Abstract

The Current study aimed at valorizing carrot pomace (CP), an abundant waste from the juice industry. A water-soluble fraction of CP was separated from solid fraction of CP (SFCP) and employed as feedstock for producing fungal biomass (FB) in bench-scale bioreactors. FB combined with SFCP were used to develop mycelium-based papers (MBP) using the wet-laid method. The potential and capacity of FB, SFCP and MBP to remove dye (methylene blue) from wastewater was then investigated. The maximum achieved dye removal was 92% when using a mixture of SFCP and FB in their suspended forms. The MBP with the lowest density (549 kg/m3) reached 83% dye elimination. The findings of this study support the valorization of carrot pomace, through environmentally benign processes, to mycelium-based papers with potential application in wastewater treatment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The mycelium-based materials have captured considerable attention across various industries and sustainability initiatives. Bio-fabrication technologies involving fungal cultivation on organic waste have been developed to accommodate mycelium-based materials for various products including packaging materials [1], bricks and panels [2], imitation leather [3], films [4], textile fibers [5], and composites [1]. Mycelium-based materials can entirely be composed of fungal mycelium or may contain lignocellulosic residues that are bounded by fungal mycelium [6].

The substantial quantities of fruit and vegetable waste that are generated during industrial processes can serve as nutritious sources for fungal cultivation. The global production of carrots was 44.80 million tons in 2019 and has an annual growth rate of approximately 10.5% [7]. Notably, carrot wastes, in the form of carrot pomace (CP) and carrot mash, constitute 40% of the initial carrot which often are discarded during juicing and peeling processes, respectively [8]. Besides the presence of sugars in CP, which can be used as carbon source for fungal cultivation [9], these wastes also contain cellulose constituents that could be utilized in different applications such as fillers for e.g. treatment of wastewater from different industries such as textile industry [10] and reinforcing agents in packaging films and light composites [11, 12].

The textile industry is growing to meet the demands and as a result usage of dyes by this industry is increasing. Approximately 10–15 percent of dyes are lost and discharged in the wastewater [13]. Consequently, the need for dye removal from the industrial wastewater has increased. The removal of dyes from aqueous effluents has been achieved through physical methods, involving adsorption on various agricultural waste, such as mango, banana, apple, pomegranate [14]. Dye adsorption capacity for bamboo, sugarcane bagasse, and orange peel was reported to be 215, 331, and 108 mg/g, respectively [15,16,17]. Additionally, biological materials such as mycelium have been utilized for dye removal purposes [18]. The simplicity, high efficiency, operational flexibility, and cost-effectiveness of biological materials introduce them as promising alternatives for treatment of wastewater of textile industry [19,20,21]. However, utilizing these materials in suspended form results in the generation of dispersed sludges, which are suspended in wastewater and pose new challenges in wastewater treatment. The Use of filters and membranes has been proposed as an alternative which facilitates treatment of large amounts of wastewater with continuous flow [22].

To fabricate high-performance biobased membranes and filters for wastewater treatment, mycelium, and its derivatives, such as chitin and chitosan have been integrated with other polymers. Chitosan membranes [23], chitosan-lignin membranes [24], Fe-loaded chitosan film [25], fungal chitin-cellulose nano papers [26], and hybrid filter made of mushroom-derived chitosan-glucan and cellulose [27] are examples of the developed materials for wastewater treatment.

In previous research, the successful valorization of carrot pomace into fungal biomass (utilizing the soluble fraction of carrot pomace as a substrate for fungal cultivation) and a cellulose-rich solid fraction were demonstrated [9]. Building upon this research, the regenerated fungal biomass derived from carrot pomace and the cellulose-rich part of CP were utilized to produce mycelium-based papers, aiming to assess and demonstrate a novel application of these filter papers in dye removal from wastewater. In addition to being examined for dye removal, the obtained filter papers were characterized in terms of physical, mechanical, and thermal properties.

Experimental Details

Materials

Carrot pomace was kindly provided by Herrljunga Cider AB (Sweden) and stored at − 18 °C until use. The fungus Rhizopus delemar, CBS 145,940, which was originally isolated from banana leaves used in tempeh production, was provided by Centraalbureau voor Schimmelcultutres (Westerdijk Institute, Utrecht, the Netherlands) [28]. Yeast extract, agar, hydrochloric acid (HCl), sodium hydroxide (NaOH), peptone, glucose, and invertase from baker’s yeast (S. cerevisiae) were purchased from Sigma Aldrich (St. Louis, MO, USA). Agar plates inoculated with spores of the fungus were prepared according to the previous work [9] and stored in a refrigerator at 4 °C until use. Methylene blue (C16H18ClN3S) with Mw (319.85 g/mol) and reactive black 5 (C26H21N5Na4O19S6) with Mw (991.82 g/mol) were purchased from Sigma–Aldrich.

Pretreatment of the Carrot Pomace by Invertase

Carrot pomace was pretreated using invertase to hydrolyze the available sucrose and to extract the nutrients according to our previous work [9]. After pretreatment, the liquid fraction (LFCP) was separated from the solid fraction (SFCP) of the carrot pomace. LFCP was utilized as a substrate for fungal cultivation, while the SFCP was preserved in freezer at − 18 °C, for subsequent experiments. The process flow diagram is shown in Fig. 1. Also, the list of abbreviations is presented in Table 1.

Fungal Cultivation in Bench Scale Bioreactors

Fungal cultivation was conducted using bench-scale bubble column bioreactors (Belach Bioteknik AB, Skogås, Sweden) with a working volume of 3.5 L. The bioreactors were filled with the LFCP and sterilized in an autoclave for 20 min. After sterilization, the reactors were inoculated with spore suspension at the ratio of 0.02 mL/mL of the substrate. The fungal cultivation was carried out at a temperature of 35 °C for 72 h, with an aeration rate of 2 vvm (volume of air per volume of liquid per minute) [9]. Following the cultivation period, the fungal biomass was harvested by sieving. The biomass was then washed and stored at − 18 °C for further use.

