Abstract

Due to the increase in horticultural production intensive techniques are needed. These techniques generate soil degradation, since the natural recovery time between crops is insufficient. The usual way to solve this problem is the use of fertilizers, as they are effective in the short time available. Conventional fertilizers are highly soluble salts, allowing their absorption by plant roots. However, they are dumped on the soils in more quantity than plants need, thus, the excess of unassimilated nutrients contaminates both the soil and groundwater. The main objective of this work was to develop and evaluate an alternative to conventional fertilizers, creating slow-release matrices from a protein by-product to which iron was incorporated. To carry out a more complete study, iron was incorporated in concentrations of 2.5, 5.0 and 10 wt%, using two different salts: iron(II) sulfate heptahydrate (FeSO4·7H2O) and iron chelated with N,N′-ethylenediamine-bis (2-hydroxyphenyl) acetic acid (Fe-EDDHA). Several tests were performed to compare their mechanical properties, micronutrient release profile, water absorption capacity and biodegradability, as well as their final effectiveness in crops. The protein-based matrices with both salts incorporated presented good mechanical properties. However, Fe-EDDHA matrices had a greater water absorption capacity, while FeSO4·7H2O matrices were more efficient in their final application in plants and had a longer biodegradation time. In conclusion, protein-based matrices present a high potential for the slow release of iron, thereby improving crop properties.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

The Oxford English Dictionary defines horticulture as a garden cultivation technique that includes the growing of vegetables, fruit and flowers [1]. The consumption of these crops has increased due to the population growth, and the trend towards healthy nutrition [2]. In this way, the Organization for Economic Cooperation and Development (OECD) estimates that, to cover the demand in 2050, agriculture will have to produce almost 50% more crops than those produced in 2012 [3]. To satisfy this demand, intensive horticulture techniques are being applied, whose objectives are to maximize production and minimize the time between crops [4]. Nevertheless, these actions have long-term consequences, such as exhaustion of fertile farmland (erosion or desertification); contamination of soils, groundwater and aquifers by the leaching of fertilizers that are not assimilated by the plant; and development of resistance to the pesticides used [5, 6].

Fertilizers are used to improve crop yields due to the fact that they rapidly supply the nutrients required by plants, without the need to wait for the natural recovery time of the farmland. They are organic or inorganic substances of natural or synthetic origin [4]. The most common fertilizers present a mineral composition and are used due to their more competitive price, ease of acquisition and high efficiency [7]. They are usually scattered on the ground (conventional fertilization). Nevertheless, this technique has a great disadvantage: nutrients are displaced to the subsoil due to the high solubility of used salts, generating a low assimilation efficiency by the crop and a subsoil contamination from excess of nutrients [8]. In this way, different studies work to obtain more efficient and sustainable fertilizers. Some examples of novel fertilizers include biofertilizers [9] and slow-release fertilizers [10]. Biofertilizers are microorganisms (mainly bacteria and fungi) that perform functions such as atmospheric nitrogen fixation, solubilization of insoluble phosphorus present in the soil, antibiosis and stimulation of vegetative growth and development [11].

On the other hand, slow-release fertilizers try to assimilate the nutrient absorption profile of the target crop plant to improve fertilization efficiency. The nutrients are released through irrigation or system biodegradation, thereby preventing leaching and increasing their availability to crops for a longer time [10]. Thus, they have several advantages, such as less fertilizer is needed. This reduces cost (less raw material to buy) and improves efficiency (less fertilizer poured into the soil compared to that needed by the plant) [12]. There are already slow-release systems on the market that provide nutrients to crops, such as “Nutricote” by Projar [13]. Nevertheless, their principle is to cover the fertilizer with expensive polymeric layers, which decrease the industrial competitiveness of these [14]. Therefore, some researchers are aiming for cheaper alternatives to develop slow-release systems, such as the use of protein-based matrices [15]. Proteins could be obtained from agro-food wastes or by-products, being a cheap raw material. In addition, proteins have a biostimulant effect on plant growth, enhancing the quality of slow-release systems [16].

