Abstract

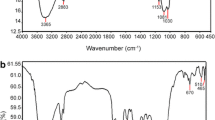

Biobased polyurethane nanocellulose nanocomposites were synthesized from cottonseed oil as the source for the biopolyol. The prepared composites were used to study the adsorption of Rhodamine B dye from water. Low functional polyol was derived from cottonseed oil using one-pot synthesis method. Nanocellulose was derived from pineapple leaves and then it was surface-functionalized via silylation. In-situ polymerization technique was used to incorporate the silylated nanocellulose into the polyurethane matrix. The prepared polyol from cottonseed oil was found to have an OH functionality of 2 which was confirmed by Fourier transform infrared spectroscopy (FT-IR) and Nuclear magnetic resonance (NMR) spectroscopy. Low functionality of polyol is the key factor in achieving flexible porous polyurethane. The silylated nanocellulose, polyurethane, and composites were characterized by FT-IR, X-ray diffraction analysis (XRD), and Scanning electron microscopy (SEM). The adsorption parameters were optimized using the Taguchi methodology and the adsorption efficiency was determined by carrying out adsorption at optimized parameters (5 wt% loading of silylated nanocellulose, pH 9, and temperature of 30 °C) for 8 h. Studies showed that the prepared composite has a high adsorption efficiency of 597 mg/g of silylated nanocellulose towards Rh-B.

Similar content being viewed by others

Abbreviations

- FT-IR:

-

Fourier transform–infrared spectroscopy

- NMR:

-

Nuclear magnetic resonance

- XRD:

-

X-ray diffraction analysis

- SEM:

-

Scanning electron microscopy

- FESEM:

-

Field emission scanning electron microscopy

- Rh-B:

-

Rhodamine B

- APTES:

-

3-Aminopropyltriethoxysilane

- MDI:

-

Methylene diphenyl diisocyanate

- DABCO:

-

1,4-Diazabicyclo [2] Octane

- PEG-6000:

-

Polyethylene glycol

- CSO:

-

Cottonseed oil

- FECSP:

-

Formiated epoxy cottonseed polyol

References

Zhao W, Chen IW, Huang F (2019) Toward large-scale water treatment using nanomaterials. Nano Today. https://doi.org/10.1016/j.nantod.2019.05.003

Boelee E, Geerling G, van der Zaan B et al (2019) Water and health: from environmental pressures to integrated responses. Acta Trop 193:217–226. https://doi.org/10.1016/j.actatropica.2019.03.011

Kumari P, Alam M, Siddiqi WA (2019) Usage of nanoparticles as adsorbents for waste water treatment: an emerging trend. Sustain Mater Technol. https://doi.org/10.1016/j.susmat.2019.e00128

Rajasulochana P, Preethy V (2016) Comparison on efficiency of various techniques in treatment of waste and sewage water−a comprehensive review. Resour-effic Technol 2:175–184. https://doi.org/10.1016/j.reffit.2016.09.004

Ali I, Gupta VK (2007) Adv Water Treat Adsorp Technol 1:2661–2667. https://doi.org/10.1038/nprot.2006.370

Verdolotti L, Di Caprio MR, Lavorgna M, Buonocore GG (2017) Polyurethane nanocomposite foams: correlation between nanofillers, porous morphology, and structural and functional properties. Polyurethane Polym. https://doi.org/10.1016/B978-0-12-804065-2.00009-7

Haryanto Mansoob Khan, M, (2018) Polymer nanocomposite application in sorption processes for removal of environmental contaminants. Polymer-based nanocomposites for energy and environmental applications. Elsevier, University of Ottawa Press, pp 491–505

Bassyouni M, Abdel-Aziz MH, Zoromba MS et al (2019) A Review of polymeric nanocomposite membranes for water purification. J Ind Eng Chem 73:19–46

Machado Centenaro GSN, Facin BR, Valério A et al (2017) Application of polyurethane foam chitosan-coated as a low-cost adsorbent in the effluent treatment. J Water Process Eng 20:201–206. https://doi.org/10.1016/J.JWPE.2017.11.008

