Abstract

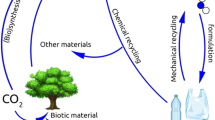

Concerns are constantly growing about our dependance on plastics derived from fossil feedstock, leading to the development of bio-based alternatives. The bio-based polyester poly(ethylene furanoate) (PEF) has attracted increasing attention from the scientific community due to its potential to replace mass-produced poly(ethylene terephtalate) (PET), mainly used in the packaging, film and fibre sectors. PEF can be 100% bio-based since both its monomers can be produced from biological resources, and exhibits superior properties compared to PET, such as its mechanical and gas barrier properties. As PEF gets closer to being produced at a large scale and entering the plastic market, its end-of-life management should be carefully studied in order to mitigate its environmental footprint. This review focusses on the state-of-the art of the main scenarios related to polymers waste, including mechanical and chemical recycling, composting and incineration.

Similar content being viewed by others

Data Availability

No datasets were generated or analysed during the current study.

References

Statista Research Department (2023) Annual production of plastics worldwide from 1950 to 2021. https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/. Accessed 25 Oct 2023

Statista Research Department (2023) Market volume of polyethylene terephthalate worldwide from 2015 to 2022, with a forecast for 2023 to 2030. https://www.statista.com/statistics/1245264/polyethylene-terephthalate-market-volume-worldwide/. Accessed 25 Oct 2023

Nisticò R (2020) Polyethylene terephthalate (PET) in the packaging industry. Polym Test 90. https://doi.org/10.1016/j.polymertesting.2020.106707

de Jong E, Visser HA, Dias AS et al (2022) The Road to bring FDCA and PEF to the market. Polym (Basel) 14:1–32. https://doi.org/10.3390/polym14050943

Van Berkel JG, Guigo N, Visser HA et al (2018) Chain structure and Molecular Weight Dependent mechanics of poly(ethylene 2,5-furandicarboxylate) compared to poly(ethylene terephthalate). Macromolecules 51:8539–8549. https://doi.org/10.1021/acs.macromol.8b01831

Burgess SK, Kriegel RM, Koros WJ (2015) Carbon Dioxide Sorption and Transport in Amorphous Poly(ethylene furanoate). https://doi.org/10.1021/acs.macromol.5b00333

Burgess SK, Leisen JE, Kraftschik BE et al (2014) Chain mobility, Thermal, and Mechanical properties of Poly(ethylene furanoate) compared to poly(ethylene terephthalate). Macromolecules 47:1383–1391. https://doi.org/10.1021/ma5000199

Burgess SK, Mikkilineni DS, Yu DB et al (2014) Water sorption in poly(ethylene furanoate) compared to poly(ethylene terephthalate). Part 1: equilibrium sorption. Polym (Guildf) 55:6861–6869. https://doi.org/10.1016/j.polymer.2014.10.047

Burgess SK, Mikkilineni DS, Yu DB et al (2014) Water sorption in poly(ethylene furanoate) compared to poly(ethylene terephthalate). Part 2: kinetic sorption. Polym (Guildf) 55:6870–6882. https://doi.org/10.1016/j.polymer.2014.10.065

Gandini A, Silvestre AJD, Neto CP et al (2009) The Furan Counterpart of Polyethylene Terephthalate: an alternative material based on renewable resources. J Polym Sci Polym Chem 47:295–298. https://doi.org/10.1002/pola.23130

Grand View Research Polyethylene Furanoate Market Size, Share & Trends Analysis Report By Application (Bottles, Fibers, Films), By Region (North America, Europe, APAC, Central & South America, MEA), And Segment Forecasts, 2020–2027. https://www.grandviewresearch.com/industry-analysis/polyethylene-furanoate-pef-market. Accessed 25 Oct 2023

Chen GQ, Patel MK (2012) Plastics derived from biological sources: Present and future: a technical and environmental review. Chem Rev 112:2082–2099. https://doi.org/10.1021/cr200162d

Rosenboom JG, Langer R, Traverso G (2022) Bioplastics for a circular economy. Nat Rev Mater 7:117–137. https://doi.org/10.1038/s41578-021-00407-8

Zheng J, Suh S (2019) Strategies to reduce the global carbon footprint of plastics. Nat Clim Chang 9:374–378. https://doi.org/10.1038/s41558-019-0459-z

Alaerts L, Augustinus M, Van Acker K (2018) Impact of bio-based plastics on current recycling of plastics. Sustain (Switzerland) 10(5):1487. https://doi.org/10.3390/su10051487