In this way, the novelty of this work is the use of soy protein-based matrices for the slow release of iron. Iron is a micronutrient whose main function is the synthesis of chlorophyll. However, it presents some secondary functions, such as participating in the capture and transfer of energy in photosynthesis and respiration, and in the reduction of nitrates [17]. Its need depends on the crop, but generally each vegetable need at least 50 ppm of iron (less concentration in soil is considered deficit) [18]. Iron deficiency in crops could be caused by its absence in the assimilated form (Fe2+ or chelated) in the soil [17]. The main effect of iron deficiency in a plant is iron chlorosis [19]. One of the most effective ways to correct this deficiency is the application of chelated iron. However, chelated iron can leach and reach the subsoil [20]. Therefore, iron deficiency is also solved by applying iron sulphates [21, 22]. Slow-release systems could provide advantages for iron release, since the release will be trying to fit according to the plants requirements, without being affected by external factors that may cause its loss.

Therefore, the main objective of this work was to evaluate the use of different iron salts in soy protein-based matrices as an alternative to conventional fertilizers. Thus, its influence in the mechanical and functional properties (including plant analysis) of the protein-based matrices has been evaluated in order to obtain a system with an optimal concentration of micronutrients that allow for their slow release and correct assimilation by the crop.

Experimental Section

Materials

The soy protein used as biopolymer in the matrix is a protein isolate supplied by Protein Technologies International (Ieper, Belgium). Its chemical composition corresponds to 91 wt% protein, 5.0 wt% moisture, 2.1 wt% ash, 1.0 wt% lipids, 0.9 wt% carbohydrates. Its maximum humidity is 6.0% and its pH value is in a range between 6.9 and 7.4 [23].

Glycerol, which was purchased from Escuder (Barcelona, Spain), was used as plasticizer to facilitate the cohesion of the components and the formation of both a homogeneous dough in the mixing process and a stable matrix in the injection molding process.

To incorporate the micronutrient, iron(II) sulfate heptahydrate (FeSO4·7H2O) and iron chelated by EDDHA (Fe-EDDHA, 6% of iron, with 4.8% in the ortho-ortho position) were used. They were purchased from Panreac Química S.A. (Barcelona, Spain) and Batlle (Barcelona, Spain), respectively.

Processing of Slow-Release Matrices

The process of obtaining the different matrices consisted of three main stages: mixing, injection molding and plasticizer removal. This process has been optimized in previous works [24]. Briefly, the raw materials were homogenized in a Haake Polylab QC batch mixer (Thermo Scientific, Dreieich, Germany). To this end, the soy protein isolate was mixed with glycerol in a 1:1 weight ratio. Different concentrations of FeSO4·7H2O and Fe-EDDHA (2.5, 5.0 and 10 wt%) were incorporated. The mixing was performed for 10 min at 50 rpm in adiabatic conditions. This dough-like blend was subsequently processed by injection molding using a MiniJet Piston Molding System II (Thermo Scientific, Dreieich, Germany) to obtain the bioplastics (60 × 10 × 1 mm3). This process was performed using 40 and 90 °C in the cylinder and mold, respectively. In addition, an injection pressure of 600 bar (20 s) and a holding pressure of 200 bar (300 s) were used. Finally, the plasticizer (glycerol) was removed. For this, each bioplastic was immersed in 10 mL of ethanol for 24 h (to solubilize the glycerol) and subjected to a freeze-drying step in a LyoQuest equipment (Telstar, Barcelona, Spain), where the systems were subjected to vacuum and − 80 °C in order to eliminate the ethanol that the matrices may have retained.

Characterization of Slow-Release Matrices

Mechanical Properties

A dynamic-mechanical RSA3 analyzer (TA Instruments, New Castle, Delaware, USA) with plate-plate geometry (8 mm diameter) was used to obtain the mechanical properties of the different matrices by dynamic compression tests. Two different types of tests were carried out: a strain sweep test (0.002–2% of strain at a constant frequency of 1 Hz) to determine the linear viscoelastic range of each system; and a frequency sweep test (0.02–20 Hz at a constant strain in the linear viscoelastic range) to determine how the stress application time affects the matrix mechanical properties. All mechanical tests were performed at room temperature (20 ± 2 °C).

Release Analysis

Water Release Analysis

These tests were carried out by inserting the matrices into containers with 300 mL of distilled water and measuring the medium conductivity every 10 min until a constant value was reached [25]. The equipment used to measure conductivity was a BASIC 30 EC-Meter (Crison, Barcelona, Spain). Conductivity presents a relation with the micronutrient release, thus, it was estimated with the Eq. 1.