Orgilés-Calpena E, Arán-Aís F, Torró-Palau AM, Orgilés-Barceló C (2014) Synthesis and characterisation of potentially biodegradable polyurethane adhesives from soybased. Polyols 5:99–114

Zhang C, Madbouly SA, Kessler MR (2015) Biobased polyurethanes prepared from different vegetable oils. ACS Appl Mater Interfaces 7:1226–1233. https://doi.org/10.1021/am5071333

Ma H, Hsiao BS, Chu B (2011) Ultrafine cellulose nanofibers as efficient adsorbents for removal of uo22+ in water. ACS Macro Lett 1:213–216. https://doi.org/10.1021/MZ200047Q

Batmaz R, Mohammed N, Zaman M et al (2014) Cellulose nanocrystals as promising adsorbents for the removal of cationic dyes. Cellulose 21:1655–1665. https://doi.org/10.1007/s10570-014-0168-8

Köse K, Mavlan M, Youngblood JP (2020) Applications and impact of nanocellulose based adsorbents. Cellulose 27:2967–2990

Mahfoudhi N, Boufi S (2017) Nanocellulose as a novel nanostructured adsorbent for environmental remediation: a review. Cellulose 24:1171–1197. https://doi.org/10.1007/s10570-017-1194-0

Duarah R, Karak N (2019) Hyperbranched polyurethane/reduced carbon dot-zinc oxide nanocomposite-mediated solar-assisted photocatalytic degradation of organic contaminant: an approach towards environmental remediation. Chem Eng J 370:716–728. https://doi.org/10.1016/J.CEJ.2019.03.248

Góes MM, Keller M, Masiero Oliveira V et al (2016) Polyurethane foams synthesized from cellulose-based wastes: kinetics studies of dye adsorption. Ind Crops Prod 85:149–158. https://doi.org/10.1016/j.indcrop.2016.02.051

Li X, Li J, Sun X et al (2015) Preparation and malachite green adsorption behavior of polyurethane/chitosan composite foam. J Cell Plast 51:373–386. https://doi.org/10.1177/0021955X14542538

Zia F, Zia KM, Zuber M et al (2015) Starch based polyurethanes: a critical review updating recent literature. Carbohydr Polym 134:784–798. https://doi.org/10.1016/j.carbpol.2015.08.034

Monteavaro LL, da Silva EO, Costa APO et al (2005) Polyurethane networks from formiated soy polyols: synthesis and mechanical characterization. J Am Oil Chem Soc 82:365–371. https://doi.org/10.1007/s11746-005-1079-0

Siji Vargheese, Dr. Jineesh A.G DrAPN (2018) Development of functionalized nanocellulose based cross-linked gel for water purification. MS Ramaiah University of Applied Sciences

Chandrashekhar A, Gopi JA, Prabhu TN (2020) Development of flexible bio based porous polyurethane nanocellulose composites for wastewater treatment. In: AIP Conference Proceedings AIP Inc.

Khanjanzadeh H, Behrooz R, Bahramifar N et al (2018) Surface chemical functionalization of cellulose nanocrystals by 3-aminopropyltriethoxysilane. Int J Biol Macromol 106:1288–1296. https://doi.org/10.1016/j.ijbiomac.2017.08.136

Oliviero M, Verdolotti L, Stanzione M et al (2017) Bio-based flexible polyurethane foams derived from succinic polyol: mechanical and acoustic performances. J Appl Polym Sci 134:45113. https://doi.org/10.1002/app.45113

Gopi JA, Nando GB (2012) Optimization of the processing parameters in melt blending of thermoplastic polyurethane and poly dimethyl siloxane rubber. J Elastomers Plast 44:189–204. https://doi.org/10.1177/0095244311425998