Rahimi AR, Garciá JM (2017) Chemical recycling of waste plastics for new materials production. Nat Rev Chem 1:1–11. https://doi.org/10.1038/s41570-017-0046

Serranti S, Bonifazi G (2019) Techniques for separation of plastic wastes. In: Use of Recycled Plastics in Eco-efficient Concrete. Woodhead Publishing, pp 9–37. https://doi.org/10.1016/b978-0-08-102676-2.00002-5

Lange JP (2021) Managing Plastic Waste-Sorting, Recycling, Disposal, and product redesign. ACS Sustain Chem Eng 9:15722–15738. https://doi.org/10.1021/acssuschemeng.1c05013

Ragaert K, Delva L, Geem K, Van (2017) Mechanical and chemical recycling of solid plastic waste. Waste Manag 69:24–58. https://doi.org/10.1016/j.wasman.2017.07.044

European PET, Bottle Platform (2022) European PET Bottle Platform Technical Opinion - Avantium Renewable Polymers BV-Poly(ethylene 2,5-furandicarboxylate) resin as barrier material in PET bottles. https://www.epbp.org/download/347/avantium-renewable-polymers-pef-as-barrier-material-in-pet-bottles. Accessed 25 Oct 2023

European PET Bottle Platform technical opinion - Interim Approval - Synvina’s poly(ethylene 2,5-furandicarboxylate) or PEF https://www.epbp.org/download/319/interim-approval-synvinas-polyethylene-25-furandicarboxylate-or-pef. Accessed 05 Mar 2024

De Jong E, Dam MA, Sipos L, Gruter GJM (2012) Furandicarboxylic acid (FDCA), A versatile building block for a very interesting class of polyesters. ACS Symposium Series 1105:1–13. https://doi.org/10.1021/bk-2012-1105.ch001

La Mantia FP (1996) Recycling of PVC and Mixed Plastic Waste. ChemTech Publishing, pp 64–66.

Colin X, Tcharkhtchi A (2013) Thermal degradation of polymers during their mechanical recycling. In: Culleri JC (ed) Recycling: Technological systems, management practices and environmental impact. Nova Science, pp 57–95. https://hal.science/hal-02618344

Ghosal K, Nayak C (2022) Recent advances in chemical recycling of polyethylene terephthalate waste into value added products for sustainable coating solutions-hope vs. hype Mater Adv 3:1974–1992. https://doi.org/10.1039/d1ma01112j

Velásquez EJ, Garrido L, Guarda A et al (2019) Increasing the incorporation of recycled PET on polymeric blends through the reinforcement with commercial nanoclays. Applied Clay Science 180:105185. https://doi.org/10.1016/j.clay.2019.105185

Grigore ME (2017) Methods of recycling, properties and applications of recycled thermoplastic polymers. Recycling 2:1–11. https://doi.org/10.3390/recycling2040024

Terzopoulou Z, Karakatsianopoulou E, Kasmi N et al (2017) Effect of catalyst type on recyclability and decomposition mechanism of poly(ethylene furanoate) biobased polyester. J Anal Appl Pyrol 126:357–370. https://doi.org/10.1016/j.jaap.2017.05.010

Hahladakis JN, Velis CA, Weber R et al (2018) An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J Hazard Mater 344:179–199. https://doi.org/10.1016/j.jhazmat.2017.10.014

Terzopoulou Z, Wahbi M, Kasmi N et al (2020) Effect of additives on the thermal and thermo-oxidative stability of poly(ethylene furanoate) biobased polyester. Thermochim Acta 686:178549. https://doi.org/10.1016/j.tca.2020.178549

Kucherov FA, Gordeev EG, Kashin AS, Ananikov VP (2017) Three-Dimensional Printing with Biomass-derived PEF for Carbon-Neutral Manufacturing. Angew Chem 129:16147–16151. https://doi.org/10.1002/ange.201708528

Paszkiewicz S, Walkowiak K, Irska I et al (2023) Influence of the multiple injection moulding and composting time on the properties of selected packaging and Furan-based polyesters. J Polym Environ 31:722–742. https://doi.org/10.1007/s10924-022-02657-1

Cruz SA, Zanin M (2006) PET recycling: evaluation of the solid state polymerization process. J Appl Polym Sci 99:2117–2123. https://doi.org/10.1002/app.22526

Chebbi Y, Kasmi N, Majdoub M et al (2019) Solid-state polymerization of poly(ethylene furanoate) biobased polyester, III: extended study on effect of catalyst type on molecular weight increase. Polym (Basel) 11. https://doi.org/10.3390/polym11030438

