Abstract

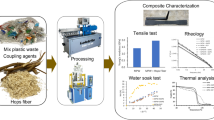

This work aimed to investigate the biopolyethylene (BioPE)/wood powder (WP) composites compatibilized with polyethylene-grafted maleic anhydride (PE-g-MA), using macaíba oil (OM) as a processing aid. The composites were prepared, fist, in an internal mixer and, later, the crushed flakes were molded by injection. Mechanical properties (impact, tensile, flexural and Shore D hardness), heat deflection temperature (HDT), differential scanning calorimetry (DSC), thermogravimetry (TG), water absorption, torque rheometry and scanning electron microscopy (SEM) were evaluated. The addition of 30% wood powder to the BioPE matrix increased the elastic modulus (tensile and flexural), Shore D hardness and heat deflection temperature (HDT), compared to neat BioPE. These properties were improved when 10% of the PE-g-MA compatibilizer was added, compared to neat BioPE and the non-compatibilized composite. There was a significant reduction in the torque of the composites with the addition of macaíba oil, indicating that it improved the processability. In addition, the incorporation of macaíba oil into the composites helped to reduce water absorption, as well as to increase impact strength. SEM micrographs illustrated a greater degree of interfacial adhesion when PE-g-MA and macaiba oil were added.

Similar content being viewed by others

References

Luna CBB, Siqueira DD, Ferreira ESB, Silva WA, Nogueira JAS, Araújo EM (2020) From disposal to technological potential: reuse of polypropylene waste from industrial containers as a polystyrene impact modifier. Sustainability 12(13):5272–5291

Marinho VAD, Almeida TG, Carvalho LH, Canedo EL (2018) Aditivação e biodegradação de compósitos PHB/babaçu. Revista Eletrônica de Materiais e Processos 13(1):37–41

Geyer R, Jambeck JR, Law KL (2017) Production, use, and fate of all plastics ever made. Sci Adv 3(7):1–6

Blanco I (2014) End-life prediction of commercial PLA used for food packaging through short term TGA experiments: Real chance or low reliability. Chin J Polym Sci 32(6):681–689

Blanco I (2018) Lifetime prediction of polymers: to bet, or not to bet—is this the question? Materials 11(8):1–13

Ramos RRF, Siqueira DD, Wellen RMR, Leite IL, Glenn GM, Medeiros ES (2019) Development of green composites based on polypropylene and corncob agricultural residue. J Polym Environ 27(5):1677–1685

Oliveira TA, Barbosa R, Mesquita ABS, Ferreira JHL, Carvalho LH, Alves TS (2020) Fungal degradation of reprocessed PP/PBAT/thermoplastic starch blends. J Market Res 9(2):2338–2349

Siracusa V, Blanco I (2020) Bio-Polyethylene (Bio-PE), Bio-Polypropylene (Bio-PP) and Bio-Poly (ethylene terephthalate)(Bio-PET): recent developments in bio-based polymers analogous to petroleum-derived ones for packaging and engineering applications. Polymers 12(8):1–17

Siqueira DD, Luna CBB, Araújo EM, Ferreira ESB, Wellen RMR (2019) Biocomposites based on PCL and macaiba fiber. Detailed characterization of main properties. Mater Res Express 6(9):095335

Wearn YN, Montagna LS, Passador FR (2020) Coconut fiber/LDPE composites: effect of surface treatment of coconut fibers to produced green composites. Matéria (Rio J) 25(1):e-12548

Oliveira TA, Mota IO, Mousinho FEP, Barbosa R, Carvalho LH, Alves TS (2019) Biodegradation of mulch films from poly(butylene adipate co-terephthalate), carnauba wax, and sugarcane residue. J Appl Polym Sci 136(47):48240

Luna CBB, Siqueira DD, Ferreira ESB, Araújo EM, Wellen RMR (2019) Reactive compatilization of PCL/WP upon addition of PCL-MA. Smart option for recycling industry. Mater Res Express 6(12):125317