Homogenization of Fungal Biomass and Carrot Residue

To homogenize the fungal biomass and SFCP suspensions in water for next stages, 2% suspensions were passed separately through a disk mill grinder called supermasscolloider (MKCA6-5 J, Masuko Sangyo, Kawaguchi, Japan). 20 and 30 cycles were performed for fungal biomass and SFCP, respectively, using MKE46 grinding stones which are fine silicon carbide standard grinding stones for soft materials to achieve homogenous suspensions. The rotation speed was 2700 rpm and the gap between the grinder stones was adjusted to 50 µm (open gap). The ground suspensions were stored in refrigerator at 4 °C.

FluidScope™ Scanning (oCelloScope)

Fluid Scope™ scanning analysis using the oCelloScope (BioScience Solutions, Denmark) was conducted to measure size of fungal mycelium and the dimensions of the SFCP particle. Images were captured by diluting the ground suspensions of FB and SFCP (to 0.5 wt %) and adding 0.5 ml of each suspension to a 24-wells plate (Sigma-Aldrich, USA). The default setting captured 20 images for each sample by Uni Explorer software.

Preparation of Mycelium-Based Paper (MBP)

The vacuum funnel assembly (Sterlitech, USA), which is similar to wet-laid method, was used for MBP production. Circular sheets with a diameter of 7 cm were created by filtering the suspension of ground FB, SFCP, or their mixture with different ratios according to Table 2. The concentration of total suspended solids was adjusted to 1 g/L before filtration. The filtration was performed through a membrane (Spectra Mesh® woven filters–Nylon, Thermo Fisher Scientific, USA) with 70 μm pore size. To remove excess water from the sheets, blotting papers (Ahlstrom-Munksjö Falun AB, Sweden) were used in the dewatering process. To prevent shrinkage, the wet mycelium-based papers were fixed between flat Plexi glass sheets and rings and the drying was conducted in an oven at 30 °C for 24 h. To provide support and maintain the shape, a 3 kg metal weight was placed on top of 5 Plexi glass sheets and rings with samples during the drying process.

Characterization of Mycelium-Based Paper (MBP)

Morphology and Physical Properties

Surface images of mycelium-based papers were visualized using an optical microscope (Nikon Eclipse LV150, Nikon Corporation, Tokyo, Japan) equipped with a Nikon DS‐FI1 digital image acquisition system. To study the morphology of the surface, images were taken with an ultrahigh-resolution FE-SEM instrument (Zeiss, Sigma, Germany). Surface images of samples were taken after the samples were attached to carbon tape and coated with gold. Photomicrographs were taken at 300 × magnification with an accelerating voltage of 20.00 kV.

The thickness (d) of the produced mycelium-based papers was calculated as an average of 10 measurements across the MBP using a digital micrometer (Mitutoyo, Japan). The grammage of MBP was determined by measuring the mass of a sample divided by area of 7 cm diameter specimens (r = 3.5 cm). Density (kg/m3) was calculated by dividing the sample’s weight by its thickness (m) in the given area (m2). The pore sizes of the MBP were determined by PSM 165 porosimeter (Germany, Topas GmbH, PSM 165). The gas permeability of the sheets was examined by an air permeability tester under a pressure of 2000 mb and 70 L/min. Since some of samples exhibited insufficient strength against air flow in the air permeability test, theoretical porosity of MBP was calculated as described in [29] according to Eq. 1. Density of fungal biomass and carrot as ingredients of MBP was considered in 0.1–0.5 and 1.3–1.5 range and based on the ratio of these ingredients in MBP, the final density was estimated.

Mechanical Properties

To measure mechanical properties, the MBP specimens were cut into dog-bone specimens according to ISO 527-2 (2012) using a press knife (Elastocon, Sweden). The cut specimens were subjected to mechanical property analysis using a tensile testing machine (H10KT, Tinius Olsen, USA) equipped with a 100 N load cell and a gauge length of 26 mm. The test was performed at a speed of 5 mm/min and the preload was 0 N. The tensile strength (MPa) and elongation at break (%) were determined using the software (QMat, Tinius Olsen, USA). Young’s modulus (E) was calculated from the slope of stress-strain curve in linear part between 0.1 and 0.5 percent of strain.

Material Selection Plots

To determine the position of the MBP compared to commercially available materials Ashby’s bubble chart was employed to visually represent material properties and compare them with other materials. The graph was generated using Granta Edupack 2021 R2 version: 21.2.0 (Ansys Inc. USA).

Fourier Transform Infrared (FTIR) Spectroscopy

For the determination of the chemical composition of MBP, at various ratios of FB:SFCP, as well as the investigation of the reactions between MBP and dye molecules, FTIR analysis was conducted using Nicolet iS10 (Thermo Fisher Scientific, USA). The spectra were recorded from 32 scans with a resolution of 4 cm−1 and a 4000–500 cm−1 wavelength range.

Thermogravimetric Analysis (TGA)

Thermal decomposition behavior of MBP was investigated by TGA analysis with Q500 TA instruments supplied by Waters LLC (USA). 10 mg of each sample was heated from room temperature to 600 °C with a heating rate of 20 °C/min in a nitrogen atmosphere. The graphs on percentage weight loss against the temperature were obtained and the thermal stability of the produced materials was estimated.

Dye Adsorption

Preparation of Dye Solution

Standard solutions containing 3, 5, 7, 9, and 12 mg/L dye were prepared, by dilution of a stock solution containing 15,000 mg/L Methylene Blue (MB) with water. The absorption of MB at wavelengths of 664 nm was recorded to plot the calibration curve. Linear regression resulted in a calibration curve with following formula

The same procedure was followed for reactive black (RB) dye.

Dye Adsorption by FB and SFCP in Suspended Form

The adsorption of dyes MB and RB (as cationic and anionic dyes, respectively) by FB, SFCP, and their combination in suspended form was examined using UV spectroscopy. The dye removal process was conducted in conical flasks, effect of adsorbent dose, initial dye concentration, and pH was examined on the dye removal while stirring speed, contact time, and temperature were kept constant throughout the experiments. After the contact time, liquid samples were taken from each flask which were centrifuged at 4000 rpm for 15 min. Then the absorbance of supernatants was determined to evaluate the dye removal. The measurements were conducted at wavelengths of 664 and 598 nm for MB and RB, respectively. The following equations were applied to calculate dry removal (R%) and the quantity of dyes absorbed per unit mass of the adsorbent (qe).

where C0 and Ce represent the initial and final concentrations of dyes (g/L). V represents the adsorbate volume (L) and \(m\) represents the biosorbent dry mass (g).