Reference matrix (without salt) also presents conductivity. For this reason, these values were also obtained and subtracted from those presented by each matrix to only evaluate the release of the micronutrient.

Soil Release Analysis

The systems were buried in a conventional substrate in glass tubes (40 × 2 cm, height × diameter), which were open at the bottom, following the protocol of González et al. [26]. The tubes were covered with aluminum foil in order to recreate the darkness of the horticultural soil. Every 24 h, each tube was irrigated with 20 mL of water to simulate an intensive horticultural irrigation of 20 L water/m2 of soil. The conductivity of the leachates was measured with a BASIC 30 EC-meter (Crison, Barcelona, Spain) until the total absence of salts was reached. In addition, a blank, where a matrix without salt was incorporated, was performed to counteract the presence of other salts in the soil and the conductivity of the matrix. The maximum release time was estimated as the time at which the conductivity remains constant and equal to the blank for three consecutive days.

Water Uptake Capacity

Water uptake capacity was evaluated as added value of these matrices, using ASTM D570-98 standard [27]. Each matrix was immersed in a closed container with 300 mL of distilled water for 24 h at room temperature (20 ± 2 °C). The capacity of water absorption was obtained from Eq. 2:

where \({m}_{2}\) is the weight of the matrix after remaining in distilled water and \({m}_{3}\) is the weight of the matrix after drying it in an oven at 105 °C for 2 h (after absorption).

Likewise, the soluble matter loss of the different matrices during absorption was calculated from Eq. 3:

where \({m}_{1}\) is the initial weight of the matrix (before absorption).

Biodegradability

The different matrices were buried in a conventional substrate supplied by COMPO (Barcelona, Spain) and specialized for urban gardens. It maintains the C/N ratio defined by ISO 20,200 standard (“ISO 20200:2004. Plastics—Determination of the degree of disintegration of plastic materials under simulated composting conditions in a laboratory-scale test”, 2004) [28]. The relative humidity of 70–80% was maintained in a closed container. Its content (decomposition of the matrices) was visually checked every 3–5 days. The biodegradation time was defined as the time after which no piece of matrix (> 1 mm) could be unearthed.

Crop Evaluation

The functionality of the matrices as slow-release fertilizers was evaluated in plants, specifically with Italian sweet pepper (Capsicum Annuum L.). These plants were selected due to it is a plant that needs a substrate rich in iron for their growth [29]. In addition, there is a great production of Italian sweet pepper [30]. Capsicum Annum L. is an herbaceous plant with a tap root system that has a cultivation period of 80 days approximately. Its cultivation is annual and it is carried out in summer months. The plant has an erect stem (0.5–1.5 m) with oval leaves with a long petiole. The white flowers appear solitary at each node. These flowers give an elongated and narrow shape with a low caloric intake [31].

By way of comparison, a positive control (with conventional fertilization of 40 mg of FeSO4·7H2O every 7 days) and a negative control (without fertilization) were also performed. The culture was carried out outdoors (medium temperature and humidity were 22 °C and 84%, respectively) in a conventional substrate for 60 days. The plants were subjected to 12 h of natural and indirect light with an intensity of 20,000 lux. The evaluation of the crops was carried out by visual observation of the defect found in the plants (leaf spots, deformations, pitting…) which were individually counted. In addition, the weight (including the roots) and height (from the ground to the highest leaf) of each plant was measured, as well as the number of leaves presented. The dimensions of each leaf were measured giving their data as length × width, which corresponds to an average between the longest and widest side of each leaf of the plant, respectively.

The amount of iron assimilated by the crops was analyzed by inductively coupled plasma atomic emission spectroscopy (ICP-AES). For this, an ICP SpectroBlue TI (Spectro, Germany) was used, where the sample was digested with acids and then dissociated at 6000 K (plasma torch).

Statistical Analysis

Leastwise four replicates of each measure were performed. The program used to perform the Statistical analyses was SPSS 18 (IBM program), with 95% confidence (p < 0.05). ANOVA has been calculated by carrying out a Tukey analysis. The main value of the results and their corresponding standard deviation are shown.

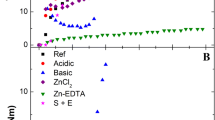

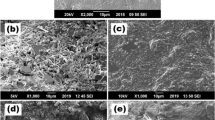

It worth be mentioned that standard deviations were not included as error bars in Fig. 1 since with the size of the symbol and the logarithm scale they couldn’t be seen properly. Furthermore, the replicates obtained for each system in Figs. 2 and 3 were not significantly different and one of the replicates was included as an example per system.