Filho PAF, Oliveira TP, Caetano MRS, Araújo IMS, Figueiredo FC, Júnior JRS (2020) Enhancement of the photodegradative potential of polymer composites containing babassu fiber. Mater Res 23(2):e20190438

Lotfi A, Li H, Dao DV, Prusty G (2019) Natural fiber–reinforced composites: A review on material, manufacturing, and machinability. J Thermoplastic Composite Mater . https://doi.org/10.1177/0892705719844546

Mei LH, Oliveira N (2017) Caracterização de um compósito polimérico biodegradável utilizando Poli (ε-caprolactona) e borra de café. Polímeros 27(1):99–109

Ferreira ESB, Luna CBB, Araújo EM, Siqueira DD, Wellen RMR (2019) Polypropylene/wood powder composites: Evaluation of PP viscosity in thermal, mechanical, thermomechanical, and morphological characters. J Thermoplastic Composite Mater. https://doi.org/10.1177/0892705719880958

Siqueira DD, Luna CBB, Ferreira ESB, Araújo EM, Wellen RMR (2020) Tailored PCL/Macaíba fiber to reach sustainable biocomposites. J Market Res 9(5):9691–9708

Li M, Pu Y, Thomas VM, Yoo CG, Ozcan S, Deng Y, Nelson K, Ragauskas AJ (2020) Recent advancements of plant-based natural fiber–reinforced composites and their applications. Compos B Eng 200(11):1–20

Cicala G, Tosto C, Latteri A, La Rosa AD, Blanco I, Elsabbagh A, Russo P, Ziegmann G (2017) Green Composites Based on Blends of Polypropylene with Liquid Wood Reinforced with Hemp Fibers: Thermomechanical Properties and the Effect of Recycling Cycles. Materials 10(9):998

Tabone MD, Cregg JJ, Beckman EJ, Landis AE (2010) Sustainability metrics: life cycle assessment and green design in polymers. Environ Sci Technol 44(21):8264–8269

Blanco I, Ingrao C, Siracusa V (2020) Life-cycle assessment in the polymeric sector: A comprehensive review of application experiences on the Italian scale. Polymers 12(6):1–42

Bezerra EB, França DC, Morais DDS, Siqueira DD, Araújo EM, Wellen RMR (2019) Toughening of bio-PE upon addition of PCL and PEgAA. REM - International Engineering Journal 72(3):469–478

Tarrés Q, Ardanuy M (2020) Evolution of interfacial shear strength and mean intrinsic single strength in biobased composites from bio-polyethylene and thermo-mechanical pulp-corn stover fibers. Polymers 12(6):1–16

Ehman NV, Nagy DI, Felissia FE, Vallejos ME, Quispe I, Area MC, Carrasco GC (2020) Biocomposites of bio-polyethylene reinforced with a hydrothermal-alkaline sugarcane bagasse pulp and coupled with a bio-based compatibilizer. Molecules 25(9):2158

Hossain MS, Razzak M, Uddin MB, Chowdhury AMS, Khan RA (2020) Physico-mechanical properties of jute fiber-reinforced LDPE-based composite: effect of disaccharide (sucrose) and gamma radiation. Radiat Eff Defects Solids 175(5):516–528

Velis HH, Golzar M, Yousefzade O (2018) Composites based on HDPE, jute fiber, wood, and thermoplastic starch in tubular pultrusion die: The correlation between mechanical performance and microstructure. Advanves in Polymer Technology 37(8):3483–3491

Costa HM, Ramos VD, Andrade MC, Nunes PSRQ (2016) Análise térmica e propriedades mecânicas de resíduos de polietileno de alta densidade (PEAD). Polímeros 26(1):75–81

Castro BD, Faria PE, Vieira LMG, Rubio CVC, Maziero R, Rodrigues PCM, Rubio JCC (2020) Recycled green PE composites reinforced with woven and randomly arranged sisal fibres processed by hot compression moulding. Acta Technologica Agriculturae 23(2):81–86

