Abstract

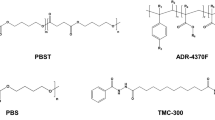

Physical cross-linking by hydrogen-bonds (H-bonds), providing a good combination of application properties of thermosets and processability of thermoplastics, is a potential strategy to resolve the recycling problem of traditional chemically cross-linked polyethylene. However, ureidopyrimidone (UPy), the most widely used H-bonding motif, is unfavorable for large-scale industrial application due to its poor thermal stability. In this work, H-bonds cross-linked polyethylene was successfully prepared by reactive melt blending maleic anhydride grafted polyethylene (PE-g-MAH) with 3-amino-1,2,4-triazole (ATA) to form amide triazole ring-carboxylic acid units. Triazole ring can easily generate multiple H-bonds with carboxylic acid and amide. More importantly, these units are more thermal stable than UPy due to the absence of unstable urea group of UPy. The introduction of H-bonds cross-linking leads to an obvious improvement in mechanical properties and creep resistance and a good maintain in thermal properties and recyclability. Furthermore, the reinforcement effect monotonically improves with increasing the density of H-bonds. The obtained good properties are mainly attributed to largely enhanced interchain interactions induced by H-bonds cross-linking and intrinsic reversibility of H-bonds. This work develops a novel way for the simple fabrication of H-bonds cross-linked PE with high performance through reactive melt blending.

Similar content being viewed by others

References

Stuerzel, M.; Mihan, S.; Muelhaupt, R. From multisite polymerization catalysis to sustainable materials and all-polyolefin composites. Chem. Rev. 2016, 116, 1398–1433.

Wang, Z. B.; Mao, Y. M.; Li, X. K.; Li Y. K.; Jarumaneeroj, C.; Thitisak, B.; Tiyapiboonchaiya, P.; Rungswang, W.; Hsiao B. S. The influence of ethyl branch on formation of shish-kebab crystals in bimodal polyethylene under shear at low temperature. Chinese J. Polym. Sci. 2021, 39, 1050–1058.

An, M. F.; Lv, Y.; Xu, H. J.; Wang, B. J.; Wang, Y. X.; Gu, Q.; Wang, Z. B. Effect of gel solution concentration on the structure and properties of gel-spun ultrahigh molecular weight polyethylene fibers. Ind. Eng. Chem. Res. 2016, 55, 8357–8363.

Gomez-Estaca, J.; Lopez-de-Dicastillo, C.; Hernandez-Munoz, P.; Catala, R.; Gavara, R. Advances in antioxidant active food packaging. Trends Food Sci. Technol. 2014, 35, 42–51.

Ryou, M. H.; Lee, Y. M.; Park, J. K.; Choi, J. W. Mussel-inspired polydopamine-treated polyethylene separators for high-power Li-ion batteries. Adv. Mater. 2011, 23, 3066–3070.

Hubert, L.; David, L.; Seguela, R.; Vigier, G.; Degoulet, C.; Germain, Y. Physical and mechanical properties of polyethylene for pipes in relation to molecular architecture. I. Microstructure and crystallisation kinetics. Polymer 2001, 42, 8425–8434.

Chen, L.; Hou, J. R.; Chen, Y. W.; Wang, H. J.; Duan, Y. X.; Zhang, J. M. Synergistic effect of conductive carbon black and silica particles for improving the pyroresistive properties of high density polyethylene composites. Compos. Part B 2019, 178, 8.

Gibb, B. C. Plastics are forever. Nat. Chem. 2019, 11, 394–395.

Du, Z. C.; Yang, H.; Luo, X. H.; Xie, Z. X.; Fu, Q.; Gao, X. Q. The role of mold temperature on morphology and mechanical properties of pe pipe produced by rotational shear. Chinese J. Polym. Sci. 2020, 38, 653–664.

Cao, W.; Wang, K.; Zhang, Q.; Du, R. N.; Fu, Q. The hierarchy structure and orientation of high density polyethylene obtained via dynamic packing injection molding. Polymer 2006, 47, 6857–6867.

Thomas, J.; Joseph, B.; Jose, J. P.; Maria, H. J.; Main, P.; Rahman, A. A.; Francis, B.; Ahmad, Z.; Thomas, S. Recent advances in cross-linked polyethylene-based nanocomposites for high voltage engineering applications: a critical review. Ind. Eng. Chem. Res. 2019, 58, 20863–20879.

Khonakdar, H. A.; Morshedian, J.; Wagenknecht, U.; Jafari, S. H. An investigation of chemical crosslinking effect on properties of high-density polyethylene. Polymer 2003, 44, 4301–4309.

Chen, Z.; Leatherman, M. D.; Daugulis, O.; Brookhart, M. Nickel-catalyzed copolymerization of ethylene and vinyltrialkoxysilanes: catalytic production of cross-linkable polyethylene and elucidation of the chain-growth mechanism. J. Am. Chem. Soc. 2017, 139, 16013–16022.