Results and Discussion

Mechanical Properties

Figure 1 shows the elastic (E’) and viscous (E’’) moduli of the different systems (Fig. 1A for iron sulfate systems and Fig. 1B for the iron chelated systems) in the frequency range studied (using a strain in the linear viscoelastic range, data not shown). As can be seen, E’ is an order of magnitude higher than E’’ in the entire studied range, showing the important solid character of these systems. Furthermore, all the systems presented a similar behavior: there was a slight increase in the moduli at higher frequencies. This behavior shows certain dependence of the matrices on the application of stress.

Table 1 presents the parameters obtained from mechanical tests in order to improve the comparison of the systems. Firstly, the critical strain of the systems decreased as the amount of salt in them increased (regardless of the salt used), possibly due to the fact that the incorporation of salt generates certain rigidity in the matrices [32]. On the other hand, E’1 (elastic modulus at 1 Hz) generally did not present significant differences regardless of the salt incorporated. Nevertheless, FeSO4·7H2O showed a maximum at 2.5 wt% and Fe-EDDHA showed a maximum at 5.0 wt%. In other words, considering the mechanical properties, iron sulfate systems are optimized when a 2.5 wt% is included, whereas chelated iron systems are optimized with a 5.0 wt%. A similar evolution was previously obtained for Zn-based salts, with a maximum obtained at 2.5 wt%. [32].

Release Analysis

Water Release Analysis

Figure 2 shows the conductivity (Fig. 2A for FeSO4·7H2O and Fig. 2B for Fe-EDDHA) results obtained in the release time in water. As can be seen, the same release profile was followed by all systems, where there was a first rapid release that slowed down until complete release. The increase in the amount of salt incorporated in the matrices produced a higher amount of salt released within the same time. Thus, the percentage of micronutrient released, considering 100% the maximum load in each matrix, (Figures C and D) was always the same. All the systems had a similar maximum release time of 100 min, being lower than that obtained in other previous works with other micronutrients [24]. The first rapid release could be due to the difference in concentrations between the aqueous medium and the matrix. In this way, the concentration gradient between the matrix and the medium causes the release to be faster at first (possibly releasing the fertilizer from the surface of the matrix) until it approaches equilibrium. This profile is similar to those proposed by Korsmeyer-Peppas model which proposed that some processes are simultaneously involved in the drug release: (i) polymer swelling, (ii) fertilizer dissolution and (iii) polymer biodegradation [33].

Soil Release Analysis

The measured conductivity of the leachate from the different systems, as well as the percentage of release of the micronutrient in the soil, is plotted in Fig. 3. Its behavior was similar to that observed in water release. In this way, a higher concentration of salt generated a higher total conductivity. However, the maximum release time was similar in all cases, emphasizing the hypothesis stated above: a higher salt load generates a greater contribution of micronutrients within the same maximum release time (about 35–40 days), similar to previous works that used the same matrix with other micronutrients [34].

Water Uptake Analysis

Table 2 shows the water uptake capacity of the different matrices. As can be seen, Fe-EDDHA allowed for a greater water uptake capacity than FeSO4·7H2O. This may be due to the electrostatic forces generated by both salts. In this sense, sulfate breaks down into ions when in contact with water, generating ionic forces that prevent the matrix from swelling [35], recording lower water uptake that the reference system (without salt). This hypothesis can be confirmed by the visual observation of the matrices before and after absorption (Figure S1). Nevertheless, the incorporation of Fe-EDDHA improve the water uptake capacity of reference systems (more pronounced at lower salt concentrations) possibly due to hydrogen bond generated between EDDHA, protein chains and water [36].

On the other hand, soluble matter loss increases as the amount of salt increases due to there are more salt to release. In this way, reference system presented the lowest soluble matter loss. Nevertheless, the more evident effect is presented by the change from sulfate to EDDHA. In this way, EDDHA showed a higher soluble matter loss possibly because it does not generate ionic forces that could maintain in the matrix due to electrostatic interactions with the protein (which is negatively charged (pH > isoelectric point)).

