Abstract

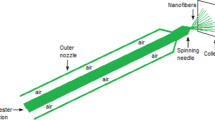

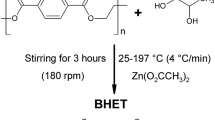

The consumption of poly(ethylene terephthalate) (PET) has experienced a surge in recent times, owing to the widespread use of single-use plastic bottles, particularly in the context of beverages and drinking water. PET, a thermoplastic polymer, is known for its recyclability, and the recycled variant is referred to as rPET. The incorporation of rPET in fiber manufacturing is favored due to its cost-effectiveness, and the functionalized rPET fibers present an innovative product that can be used in a variety of applications. This study aimed to functionalize rPET fibers using the spun-bond technique, imparting antibacterial and flame-retardant properties, which are commonly employed in thermal insulator products. Nano zinc oxide (nano-ZnO) was used to confer antibacterial functionality, while phosphorus flame retardant (PFR) was used to impart flame-retardant properties. The core-sheath bicomponent fiber structure was employed to achieve the desired outcomes. The extrusion process was used to incorporate PFR and ZnO as the core and sheath components, respectively, at various ratios. The presence of nano-ZnO on the fiber shell was confirmed by the EDX data. The flame retardant study was utilized to observe the level of burning damage. The findings of the study demonstrated that increasing the percentage of PFR (maximum 8%) resulted in a significant decrease in the damage distance of the nonwoven material, with reductions of up to 60% was observed. Furthermore, the results of the antibacterial test indicated that the inclusion of an additional 3 wt% of ZnO resulted in a considerable reduction of the bacteria S. aureus and K. pneumoniae by about 99.96 and 98.79%, respectively. Based on the results obtained, it was determined that the most effective functionalized fiber was synthesized by including 3 wt% of ZnO and 5 wt% of PFR. Moreover, the incorporation of varying proportions of additives resulted in modifications to the mechanical and thermal characteristics of the fibers. This work highlights the potential of functionalized rPET bicomponent fibers as viable candidates for thermal insulator products. The utilization of functionalized rPET bicomponent fibers as a sustainable alternative for thermal insulator products showcases the commitment to environmentally friendly solutions, contributing to the overall goal of sustainability in the manufacturing industry.

Similar content being viewed by others

Data Availability

The authors declare that the data supporting the findings of this study are available within the paper. Should any raw data files be needed in another format they are available from the corresponding author upon reasonable request.

References

Geyer R, Jambeck JR, Law KL (2017) Production, use, and fate of all plastics ever made. Sci Adv 3(7):e1700782

Hiraga K, Taniguchi I, Yoshida S, Kimura Y, Oda K (2019) Biodegradation of waste PET. EMBO Rep 20:e49365. https://doi.org/10.15252/embr.201949365

Chu J, Zhou Y, Cai Y, Wang X, Li C, Liu Q (2022) A life-cycle perspective for analyzing carbon neutrality potential of polyethylene terephthalate (PET) plastics in China. J Clean Prod 330:129872. https://doi.org/10.1016/j.jclepro.2021.129872

Walker TR, McKay DC (2021) Comment on five misperceptions surrounding the environmental impacts of single-use plastic. Environ Sci Technol 55:1339–1340

Awaja F, Pavel D (2005) Recycling of PET. Eur Polymer J 41:1453–1477. https://doi.org/10.1016/j.eurpolymj.2005.02.005

Lin CC (1998) Recycling technology of poly(ethylene terephthalate) materials. Macromolecular Symposia 135:129–135. https://doi.org/10.1002/masy.19981350115

Suhaimi NAS, Muhamad F, Abd Razak NA, Zeimaran E (2022) Recycling of polyethylene terephthalate wastes: a review of technologies, routes, and applications. Polym Eng Sci 62:2355–2375. https://doi.org/10.1002/pen.26017

Welle F, Resources (2011) Conserv Recycling 55, 865–875. https://doi.org/10.1016/j.resconrec.2011.04.009

Khoonkari M, Haghighi AH, Sefidbakht Y, Shekoohi K, Ghaderian A (2015) Chemical recycling of PET wastes with different catalysts. Int J Polym Sci. https://doi.org/10.1155/2015/124524

Lipik VT, Abadie MJ (2007) Polyethylene terephthalate chemical recycling in the melted state. Polym-Plast Technol Eng 46(7):695–701

Damayanti, Wu H-S (2021) Strategic Possibility routes of recycled PET. Polymer 13:1475. https://doi.org/10.3390/polym13091475

Li S, Cañete Vela I, Järvinen M, Seemann M (2021) Polyethylene terephthalate (PET) recycling via steam gasification – the effect of operating conditions on gas and tar composition. Waste Manag 130:117–126. https://doi.org/10.1016/j.wasman.2021.05.023

