Abstract

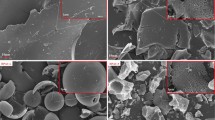

Microporous carbon adsorbents with high surface area and porosity were synthesized from lignin using an acrylic acid pretreatment strategy. Lignin was grafted with acrylic acid via hydrothermal treatment to introduce carboxyl groups, as verified by NMR and FT-IR spectroscopy. The incorporated carboxyls enabled ion exchange reactions between lignin and potassium during subsequent potassium hydroxide (KOH) activation. This optimized the dispersion of potassium, allowing effective activation even at low KOH levels. The effects of process parameters, including acrylic acid content, hydrothermal time, and KOH ratio, were investigated. Optimal conditions of 5 wt% acrylic acid and 6 h hydrothermal reaction produced a carbon adsorbent with exceptional Brunauer–Emmett–Teller (BET) surface area of 1708 m2/g and pore volume of 0.82 cm3/g at a lignin:KOH:acrylic acid ratio of 1:0.5:0.05. Characterization by FE-SEM, XRD, EDS, and Raman spectroscopy confirmed the successful synthesis of an optimized microporous carbon material. The carbon exhibited an outstanding lead ion adsorption capacity of 371 mg/g by Langmuir modeling. Adsorption kinetics followed pseudo-second-order, indicating chemisorption as the rate-controlling step. Thermodynamic analysis revealed the endothermic nature of lead adsorption, further enhanced at higher temperatures. Overall, the acrylic acid pretreatment approach enabled sustainable production of high surface area microporous carbon adsorbents from lignin using minimal KOH activation. The adsorbents demonstrated tremendous potential for removing lead ions via chemisorption mechanisms.

Similar content being viewed by others

Data Availability

No datasets were generated or analysed during the current study.

References

Xu X, Nie S, Ding H, Hou FF (2018) Nat Rev Nephrol 14(5):313–324

He S, Shi G, Xiao H, Sun G et al (2021) Chem Eng J 410:128286

Li Y, He J, Zhang K, Liu T et al (2019) RSC Adv 9(1):397–407

Mariana M, Abdul Khalil HPS, Mistar E, Yahya EB, Alfatah T, Danish M, Amayreh M (2021) J Water Process Eng 43:102221

Shahadat M, Isamil S (2018) RSC Adv 8(43):24571–24587

Zagho MM, Hassan MK, Khraisheh M, Al-Maadeed MAA et al (2021) Chem Eng J Adv 6:100091

Carrott P, Carrott MR (2007) Bioresour Technol 98(12):2301–2312

Yorgun S, Vural N, Demiral H (2009) Microporous Mesoporous Mater 122(1–3):189–194

Lillo-Ródenas M, Cazorla-Amorós D, Linares-Solano A (2003) Carbon 41(2):267–275

Gao Y, Yue Q, Gao B, Li A (2020) Sci Total Environ 746:141094

Varila T, Bergna D, Lahti R, Romar H, Hu T, Lassi U (2017) BioResources 12(4):8078–8092

Tan Y, Wang X, Xiong F, Ding J, Qing Y, Wu Y (2021) Ind Crops Prod 171:113980

Heidarinejad Z, Dehghani MH, Heidari M, Javedan G, Ali I, Sillanpää M (2020) Environ Chem Lett 18(2):393–415

Han Q, Wang J, Goodman BA, Xie J, Liu Z (2020) J Powder Technol 366:239–248

Nayak A, Bhushan B, Gupta V, Sharma P (2017) J Colloid Interf Sci 493:228–240

Zhang N, Shen Y (2019) Bioresour Technol 284:325–332

Ashori A, Menbari S, Bahrami R (2016) Ind Eng Chem 38(8):37–42

Sevilla M, Mokaya R (2014) Energy Environ Sci 7(4):1250–1280

Chiu Y-H, Lin L-Y (2019) J Taiwan Inst Chem Eng 101:177–185

Njoku V, Foo K, Asif M, Hameed B (2014) Chem Eng J 250:198–204

Wu F-C, Wu P-H, Tseng R-L, Juang R-S (2010) J Environ Manage 91(5):1097–1102

Chayid MA, Ahmed MJ (2015) J Environ Chem Eng 3(3):1592–1601

Wang B, Zhu C, Zhang Z, Zhang W et al (2016) Fuel 179:274–280

Ludwinowicz J, Jaroniec M (2015) Carbon 82:297–303

Liu Z, Zhang Z, Jia Z, Zhao L et al (2018) Chem Eng J 337:290–299

Dessbesell L, Paleologou M, Leitch M, Pulkki R, Xu CC (2020) Renew Sust Energy Rev 123:109768

Liu H, Xu T, Liu K, Zhang M, Liu W, Li H, Du H, Si C (2021) Ind Crops Prod 165:113425

Liu Y, Jin C, Yang Z, Wu G, Liu G, Kong Z (2021) Int J Biol Macromol 187:880–891

Sun J, Wang C, Stubbs LP, He C (2017) Macromol Mater Eng 302(12):1700341

Kong F, Wang S, Gao W, Fatehi P (2018) RSC Adv 8(22):12322–12336

Kinoshita K, Takano Y, Ohkouchi N, Deguchi S (2017) ACS Omega 2(6):2765–2769

Liu Z, Wan X, Wang Q, Tian D, Hu J, Huang M, Shen F, Zeng Y (2021) Renew Sust Energy Rev 50:111503

Zhang Z, Wang T, Zhang H, Liu Y, Xing B (2021) Sci Total Environ 757:143910

Bian Y, Bian Z, Zhang J, Ding A, Liu S, Zheng L, Wang H (2015) Chin J Chem Eng 23(10):1705–1711

Asuquo E, Martin A, Nzerem P, Siperstein F, Fan X (2017) J Environ Chem Eng 5(1):679–698

Funding

This work is based upon research funded by Iran National Science Foundation (INSF) under project No. 99008793.

Author information

Authors and Affiliations

Contributions

RP: investigation, methodology, formal analysis, visualization, validation. AA: investigation, methodology, formal analysis, visualization, supervision, validation. AR : supervision, conceptualization, methodology, validation, resources. AA: validation, writing—original draft preparation, writing—review and editing. AB: methodology and validation. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

None.

Research Involving Human and Animal Rights

This article does not contain any studies involving animals or human participants performed.

by any of the authors.

Additional information

Publisher’s Note

Springer nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pourbaba, R., Abdulkhani, A., Rashidi, A. et al. Sustainable Production of Hierarchically Porous Carbon from Lignin-Acrylic Acid Copolymers. J Polym Environ (2024). https://doi.org/10.1007/s10924-023-03177-2

Accepted:

Published:

DOI: https://doi.org/10.1007/s10924-023-03177-2