Abstract

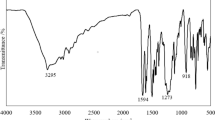

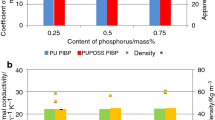

Green manufacturing and reducing our cultural dependency on petrochemicals have been the global interest currently, especially in the polyurethane industry segments. We report the fabrication of rigid polyurethane foams (RPUFs) and their flame-retardant property from hemp seed oil as an alternative to petrochemical-based polyols. The cold-pressed hemp-seed oil (HSO) was first oxidized to epoxidized triglyceride oils with acetic acid and hydrogen peroxide, followed by a ring-opening reaction with methanol to fabricate hemp bio-polyols. The formation of polyols was characterized using FT-IR, hydroxyl, and acid values. The bio-polyol was used in different proportions with commercial polyols and other foaming ingredients to produce rigid polyurethane foams via a one-step process. Dimethyl methylphosphonate (DMMP), triethyl phosphate (TEP), and expandable graphite (EG) were added during the foam preparation to improve flame retardancy. The produced foams were analyzed for their apparent density, mechanical properties, thermal degradation behavior, closed cell content, flammability, and cellular morphology. The effect of different flame retardants had a significant influence on the cellular structures, closed-cell content, density, and compressive strength of the polyurethane. A significant improvement in anti-flaming properties was observed as the neat HSO-based foam showed a burning time of 110 s and a weight loss of 82%, whereas 10 wt% of TEP displayed a reduced burning time and weight loss of 19 s and 5%, respectively. DMMP and EG-based RPUFs exhibited similar flame retardancy and mechanical properties relative to neat HSO-based foam. The results demonstrated in this work proposed a potential combination of bio-polyols and commercial polyols as a strategy to fabricate flame-retardant polyurethane foam for high-performance applications.

Graphical Abstract

Similar content being viewed by others

References

Szycher M (1999) Handbook of polyurethanes. CRC, Boca Raton, FL

Gama NV, Ferreira A, Barros-Timmons A (2018) Polyurethane foams: past, present, and future. Materials 11:1841

Akindoyo JO, Beg MDH, Ghazali S, Islam MR, Jeyaratnam N, Yuvaraj AR (2016) Polyurethane types, synthesis and applications-a review. RSC Adv 6:114453–114482

Wendels S, Av´erous L (2021) Biobased polyurethanes for biomedical applications. Bioact Mater 6:1083–1106

Engels HW, Pirkl HG, Albers R, Albach RW, Krause J, Hoffmann A, Casselmann H, Dormish J (2013) Polyurethanes: versatile materials and sustainable problem solvers for today’s challenges. Angew Chem Int Ed 52:9422–9441

Hai TAP, Tessman M, Neelakantan N, Samoylov AA, Ito Y, Rajput BS, Pourahmady N, Burkart MD (2021) Renewable polyurethanes from sustainable Biological precursors. Biomacromolecules 22:1770–1794

Zhu Y, Romain C, Williams C (2016) Sustainable polymers from renewable resources. Nature 540:354–362

Xia Y, Larock RC (2010) Vegetable oil-based polymeric materials: synthesis, properties, and applications. Green Chem 12:1893–1909

Sardon H, Mecerreyes D, Basterretxea A, Avérous L, Jehanno C (2021) From lab to market: current strategies for the production of Biobased Polyols. ACS Sustain Chem Eng 9:10664–10677

Li Y, Luo X, Hu S (2015) Polyols and polyurethanes from Vegetable oils and their derivatives Á vegetable oils Á fatty acids Á. Springer, Berlin/Heidelberg, Germany

Cabulis U, Ivdre A (2023) Recent developments in the sustainability of the production of polyurethane foams from polyols based on the first- to the fourth-generation of biomass feedstock, current opinion in Green and Sustainable Chemistry, 44, 100866

Kirpluks M, Kalnbunde D, Benes H, Cabulis U (2018) Natural oil-based highly functional polyols as feedstock for rigid polyurethane foam thermal insulation. Ind Crops Prod 122:627–636

Petrovic ZS (2008) Polyurethanes from Vegetable oils. Polym Rev 48:109–155

Zhang C, Garrison TF, Madbouly SA, Kessler MR (2017) Recent advances in Vegetable Oil-based polymers and their composites. Prog Polym Sci 71:91–143

Miao SD, Zhang SP, Su ZG, Wang P (2013) Synthesis of Biobased polyurethanes from Epoxidized Soybean Oil and Isopropanolamine. J Appl Polym Sci 127:1929–1936