Dye Adsorption by Mycelium-Based Papers

Following the successful adsorption of Methylene blue by suspended forms of FB and SFCP compared to RB, this dye was used in the rest of experiments. The mycelium-based papers, with 7 cm diameter and ingredient ratios reported in Table 2, were placed on a vacuum Buchner funnel to facilitate the separation of the MB solution by gravity-driven filtration. 50 mL of 15 mg/L MB dye solution passed through the MBP and Buchner funnel in 30 cycles until dye removal was visible. The final adsorption value of the filtrate water was determined using a UV−Vis spectrophotometer at 664 nm and the dye removal was calculated according to Eq. 3. The point of zero-charge was determined according to [30]. First, 20 mL of 0.05 mol/ L NaCl solutions at a specified initial pH, ranging from 2 to 10 (adjusting with 0.1 mol/ L HCl or NaOH) were prepared in 50 ml flasks. Then, 50 mg MBP was added to each flask and subjected mixing at 200 rpm, at 25 °C in a shaker (New Brunsiwick TM Excella® E 24, New Jersey, USA) for 48 h to reach the equilibrium. The final pH was then measured, and the final pH was plotted against the initial pH. This process was performed duplicate. The pH at which the final pH was equal to the initial pH was considered as point of zero charge of the MBP.

Statistical Analysis

All the experiments were performed in duplicate unless otherwise stated and average values were reported. Statistical analysis was conducted using analysis of variance (ANOVA) and post hoc Tukey test. P-values smaller than 0.05 were considered to indicate significant differences.

Result and Discussion

The filamentous fungus (Rhizopus Delemar) was cultivated on liquid fraction of carrot pomace after extraction of nutrients by enzyme treatment. The obtained fungal biomass (FB) was combined with solid residue of carrot pomace (SFCP), to make wet-laid mycelium-based papers (MBP). The effectiveness of FB and SFCP, both in their suspended form and within the hybrid filter paper structure, was evaluated for dye removal. Moreover, the MBPs were characterized to gain insight into their properties and explore their potential applications.

Pretreatment of CP and Fungal Cultivation

Approximately, 24.1% of CP was dissolved during the invertase treatment to release the water-soluble fraction of CP. The dissolved fraction had a concentration of 2.9% (Wt. % of soluble solid) which was used as nutrient for fungal cultivation. The concentration of soluble materials was reduced to 0.79% at the end of cultivation due to consumption by fungi. The concentration of harvested fungal biomass was 5.01 g/l after 72 h cultivation in bench scale reactors. In a previous study we compared the effect of pretreatments of CP with different enzymes and the highest biomass concentration was obtained after invertase pretreatment [9]. This was because of hydrolysis of sucrose by the enzyme which enhanced the amount of the consumable sugars for Rhizopus delemar. The same condition was used in the current study. The remaining solid fraction (SFCP) represented 75.9% (yield) of CP contained 29% glucan and 12% hemicellulose (including xylan, arabinan, and galactan). Berglund et al. [31] reported a 79% yield of carrot residue after the washing step, and it contained 45% cellulose and 26% hemicellulose before bleaching steps. Their findings regarding yield percentage were closely aligned with the outcomes of the current study. The slight variation in components may be attributed to differences in pretreatment methods or the source of the used carrots.

Fluidscope™ Scanning (oCelloScope)

Suspensions of FB and SFCP with a concentration of 2% (w/w) were individually passed through the grinder. The materials became uniformly dispersed after 20 and 30 passes for FB and SFCP, respectively, as illustrated in Fig. 2 a, b. The distribution of FB indicated the branch structure of hypha, while SFCP particles were detected within the accumulated mass in different shapes. The structure of the observed hyphae was tubular and elongated, which is common for Rhizopus delemar. The previous research reported a similar structure of hyphae for this fungus [3, 5].

Mycelium-Based Paper (MBP)

Fabrication of MBP and Evaluation of Their Physical Properties

After completing the grinding steps, the suspensions were diluted to 1% by addition of water. Initial wet-laid trials aimed at formation of sheets from ground SFCP, however, formation of a uniform and flexible sheet was impossible due to weak attachments of SFCP particles. Furthermore, preliminary experiment showed that preparing the sheets from only fungal biomass takes a long time due to the low water flow in the wet-laid process. Therefore, a combination of FB and SFCP was used for formation of mycelium papers. Accordingly, successful formation of sheets from FB which was embedded with SFCP particles at various mixing ratios was achieved (Fig. 3a). The details of combination of mycelium-based papers are described in Table 2. Microscopy images of the MBP revealed a densely bonded surface, free of large pores and cracks. The color of the MBP was changed from light brown for papers having the lowest thickness and density to dark brown for papers having highest thickness and density. Figure 3b, c illustrate the surface morphology and a 3-dimensional image of mycelium-based paper, respectively.

Physical properties of the MBP are provided in Table 2. The MBPs were configured with six different conditions, including two ratios of SFCP and FB (1:1 and 6:1) and different total dry weights (0.2, 0.4 and 0.6 g). The retention times in Table 2 refer to filtration time for the suspension of SFCP and FB in the wet-laid process to form the MBP. This value increased as the total amount of suspended solids increased. At both tested ratio of SFCP and FB, a fraction of the suspended solids passed through the nylon membrane (70 μm pore size) in the wet-laid process (18–37%). This fraction is expected to be mostly small particles of SFCP. Increase of total suspended solids in the wet-laid process, resulted in reduction of the fraction of missing particles. This might be due to the formation of a dense network of mycelium and SFCP particles close to the nylon membrane surface, which avoids passage of the smaller particles through the membrane. The same dense network could be attributed to the longer filtration time in (H-CF). Total weight of the mycelium papers, as well as their grammage, density, and thickness was also enhanced by increasing the total amount of suspended solids.

For the mycelium papers with thickness higher than 0.07 mm, 6:1 ratio of SFCP and FB demonstrated higher grammage and thickness, while the 1:1 ratio resulted in higher density. This indicates that higher concentration of mycelium (FB) results in formation of a denser structure with lower porosity. This is confirmed by the porosity results. Results of this study align with the findings reported in the literature. Rathinamoorthy et al. reported 0.18 mm, 125 (g/m2) and 53.08% for thickness, grammage, and porosity, respectively, for the sheets made of mycelium of Penicillium Camemberti [32], while Aiduang et al. mentioned in their review paper that the density of mycelium based composites is generally in the range of 25–954 kg/m3[1].