Achilias DS, Chondroyiannis A, Nerantzaki M et al (2017) Solid State Polymerization of Poly(Ethylene Furanoate) and its nanocomposites with SiO 2 and TiO 2. https://doi.org/10.1002/mame.201700012

Höhnemann T, Steinmann M, Schindler S et al (2021) Poly(Ethylene Furanoate) along its life-cycle from a Polycondensation Approach to High-Performance Yarn and its recyclate. Materials 14(4):1044. https://doi.org/10.3390/ma14041044

Gabirondo E, Melendez-Rodriguez B, Arnal C et al (2021) Organocatalyzed closed-loop chemical recycling of thermo-compressed films of poly(ethylene furanoate). Polym Chem 12:1571–1580. https://doi.org/10.1039/d0py01623c

Payne J, Jones MD (2021) The Chemical Recycling of Polyesters for a circular Plastics Economy: challenges and Emerging opportunities. Chemsuschem 14:4041–4070. https://doi.org/10.1002/cssc.202100400

Crippa M, Morico B (2019) PET depolymerization: a novel process for plastic waste chemical recycling. Studies in Surface Science and Catalysis. Elsevier, pp 215–229. https://doi.org/10.1016/b978-0-444-64337-7.00012-4

Sipos L, Leroy Olson M (2015) Process for the Depolymerization of a Furandicarboxylate Containing Polyester. United States Patent. https://ppubs.uspto.gov/dirsearch-public/print/downloadPdf/9073886. Accessed 05 Mar 2024

Alberti C, Matthiesen K, Wehrmeister M et al (2021) Zinc-catalyzed depolymerization of the end-of-life poly(ethylene 2,5-furandicarboxylate). ChemistrySelect 6:7972–7975. https://doi.org/10.1002/slct.202102427

Agostinho B, Silvestre AJD, Sousa AF (2022) From PEF to rPEF: disclosing the potential of deep eutectic solvents in continuous de-/re-polymerization recycling of biobased polyesters. Green Chem 24. https://doi.org/10.1039/d2gc00074a

Yoshida S, Hiraga K, Takehana T et al (2016) A bacterium that degrades and assimilates poly(ethylene terephthalate). Sci (1979) 351:1196–1199. https://doi.org/10.1126/SCIENCE.AAD6359

Paparella AN, Perrone S, Salomone A et al (2023) Use of Deep Eutectic solvents in Plastic depolymerization. Catalysts 13(7):1035 https://doi.org/10.3390/catal13071035

Pellis A, Haernvall K, Pichler CM et al (2016) Enzymatic hydrolysis of poly(ethylene furanoate). J Biotechnol 235:47–53. https://doi.org/10.1016/j.jbiotec.2016.02.006

Weinberger S, Haernvall K, Scaini D et al (2017) Enzymatic surface hydrolysis of poly(ethylene furanoate) thin films of various crystallinities. Green Chem 19:5381–5384. https://doi.org/10.1039/c7gc02905e

Weinberger S, Canadell J, Quartinello F et al (2017) Enzymatic degradation of poly(ethylene 2,5-furanoate) powders and amorphous films. Catalysts 7:318. https://doi.org/10.3390/catal7110318

Kawai F, Furushima Y, Mochizuki N et al (2022) Efficient depolymerization of polyethylene terephthalate (PET) and polyethylene furanoate by engineered PET hydrolase Cut190. AMB Express 12:. https://doi.org/10.1186/s13568-022-01474-y

Williams PT, Bagri R (2004) Hydrocarbon gases and soils from the recycling of polystyrene waste by catalytic pyrolysis. Int J Energy Res 28:31–44. https://doi.org/10.1002/er.949

Gebre SH, Sendeku MG, Bahri M (2021) Recent trends in the pyrolysis of Non-degradable Waste Plastics. ChemistryOpen 10:1202–1226. https://doi.org/10.1002/open.202100184

Güneri A, Bernardo CA, Leidner J et al (1998) Frontiers in the Science and Technology of Polymer Recycling. Springer Dordrecht

Tsanaktsis V, Vouvoudi E, Papageorgiou GZ et al (2015) Thermal degradation kinetics and decomposition mechanism of polyesters based on 2,5-furandicarboxylic acid and low molecular weight aliphatic diols. J Anal Appl Pyrol 112:369–378. https://doi.org/10.1016/j.jaap.2014.12.016