Wang, B.; Wang, M.; Xing, Z.; Zeng, H.; Wu, G. Preparation of radiation crosslinked foams from low-density polyethylene/ethylene-vinyl acetate (LDPE/EVA) copolymer blend with a supercritical carbon dioxide approach. J. Appl. Polym. Sci. 2013, 127, 912–918.

Lehn, J. M. Dynamic combinatorial chemistry and virtual combinatorial libraries. Chem. Eur. J. 1999, 5, 2455–2463.

Jin, Y.; Yu, C.; Denman, R. J.; Zhang, W. Recent advances in dynamic covalent chemistry. Chem. Soc. Rev. 2013, 42, 6634–54.

Hu, Z.; Li, Y.; Xu, X.; Yuan, W.; Yang, L.; Shao, Q.; Guo, Z.; Ding, T.; Huang, Y. Efficient intrinsic self-healing epoxy acrylate formed from host-guest chemistry. Polymer 2019, 164, 79–85.

Xia, S.; Song, S.; Gao, G. Robust and flexible strain sensors based on dual physically cross-linked double network hydrogels for monitoring human-motion. Chem. Eng. J. 2018, 354, 817–824.

Wei, H.; Tong, L.; Yu, S.; Zhang, J.; Dong, Y.; Li, X.; Ding, Y. Non-covalently crosslinked anion exchange membranes: effect of urea hydrogen-bonding group position. Polymer 2019, 179, 121654.

Wojtecki, R. J.; Meador, M. A.; Rowan, S. J. Using the dynamic bond to access macroscopically responsive structurally dynamic polymers. Nat. Mater. 2011, 10, 14–27.

Feng, P.; Wang, W.; Hou, J.; Wang, K.; Cheng, S.; Jiang, K. A 3D coral-like structured NaVPO4F/C constructed by a novel synthesis route as high-performance cathode material for sodium-ion battery. Chem. Eng. J. 2018, 353, 25–33.

Dong, H.; Xin, Z.; Lu, X.; Lv, Y. Effect of N-substituents on the surface characteristics and hydrogen bonding network of polybenzoxazines. Polymer 2011, 52, 1092–1101.

Grande, A. M.; Bijleveld, J. C.; Garcia, S. J.; van der Zwaag, S. A combined fracture mechanical-rheological study to separate the contributions of hydrogen bonds and disulphide linkages to the healing of poly(urea-urethane) networks. Polymer 2016, 96, 26–34.

Sijbesma, R. P.; Beijer, F. H.; Brunsveld, L.; Folmer, B. J. B.; Hirschberg, J.; Lange, R. F. M.; Lowe, J. K. L.; Meijer, E. W. Reversible polymers formed from self-complementary monomers using quadruple hydrogen bonding. Science 1997, 278, 1601–1604.

Lin, Y. L.; Li, G. J. An intermolecular quadruple hydrogen-bonding strategy to fabricate self-healing and highly deformable polyurethane hydrogels. J. Mater. Chem. B 2014, 2, 6878–6885.

Houston, K. R.; Jackson, A. M. S.; Yost, R. W.; Carman, H. S.; Ashby, V. S. Supramolecular engineering polyesters: endgroup functionalization of glycol modified PET with ureidopyrimidinone. Polym. Chem. 2016, 7, 6744–6751.

Hympanova, L.; Mori daCunha, M. G. M. C.; Rynkevic, R.; Wachf, R. A.; Olejnik, A. K.; Dankers, P. Y. W.; Arts, B.; Mes, T.; Bosman, A. W.; Albersen, M.; Deprest, J. Experimental reconstruction of an abdominal wall defect with electrospun polycaprolactone-ureidopyrimidinone mesh conserves compliance yet may have insufficient strength. J. Mech. Behav. Biomed. Mater. 2018, 88, 431–441.

Zhang, J. P.; Zhang, F. S. Recycling waste polyethylene film for amphoteric superabsorbent resin synthesis. Chem. Eng. J. 2018, 331, 169–176.

Zych, A.; Verdelli, A.; Soliman, M.; Pinalli, R.; Vachon, J.; Dalcanale, E. Physically cross-linked polyethylene via reactive extrusion. Polym. Chem. 2019, 10, 1741–1750.

Tellers, J.; Canossa, S.; Pinalli, R.; Soliman, M.; Vachon, J.; Dalcanale, E. Dynamic cross-linking of polyethylene via sextuple hydrogen bonding array. Macromolecules 2018, 51, 7680–7691.

van Beek, D. J. M.; Spiering, A. J. H.; Peters, G. W. M.; te Nijenhuis, K.; Sijbesma, R. P. Unidirectional dimerization and stacking of ureidopyrimidinone end groups in polycaprolactone supramolecular polymers. Macromolecules 2007, 40, 8464–8475.

Wang, P.; Cai, Z. S. Highly efficient flame-retardant epoxy resin with a novel DOPO-based triazole compound: thermal stability, flame retardancy and mechanism. Polym. Degrad. Stabil. 2017, 137, 138–150.