FESEM images reveal the surface morphology of the mycelium-based papers. Notably, irregular distribution of fungal mycelium was visible in all samples. In the mycelium-based paper (H-CF), the interaction between FB and SFCP was clearly observed in Fig. 4. The lack of adequate pores was further supported by porosity and water permeability tests conducted on this sample. The low-density filter paper (L-CF) in Fig. 4 exhibited a more porous structure compared to the (H-CF) filter paper. The placement pattern of fungal mycelium in the paper with a ratio of 6SFCP to 1FB differed from the 1:1 ratio. Figure 4e–h provides insights into the distribution of fungal mycelium on the matrix of carrot pomace particles across the surface of mycelium-based filter paper (L-C6F1) and (M-C6F1) where it synergistically integrates. This positive interaction highlights the compatibility between carrot pomace and fungal biomass. Janesch et al. previously observed the surface morphologies and visible fibrils in nanopapers fabricated from mushroom-derived chitosan-glucan [27]. Additionally, Köhnlein et al. produced fungal biomass by cultivation Rhizopus delemar on bread waste. SEM images showed a uniform surface and interior microstructures of the fungal biomass films [4]. These earlier studies are in line with this research observation concerning the texture of produced MBP.

Mechanical Propertise of Mycelim-Based Paper

Mechanical properties (presented in Table 3) play a crucial role in determining the efficiency of MBP for various applications. The heterogeneous distribution of ingredients and different grammage of MBP resulted in variations in the mechanical properties. The mycelium-based peper, H-C6F1, contains a higher ratio of SFCP:FB (6:1) and demonstrates the highest tensile strength of 34.3 MPa, with respective elongation at break and Young’s modulus (E) of 7.2% and 1362 MPa, among all samples (p < 0.05). This can be attributed to the presence of polysaccharides, which provide stiffness to the MBP. Additionally, microfibrilar structure of FB, which contains chitin and chitosan, contributes to mechanical strength of the MBP. Moreover, proteins and lipids available in FB may act as plasticizers, enabling the cell wall to withstand significant internal pressures, providing physical protection, and retaining internal moisture [6, 33].

However, utilizing a higher proportion of FB (0.3 g) in H-CF filter negativelty influenced the mechanical performance in tensile strength (3.7 MPa), and modulus (75 MPa) and hindered its application. The increasing the FB from 0.1 g to 0.3 g in MBP led to a reduced the bonding regions, as the low mechanical strength can be related to the inadequate bonding between functional group of ingredients [10]. In previous studies, pure mycelium sheets from different fungal strains reached the tensile strength of 1.5 MPa and a modulus of 128 MPa [34] Köhnlein et al. [4] achieved a tensile strength of 9.4 MPa for films obtained from fungal biomass after alkaline treatment. Meanwhile, Amoroso et al. achieved a tensile strength of approximately 46 MPa and an elongation of 3.7% when developing cellulose nanofiber films from carrot pomace [11]. Additionally, inclusion of 5% carrot fiber within chitosan film resulted in 14% elongation and 1057 MPa in elasticity modulus [10]. Totally, these results are in line with this research and the minor variation could be attributed to difference in the ingredients percentages within the MBP used in this study. The methodology and properties of the recently developed mycelium-based sheet are provided in Table 4.

Material Comparison with Ashby’s Plots

The Ashby Chart is a graphical tool used in engineering and materials science to aid in the selection of materials for a specific design application. In Fig. 5, Ashby plot incorporates widely recognized material categories, with tensile strength plotted on the y-axis and density (kg/m3) on the x-axis. Accordingly, the mycelium papers in this work, (except H-CF), exhibited properties commonly associated with the wood and paper products as they are in same bubble. The presence of cellulose fibers (from carrot pomace) and fungal microfibers, in the MBP has resulted in a material behavior like traditional paper products. Therefore, it is expected that the MBP made of carrot pomace are promising candidates for different applications where conventional paper products are used such as filters and packaging materials.

Fourier Transform Infrared Spectroscopy of Mycelium Papers

The Fourier transform infrared (FTIR) spectra of mycelium-based papers are reported in Fig. 6. These spectra show the chemical composition of the mycelium-based sheet, which is derived from FB, and SFCP. The MBP showed a broad peak between 3500 and 3000 cm−1 which is attributed to the stretching of –OH groups together with the –NH stretching vibrations found in FB and SFCP [10]. The region between 2850 and 2920 cm−1 on the spectrum showed the occurrence of CH2 symmetric stretching, which was associated with the presence of lipids. The peak at 1622 cm−1 indicates the C=O stretching conjugated to a –NH deformation of the –CN (amide 1) group of protein-peptide bond and chitosan. The amide II vibration at 1540 cm−1 indicates the presence of protein in the developed sheet [29, 39]. The spectra display significant peaks at 1400 cm−1 and 1140 cm−1, indicating the presence of chitin. These peaks correspond to CH2 and CH3 deformation, as well as C–O–C and C–C valence vibrations associated with chitin molecules and cellulose [29]. Identifying cellulose-derived bands of SFCP in the hybrid MBP proved challenging due to the presence of other carbohydrates like β-glucans that overlap the chemical signature [6].

Thermogravimetric Analysis of Mycelium Papers

The thermal stability and degradation behavior of MBP was investigated using thermogravimetric analysis (TGA) at a constant rate of temperature increase. The thermal degradation of the MBP was similar to the typical degradation behavior of cellulose and other biologically derived materials. The thermal degradation profile of the FB and MBP was characterized by multiple steps originating from the composition of a variety of biopolymers such as polysaccharides, lipids, and proteins as shown in Fig. 7. The initial ranges from 75 °C to 200 °C is associated with the evaporation of moisture. The subsequent range from 200 °C to 375 °C is linked to the breakdown of organic substances such as chitin, polysaccharides, and proteins, while the final range from 375 °C to 600 °C signifies the degradation of remaining char with a residual mass of 18–31%. The decrease of weight (%) between 200 and 375 °C was 47, 54% and 56% for FB, H-CF and H-C6F1, respectively. Sanchez et al. [35] in thermogravimetric analyses of mycelium film demonstrated a multiple degradation profile and the main zone between 200 and 500 °C corresponded to the complete thermal decomposition of the mycelium components including proteins, chitin, and glucans.