Dinda S, Patwardhan AV, Goud VV, Pradhan NC (2008) Epoxidation of cottonseed oil by aqueous hydrogen peroxide catalysed by liquid inorganic acids. Bioresour Technol 99:3737–3744. https://doi.org/10.1016/J.BIORTECH.2007.07.015

Abril-Milán D, Valdés O, Mirabal-Gallardo Y et al (2018) Preparation of renewable bio-polyols from two species of colliguaja for rigid polyurethane foams. Materials. https://doi.org/10.3390/ma11112244

ASTM D7253-16 standard test method for polyurethane raw materials: determination of acidity as acid number for polyether polyols. https://www.astm.org/Standards/D7253.htm. Accessed 27 Sept 2020

Alagi P, Choi YJ, Seog J, Hong SC (2016) Efficient and quantitative chemical transformation of vegetable oils to polyols through a thiol-ene reaction for thermoplastic polyurethanes. Ind Crops Prod 87:78–88. https://doi.org/10.1016/J.INDCROP.2016.04.027

Shah SN, Mahesar SA, Abro KA et al (2017) FTIR Characterization and physicochemical evaluation of cottonseed oil. Pak J Anal Environ Chem 18:46–53

Xia W, Budge SM, Lumsden MD (2016) 1H-NMR characterization of epoxides derived from polyunsaturated fatty acids. J Am Oil Chem Soc 93:467–478. https://doi.org/10.1007/s11746-016-2800-2

Fang Z, Qiu C, Ji D et al (2019) Development of high-performance biodegradable rigid polyurethane foams using full modified soy-based polyols. J Agric Food Chem 67:2220–2226. https://doi.org/10.1021/acs.jafc.8b05342

Xue B, Wen J, Sun R (2014) Lignin-based rigid polyurethane foam reinforced with pulp fiber: synthesis and characterization. ACS Sustain Chem Eng 2:1474–1480. https://doi.org/10.1021/sc5001226

Ranote S, Kumar D, Kumari S et al (2019) Green synthesis of moringa oleifera gum-based bifunctional polyurethane foam braced with ash for rapid and efficient dye removal. Chem Eng J 361:1586–1596. https://doi.org/10.1016/J.CEJ.2018.10.194

Cherian BM, Leão AL, de Souza SF et al (2010) Isolation of nanocellulose from pineapple leaf fibres by steam explosion. Carbohydr Polym 81:720–725. https://doi.org/10.1016/j.carbpol.2010.03.046

Fareez IM, Ibrahim NA, Wan Yaacob WMH et al (2018) Characteristics of cellulose extracted from josapine pineapple leaf fibre after alkali treatment followed by extensive bleaching. Cellulose 25:4407–4421. https://doi.org/10.1007/s10570-018-1878-0

Tanpichai S, Witayakran S, Boonmahitthisud A (2019) Study on structural and thermal properties of cellulose microfibers isolated from pineapple leaves using steam explosion. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2018.102836

Ravindran L, M.S. S, Thomas S, (2019) Novel processing parameters for the extraction of cellulose nanofibres (cnf) from environmentally benign pineapple leaf fibres (palf): structure-property relationships. Int J Biol Macromol 131:858–870. https://doi.org/10.1016/j.ijbiomac.2019.03.134

Balakrishnan P, Sreekala MS, Kunaver M et al (2017) Morphology, transport characteristics and viscoelastic polymer chain confinement in nanocomposites based on thermoplastic potato starch and cellulose nanofibers from pineapple leaf. Carbohydr Polym 169:176–188. https://doi.org/10.1016/j.carbpol.2017.04.017

Hettegger H, Sumerskii I, Sortino S et al (2015) Silane meets click chemistry: towards the functionalization of wet bacterial cellulose sheets. Chemsuschem 8:680–687. https://doi.org/10.1002/cssc.201402991

Pillai PKS, Li S, Bouzidi L, Narine SS (2016) Metathesized palm oil polyol for the preparation of improved bio-based rigid and flexible polyurethane foams. Ind Crops Prod 83:568–576. https://doi.org/10.1016/j.indcrop.2015.12.068