Cai, J. X.; Xie, C. P.; Xiong, J.; Zhang, J. Y.; Yin, P.; Pang, S. P. High performance and heat-resistant pyrazole-1,2,4-triazole energetic materials: tuning the thermal stability by asymmetric framework and azo-bistriazole bridge. Chem. Eng. J. 2022, 433, 134480.

Chino, K.; Ashiura, M. Themoreversible cross-linking rubber using supramolecular hydrogen-bonding networks. Macromolecules 2001, 34, 9201–9204.

Liu, J.; Liu, J.; Wang, S.; Huang, J.; Wu, S.; Tang, Z.; Guo, B.; Zhang, L. An advanced elastomer with an unprecedented combination of excellent mechanical properties and high self-healing capability. J. Mater. Chem. A 2017, 5, 25660–25671.

Xiong, C.; Li, X.; He, H.; Xue, B.; Wang, Y.; Li, J.; Zhu, Z. A thermally reversible healing EPDM based elastomer with higher tensile properties and damping properties. J. Appl. Polym. Sci. 2021, 138, e49767.

Wang, S. S.; Zhao, Z. Q.; Wang, N.; Zhao, J. R.; Feng, Y. Structure and mechanism of functional isotactic polypropylene via in situ chlorination graft copolymerization. Polym. Int. 2011, 60, 1068–1077.

Barra, G. M.; Crespo, J. S.; Bertolino, J. R.; Soldi, V.; Pires, A. T. N. Maleic anhydride grafting on EPDM: qualitative and quantitative determination. J. Braz. Chem. Soc. 1999, 10, 31–34.

Liu, J.; Wang, S.; Tang, Z.; Huang, J.; Guo, B.; Huang, G. Bioinspired engineering of two different types of sacrificial bonds into chemically cross-linked cis-1,4-polyisoprene toward a high-performance elastomer. Macromolecules 2016, 49, 8593–8604.

Song, Y.; Liu, C. Waste-reducing preparation of PE-g-MAH and PE-g-DBM via solid phase grafting reaction and their application as compatibilizers. J. Appl. Polym. Sci. 2006, 101, 3781–3790.

Nojiri, S.; Yamada, H.; Kimata, S.; Ikeda, K.; Senda, T.; Bosman, A. W. Supramolecular polypropylene with self-complementary hydrogen bonding system. Polymer 2016, 87, 308–315.

Martin, S.; Vega, J. F.; Exposito, M. T.; Flores, A.; Martinez-Salazar, J. A three-phase microstructural model to explain the mechanical relaxations of branched polyethylene: a DSC, WAXD and DMTA combined study. Colloid. Polym. Sci. 2011, 289, 257–268.

Stehling, F. C.; Mandelkern, L. The glass temperature of linear polyethylene. Macromolecules 1970, 3, 242–252.

Armstrong, G.; Buggy, M. Thermal stability of some self-assembling hydrogen-bonded polymers and related model complexes. Polym. Int. 2002, 51, 1219–1224.

Pietrasanta; Robin, J.; Torres, N.; Boutevin, B. Mechanical performance improvement of low-density polyethylene blends. Mech. Time-Depend. Mater. 1998, 2, 85–95.

Jose, J. P.; Thomas, S. Alumina-clay nanoscale hybrid filler assembling in cross-linked polyethylene based nanocomposites: mechanics and thermal properties. Phys. Chem. Chem. Phys. 2014, 16, 14730–14740.

Liu, S. Q.; Gong, W. G.; Zheng, B. C. The effect of peroxide cross-linking on the properties of low-density polyethylene. J. Macromol. Sci. Part B-Phys. 2014, 53, 67–77.

Wang, W.; Zhang, Y.; Liu, W. Bioinspired fabrication of high strength hydrogels from non-covalent interactions. Prog. Polym. Sci. 2017, 71, 1–25.

Zhang, Q.; Cai, H.; Ren, X.; Kong, L.; Liu, J.; Jiang, X. The dynamic mechanical analysis of highly filled rice husk biochar/high-density polyethylene composites. Polymers 2017, 9, 628.

Xia, H.; Song, M.; Zhang, Z.; Richardson, M. Microphase separation, stress relaxation, and creep behavior of polyurethane nanocomposites. J. Appl. Polym. Sci. 2007, 103, 2992–3002.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51803130) and Fundamental Research Funds for Central Universities and Chongqing University Key Laboratory of Micro/Nano Materials Engineering and Technology (No. KFJJ2005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no interest conflict.

Rights and permissions

About this article

Cite this article

Mao, HD., Zhang, TT., Guo, ZY. et al. A Cross-linked Polyethylene with Recyclability and Mechanical Robustness Enabled by Establishment of Multiple Hydrogen Bonds Network via Reactive Melt Blending. Chin J Polym Sci 41, 1104–1114 (2023). https://doi.org/10.1007/s10118-023-2907-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-023-2907-5