Schaefer T, Axelsson A, Kristensen HG (2006) The apparent plasticizing effect of polyethylene glycol (PEG) on the crystallinity of spray dried lactose/PEG composites. Eur J Pharm Biopharm 64(2):206–211

Lin H, Van Wagner E, Freeman BD, Toy LG, Gupta RP (2006) Plasticization-enhanced hydrogen purification using polymeric membranes. Science 311(5761):639–642

Kanehashi S, Nakagawa T, Nagai K, Duthie X, Kentish S, Stevens G (2007) Effects of carbon dioxide-induced plasticization on the gas transport properties of glassy polyimide membranes. J Membr Sci 298(1–2):147–155

Robeson LM (2008) The upper bound revisited. J Membr Sci 320(1–2):390–400

Mubashir M, Yeong YF, Lau KK, Chew TL, Norwahyu J (2018) Efficient CO2/N2 and CO2/CH4 separation using NH2-MIL-53 (Al)/cellulose acetate (CA) mixed matrix membranes. Sep Purif Technol 199:140–151

Mehmood O et al (2021) Investigation of cellulose acetate/gamma-cyclodextrin MOF based mixed matrix membranes for CO2/CH4 gas separation. Greenhouse Gases Sci Technol 11(2):313–330

Regmi C, Ashtiani S, Sofer Z, Friess K (2021) Improved CO2/CH4 separation properties of cellulose triacetate mixed-matrix membranes with CeO2@ GO hybrid fillers. Membranes 11(10):777

Salestan SK, Rahimpour A, Abedini R (2021) Experimental and theoretical studies of biopolymers on the efficient CO2/CH4 separation of thin-film Pebax® 1657 membrane. Chem Eng Process Process Intens 163:108366

Acknowledgements

This research was funded by IAEA CRP22072 Research Contract No. 23577. The authors gratefully acknowledge Mr. Muhamad Yasin YBIC for his assistance with gamma irradiation at the Research Center for Radiation Process Technology (PRTPR-ORTN), BRIN, Jakarta, Indonesia.

Author information

Authors and Affiliations

Contributions

MS: Funding acquisition, conducted the main idea of the research. AF(1) and MS: wrote the original draft of the manuscript and data processing. RFH: synthesis and degree of grafting test. ALY: DSC analysis and interpretatation. AF(1), AF(7). and IPP: membrane performance test. Rahmawati: XRD analysis, interpretation and reviewed the manuscript. Deswita and NHA: SEM analysis and interpretation. SK: data interpretation and reviewed the manuscript. FS, DN, and KL: NMR and AFM analysis and reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Febriasari, A., Suhartini, M., Rahmawati et al. Enhancing the CO2/CH4 Separation Properties of Cellulose Acetate Membranes Using Polyethylene Glycol Methyl Ether Acrylate Radiation Grafting. J Polym Environ (2024). https://doi.org/10.1007/s10924-024-03273-x

Accepted:

Published:

DOI: https://doi.org/10.1007/s10924-024-03273-x