Sultan M (2017) Polyurethane for removal of organic dyes from textile wastewater. Environ Chem Lett 15:347–366. https://doi.org/10.1007/s10311-016-0597-8

Zhang C, Vennerberg D, Kessler MR (2015) In situ synthesis of biopolyurethane nanocomposites reinforced with modified multiwalled carbon nanotubes. J Appl Polym Sci 132:1–8. https://doi.org/10.1002/app.42515

Cao X, Habibi Y, Lucia LA (2009) One-pot polymerization, surface grafting, and processing of waterborne polyurethane-cellulose nanocrystal nanocomposites. J Mater Chem 19:7137–7145. https://doi.org/10.1039/b910517d

Sittinun A, Pisitsak P, Manuspiya H et al (2020) Utilization of palm olein-based polyol for polyurethane foam sponge synthesis: potential as a sorbent material. J Polym Environ 28:3181–3191. https://doi.org/10.1007/S10924-020-01834-4/FIGURES/9

Thakur S, Chaudhary J, Thakur A et al (2022) Highly efficient poly(acrylic acid-co-aniline) grafted itaconic acid hydrogel: application in water retention and adsorption of rhodamine B dye for a sustainable environment. Chemosphere. https://doi.org/10.1016/J.CHEMOSPHERE.2022.134917

Bai Q, Xiong Q, Li C et al (2017) Hierarchical porous cellulose/activated carbon composite monolith for efficient adsorption of dyes. Cellulose 24:4275–4289. https://doi.org/10.1007/S10570-017-1410-Y/FIGURES/11

Xiao W, Garba ZN, Sun S et al (2020) Preparation and evaluation of an effective activated carbon from white sugar for the adsorption of rhodamine B dye. J Clean Prod 253:119989. https://doi.org/10.1016/J.JCLEPRO.2020.119989

Oyekanmi AA, Ahmad A, Hossain K, Rafatullah M (2019) Adsorption of rhodamine B dye from aqueous solution onto acid treated banana peel: response surface methodology, kinetics and isotherm studies. PLoS ONE. https://doi.org/10.1371/JOURNAL.PONE.0216878

Postai DL, Demarchi CA, Zanatta F et al (2016) Adsorption of rhodamine B and methylene blue dyes using waste of seeds of aleurites moluccana, a low cost adsorbent. Alex Eng J 55:1713–1723. https://doi.org/10.1016/J.AEJ.2016.03.017

Chandrashekhar A, Gopi JA, Prabhu TN (2020) Development of flexible bio based porous polyurethane nanocellulose composites for wastewater treatment. AIP Conf Proc 2274:040002. https://doi.org/10.1063/5.0022888

Khamparia S, Jaspal D (2016) Investigation of adsorption of rhodamine B onto a natural adsorbent argemone mexicana. J Environ Manag 183:786–793. https://doi.org/10.1016/J.JENVMAN.2016.09.036

Cui W, Kang X, Zhang X, Cui X (2019) Gel-like ZnO/Zr-MOF(bpy) nanocomposite for highly efficient adsorption of rhodamine B dye from aqueous solution. J Phys Chem Solids 134:165–175. https://doi.org/10.1016/J.JPCS.2019.06.004

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

AC conducted all experimental work and prepared original manuscript draft, SV contributed for preparation of nanocellulose, JGV contributed in the synthesis of polyurethanes, JAG supervised the research, initial plan and contributed in writing the manuscript, TNP contributed in the research plan, conceptualization and editing the manuscript. All the authors have accepted responsibility for the entire content of this submitted manuscript and approved submission.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chandrashekar, A., Vargheese, S., Vijayan, J.G. et al. Highly Efficient Removal of Rhodamine B Dye Using Nanocomposites Made from Cotton Seed Oil-Based Polyurethane and Silylated Nanocellulose. J Polym Environ 30, 4999–5011 (2022). https://doi.org/10.1007/s10924-022-02567-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-022-02567-2