Mudondo J, Lee H-S, Jeong Y, Kim TH, Kim S, Sung BH, Park S-H, Park K, Cha HG, Yeon YJ, Kim HT (2023) Recent advances in the Chemobiological Upcycling of Polyethylene Terephthalate (PET) into value-added chemicals. J Microbiol Biotechnol 33:1–14. https://doi.org/10.4014/jmb.2208.08048

Straka P, Bičáková O, Šupová M (2022) Slow pyrolysis of waste polyethylene terephthalate yielding paraldehyde, ethylene glycol, benzoic acid and clean fuel. Polym Degrad Stab 198:109900. https://doi.org/10.1016/j.polymdegradstab.2022.109900

La Mantia FP, Vinci M (1994) Recycling poly(ethyleneterephthalate). Polym Degrad Stab 45:121–125. https://doi.org/10.1016/0141-3910(94)90187-2

Nait-Ali LK, Colin X, Bergeret A (2011) Kinetic analysis and modelling of PET macromolecular changes during its mechanical recycling by extrusion. Polym Degrad Stab 96:236–246. https://doi.org/10.1016/j.polymdegradstab.2010.11.004

Majumdar A, Shukla S, Singh AA, Arora S (2020) Circular fashion: Properties of fabrics made from mechanically recycled poly-ethylene terephthalate (PET) bottles. Resour Conserv Recycl 161:104915. https://doi.org/10.1016/j.resconrec.2020.104915

Benyathiar P, Kumar P, Carpenter G, Brace J, Mishra DK (2022) Polyethylene terephthalate (PET) bottle-to-bottle recycling for the Beverage Industry: a review. Polymers 14:2366. https://doi.org/10.3390/polym14122366

Badía JD, Vilaplana F, Karlsson S, Ribes-Greus A (2009) Thermal analysis as a quality tool for assessing the influence of thermo-mechanical degradation on recycled poly(ethylene terephthalate). Polym Test 28:169–175. https://doi.org/10.1016/j.polymertesting.2008.11.010

López M, del Ares Pernas MC, Abad AI, López MJ, Latorre AL, López Vilariño JM, González Rodríguez MV (2014) Assessing changes on poly(ethylene terephthalate) properties after recycling: mechanical recycling in laboratory versus postconsumer recycled material. Mater Chem Phys 147:884–894. https://doi.org/10.1016/j.matchemphys.2014.06.034

Colin X, Verdu J (2006) Polymer degradation during processing. Comptes Rendus Chimie Modification dégradation et stabilisation des polymères 9:1380–1395. https://doi.org/10.1016/j.crci.2006.06.004

Khan SU, Hassan T, Wasim M, Khan MQ, Salam A, Hassan SZU, Abbasi AMR, Mustafa T (2023) Valorization of recycled PET for yarn manufacturing and knitwear fabrics used for apparel applications. Polym Bull 80(3):2779–2799

Lou C-W, Lin J-H, Su K-H (2005) Recycling Polyester and Polypropylene Nonwoven selvages to produce functional sound absorption composites. Text Res J 75:390–394. https://doi.org/10.1177/0040517505054178

Antolinc D, Filipič KE (2021) Recycling of Nonwoven Polyethylene Terephthalate Textile into Thermal and Acoustic Insulation for more sustainable buildings. Polymers 13:3090. https://doi.org/10.3390/polym13183090

Patnaik A, Mvubu M, Muniyasamy S, Botha A, Anandjiwala RD (2015) Thermal and sound insulation materials from waste wool and recycled polyester fibers and their biodegradation studies. Energy Build 92:161–169. https://doi.org/10.1016/j.enbuild.2015.01.056

Polini A, Yang F (2017) Physicochemical characterization of nanofiber composites. Woodhead Publishing, UK, pp 97–115

Sirin H, Turan D, Ozkoc G, Gurdag S (2013) POSS reinforced PET based composite fibers: Effect of POSS type and loading level. Compos Part B: Eng 53:395–403. https://doi.org/10.1016/j.compositesb.2013.05.033

Mohsin MA, Abdulrehman T, Haik Y (2017) Reactive extrusion of polyethylene terephthalate waste and investigation of its thermal and mechanical properties after treatment. Int J Chem Eng. https://doi.org/10.1155/2017/5361251

Pearce R, Cole K, Ajji A, Dumoulin M (1997) Studies of post drawing relaxation phenomena in poly (ethylene terephthalate) by infrared spectroscopy. Polym Eng Sci 37:1795–1800

