Abstract

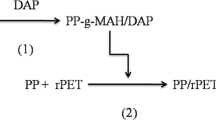

Incompatible polypropylene (PP) and polyethylene (PE) are difficult to separate in mixed recycling streams such as waste plastic packaging, which makes polyolefin mixtures unsuitable for high-quality products. In this work, based on the free radical branching reaction, a co-branching reaction of isotactic polypropylene (iPP) and high-density polyethylene (HDPE) blends was carried out in the presence of the peroxide, free radical regulator and multifunctional acrylate monomer, and a star-like long-chain branching (LCB) copolymer was obtained. The effect of in situ compatibilization on the structures and mechanical properties of iPP/HDPE was investigated, and the compatibilization mechanism was discussed. Results showed that the mechanical properties of the modified blends were largely improved, and efficient in-situ compatibilization of iPP and HDPE could be taken place in a wide process window. Moreover, the sizes of the dispersed phase in the modified blends were clearly decreased, and the interfacial thickness increased. Compared with the pure iPP/HDPE blend, the initial crystallization temperature of iPP in the modified iPP/HDPE blend was increased, and long branched chains of the LCB copolymers were physically entangled with the chemical identical homopolymers or even participated in the crystallization of iPP and HDPE. Thanks to the in situ compatibilization strategy, the compatibility of iPP/HDPE was significantly improved.

Similar content being viewed by others

References

Eagan JM, Xu J, Girolam RD, Christopher MT, Christopher WM, Anne ML, Frank SB, Geoffrey WC (2017) Combining polyethylene and polypropylene: enhanced performance with PE/iPP multiblock. Science 355:814–816

Jordan AM, Kim K, Soetrisno D, Hannah J, Bates FS, Jaffer SA, Lhost O, Macosko CW (2018) Role of crystallization on polyolefin interfaces: an improved outlook for polyolefin blends. Macromolecules 51:2506–2516

Herbort AF et al (2018) Alkoxy-silyl induced agglomeration: a new approach for the sustainable removal of microplastic from aquatic systems. J Polym Environ 26:4258–4270

Rochman CM (2018) Microplastics research-from sink to source. Science 360:28–29

Chaffin KA, Knutsen JS, Brant P, Bates FS (2000) Highstrength welds in metallocene polypropylene/polyethylene laminates. Science 288:2187–2190

Yasamin K, Ramezani KA, Denis R (2015) Compatibilization efficiency in post-consumer recycled polyethylene/polypropylene blends: Effect of contamination. Polym Eng Sci 55:2368–2376

Creton C (2017) Molecular stitches for enhanced recycling of packaging. Science 355:797–798

Camargo RD, Saron C (2020) Mechanical-Chemical Recycling of Low-Density Polyethylene Waste with Polypropylene. J Polym Environ 28(3):794–802

Carvalho VL, Safieddine C, Demarquette NR, Pinheiro LA (2019) In situ compatibilization of a polyethylene, polypropylene, and polystyrene ternary blend through Friedel-Crafts alkylation. J Appl Polym Sci 137:48295

Wang WZ, Zhang XC, Maoc ZY, Zhao WQ (2019) Effects of gamma radiation on the impact strength of polypropylene (PP)/high density polyethylene (HDPE) blends. Results Phys 12:2169–2174

Gu JQ, Xu HY, Wu CF (2013) The Effect of PP and Peroxide on the Properties and Morphology of HDPE and HDPE/PP Blends. Adv Polym Tech 32:72–72

Klimovica K, Pan SS, Lin TW, Peng XY, Ellison J (2020) Compatibilization of iPP/HDPE Blends with PE-g-iPP Graft Copolymers. Acs Macro Lett 9:1161–1166

Mohan TP, Kanny K (2013) Melt blend studies of nanoclay-filled polypropylene (PP)–high-density polyethylene (HDPE) composites. J Mater Sci 48(23):8292–8301

Jeannette MG, Megan LR (2017) The future of plastics recycling. Science 358:870–872

Xu J, Eagan JM, Kim SS, Pan SS, Lee BJ, Klimovica K, Jin KL, Lin TW, Micah JH, Ellison CJ, LaPointe AM, Coates GW, Bates FS (2018) Compatibilization of isotactic polypropylene (iPP) and high-density polyethylene (HDPE) with iPP−PE multiblock copolymers. Macromolecules 51:8585–8596

López-Barrón CR, Tsou AH (2017) Strain hardening of polyethylene /polypropylene blends via interfacial reinforcement with poly(ethylene-cb-propylene) comb block copolymers. Macromolecules 50:2986–2995

Chaffin KA, Bates FS, Brant P, Brown GM (2000) Semicrystalline blends of polyethylene and isotactic polypropylene: improving mechanical performance by enhancing the interfacial structure. J Polym Sci Pol Phys 38:108–121

Li YC, Jia S, Dua SL, Wang YF, Lu LD, Zhang JB (2018) Improved properties of recycled polypropylene by introducing the long chain branched structure through reactive extrusion. Waste Manage 76:172–179