Application of Carrot Pomace Derived Products for Dye Removal

Dye Removal by Suspended Form of FB

Before employing mycelium papers as filter for dye adsorption, extensive testing was conducted to ascertain dye adsorption efficiency in suspended forms by FB. This step was taken despite the existence of previous research on the dye adsorption capabilities of fungal biomass and organic materials. Methylene blue (MB) is a commonly utilized dye with the chemical composition of C16H18N3SCI [40]. The adsorption of dye is influenced by several key factors including pH, initial dye concentration and the adsorbent dosage [41]. Various conditions including pH (3, 5, 7, 9), dye concentrations (50, 100, 150, 200 mg/L) and FB concentrations (0.5, 1, 1.5 and 2 g/L) were considered for the dye removal experiments in suspended form. The contact time and stirring rate were kept constant at 48 h, 200 rpm at room temperature (22 °C) for all experiments.

Figure 8a shows that in the pH range of 5–9, the adsorption capacity increased rapidly within the first hour of contact time and then remained relatively constant. At pH 9, the adsorption capacity increased until 48 h due to the more negative charge on the adsorbent surface and the presence of electrostatic interactions and potential H-bonding between the adsorbate and the adsorbent [21]. Dye adsorption gradually increased over time at pH 3. To determine the effect of initial dye concentration on adsorption, studies were carried out with 50, 100, 150 and 200 mg/L dye concentration. By increasing the concentration of dye, the removal of dye was enhanced. The highest adsorption capacity, around 35 mg/g, was achieved using a concentration of 200 mg/L on 0.5 g/L of fungal biomass after 48 h (Fig. 8b). The amount of adsorbent directly affects the efficiency by providing more adsorption sites for dye adsorption. The effect of FB dosage on dye removal and adsorption equilibrium showed a downward trend of removal rate when using 0.5 g/L, indicating that the active sites were fully saturated. Using fungal biomass dosages of 1, 1.5 and 2 g/L led to around 10 mg/L dye adsorption capacity which was less than 0.5 g/L dosage (16 mg/L) which was observed at 24 h of the adsorption process (Fig. 8c). Therefore, an optimum adsorbent dosage of 0.5 g/L was chosen to minimize costs and excessive use of adsorbent while still achieving high adsorption efficiency.

a Effect of pH on the adsorption of MB on fungal biomass (concentration of FB: 0.5 g/L, MB concentration: 100 mg/L). b Effect of MB concentration on dye adsorption by FB (pH:7, concentration of FB: 0.5 g/L). c Effect of fungal biomass concentration on dye adsorption (pH: 7, MB concentration: 100 mg/L)

The supplementary file (Fig. S2) displays the microscopy images of fungal biomass for removal MB, which clearly illustrates the dye accumulation on the adsorbent surfaces. The images show the rough and irregular surface morphology of the adsorbent, offering a significant area for interaction between the dye and the surface. As well the FTIR analysis result, which is attached in the supplementary file (Fig. S3) provided the chemical functionalities of MB and fungal biomass, before and after the adsorption. Generally, similar peaks were observed in the samples, before and after the adsorption process. However, after the adsorption process, the peaks shifted to higher wavenumbers. The bonds established because of electrostatic interactions between the functional groups of the adsorbent and dye molecules are responsible for these shifts. Also, these shifts indicate that the hydroxyl, amine, and carboxyl groups on the surface of the composite acted as active sites during the adsorption process.

Similar experiments were conducted for the anionic dye Reactive Black (RB). The adsorption kinetics of dye RB on FB are presented in Fig S1 in the supplementary file. However, it was observed that the efficiency of dye removal by FB was around 40% which is significantly lower compared to MB. The anionic nature of RB dye hindered its ability to effectively interact with the functional groups present on the fungal biomass. As result, MB was used in the rest of the experiments.

Dye Removal by a Combination of FB and SFCP in Suspended Form

Following the successful adsorption of MB by FB, the evaluation of FB and SFCP as individual adsorbents, as well as their mixture in suspended form, to remove MB from aqueous solution under specific conditions (pH 7, adsorbent dose: 0.5 g/L and 100 mg/L) was performed. The contact time and stirring were kept constant at 48 h and 200 rpm at room temperature. As depicted in Fig. 9a, the removal of MB began within the initial minutes of exposure to the adsorbent. Notably, dye removal and adsorption capacity remained constant until 72 h. However, statistical analysis of corresponding dye removal adsorption capacity for FB and SFCP (Table S1) showed that there was a significant difference between the dye removal data (P < 0.05), while no significant difference was observed between adsorption capacity data (Table S2) (P > 0.05). The results of ANOVA analysis are shown in Table S3 and S4. However, a slight desorption occurred during the final hours. Subsequently, the combination of these two fractions was tested at two concentrations (0.2 and 0.5 g/L) with mixture of FB and SFCP in equal ratio (Fig. 9b). Dye removal showed insignificant variation between the two concentrations (P > 0.05), while adsorption capacity showed significant differences between 0.2 and 0.5 g/L (P < 0.05). Data and the results of ANOVA analysis are presented in Tables S5–S8. Since in the previous section, the maximum adsorption capacity occurred at lowest fungal biomass loading (0.5 mg/L), it is reasonable to conclude that adsorption is most effective at a specific adsorbent quantity, and extra adsorbent does not contribute to enhancing the ultimate adsorption capacity. The reusability of adsorbent materials is vital for reducing cost and minimizing waste. Several studies have focused on addressing this issue. For example, Hamed et al. proposed a solution involving the carbonization of toxic mushroom sludge, which is a byproduct of fungal membrane-based membrane wastewater treatment. By transforming residual sludge into active carbon, a sustainable approach to enhancing bio sorbent reusability is achieved [42]. In other research, the reusability and bio sorption percentage of fungal composite beads were confirmed after washing with 0.1 M HCl solution [43]. Additionally, novel adsorbents were developed by successfully synthesizing beads from gelatin recovered from leather wastes, targeting the removal of emerging contaminants, including tartrazine yellow dye [30].

