Abstract

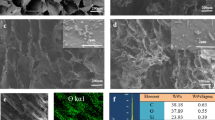

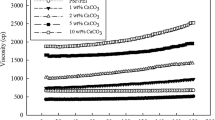

In this study, pure cellulose acetate (CA) and rubber (Hevea brasiliensis) seed shell activated carbon (RSSAC) blended CA membranes were fabricated by the phase-inversion technique. Results indicate that the composite membranes exhibit increased water content, porosity and pore size. Field emission scanning electron microscopy (FESEM) images reveal that no pores visibly found at the surface of membrane. The atomic force microscopic images (AFM) indicate an decreased squared average roughness (Rq) of membrane upto 1 wt% of RSSAC additives. Filtration experiments were conducted to evaluate the performance of membranes for the chemical oxygen demand (COD) and waste engine oil removal efficiency. The results evince that the COD and waste engine oil removal efficiency of composite membrane increased than the pure CA membrane, which is due to the attraction of hydrocarbon towards the composite membrane. Further, in comparison with pure CA, the antifouling properties of the composite membranes were found to be significantly improved.

Similar content being viewed by others

References

Li J, Liu Q, Liu Y, Xie J (2017) Development of electro-active forward osmosis membranes to remove phenolic compounds and reject salts. Environ Sci Water Res Technol 3(1):139–146. https://doi.org/10.1039/C6EW00275G

Zhu Y, Wang D, Jiang L, Jin J (2014) Recent progress in developing advanced membranes for emulsified oil/water separation. NPG Asia Mater 6(5):e101. https://doi.org/10.1038/am.2014.23

Ahmad AL, Majid MA, Ooi BS (2011) Functionalized PSf/SiO2 nanocomposite membrane for oil-in-water emulsion separation. Desalination 268:266–269. https://doi.org/10.1016/j.desal.2010.10.017

Mansourizadeh A, Azad AJ (2014) Preparation of blend polyethersulfone/cellulose acetate/polyethylene glycol asymmetric membranes for oil–water separation. J Polym Res 21(375):1–9. https://doi.org/10.1007/s10965-014-0375-x

Velu S, Rambabu K, Muruganandam L (2014) Development, characterization and application studies of cellulose acetate–activated carbon blend ultra filtration membranes. IJCRGG 6(1):565–577

Zhou J, Chen J, He M, Yao J (2016) Cellulose acetate ultrafiltration membranes reinforced by cellulose nanocrystals: preparation and characterization. J Appl Polym Sci 133:1–7. https://doi.org/10.1002/app.43946

Mukherjee R, De S (2016) Preparation, characterization and application of powdered activated carbon–cellulose acetate phthalate mixed matrix membrane for treatment of steel plant effluent. Polym Adv Technol 27:444–459. https://doi.org/10.1002/pat.3690

Rana D, Scheier B, Narbaitz RM, Matsuura T, Tabe S, Jasim SY, Khulbe KC (2012) Comparison of cellulose acetate (CA) membrane and novel CA membranes containing surface modifying macromolecules to remove pharmaceutical and personal care product micropollutants from drinking water. J Membr Sci 409:346–354. https://doi.org/10.1016/j.memsci.2012.04.005

Savova D, Apak E, Ekinci E, Yardim F, Petrov N, Budinova T, Razvigorova M, Minkova V (2001) Biomass conversion to carbon adsorbents and gas. Biomass Bioenergy 21(2):133–142. https://doi.org/10.1016/S0961-9534(01)00027-7

Ioannidou O, Zabaniotou A (2007) Agricultural residues as precursors for activated carbon production—a review. Renew Sustain Energy Rev 11(9):1966–2005. https://doi.org/10.1016/j.rser.2006.03.013

Abduh MY, Manurung R, Heeres HJ (2017) Techno-economic analysis for small scale production of rubber seed oil and biodiesel in Palangkaraya, Indonesia. J Clean Energy Technol 5(4):268–273. https://doi.org/10.18178/jocet.2017.5.4.381

Deng J, Xiong T, Wang H, Zheng A, Wang Y (2016) Effects of cellulose, hemicellulose, and lignin on the structure and morphology of porous carbons. ACS Sustain Chem Eng 4(7):3750–3756. https://doi.org/10.1021/acssuschemeng.6b00388

Bagheri S, Julkapli NM (2016) Effect of hybridization on the value-added activated carbon materials. Int J Ind Chem 7(3):249–264

Imanah JE, Okieimen FE (2003) Rheological and mechanical properties of natural rubber reinforced with agricultural byproduct. J Appl Polym Sci 90(13):3718–3722. https://doi.org/10.1002/app.13058

Osabohien E, Egboh SHO (2007) Cure characteristics and physico-mechanical properties of natural rubber filled with the seed shells of cherry (Chrysophyllum albidum). J Appl Environ Manag 11(2):43–48. https://doi.org/10.4314/jasem.v11i2.54983

Khalil HPS, Jawaid M, Firoozian P, Rashid U, Islam A, Akil HM (2013) Activated carbon from various agricultural wastes by chemical activation with KOH: preparation and characterization. J Biobased Mater 7(6):708–714. https://doi.org/10.1166/jbmb.2013.1379