Ren L, Yang S, Wang J et al (2023) Electrocatalytic valorization of waste polyethylene furanoate (PEF) bioplastics for the production of formic acid and hydrogen energy. React Chem Eng 8:1937–1942. https://doi.org/10.1039/d3re00028a

Al-Tamreh SA, Ibrahim MH, El-Naas MH et al (2021) Electroreduction of Carbon Dioxide into Formate: a Comprehensive Review. ChemElectroChem 8:3207–3220. https://doi.org/10.1002/celc.202100438

Kim MS, Chang H, Zheng L et al (2022) A review of biodegradable plastics: Chemistry, Applications, Properties, and Future Research needs. Chem Rev 123:9915–9939. https://doi.org/10.1021/acs.chemrev.2c00876

Siddiqui MN, Redhwi HH, Al-Arfaj AA, Achilias DS (2021) Chemical recycling of PET in the presence of the bio-based polymers, PLA, PHB and PEF: a review. Sustain (Switzerland) 13(19):10528. https://doi.org/10.3390/su131910528

Wilde B, De, Mortier N, Verstichel S et al (2013) Report on current relevant biodegradation and ecotoxicity standards. https://www.biobasedeconomy.eu/app/uploads/sites/2/2017/03/Current-relevant-biodegradation-and-ecotoxicity-standards-chapter-5-10.pdf. Accessed 25 Oct 2023

Gruter GJ (2019) Technology & Markets Day Path to the Future. https://www.avantium.com/wp-content/uploads/2019/06/20190606-Technology-Day_CTO_Gert-Jan_Gruter_breakout_final_.pdf. Accessed 25 Oct 2023

Abraham A, Park H, Choi O, Sang BI (2021) Anaerobic co-digestion of bioplastics as a sustainable mode of waste management with improved energy production – A review. Bioresour Technol 322:124537. https://doi.org/10.1016/j.biortech.2020.124537

Kunatsa T, Xia X (2022) A review on anaerobic digestion with focus on the role of biomass co-digestion, modelling and optimisation on biogas production and enhancement. Bioresour Technol 344:126311. https://doi.org/10.1016/j.biortech.2021.126311

Wei W, Huang QS, Sun J et al (2019) Revealing the mechanisms of Polyethylene Microplastics affecting anaerobic digestion of Waste activated Sludge. Environ Sci Technol 53:9604–9613. https://doi.org/10.1021/acs.est.9b02971

Dilara Hatinoglu M, Dilek Sanin F (2022) Fate and effects of polyethylene terephthalate (PET) microplastics during anaerobic digestion of alkaline-thermal pretreated sludge. Waste Manag 153:376–385. https://doi.org/10.1016/j.wasman.2022.09.016

Marten E, Müller RJ, Deckwer WD (2003) Studies on the enzymatic hydrolysis of polyesters - I. Low molecular mass model esters and aliphatic polyesters. Polym Degrad Stab 80:485–501. https://doi.org/10.1016/S0141-3910(03)00032-6

Terzopoulou Z, Tsanaktsis V, Bikiaris DN et al (2016) Biobased poly(ethylene furanoate-co-ethylene succinate) copolyesters: solid state structure, melting point depression and biodegradability. RSC Adv 6:84003–84015. https://doi.org/10.1039/c6ra15994j

Matos M, Sousa AF, Fonseca AC et al (2014) A new generation of furanic copolyesters with enhanced degradability: poly(ethylene 2,5-furandicarboxylate)-co-poly(lactic acid) copolyesters. Macromol Chem Phys 215:2175–2184. https://doi.org/10.1002/macp.201400175

Li X, Lin Y, Liu M et al (2023) A review of research and application of polylactic acid composites. J Appl Polym Sci 140:1–22. https://doi.org/10.1002/app.53477

Wu H, Wen B, Zhou H et al (2015) Synthesis and degradability of copolyesters of 2, 5-furandicarboxylic acid, lactic acid, and ethylene glycol. Polym Degrad Stab 121:100–104. https://doi.org/10.1016/j.polymdegradstab.2015.08.009

Lu J, Qiu Z, Yang W (2007) Fully biodegradable blends of poly(l-lactide) and poly(ethylene succinate): Miscibility, crystallization, and mechanical properties. Polym 48(14):4196–4204. https://doi.org/10.1016/j.polymer.2007.05.035

Wu L, Mincheva R, Xu Y et al (2012) High molecular weight poly(butylene succinate-co-butylene furandicarboxylate) copolyesters: from catalyzed polycondensation reaction to thermomechanical properties. Biomacromolecules 13:2973–2981. https://doi.org/10.1021/bm301044f