a Comparison of MB adsorption on FB and SFCP separately (adsorbent dose, 0.5 g/L, MB concentration: 100 mg/L stirring rate: 200 rpm, pH: 7 and room temperature), b comparison of MB adsorption on mixture of FB and SFCP in 0.5 g/L and 0.2 g/L dosage concentration (MB concentration: 100 mg/L stirring rate: 200 rpm, pH: 7 and room temperature)

Dye Adsorption by MBP

Use of adsorbents for dye removal in their suspended form is mostly suitable for small-volume applications and not compatible with continuous flow in wastewater treatment. Therefore, adsorption through filtration could be a better option on an industrial scale for wastewater treatment. Since the preparation of filter paper solely with FB or SFCP faced limitations, a hybrid approach in mycelium-based filters paper seems promising for effective dye removal. In last Section, it was shown that simultaneous use of FB and SFCP demonstrated acceptable dye removal performance at 0.2 g of adsorbents. Thus, the mycelium papers were tested for the dye adsorption capacity. A 50 mL of MB dye solution with a concentration of 15 mg/L was passed through the MBP (Table 1), in a total of 30 times to achieve a clear and transparent filtrate (Fig. 10).

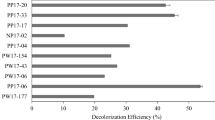

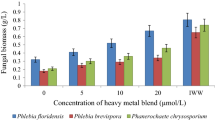

The filtration process was not successful for the MBP with a high FB content (H-CF) due to its low porosity (0.9 µm), which hindered the passage of the dye solution. The MBP (L-C6F1) containing a higher ratio of SFCP (6:1) and lower density, exhibited the best dye removal, reaching 83%. The next best performer was MBP (M-C6F1), which had a removal efficiency of 73% (Fig. 11). Theses specimens showed significant differences in dye removal and adsorption capacity (p < 0.05) which might be due to differences in weight and density of different MBP. Compared data and the results of ANOVA analysis are presented in Table S9-S11.

Contact time is another crucial factor in dye adsorption. In the filtration process, the rapid passage of dye solution did not allow for extended contact between dye and the surface of mycelium paper. Therefore, it can be one of the reasons for the higher dye removal between the suspended form (92%) compared with mycelium paper form (83%). Using MBP however facilitates the continuous process of dye removal which is the requirement for large scale water treatment.

The possibility for presence of positive and negative charges on the surface of mycelium-based paper (LC6F1) was investigated by Point of zero charge (pHPZC). This point is the pH value where the sum of the positive and negative charges presents on the surface of a solid is zero [44].The result of experiment indicated that the pHPZC was around 5 (Fig. 10). Therefore, at pH 5 the number of positive and negative charges at the surface of the material are equal. At pH below 5, the final pH after the equilibrium was higher than the initial pH. This indicates that the material has reacted with some of the H+ available in the solution. This is due to the presence of negative charges on the surface of the material that has neutralized some of the available H+. This led to reducing the number of available negative groups on the surface of the material. At pH above 5, however, the final pH is below the initial pH. This indicated releasing of some H+ from the surface of the material to the solution. Consequently, there will be more negative charges available on the surface of the material that can react with the dye molecules.

The mechanism of dye adsorption on the surface of hybrid mycelium paper may be attributed to the hydrogen bonds and ionic interactions between dyes and the surface of mycelium-based paper. Cellulosic particles present in the mycelium-based paper typically displayed remarkable negative charges, which create strong interaction with positively charged methylene blue through electrostatic interactions and hydrogen bonding. According to literature, the surface charge of fungal biomass is generally negative across a wide range of pH values due to the presence of various functional groups such as carboxylate, hydroxyl, sulfate and phosphate groups on the cell wall [45]. The presence of negative charges on the surface of mycelium paper, in this study, was confirmed in the pHPZC test. However, the magnitude of the negative surface charge may vary depending on the fungal species and the environmental conditions. The negative surface charge plays a crucial role in the ability of MBP to adsorb metal ions and dyes from aqueous solutions [46].

Conclusions

Carrot pomace was first valorized to fungal biomass and a solid residue rich in cellulose through a scalable process. The potential of the carrot-based products for dye removal was confirmed in their suspended form, with maximum achieved dye removal of 92% when using a mixture of SFCP and FB in suspended form. Subsequently, using conventional wet-laid method, porous mycelium-based papers were developed by combining fungal biomass and solid residue of carrot pomace. Paper production from only carrot pomace was not possible. The porous structure of mycelium-based paper with a low density of 549 kg/m3 played a key role in enabling simultaneous and effective filtration and dye removal of around 83%. Furthermore, mycelium-based paper exhibited comparable mechanical properties to conventional paper products, indicating its potential for various applications, such as packaging.

Data Availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request.

References

Aiduang W, Chanthaluck A, Kumla J, Jatuwong K, Srinuanpan S, Waroonkun T, Oranratmanee R, Lumyong S, Suwannarach N (2022) Amazing fungi for eco-friendly composite materials: a comprehensive review. J Fungus 8:842. https://doi.org/10.3390/jof8080842

Islam MR, Tudryn G, Bucinell R, Schadler L, Picu RC (2018) Stochastic continuum model for mycelium-based bio-foam. Mater Des 160:549–556. https://doi.org/10.1016/j.matdes.2018.09.046

Wijayarathna ERKB, Mohammadkhani G, Soufiani AM, Adolfsson KH, Ferreira JA, Hakkarainen M, Berglund L, Heinmaa I, Root A, Zamani A (2022) Fungal textile alternatives from bread waste with leather-like properties. Resour Conserv Recycl 179:106041. https://doi.org/10.1016/j.resconrec.2021.106041

Köhnlein MBM, Abitbol T, Oliveira AO, Magnusson MS, Adolfsson KH, Svensson SE, Ferreira JA, Hakkarainen M, Zamani A (2022) Bioconversion of food waste to biocompatible wet-laid fungal films. Mater Des 216:110534. https://doi.org/10.1016/j.matdes.2022.110534

Svensson SE, Ferreira JA, Hakkarainen M, Adolfsson KH, Zamani A (2021) Fungal textiles: wet spinning of fungal microfibers to produce monofilament yarns. SM&T 28:e00256. https://doi.org/10.1016/j.susmat.2021.e00256

Attias N, Livne A, Abitbol T (2021) State of the art, recent advances, and challenges in the field of fungal mycelium materials: a snapshot of the 2021 Mini Meeting. Fungal Biol Biotechnol 8:1–5. https://doi.org/10.1186/s40694-021-00118-3