Andrzejewski J, Szostak M, Krasucki J, Barczewski M, Sterzyński T (2015) Development and characterization of the injection-molded polymer composites made from Bicomponent fibers. Polym-Plast Technol Eng 54:33–46. https://doi.org/10.1080/03602559.2014.935414

Dasdemir M, Maze B, Anantharamaiah N, Pourdeyhimi B (2012) Influence of polymer type, composition, and interface on the structural and mechanical properties of core/sheath type bicomponent nonwoven fibers. J Mater Sci 47:5955–5969. https://doi.org/10.1007/s10853-012-6499-7

Takematsu MM, Diniz MF, Mattos EdaC, de Dutra R C.L (2018) Sheath-core bicomponent fiber characterization by FT-IR and other analytical methodologies. Polímeros 28:339–347

Jiang X, Luo S, Sun K, Chen X (2007) Effect of nucleating agents on crystallization kinetics of PET. Express Polym Lett 1:245–251

Kordahi R (2020) Controlled Crystallization of PET Filaments in Additive Manufacturing. Williams Honors College, Honors Research Projects. 1137

Ge Y, Yao S, Xu M, Gao L, Fang Z, Zhao L, Liu T (2019) Improvement of poly (ethylene terephthalate) melt-foamability by long-chain branching with the combination of pyromellitic dianhydride and triglycidyl isocyanurate. Ind Eng Chem Res 58(9):3666–3678

Chang S-J, Chang F-C (1999) Synthesis and characterization of copolyesters containing the phosphorus linking pendent groups. J Appl Polym Sci 72:109–122

He J, Shao W, Zhang L, Deng C, Li C (2009) Crystallization behaviour and UV-protection property of PET‐ZnO nanocomposites prepared by in situ polymerization. J Appl Polym Sci 114:1303–1311

Gooneie A, Simonetti P, Rupper P, Nazir R, Jovic M, Gaan S, Heuberger MP, Hufenus R (2020) Stabilizing effects of novel phosphorus flame retardant on PET for high-temperature applications. Mater Lett 276:128225. https://doi.org/10.1016/j.matlet.2020.128225

Zhao S, Xu B, Shan H, Zhang Q, Wang X (2023) How do phosphorus compounds with different valence states affect the flame retardancy of PET? Polymers. https://doi.org/10.3390/polym15081917

Anderson AM, Carroll MK (2011) Hydrophobic silica aerogels: review of synthesis, properties and applications. Aerogels Handb 47–77

Liao J, Gao P, Xu L, Feng J (2018) A study of morphological properties of SiO 2 aerogels obtained at different temperatures. J Adv Ceram 7:307–316

Tao Y, Liu C, Li P, Wang B, Xu Y-J, Jiang Z-M, Liu Y, Zhu P (2021) A flame-retardant PET fabric coating: flammability, anti-dripping properties, and flame-retardant mechanism. Prog Org Coat 150:105971

Chen X, Afreen S, Yu X, Dong C, Kong Q (2019) Modified melamine-formaldehyde resins improve tensile strength along with antifouling and flame retardancy in impregnation of cellulose paper. RSC Adv 9:36788–36795

Cheng X-W, Guan J-P, Tang R-C, Liu K-Q (2016) Phytic acid as a bio-based phosphorus flame retardant for poly(lactic acid) nonwoven fabric. J Clean Prod 124:114–119. https://doi.org/10.1016/j.jclepro.2016.02.113

Schartel B (2010) Phosphorus-based flame retardancy mechanisms - old hat or a starting point for future development? Materials 3(10):4710–4745. https://doi.org/10.3390/ma3104710

Khanal S, Lu Y, Dang L, Ali M, Xu S (2020) Effects of α-zirconium phosphate and zirconium organophosphonate on the thermal, mechanical and flame retardant properties of intumescent flame retardant high density polyethylene composites. RSC Adv 10:30990–31002

Jiang Z, Jin J, Xiao C, Li X (2012) Effect of surface modification of carbon black (CB) on the morphology and crystallization of poly (ethylene terephthalate)/CB masterbatch. Colloids Surf a 395:105–115

Satheesh Kumar MN, Siddaramaiah, Kotresh TM, Shekar I, Jagganath JH (2009) Effect of Flame Retardant on the Combustion behavior of polyvinyl acetate (PVAc) - melamine-formaldehyde-polyester Nonwoven Fabric composites. J Reinf Plast Compos 28:537–549

Gawish SM, Ramadan AM (2015) Effect of Nano ZnO on the properties of PP/ZnO Composite yarns II–Thermal and Mechanical properties

Yalcinkaya F, Komarek M, Lubasova D, Sanetrnik F, Maryska J (2016) Preparation of antibacterial nanofibre/nanoparticle covered composite yarns. J Nanomater. https://doi.org/10.1155/2016/7565972