Rengaraj S, Moon SH, Sivabalan R, Arabindoo B, Murugesan V (2002) Removal of phenol from aqueous solution and resin manufacturing industry wastewater using an agricultural waste: rubber seed coat. J Hazard Mater 89:185–196. https://doi.org/10.1016/S0304-3894(01)00308-9

Hameed BH, Daud FBM (2008) Adsorption studies of basic dye on activated carbon derived from agricultural waste: Hevea brasiliensis seed coat. Chem Eng J 139(1):48–55. https://doi.org/10.1016/j.cej.2007.07.089

Liou TH (2010) Development of mesoporous structure and high adsorption capacity of biomass-based activated carbon by phosphoric acid and zinc chloride activation. Chem Eng J 158(2):129–142. https://doi.org/10.1016/j.cej.2009.12.016

Bai H, Zhou Y, Wang X, Zhang L (2012) The permeability and mechanical properties of cellulose acetate membranes blended with polyethylene glycol 600 for treatment of municipal sewage. Procedia Environ Sci 16:346–351. https://doi.org/10.1016/j.proenv.2012.10.049

Shoba B, Jeyanthi J, Vairam S (2020) Synthesis, characterization of cellulose acetate membrane and application for the treatment of oily wastewater. Environ Technol 41(12):1590–1605. https://doi.org/10.1080/09593330.2018.1543353

Kumar A, Jena HM (2016) Preparation and characterization of high surface area activated carbon from Fox nut (Euryale ferox) shell by chemical activation with H3PO4. Results Phys 6:651–658. https://doi.org/10.1016/j.rinp.2016.09.012

Senthilkumar ST, Senthilkumar B, Balaji S, Sanjeeviraja C, Kalai Selvan R (2011) Preparation of activated carbon from sorghum pith and its structural and electrochemical properties. Mater Res Bull 46(3):413–419. https://doi.org/10.1016/j.materresbull.2010.12.002

Isahak WNRW, Hisham MWM, Yarmo MA (2013) Highly porous carbon materials from biomass by chemical and carbonization method: a comparison study. J Chem. https://doi.org/10.1155/2013/620346

Demirbas E, Dizge N, Sulak MT, Kobya M (2009) Adsorption kinetics and equilibrium of copper from aqueous solutions using hazelnut shell activated carbon. Chem Eng J 148(2–3):480–487. https://doi.org/10.1016/j.cej.2008.09.027

Rao MM, Ramesh A, Rao GPC, Seshaiah K (2006) Removal of copper and cadmium from the aqueous solutions by activated carbon derived from Ceiba pentandra hulls. J Hazard Mater 129(1–3):123–129. https://doi.org/10.1016/j.jhazmat.2005.08.018

Khenniche L, Benissad-Aissani F (2010) Adsorptive removal of phenol by coffee residue activated carbon and commercial activated carbon: Equilibrium, kinetics, and thermodynamics. J Chem Eng Data 55(11):4677–4686. https://doi.org/10.1021/je100302e

Rodrigues LA, da Silva MLCP, Alvarez-Mendes MO, dos Reis Coutinho A, Thim GP (2011) Phenol removal from aqueous solution by activated carbon produced from avocado kernel seeds. Chem Eng J 174(1):49–57. https://doi.org/10.1016/j.cej.2011.08.027

Sivakumar B, Kannan C, Karthikeyan S (2012) Preparation and characterization of activated carbon prepared from balsamodendron caudatum wood waste through various activation processes. Rasayan J Chem 5:321–327

van den Berg T, Ulbricht M (2020) Polymer nanocomposite ultrafiltration membranes: the influence of polymeric additive, dispersion quality and particle modification on the integration of zinc oxide nanoparticles into polyvinylidene difluoride membranes. Membranes 10(9):197

Nada AA, Abdellatif FHH, Soliman AA, Shen J, Hudson SM, Abou-Zeid NY (2019) Fabrication and bioevaluation of a medicated electrospun mat based on azido-cellulose acetate via click chemistry. Cellulose 26(18):9721–9736

Bagheripour E, Moghadassi AR, Hosseini SM, Ray MB, Parvizian F, Van der Bruggen B (2018) Highly hydrophilic and antifouling nanofiltration membrane incorporated with water-dispersible composite activated carbon/chitosan nanoparticles. Chem Eng Res Des 132:812–821. https://doi.org/10.1016/j.cherd.2018.02.027

Hong CH, Ki SJ, Jeon JH, Che HL, Park IK, Kee CD, Oh IK (2013) Electroactive bio-composite actuators based on cellulose acetate nanofibers with specially chopped polyaniline nanoparticles through electrospinning. Compos Sci Technol 87:135–141. https://doi.org/10.1016/j.compscitech.2013.08.006

Hassan M, Berglund L, Abou-Zeid R, Hassan E, Abou-Elseoud W, Oksman K (2019) Nanocomposite film based on cellulose acetate and lignin-rich rice straw nanofibers. Materials 12(4):595. https://doi.org/10.3390/ma12040595