Biodegradability

Table 2 also shows the biodegradation time of the different matrices. The visual appearance of the matrices during this analysis can also be seen in Figure S2 and S3 for FeSO4·7H2O and Fe-EDDHA, respectively. A higher amount of salt (FeSO4·7H2O or Fe-EDDHA) resulted in a longer biodegradation time. This behavior may be due to the fact that both salts have a certain antimicrobial character, inhibiting the attack of microorganisms [37, 38]. Moreover, the matrices with FeSO4·7H2O have a longer biodegradation time. This effect could be due to two factors: (i) their greater antimicrobial character [39] and (ii) their lower water uptake capacity that inhibits protein hydrolysis, the main biodegradation factor of these systems [40]. In addition, this biodegradation time is similar to the maximum soil release time. In this way, it seems that the release of the micronutrient takes place during the matrix biodegradation, thus being a slow release during its biodegradation.

Crop Evaluation

Table 3 shows the results of the matrices assimilation by Italian sweet pepper plants, while the plants can be observed in Fig. 4. Firstly, the negative control was the one with the lowest values.

Comparing both salts, FeSO4·7H2O (especially 5 wt%) was more efficient as it achieved the greatest iron assimilation by the plant, obtaining dimensions similar to those obtained in the positive control (conventional fertilization). This behavior could be due to the fact that the presence of sulfate causes the slight acidification (sulfate reacts with water forming sulfuric acid) of the soil, improving the micronutrient absorption of the plant [17]. Nevertheless, this acidification can be harmful if it is more relevant, being able to explain why the 10 wt% system does not improve crops.

For each type of salt, it is observed that the plants that received the matrices with a concentration of 5.0 wt% are the ones that presented the highest value of weight and iron content. This may explain the fact that the amount of iron required by plants depends on the type of crop (i.e. pepper needs more iron than tomatoes, 70 and 60 mg/kg, respectively) and the time of maturation (i.e. crops need more iron during fruit formation than plant growth). Therefore, for this type of vegetable, the ideal amount would be 5.0 wt%, since applying a lower amount would cause a deficit in the plant and applying more iron would be counterproductive (the plant does not assimilate it). Finally, the incorporation of matrices prevented the appearance of visual defects in plants, such as those observed in the negative control leaves (Figure S4).

Conclusions

This work proved the high potential of matrices processed from soy protein for the slow release of iron during crop growth. In addition, their wide versatility was also demonstrated, since it is possible to incorporate different types of salts (FeSO4·7H2O and Fe-EDDHA) at different concentrations (2.5, 5.0 and 10 wt%).

More specifically, the mechanical properties of both types of matrices allow correct matrix production, packaging, transportation and application in the soil because they would not fracture during handling. All the systems follow the same profile release in water and soil, where there is a first fast release that slows down until complete release. All the systems presented a similar maximum release time, where an increase in the amount of salt in the matrices means a greater iron contribution to the plant, but at the same time. Fe-EDDHA matrices had a greater water uptake capacity and, consequently, greater biodegradability. Nevertheless, those with FeSO4·7H2O proved to be more efficient to incorporate iron to plant, probably due to their higher amount of iron. However, all the plants cultivated with matrices do not present defects. Therefore, the matrices with FeSO4·7H2O, especially those with 5.0 wt%, were selected as the best systems.

References

Oxford English Dictionary (2022) Horticulture. www.oed.com. Accessed 21 Jul 2022

Giller KE, Delaune T, Silva JV et al (2021) The future of farming: who will produce our food? Food Secur 13:1073–1099. https://doi.org/10.1007/s12571-021-01184-6

OECD (2020) El futuro de la alimentación y la agricultura. https://www.oecd.org/agriculture/entendiendo-el-sistema-alimentario-global/el-futuro-de-la-alimentacion-y-la-agricultura/. Accessed 21 Jul 2022

Hazell P, Wood S (2008) Drivers of change in global agriculture. Philos Trans R Soc B Biol Sci. https://doi.org/10.1098/rstb.2007.2166

Gardner R (1974) Intensive horticulture in Eastern Europe. Outlook Agric 8:70–73. https://doi.org/10.1177/003072707400800203

Taha AM (2022) Fertigation: a pathway to sustainable Food production. Springer International Publishing, Cham

Brumfield RG (2000) An examination of the Economics of sustainable and conventional horticulture. Horttechnology 10:687–691. https://doi.org/10.21273/HORTTECH.10.4.687