Liu X, Zhao G, Sun S et al (2022) Biosynthetic Pathway and Metabolic Engineering of Succinic Acid. Front Bioeng Biotechnol 10:1–16. https://doi.org/10.3389/fbioe.2022.843887

Jia Z, Wang J, Sun L et al (2018) Fully bio-based polyesters derived from 2,5-furandicarboxylic acid (2,5-FDCA) and dodecanedioic acid (DDCA): from semicrystalline thermoplastic to amorphous elastomer. J Appl Polym Sci 135:46076. https://doi.org/10.1002/app.46076

Papadopoulos L, Magaziotis A, Nerantzaki M et al (2018) Synthesis and characterization of novel poly(ethylene furanoate-co-adipate) random copolyesters with enhanced biodegradability. Polym Degrad Stab 156:32–42. https://doi.org/10.1016/j.polymdegradstab.2018.08.002

Li J, Tu Y, Lu H et al (2021) Rapid synthesis of sustainable poly(ethylene 2,5-furandicarboxylate)-block-poly(tetramethylene oxide) multiblock copolymers with tailor-made properties via a cascade polymerization route. Polym (Guildf) 237:124313. https://doi.org/10.1016/j.polymer.2021.124313

Lotfi Choobbari M, Ferguson J, Van den Brande N et al (2023) Studying the concentration of polymers in blended microplastics using 2D and 3D raman mapping. Sci Rep 13:1–8. https://doi.org/10.1038/s41598-023-35010-0

Kaur H, Rawat D, Poria P et al (2022) Ecotoxic effects of microplastics and contaminated microplastics – emerging evidence and perspective. Sci Total Environ 841:156593. https://doi.org/10.1016/j.scitotenv.2022.156593

Zhang X, Li Y, Lei J et al (2023) Time-dependent effects of microplastics on soil bacteriome. J Hazard Mater 447:130762. https://doi.org/10.1016/J.JHAZMAT.2023.130762

Zhang Y, Zhang C, Jiang M, Zhou G (2022) Bio-effects of bio-based and fossil-based microplastics: Case study with lettuce-soil system. Environ Pollut 306:119395. https://doi.org/10.1016/j.envpol.2022.119395

Makarichi L, Jutidamrongphan W, Techato Kanan (2018) The evolution of waste-to-energy incineration: a review. Renew Sustain Energy Rev 91:812–821. https://doi.org/10.1016/j.rser.2018.04.088

Chirayil CJ, Mishra RK, Thomas S (2019) Materials recovery, direct reuse and incineration of PET bottles. In: Thomas S, Kanny K, Thomas MG et al (eds) Recycling of polyethylene terephthalate bottles. Springer, pp 37–60

nova-Institute (2022) PEF bottles - a sustainable packaging material - ISO Certified LCA of Avantium’s PEF products. https://www.avantium.com/wp-content/uploads/2022/02/20220221-PEF-bottles-–-a-sustainable-packaging-material-ISO-certified-LCA.pdf. Accessed 26 Oct 2023

Stegmann P, Gerritse T, Shen L et al (2023) The global warming potential and the material utility of PET and bio-based PEF bottles over multiple recycling trips. J Clean Prod 395. https://doi.org/10.1016/j.jclepro.2023.136426

Avantium (2023) Press release - Avantium awarded €0.76 million EU funding for its participation in the Rebiolution project. https://www.avantium.com/2023/avantium-awarded-e0-76-million-eu-funding-for-its-participation-in-the-rebiolution-project/. Accessed 05 Mar 2024

Acknowledgements

The authors are thankful to the Natural Sciences and Engineering Research Council of Canada and the Canada Research Chair in Biomass Valorization (to M.-J. D.) for the financial support.

Author information

Authors and Affiliations

Contributions

L.S., MSc. student, drafted the manuscript. M.M., Post Doctoral Fellow, provided comments and knowledge on some technical aspects of the manuscript. Prof. M.J.D., supervisor of L.S. and M.M., contributed to all aspects of this work, including research expertise, manuscript review and editing, and funding.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Silverwood, L., Mottoul, M. & Dumont, MJ. A Review of End-of-Life Pathways for Poly(Ethylene Furanoate) and its Derivatives. J Polym Environ (2024). https://doi.org/10.1007/s10924-024-03229-1

Accepted:

Published:

DOI: https://doi.org/10.1007/s10924-024-03229-1