Seifu B, Singh B, Gutu JM, Legesse D (2020) Mechanical behaviours of hybrid ensete/sisal fiber, reinforced polyethylene composite materials for injection moulding. SN Applied Sciences 2(4):1–25

Bazan P, Nosal P, Kozub B, Kuciel S (2020) Biobased polyethylene hybrid composites with natural fiber: mechanical, thermal properties, and micromechanics. Materials 13(13):1–13

Amoako G, Amoah PM, Sam F, Sackey SS (2018) Some mechanical properties of coconut fiber reinforced polyethylene composite to control environmental waste in Ghana. Energy and Environment Research 8(1):1–9

Duarte, I. D. Rheological behavior of hybrid composites made of polyethylene/cotton fiber/montmothilonite clay. Graduation Conclusion Thesis, Federal University of Rio Grande do Norte, Natal-Brazil, 2019.

Bosenbecker MW, Cholant GM, Silva GEH, Paniz OG, Carreño NLV, Marini J, Oliveira AD (2019) Mechanical characterization of HDPE reinforced with cellulose from rice husk biomass. Polímeros 29(4):e2019058

Gulitah V, Liew KC (2019) Morpho-mechanical properties of wood fiber plastic composite (WFPC) based on three different recycled plastic codes. International Journal of Biobased Plastics 1(1):22–30

Murayama K, Ueno T, Kobori H, Kojima Y, Suzuki S, Aoki K, Ito H, Ogoe S, Okamoto M (2019) Mechanical properties of wood/plastic composites formed using wood flour produced by wet ball-milling under various milling times and drying methods. J Wood Sci 65(5):1–10

Castro DO, Passador F, Filho AR, Frollini E (2017) Use of castor and canola oils in “biopolyethylene” curauá fiber composites. Compos A Appl Sci Manuf 95(4):22–30

Koohestani B, Darban AK, Mokhtari P, Yilmaz E, Darezereski E (2019) Comparison of different natural fiber treatments: a literature review. Int J Environ Sci Technol 16(7):629–642

Kumar SS, Anbumalar V (2015) Selection and Evaluation of Natural Fibers –A Literature Review. IJISET - International Journal of Innovative Science, Engineering & Technology 2(11):929–939

Poleto M (2016) Effect of styrene maleic anhydride on physical and mechanical properties of recycled polystyrene wood flour composites. Maderas Ciencia y tecnología 18(4):533–542

Poleto M (2017) Mechanical, dynamic mechanical and morphological properties of composites based on recycled polystyrene filled with wood flour wastes. Maderas Ciencia y tecnología 19(4):433–442

Amaral FP, Broetto F, Batistella CB, Jorge SMA (2011) Extração e caracterização qualitativa do óleo da polpa e amendoas de frutos de macaúba coletada na região de Botucatu – SP. Revista Energia na Agricultura 26(1):12–20

Fonseca, J. S.; Martins, G. A. Curso de Estatística, 3rd ed.; Editora Atlas: São Paulo, Brazil, 1986, pp. 286.

Feng C, Li Z, Wang Z, Wang B, Wang Z (2019) Optimizing torque rheometry parameters for assessing the rheological characteristics and extrusion processability of wood plastic composites. J Thermoplast Compos Mater 32(1):123–140

Ogah AO, Afiukwa JN, Nduji AA (2014) Characterization and comparison of rheological properties of agro fiber filled high-density polyethylene bio-composites. Open Journal of Polymer Chemistry 4(1):12–19

Ferreira ESB, Luna CBB, Araújo EM, Siqueira DD, Wellen RMR (2021) Polypropylene/wood powder/ethylene propylene diene monomer rubber-maleic anhydride composites: Effect of PP melt flow index on the thermal, mechanical, thermomechanical, water absorption, and morphological parameters. Polym Compos 42(1):484–497

Baptista CA, Canevarolo SV (2019) Grafting polypropylene over hollow glass microspheres by reactive extrusion. Polímeros 29(3):e2019037