Kondraju TT, Rajan KS (2019) Excessive fertilizer usage drives agriculture growth but depletes water quality. ISPRS Ann Photogramm Remote Sens Spat Inf Sci IV-3/W1:17–23. https://doi.org/10.5194/isprs-annals-IV-3-W1-17-2019

Brahmaprakash GP, Sahu PK (2012) Biofertilizers for sustainability. J Indiam Inst Sci 92:37–62

Mortain L, Dez I, Madec PJ (2004) Development of new composites materials, carriers of active agents, from biodegradable polymers and wood. Comptes Rendus Chim 7:635–640. https://doi.org/10.1016/j.crci.2004.03.006

Mitter EK, Tosi M, Obregón D et al (2021) Rethinking crop nutrition in times of modern microbiology: innovative biofertilizer technologies. Front Sustain Food Syst. https://doi.org/10.3389/fsufs.2021.606815

Lubkowski K, Grzmil B (2007) Controlled release fertilizers. Pol J Chem Technol 9:81–84

Projar (2020) Nutricote: controlled release fertilizer. https://www.projar.es/productos/productos-hortofruticultura-jardineria/fertilizantes/abonos_minerales/fertilizantes-de-liberacion-controlada/fertilizante-de-liberacion-controlada-nutricote/. Accessed 17 Aug 2020

Vejan P, Khadiran T, Abdullah R, Ahmad N (2021) Controlled release fertilizer: a review on developments, applications and potential in agriculture. J Control Release 339:321–334. https://doi.org/10.1016/j.jconrel.2021.10.003

Jiménez-Rosado M, Perez-Puyana V, Guerrero A, Romero A (2021) Controlled release of zinc from soy protein-based matrices to plants. Agronomy 11:580. https://doi.org/10.3390/agronomy11030580

Colla G, Hoagland L, Ruzzi M et al (2017) Biostimulant action of protein hydrolysates: unraveling their effects on plant physiology and microbiome. Front Plant Sci 8:1–14. https://doi.org/10.3389/fpls.2017.02202

García-Serrano P, Lucena JJ, Ruano S, Nogales M (2009) Guía práctica de la fertilización racional de los productos en España. Ministerio de Medio Ambiente y Medio Rural y Marino, Madrid

Maroto JV (2008) Elementos de horticultura general. Ediciones Mundi-Prensa, Madrid

Adams CR (2012) Principles of horticulture. Routledge, London

de la Cruz-Salazar F, Arizmendi-Galicia N, Rivera-Ortiz P et al (2011) Lixiviación de hierro quelatado en suelos calcáreos. Terra Latinoam 29:231–237

Tagliavini M, Abadía J, Rombolà AD et al (2000) Agronomic means for the control of iron deficiency chlorosis in deciduous fruit trees. J Plant Nutr 23:2007–2022. https://doi.org/10.1080/01904160009382161

Chaud MV, Izumi C, Nahaal Z et al (2002) Iron derivatives from casein hydrolysates as a potential source in the treatment of iron deficiency. J Agric Food Chem 50:871–877. https://doi.org/10.1021/jf0111312

Jiménez-Rosado M, Maigret J-E, Perez-Puyana V et al (2022) Revaluation of a soy protein by-product in eco-friendly bioplastics by Extrusion. J Polym Environ 30:1587–1599. https://doi.org/10.1007/s10924-021-02303-2

Jiménez-Rosado M, Rubio-Valle JF, Perez-Puyana V et al (2021) Eco-friendly protein-based materials for a sustainable fertilization in horticulture. J Clean Prod 286:124948. https://doi.org/10.1016/j.jclepro.2020.124948

Essawy HA, Ghazy MBM, El-Hai FA, Mohamed MF (2016) Superabsorbent hydrogels via graft polymerization of acrylic acid from chitosan-cellulose hybrid and their potential in controlled release of soil nutrients. Int J Biol Macromol 89:144–151. https://doi.org/10.1016/j.ijbiomac.2016.04.071

González ME, Cea M, Medina J et al (2015) Evaluation of biodegradable polymers as encapsulating agents for the development of a urea controlled-release fertilizer using biochar as support material. Sci Total Environ 505:446–453. https://doi.org/10.1016/j.scitotenv.2014.10.014