Yao Z, Lu ZQ, Zhao X, Qu BW, Shen ZC, Cao K (2009) Synthesis and characterization of High-Density Polypropylene-grafted polyethylene via a macromolecular reaction and its rheological behavior. J Appl Polym Sci 111:2553–2561

Li Y, Yao Z, Chen ZH, Qiu SL, Zeng CC, Cao K (2015) High melt strength polypropylene by ionic modification: Preparation, rheological properties and foaming behaviors. Polymer 70:207–214

Liu JY, Yu W, Zhou CX (2011) Polymer chain topological map as determined by linear viscoelasticity. J Rheol 55:545–570

Zhang ZJ, Xing HP, Qiu J, Jiang ZW, Yu HO, Du XH, Wang YH, Ma L, Tang T (2010) Controlling melt reactions during preparing long chain branched polypropylene using copper N, N-dimethyldithiocarbamate. Polymer 51:1593–1598

Li SZ, Xiao MM, Guan Y, Wei DF, Xiao HN, Zheng NN (2012) A novel strategy for the preparation of long chain branching polypropylene and the investigation on foamability and rheology. Eur Polym J 48:362–371

Münstedt H, Schwarzl FR (2011) Rheological properties and molecular structure of polymer melts. Soft Matter 7:2273–2283

Blom HP, Teh JW, Rudin A (1996) iPP/HDPE blends II Modification with EPDM and EVA. J Appl Polym Sci 60:1405–1417

Ha MH, Kim BK, Kim EY (2004) Effects of Dispersed Phase Composition on Thermoplastic Polyolefins. J Appl Polym Sci 93:179–188

Zhang C, Yi XS, Asai S, Sumita M (2000) Morphology, crystallization and melting behaviors of isotactic polypropylene/high density polyethylene blend: effect of the addition of short carbon fiber. J Mater Sci 35:673–683

Prokhorov KA, Nikolaeva GY, Sagitova EA, Pashinin PP, Guseva MA, Shklyaruk BF, Gerasin VA (2018) Raman structural study of melt-mixed blends of isotactic polypropylene with polyethylene of various densities. Laser Phys 28:045702

Samuel AZ (2020) Direct estimation of polymer crystallinity with Raman spectroscopy using ratio of scattering cross-sections estimated from variable temperature measurements. Spectrochim Acta A 224:117431

López-Barrón CR, Macosko CW (2014) Rheology of compatibilized immiscible blends with droplet-matrix and cocontinuous morphologies during coarsening. J Rheol 58:1935–1953

Martin JD, Velankar SS (2007) Effects of compatibilizer on immiscible polymer blends near phase inversion. J Rheol 51:669–692

Wu DF, Zhang YS, Zhang M, Wu LF (2007) Morphology, nonisothermal crystallization behavior, and kinetics of poly(phenylene sulfide)/polycarbonate blend. J Appl Polym Sci 105:739–748

Kempf M, Ahirwal D, Cziep M, Wilhelm M (2013) Synthesis and linear and nonlinear melt rheology of well-defined comb architectures of PS and PpMS with a low and controlled degree of long-chain branching. Macromolecules 46:4978–4994

Lohse DJ, Milner ST, Fetters LJ, Xenidou M, Hadjichristidis N, Mendelson R (2002) A Well-defined, model long chain branched polyethylene 2 Melt rheological behavior. Macromolecules 35:3066–3075

Trinkle S, Friedrich C (2001) Van Gurp-Palmen-plot: a way to characterize polydispersity of linear polymers. Rheol Acta 40:322–328

Kanso MA, Giacomin AJ (2020) Van Gurp-Palmen relations for long-chain branching from general rigid bead-rod theory. Phys Fluids 32:033101

Stadler FJ, Chun YS, Han JH, Lee E, Park SH, Yang CB, Choi C (2016) Deriving comprehensive structural information on long-chain branched polyethylenes from analysis of thermos-rheological complexity. Polymer 104:179–192

López-Barrón C, Patrick B, Maksim S, Lu JM, Kang SH, Throckmorton J, Trent M, Truyen P, Rebecca C (2018) Long-chain hyperbranched comb block copolymers: synthesis, microstructure, rheology, and thermal behavior. Macromolecules 51:5720–5731

Tsou AH, López-Barrón CR, Jiang P, Crowther DJ, Zeng Y (2016) Bimodal poly(ethylene-cb-propylene) comb block copolymers from serial reactors: synthesis and applications as processability additives and blend compatibilizers. Polymer 104:72–82

Tian Z, Chen KR, Liu BP, Luo N, Du WL, Qian F (2015) Short-chain branching distribution oriented model development for Borstar bimodal polyethylene process and its correlation with product performance of slow crack growth. Chem Eng Sci 130:41–55

Acknowledgements

This study was funded by the National Key R & D Plan of China (2019YFC1908200).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, J., Yang, L., Li, X. et al. In Situ Compatibilization of Isotactic Polypropylene and High-Density Polyethylene by a Melt Cobranching Reaction. J Polym Environ 30, 1127–1140 (2022). https://doi.org/10.1007/s10924-021-02263-7

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02263-7