Kaur N, Aggarwal P, Kaur S (2023) Phytochemical profile and techno-functional properties of black carrot (Daucus carota) pomace powder for the formulation of nutraceutical tablets: an impact of drying methods. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-023-04511-3

Otoni CG, Lodi BD, Lorevice MV, Leitão RC, Ferreira MD, Moura MRd, Mattoso LHC (2018) Optimized and scaled-up production of cellulose-reinforced biodegradable composite films made up of carrot processing waste. Ind Crops Prod 121:66–72. https://doi.org/10.1016/j.indcrop.2018.05.003

Mousavi SN, Parchami M, Ramamoorthy SK, Soufiani AM, Hakkarainen M, Zamani A (2023) Bioconversion of carrot pomace to value-added products: Rhizopus delemar fungal biomass and cellulose. Ferment 9:374. https://doi.org/10.3390/fermentation9040374

Sogut E, Cakmak H (2020) Utilization of carrot (Daucus carota L.) fiber as a filler for chitosan based films. Food Hydrocoll. https://doi.org/10.1016/j.foodhyd.2020.105861

Amoroso L, De France KJ, Milz CI, Siqueira G, Zimmermann T, Nystrom G (2021) Sustainable cellulose nanofiber films from carrot pomace as sprayable coatings for food packaging applications. ACS Sustain Chem Eng 10:342–352. https://doi.org/10.1021/acssuschemeng.1c06345

Patil AY, Banapurmath NR, Yaradoddi JS, Kotturshettar BB, Shettar AS, Basavaraj GD, Keshavamurthy R, Yunus Khan TM, Mathad SN (2019) Experimental and simulation studies on waste vegetable peels as bio-composite fillers for light duty applications. Arab J Sci Eng 44:7895–7907. https://doi.org/10.1007/s13369-019-03951-2

Khan MJ, Karim Z, Charnnok B, Poonsawat T, Posoknistakul P, Laosiripojana N, Wu KCW, Sakdaronnarong C (2023) Fabrication and characterization of functional biobased membranes from postconsumer cotton fabrics and palm waste for the removal of dyes. Int J Mol Sci 24:6030. https://doi.org/10.3390/ijms24076030

Ahmad MA, Ahmad Puad NA, Bello OS (2014) Kinetic, equilibrium and thermodynamic studies of synthetic dye removal using pomegranate peel activated carbon prepared by microwave-induced KOH activation. Water Resour Ind 6:18–35. https://doi.org/10.1016/j.wri.2014.06.002

Hassan MM, Carr CM (2021) Biomass-derived porous carbonaceous materials and their composites as adsorbents for cationic and anionic dyes: a review. Chemosphere 265:129087

Amin NK (2008) Removal of reactive dye from aqueous solutions by adsorption onto activated carbons prepared from sugarcane bagasse pith. Desalination 223:152–161. https://doi.org/10.1016/j.desal.2007.01.203

Khaled A, Nemr AE, El-Sikaily A, Abdelwahab O (2009) Removal of direct N blue-106 from artificial textile dye effluent using activated carbon from orange peel: adsorption isotherm and kinetic studies. J Hazard Mater 165:100–110. https://doi.org/10.1016/j.jhazmat.2008.09.122

Kumar R, Negi S, Sharma P, Prasher IB, Chaudhary S, Dhau JS, Umar A (2018) Wastewater cleanup using Phlebia acerina fungi: an insight into mycoremediation. J Environ Manage 228:130–139. https://doi.org/10.1016/j.jenvman.2018.07.091

Li S, Huang J, Mao J, Zhang L, He C, Chen G, Parkin IP, Lai Y (2019) In vivo and in vitro efficient textile wastewater remediation by Aspergillus niger biosorbent. Nanoscale Adv 1:168–176. https://doi.org/10.1039/c8na00132d

Sirajudheen P, Poovathumkuzhi NC, Vigneshwaran S, Chelaveettil BM, Meenakshi S (2021) Applications of chitin and chitosan based biomaterials for the adsorptive removal of textile dyes from water—a comprehensive review. Carbohydr Polym 273:118604. https://doi.org/10.1016/j.carbpol.2021.118604

Sintakindi A, Ankamwar B (2020) Uptake of methylene blue from aqueous solution by naturally grown Daedalea africana and Phellinus adamantinus fungi. ACS Omega 5:12905–12914. https://doi.org/10.1021/acsomega.0c00673

Gholami Derami H, Gupta P, Gupta R, Rathi P, Morrissey JJ, Singamaneni S (2020) Palladium nanoparticle-decorated mesoporous polydopamine/bacterial nanocellulose as a catalytically active universal dye removal ultrafiltration membrane. ACS Appl Nano Mater 3:5437–5448. https://doi.org/10.1021/acsanm.0c00787

Nakayama R-i, Katsumata K, Niwa Y, Namiki N (2020) Dependence of water-permeable chitosan membranes on chitosan molecular weight and alkali treatment. Membranes 10:351. https://doi.org/10.3390/membranes10110351

Vedula SS, Yadav GD (2022) Wastewater treatment containing methylene blue dye as pollutant using adsorption by chitosan lignin membrane: development of membrane, characterization and kinetics of adsorption. J Indian Chem Soc 99:100263. https://doi.org/10.1016/j.jics.2021.100263

Abdul Mubarak NS, Chuan TW, Khor HP, Jawad AH, Wilson LD, Sabar S (2021) Immobilized Fe-loaded chitosan film for methyl orange dye removal: competitive ions, reusability, and mechanism. J Polym Environ 29:1050–1062. https://doi.org/10.1007/978-94-007-0443-5_6

Yousefi N, Jones M, Bismarck A, Mautner A (2021) Fungal chitin-glucan nanopapers with heavy metal adsorption properties for ultrafiltration of organic solvents and water. Carbohydr Polym 253:117273. https://doi.org/10.1016/j.carbpol.2020.117273

Janesch J, Jones M, Bacher M, Kontturi E, Bismarck A, Mautner A (2020) Mushroom-derived chitosan-glucan nanopaper filters for the treatment of water. React Funct Polym 146:104428. https://doi.org/10.1016/j.reactfunctpolym.2019.104428