ASTM D570-98: Standard test method for water absorption of plastics

ISO 20200:2004. Plastics — Determination of the degree of disintegration of plastic materials under simulated composting conditions in a laboratory-scale test

Reid RM (1992) Cultural and medical perspectives on geophagia. Med Anthropol 13:337–351. https://doi.org/10.1080/01459740.1992.9966056

Organización de las Naciones Unidas para la Alimentación y la Agricultura (2022) Datos de alimentación y agricultura. http://www.fao.org/. Accessed 28 Mar 2022

Stommel JR, Bosland PW (2007) Ornamental pepper. Flower breeding and Genetics. Springer Netherlands, Dordrecht, pp 561–599

Jiménez-Rosado M, Perez-Puyana V, Cordobés F et al (2018) Development of soy protein-based matrices containing zinc as micronutrient for horticulture. Ind Crops Prod 121:345–351. https://doi.org/10.1016/j.indcrop.2018.05.039

Siepmann J, Siepmann F (2008) Mathematical modeling of drug delivery. Int J Pharm 364:328–343. https://doi.org/10.1016/j.ijpharm.2008.09.004

Jiménez-Rosado M, Perez-Puyana V, Guerrero A, Romero A (2022) Micronutrient-controlled-release protein-based systems for horticulture: Micro vs. nanoparticles. Ind Crops Prod 185:115128. https://doi.org/10.1016/j.indcrop.2022.115128

Maderuelo C, Zarzuelo A, Lanao JM (2011) Critical factors in the release of drugs from sustained release hydrophilic matrices. J Control Release 154:2–19. https://doi.org/10.1016/j.jconrel.2011.04.002

Jiménez-Rosado M, Perez-Puyana V, Cordobés F et al (2019) Development of superabsorbent soy protein-based bioplastic matrices with incorporated zinc for horticulture. J Sci Food Agric. https://doi.org/10.1002/jsfa.9738

Gholami A, Mohammadi F, Ghasemi Y et al (2020) Antibacterial activity of SPIONs versus ferrous and ferric ions under aerobic and anaerobic conditions: a preliminary mechanism study. IET Nanobiotechnol 14:155–160. https://doi.org/10.1049/iet-nbt.2019.0266

Oglesby-Sherrouse AG, Djapgne L, Nguyen AT et al (2014) The complex interplay of iron, biofilm formation, and mucoidy affecting antimicrobial resistance of Pseudomonas aeruginosa. Pathog Dis 70:307–320. https://doi.org/10.1111/2049-632X.12132

Mohatt JL, Hu L, Finneran KT, Strathmann TJ (2011) Microbially mediated abiotic transformation of the antimicrobial agent sulfamethoxazole under iron-reducing soil conditions. Environ Sci Technol 45:4793–4801. https://doi.org/10.1021/es200413g

Kale G, Kijchavengkul T, Auras R et al (2007) Compostability of bioplastic packaging materials: an overview. Macromol Biosci 7:255–277. https://doi.org/10.1002/mabi.200600168

Acknowledgements

Authors acknowledge the financial support of the Spanish Government (MCI/AEI/FEDER, EU) through the sponsored project with ref. PID2021-124294OB-C21. Authors also acknowledge the predoctoral (FPU2017/01718) and postdoctoral (Talento Doctores, Junta de Andalucía-Fondo Social Europeo, Convocatoria 2019–2020, DOC_00586) contracts of Mercedes Jiménez Rosado and Víctor M. Pérez Puyana, respectively.

Funding

Funding for open access publishing: Universidad de Sevilla/CBUA. Results funded by Project PID2021-124294OB-C21 financed by MCIN/ AEI /10.13039/501100011033/ and by FEDER A way of making Europe.

Author information

Authors and Affiliations

Contributions

AC-RM: conceptualization, methodology, formal analysis, data curation, writing. MJ-R: conceptualization, methodology, formal analysis, validation, writing, supervision. VMP-P: conceptualization, formal analysis, validation, resources, writing, supervision. AR: conceptualization, methodology, validation, resources, writing, supervision, funding acquisition.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cuenca-Romero Molinillo, A., Jiménez-Rosado, M., Pérez-Puyana, V.M. et al. Effect of Iron Salt on Slow Fertilization Through Soy Protein-Based Matrices. J Polym Environ 31, 5225–5233 (2023). https://doi.org/10.1007/s10924-023-02922-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-023-02922-x