Tayel AA, EL-TRAS WF, Moussa S, EL‐BAZ AF, Mahrous H, Salem MF, Brimer L (2011) Antibacterial action of zinc oxide nanoparticles against foodborne pathogens. J Food Saf 31:211–218

Yusof NAA, Zain NM, Pauzi N (2019) Synthesis of ZnO nanoparticles with chitosan as stabilizing agent and their antibacterial properties against Gram-positive and Gram-negative bacteria. Int J Biol Macromol 124:1132–1136. https://doi.org/10.1016/j.ijbiomac.2018.11.228

Premanathan M, Karthikeyan K, Jeyasubramanian K, Manivannan G (2011) Selective toxicity of ZnO nanoparticles toward Gram-positive bacteria and cancer cells by apoptosis through lipid peroxidation. Nanomed Nanotechnol Biol Med 7(2):184–192. https://doi.org/10.1016/j.nano.2010.10.001

Gudkov SV, Burmistrov DE, Serov DA, Rebezov MB, Semenova AA, Lisitsyn AB (2021) A mini review of antibacterial properties of ZnO nanoparticles. Front Phys 9:641481. https://doi.org/10.3389/fphy.2021.641481

Babayevska N, Przysiecka Ł, Iatsunskyi I, Nowaczyk G, Jarek M, Janiszewska E, Jurga S (2022) ZnO size and shape effect on antibacterial activity and cytotoxicity profile. Sci Rep 12(1):8148. https://doi.org/10.1038/s41598-022-12134-3

Lallo da Silva B, Abuçafy MP, Berbel Manaia E, Oshiro Junior JA, Chiari-Andréo BG, Pietro RCR, Chiavacci LA (2019) Relationship between structure and antimicrobial activity of zinc oxide nanoparticles: an overview. Int J Nanomed. https://doi.org/10.2147/IJN.S216204

Salam A, Hassan T, Jabri T, Riaz S, Khan A, Iqbal KM, Khan S, Wasim M, Shah MR, Khan MQ, Kim IS (2021) Electrospun nanofiber-based viroblock/ZnO/PAN hybrid antiviral nanocomposite for personal protective applications. Nanomaterials 11(9):2208. https://doi.org/10.3390/nano11092208

Gudkov SV, Burmistrov DE, Serov DA, Rebezov MB, Semenova AA, Lisitsyn AB (2021) A mini review of antibacterial properties of ZnO nanoparticles. Front Phys. https://doi.org/10.3389/fphy.2021.641481

Hu X, Cook S, Wang P, Hwang H (2009) In vitro evaluation of cytotoxicity of engineered metal oxide nanoparticles. Sci Total Environ 407:3070–3072. https://doi.org/10.1016/j.scitotenv.2009.01.033

Siddiqi KS, Husen A (2018) Properties of zinc oxide nanoparticles and their activity against microbes. Nanoscale Res Lett 13:1–13

Yalcinkaya F, Lubasova D (2017) Quantitative evaluation of antibacterial activities of nanoparticles (ZnO, TiO2, ZnO/TiO2, SnO2, CuO, ZrO2, and AgNO3) incorporated into polyvinyl butyral nanofibers. Polym Adv Technol 28:137–140. https://doi.org/10.1002/pat.3883

Acknowledgements

The authors would like to acknowledge to Thailand’s Ministry of Higher Education, Science, Research and Innovation for the research grants under the Research and Researchers for Industries (RRi) Project (Code: PHD61I0008).

Funding

The authors disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: This work was supported by Research and Researchers for Industries (RRi) Project (Code: PHD61I0008), Ministry of Higher Education, Science, Research and Innovation of Thailand.

Author information

Authors and Affiliations

Contributions

DH and WPA: Carried out experimental, analysis of recycled poly(ethylene terephthalate) fibres, summarized the literature reviews and references and wrote and revised the manuscript text and discussion. NR and SB: Carried out experimental, analysis of recycled poly(ethylene terephthalate) fibres, summa¬rized the references and wrote the manuscript discussion. FY: Wrote and revised the abstract, introduction, manuscript discussion and conclusion. SPA: Carried out experimental, summarized the references, wrote and revised the manuscript discussion and the main manuscript text. All authors reviewed the manuscript and discussed the additional experiments.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hunskunatai, D., Pivsa-Art, W., Roungpaisan, N. et al. Multi-functional Core/Sheath Bicomponent Nonwoven of Recycled Poly(ethylene terephthalate) Fibres as Thermal Insulators. J Polym Environ (2023). https://doi.org/10.1007/s10924-023-03116-1

Accepted:

Published:

DOI: https://doi.org/10.1007/s10924-023-03116-1