Wikandari R, Millati R, Lennartsson PR, Harmayani E, Taherzadeh MJ (2012) Isolation and characterization of zygomycetes fungi from tempe for ethanol production and biomass applications. Biotechnol Appl Biochem 167:1501–1512. https://doi.org/10.1007/s12010-012-9587-x

Rathinamoorthy R, Bharathi TS, Snehaa M, Swetha C (2023) Structural and chemical characterization of mycelium sheets developed from Penicillium camemberti. J Polym Environ. https://doi.org/10.1007/s10924-023-02941-8

Rigueto CVT, Nazari MT, Rosseto M, Massuda LA, Alessandretti I, Piccin JS, Dettmer A (2021) Emerging contaminants adsorption by beads from chromium (III) tanned leather waste recovered gelatin. J Mol Liq 330:115638. https://doi.org/10.1016/j.molliq.2021.115638

Berglund L, Noël M, Aitomäki Y, Öman T, Oksman K (2016) Production potential of cellulose nanofibers from industrial residues: efficiency and nanofiber characteristics. Ind Crops Prod 92:84–92. https://doi.org/10.1016/j.indcrop.2016.08.003

Ren W, Zhu J, Guo F, Guo J, Zhang X, Wang H, Yu Y (2022) Structural evolution of cellulose from bamboo fibers and parenchyma cells during ionic liquid pretreatment for enhanced hydrolysis. Biomacromol 23:1938–1948. https://doi.org/10.1021/acs.biomac.1c01521

Tacer-Caba Z, Varis JJ, Lankinen P, Mikkonen KS (2020) Comparison of novel fungal mycelia strains and sustainable growth substrates to produce humidity-resistant biocomposites. Mater Des 192:108728. https://doi.org/10.1016/j.matdes.2020.108728

Cesar E, Canche-Escamilla G, Montoya L, Ramos A, Duarte-Aranda S, Bandala VM (2021) Characterization and physical properties of mycelium films obtained from wild fungi: natural materials for potential biotechnological applications. J Polym Environ 29:4098–4105. https://doi.org/10.1007/s10924-021-02178-3

Sanchez-Díaz MR, Lazarte MS, Moavro A, Peltzer MA, Ludemann V (2023) Naturally multicomponent materials obtained from filamentous fungi: impact of different cell rupture treatment on film properties. J Polym Environ 31:2347–2363. https://doi.org/10.1007/s10924-023-02766-5

Lago A, Delgado JF, Rezzani GD, Cottet C, Ramírez Tapias YA, Peltzer MA, Salvay AG (2023) Multi-component biodegradable materials based on water kefir grains and yeast biomasses: effect of the mixing ratio on the properties of the films. Polymers 15:2594. https://doi.org/10.3390/polym15122594

Attias N, Reid M, Mijowska SC, Dobryden I, Isaksson M, Pokroy B, Grobman YJ, Abitbol T (2021) Biofabrication of nanocellulose–mycelium hybrid materials. Adv Sustain Syst 5:2000196. https://doi.org/10.1002/adsu.202000196

Cartabia M, Girometta CE, Milanese C, Baiguera RM, Buratti S, Branciforti DS, Vadivel D, Girella A, Babbini S, Savino E (2021) Collection and characterization of wood decay fungal strains for developing pure mycelium mats. J Fungus 7:1008. https://doi.org/10.3390/jof7121008

Haneef M, Ceseracciu L, Canale C, Bayer IS, Heredia-Guerrero JA, Athanassiou A (2017) Advanced materials from fungal mycelium: fabrication and tuning of physical properties. Sci Rep 7:41292. https://doi.org/10.1038/srep41292

Hamad HN, Idrus S (2022) Recent developments in the application of bio-waste-derived adsorbents for the removal of methylene blue from wastewater: a review. Polymers 14:783. https://doi.org/10.3390/polym14040783

Zhou Y, Lu J, Zhou Y, Liu Y (2019) Recent advances for dyes removal using novel adsorbents: a review. Environ Pollut 252:352–365. https://doi.org/10.1016/j.envpol.2019.05.072

Hamad H, Moustafa MT (2023) Optimization study of the adsorption of malachite green removal by MgO nano-composite, nano-bentonite and fungal immobilization on active carbon using response surface methodology and kinetic study. Environ Sci Eur 35:1–37. https://doi.org/10.1186/s12302-023-00728-1

Bilgi M, Ugraskan V, Isik B (2023) Biosorption studies of methylene blue dye using NaOH-treated Aspergillus niger-filled sodium alginate microbeads. Chem Eng Commun 210:1405–1419. https://doi.org/10.1080/00986445.2022.2103685

De Rossi A, Rigueto CVT, Dettmer A, Colla LM, Piccin JS (2020) Synthesis, characterization, and application of Saccharomyces cerevisiae/alginate composites beads for adsorption of heavy metals. J Environ Chem Eng 8:104009. https://doi.org/10.1016/j.jece.2020.104009

Viraraghavan T, Srinivasan A (2011) Fungal Biosorption and Biosorbents. In: Kotrba P, Mackova M, Macek T (eds) Microbial biosorption of metals. Springer, Dordrecht

Nouri H, Azin E, Kamyabi A, Moghimi H (2021) Biosorption performance and cell surface properties of a fungal-based sorbent in azo dye removal coupled with textile wastewater. Int J Environ Sci Technol 18:2545–2558. https://doi.org/10.1007/s13762-020-03011-5

Funding

Open access funding provided by University of Boras. This research was funded by Åforsk, grant number 21-78.

Author information

Authors and Affiliations

Contributions

.All authors have read and agreed to the published version of the manuscript. All authors contributed to the study’s conception. Supervision by A.Z. Material preparation, investigation, methodology, and formal analysis were performed by A.Z. and S.N.M. Data collection, Result analysis and the first draft of the manuscript was written by S.N.M. Review and editing on previous versions of the manuscript by A.Z., M.H., S.K.R. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mousavi, S.N., Ramamoorthy, S.K., Hakkarainen, M. et al. Production of Mycelium-Based Papers from Carrot Pomace and Their Potential Applications for Dye Removal. J Polym Environ (2024). https://doi.org/10.1007/s10924-024-03238-0

Accepted:

Published:

DOI: https://doi.org/10.1007/s10924-024-03238-0