Han B, Zhang D, Shao Z, Kong L, Lv S (2013) Preparation and characterization of cellulose acetate/carboxymethyl cellulose acetate blend ultrafiltration membranes. Desalination 311:80–89. https://doi.org/10.1016/j.desal.2012.11.002

Zinadini S, Zinatizadeh AA, Rahimi M, Vatanpour V, Zangeneh H (2014) Preparation of a novel antifouling mixed matrix PES membrane by embedding graphene oxide nanoplates. J Membr Sci 453:292–301. https://doi.org/10.1016/j.memsci.2013.10.070

Arif Z, Sethy NK, Kumari L, Mishra PK, Verma B (2019) Antifouling behaviour of PVDF/TiO2 composite membrane: a quantitative and qualitative assessment. Iran Polym J 28(4):301–312. https://doi.org/10.1007/s13726-019-00700-y

Arthanareeswaran G, Devi TS, Raajenthiren M (2008) Effect of silica particles on cellulose acetate blend ultrafiltration membranes: Part I. Sep Purif Technol 64(1):38–47. https://doi.org/10.1016/j.seppur.2008.08.010

Yan L, Li YS, Xiang CB (2005) Preparation of poly(vinylidene fluoride) (PVDF) ultrafiltration membrane modified by nano-sized alumina (Al2O3) and its antifouling research. Polymer 46:7701–7706. https://doi.org/10.1016/j.polymer.2005.05.155

Jusoh N, Keong LK, Mohd Shariff A (2014) Preparation and characterization of polysulfone membrane for gas separation. Adv Mater Res 917:307–316

Huang J, Zhang K, Wang K, Xie Z, Ladewig B, Wang H (2012) Fabrication of polyethersulfone–mesoporous silica nanocomposite ultrafiltration membranes with antifouling properties. J Membr Sci 423:362–370. https://doi.org/10.1016/j.memsci.2012.08.029

Setiawan WK, Chiang KY (2019) Silica applied as mixed matrix membrane inorganic filler for gas separation: a review. Sustain Environ Res 29(1):1–21

Hong SK, Bae S, Jeon H, Kim M, Cho SJ, Lim G (2018) An underwater superoleophobic nanofibrous cellulosic membrane for oil/water separation with high separation flux and high chemical stability. Nanoscale 10(6):3037–3045

Li HJ, Cao YM, Qin JJ, Jie XM, Wang TH, Liu JH, Yuan Q (2006) Development and characterization of anti-fouling cellulose hollow fiber UF membranes for oil–water separation. J Membr Sci 279(1–2):328–335

Chakrabarty B, Ghoshal AK, Purkait MK (2008) Ultrafiltration of stable oil-in-water emulsion by polysulfone membrane. J Membr Sci 325(1):427–437

Salahi A, Gheshlaghi A, Mohammadi T, Madaeni SS (2010) Experimental performance evaluation of polymeric membranes for treatment of an industrial oily wastewater. Desalination 262(1–3):235–242

Fang J, Qin G, Wei W, Zhao X, Jiang L (2013) Elaboration of new ceramic membrane from spherical fly ash for microfiltration of rigid particle suspension and oil-in-water emulsion. Desalination 311:113–126

Suresh K, Srinu T, Ghoshal AK, Pugazhenthi G (2016) Preparation and characterization of TiO2 and γ-Al2O3 composite membranes for the separation of oil-in-water emulsions. RSC Adv 6(6):4877–4888

Li J, Xu C, Tian H, Zha F, Qi W, Wang Q (2018) Blend-electrospun poly(vinylidene fluoride)/stearic acid membranes for efficient separation of water-in-oil emulsions. Colloids Surf A 538:494–499

Hong X, Zhang B, Zhang X, Wu Y, Wang T, Qiu J (2019) Tailoring the structure and property of microfiltration carbon membranes by polyacrylonitrile-based microspheres for oil–water emulsion separation. J Water Process Eng 32:100973

Zioui D, Salazar H, Aoudjit L, Martins PM, Lanceros-Méndez S (2020) Polymer-based membranes for oily wastewater remediation. Polymers 12(1):42

Arthanareeswaran G, Thanikaivelan P (2010) Fabrication of cellulose acetate–zirconia hybrid membranes for ultrafiltration applications: performance, structure and fouling analysis. Sep Purif Technol 74(2):230–235. https://doi.org/10.1016/j.seppur.2010.06.010

Yin J, Fan H, Zhou J (2016) Cellulose acetate/poly (vinyl alcohol) and cellulose acetate/crosslinked poly (vinyl alcohol) blend membranes: preparation, characterization, and antifouling properties. Desalin Water Treat 57(23):10572–10584

Acknowledgements

We would like to show our gratitude to the Centre of Excellence for Environmental Studies, Government College of Technology, Coimbatore, Tamil Nadu, India for providing facilities required for this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shoba, B., Jeyanthi, J. Performance Analysis of Rubber Seed Shell Activated Carbon Incorporated Polymeric Membrane for the Separation of Oil-in-Water Emulsion. J Polym Environ 30, 1055–1071 (2022). https://doi.org/10.1007/s10924-021-02261-9

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02261-9