Lu YS, Larock RC (2008) Soybean-oil-based Waterborne polyurethane dispersions: effects of Polyol Functionality and Hard Segment Content on properties. Biomacromolecules 9:3332–3340

Bähra M, Mülhaupta R (2012) Linseed and soybean oil-based polyurethanes prepared via the non-isocyanate route and catalytic carbon dioxide conversion. Green Chem 14:483–489

Zhang CQ, Xia Y, Chen RQ, Huh S, Johnston PA, Kessler MR (2013) Soy-Castor Oil-based polyols prepared using a Solvent free and Catalyst-free Method and polyurethanes Therefrom. Green Chem 15:1477–1484

Calvo-Correas T, Mosiewicki MA, Corcuera MA, Eceiza A, Aranguren MI (2015) Linseed oil-based polyurethane rigid foams: synthesis and characterization. J Renew Mat 3:3–13

Tanaka R, Hirose S, Hatakeyama H (2008) Preparation and characterization of polyurethane foams using a Palm Oil-based Polyol. Bioresour Technol 99:3810–3816

Zhang C, Madbouly SA, Kessler MR (2015) Biobased polyurethanes prepared from different vegetable oils. ACS Appl Mater Interfaces 7:1226–1233

Bhoyate S, Ionescu M, Kahol PK, Gupta RK (2019) Castor-oil-derived nonhalogenated reactive flame-retardant-based polyurethane foams with significant reduced heat release rate. J Appl Polym Sci 136:47276

Dworakowska S, Bogdal D, Prociak A (2012) Microwave-assisted synthesis of polyols from Rapeseed Oil and properties of Flexible polyurethane foams. Polymers-Basel 4:1462–1477

Burton RA, Andres M, Cole M (2022) Industrial Hemp seed: from the field to value-added food ingredients. J Cannabis Res 4:45

Cherney JH, Small E (2016) Industrial Hemp in North America: production, politics and potential. Agronomy 6:58

Kostić MD, Joković NM, Stamenković OS, Rajković KM, Milić PS, Veljković VB (2013) Optimization of hempseed oil extraction by n-hexane. Ind Crops Prod 48:133–143

Li R, Zhang P, Liu T, Muhunthan B, Xin J, Zhang J (2018) Use of Hempseed-Oil-Derived Polyacid and Rosin-Derived Anhydride Acid as Cocuring agents for Epoxy materials. ACS Sustain Chem Eng 6:4016–4025

Moser BR, Cermak SC, Doll KM, Kenar JA, Sharma BK (2022) A review of fatty Epoxide Ring opening reactions: Chemistry, recent advances, and applications. J Am Oil Chem Soc 99:801–842

Manthey NW, Cardona F, Francucci G, Aravinthan T (2013) Thermo-Mechanical properties of Epoxidized Hemp Oil-based bioresins and biocomposites. J Reinf Plast Compos 32:1444–1456

Ho YH, Parthiban A, Thian MC, Ban ZH (2022) Siwayanan, P. Acrylated Biopolymers Derived via Epoxidation and Subsequent Acrylation of Vegetable Oils. Int J Polym Sci 2022: 1–12

Surender R, Mahendran AR, Wuzella G, Vijayakumar CT (2016) Synthesis, characterization and degradation behavior of Thermoplastic polyurethane from hydroxylated hemp seed oil. J Therm Anal Calorim 123:525–533

Benaniba MT, Belhaneche-Bensemra N, Gelbard G (2008) Epoxidation of sunflower oil with peroxoacetic acid in the presence of ion exchange resin by various processes. Energy Educ Sci Technol 21:71–82

Lerma-García MJ, Ramis-Ramos G, Herrero-Martínez JM, Simó-Alfonso EF (2010) Authentication of extra virgin olive oils by Fourier-transform infrared spectroscopy. Food Chem 118:78–83

Guo Y, Hardesty JH, Mannari VM, Massingill JL (2007) Hydrolysis of Epoxidized Soybean Oil in the Presence of Phosphoric Acid. J Am Oil Chem Soc 84:929–935

Gupta RK, Ionescu M, Wan X, Radojcic D, Petrovic ZS (2015) Synthesis of a Novel Limonene based Mannich Polyol for rigid polyurethane foams. J Polym Environ 23:261–268

Lee ST, Ramesh NS (2004) Polymeric foams: mechanisms and materials, vol 1, 1st edn. CRC, Boca Raton, FL, USA, p 360

Thirumal M, Khastgir D, Nando GB, Naik YP, Singha NK (2010) Halogen-free flame retardant PUF: effect of melamine compounds on mechanical, thermal, and flame retardant properties. Polym Degrad Stab 95:1138–1145

Kairytė A, Kremensas A, Balčiūnas G, Członka S, Strąkowska A (2020) Closed cell rigid polyurethane foams based on low functionality polyols: research of Dimensional Stability and standardized Performance Properties. Materials 13:1438

Czupry ´nski B, Paciorek-Sadowska J, Liszkowska J (2010) Properties of rigid polyurethane-polyisocyanurate foams modified with the selected fillers. J Appl Polym Sci 115:2460–2469

Polaczek K, Kura ´nska M (2022) Hemp seed oil and oilseed Radish Oil as New sources of raw materials for the synthesis of Bio-polyols for Open-Cell polyurethane foams. Materials 15:8891

Bhoyate S, Ionescu M, Kahol PK, Chen J, Mishra SR, Gupta RK (2018) Highly flame-retardant polyurethane foam based on reactive phosphorus polyol and limonene-based polyol. J Appl Polym Sci 135:16–19

Asare MA, Kote P, Chaudhary S, de Souza FM, Gupta RK (2022) Sunflower Oil as a renewable resource for polyurethane foams: effects of Flame-Retardants. Polymers 14:5282

Kaur R, Kumar M (2020) Addition of anti-flaming agents in castor oil based rigid polyurethane foams: studies on mechanical and flammable behavior. Mater Res Express 7:015333

Choe H, Choi Y, Kim JH (2019) Threshold cell diameter for high thermal insulation of water-blown rigid polyurethane foams. J Ind Eng Chem 73:344–350

Wang Y, Zhang J (2013) Thermal stabilities of drops of burning thermoplastics under the UL 94 vertical test conditions. J Hazard Matter 246–247:103–109

Chattopadhyay DK, Webster DC (2009) Thermal stability and flame retardancy of polyurethanes. Prog Polym Sci 34:1068–1133

Günther M, Lorenzetti A, Schartel B (2018) Fire phenomena of rigid polyurethane foams. Polymers 10:1166

Camino G, Costa L, di Cortemiglia MPL (1991) Overview of fire-retardant mechanisms. Polym Degrad Stab 33:131–154

Günther M, Levchik SV, Schartel B (2020) Bubbles, and collapses: Fire Phenomena of Flame-Retarded Flexible polyurethane foams. Polym Adv Technol 31:2185–2198

Kirpluks M, Cabulis U, Zeltins V, Stiebra L, Avots A (2014) Rigid polyurethane Foam Thermal Insulation protected with Mineral Intumescent Mat. Autex Res J 14(4):259–269

Bian XC, Tang JH, Li ZM, Lu ZY, Lu A (2007) Dependence of Flame-Retardant properties on Density of Expandable Graphite filled rigid polyurethane foam. J Appl Polym Sci 104:3347–3355

Ming G, Chen S, Sun YJ, Wang YX (2017) Flame retardancy and Thermal properties of Flexible polyurethane foam containing expanded Graphite. Combust Sci Technol 189:793–805

Petrovi´c ZS, Zavargo Z, Flyn JH, Macknight WJ (1994) Thermal degradation of segmented polyurethanes. J Appl Polym Sci 51:1087–1095

Yang L, Shroll RM, Zhang J, Lourderaj U, Hase WL (2009) Theoretical investigation of mechanisms for the gas-phase unimolecular decomposition of DMMP. J Phys Chem A 113:13762–13771

Schartel B (2010) Phosphorus-based flame retardancy mechanisms-old hat or a starting point for Future Development? Materials 3:4710–4745

Lorenzetti A, Dittrich B, Schartel B, Roso M, Modesti M (2017) Expandable Graphite in polyurethane foams: the effect of expansion volume and intercalants on Flame Retardancy. J Appl Polym Sci 134:45173

Acknowledgements

The authors are grateful to the National Institute of Standards and Technology (NIST award number 70NANB20D146) and the U.S. Economic Development Administration (US-EDA award number 05-79-06038) for providing research infrastructure funding.

Author information

Authors and Affiliations

Contributions

S.J.: Investigation, Methodology, Data curation. Y.N.D.: Data curation, Formal analysis. P.S.: Formal analysis, Writing-original draft; Writing-review & editing. R.K.G.: Conceptualization, Resources, Project administration, Funding acquisition, Validation, Writing-review & editing.

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no competing financial interests towards any individual or organization.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jariwala, S., Desai, Y.N., Sahu, P. et al. Hemp Seed Oil Derived Rigid Polyurethane Foams and Their Underlying Flame Retardancy Properties. J Polym Environ (2024). https://doi.org/10.1007/s10924-024-03215-7

Accepted:

Published:

DOI: https://doi.org/10.1007/s10924-024-03215-7