Poletto M (2019) Maleated soybean oil as coupling agent in recycled polypropylene/wood flour composites: Mechanical, thermal, and morphological properties. J Thermoplast Compos Mater 32(8):1056–1067

Poletto M (2020) Natural oils as coupling agents in recycled polypropylene wood flour composites: Mechanical, thermal and morphological properties. J Thermoplast Compos Mater 28(7):443–450

França DC, Almeida TG, Abels G, Canedo EL, Carvalho LH, Wellen RMR, Haag K, Koschek K (2019) Tailoring PBAT/PLA/Babassu films for suitability of agriculture mulch application. Journal of Natural Fibers 16(7):933–943

Seixas JN, Granada JE, Melo CCN, Silva GEH, Passador FR, Cholant GM, Oliveira AD, Beatrice CAG, Gonçalves MRF, Carreno NNLV (2018) Compósitos de polipropileno reforçados com fibras naturais do talo da banana em diferentes granulometrias. Revista Brasileira de Engenharia e Sustentabilidade 5(1):32–37

Jiang X, Wang J, Wu G, Peng X, Ma X (2019) Significant reinforcement of polypropylene/wood flour composites by high extent of interfacial interaction. J Thermoplast Compos Mater 32(5):577–592

Guo C, Li L, Li H (2019) Evaluation of interfacial compatibility in wood flour/polypropylene composites by grafting isocyanate silane coupling agent on polypropylene. J Adhes Sci Technol 33(5):468–478

Guo C, Li L, Li H (2019) Evaluation of interfacial compatibility in wood flour/polypropylene composites by grafting isocyanate silane coupling agent on polypropylene. Journal Journal of Adhesion Science and Technology 33(5):468–478

Hao X, Yi X, Sun L, Tu D, Wang Q, Ou R (2019) Mechanical properties, creep resistance, and dimensional stability of core/shell structured wood flour/polyethylene composites with highly filled core layer. Constr Build Mater 226(11):879–887

Lin, H.; Li, R.; Li, D.; Huang, Z.; Pang, J.; X.; Liu, W.; Yang, W. Hydrophobic wood flour derived from a novel p-TsOH treatment for improving interfacial compatibility of wood/HDPE composites. Cellulose 2020, 27(2), 4053–4065.

Anbupalani M, Venkatachalam CD, Rathanasamy R (2020) Influence of coupling agent on altering the reinforcing efficiency of natural fibre-incorporated polymers – A review. J Reinf Plast Compos 39(13–14):520–544

Latif R, Wakeel S, Khan NZ, Siddiquee AN, Verma SL, Khan ZA (2019) Surface treatments of plant fibers and their effects on mechanical properties of fiber-reinforced composites: A review. J Reinf Plast Compos 38(1):15–30

Venancio, M. M. H.; Mazzafera, P.; Carvalho, C. L.; Silveira, L. H.; Filho, J. A. A.; Bazzo, B. R.; Colombo, C. A. Teor de óleo e perfil de ácidos graxos durante o desenvolvimento de frutos de macaúba. 6° Congresso da Rede Brasileira de Tecnologia de Biodiesel, Rio Grande do Norte, Natal, p. 333–334, 2016.

Poletto M (2017) Compósitos termoplásticos com madeira - uma breve revisão. Revista Interdisciplinar da Ciência Aplicada 2(4):42–48

Hejna A, Romatowska MP, Kosmela P, Zedler L, Korol J, Formela K (2020) Recent advances in compatibilization strategies of wood-polymer composites by isocyanates. Wood Sci Technol 54(7):1091–1119

Ali JB, Danladi A, Bukhari MM, Mamza P, Zurina M (2020) Effects of Org-MMT on mechanical and morphological properties of HDPE/ HD-g-MAH /maize-cobs nanocomposites. SLU Journal of Science and Technology 1(1):24–32

Migneault S, Kounaa A, Perré P, Rieldl B (2015) Effects of wood fiber surface chemistry on strength of wood–plastic composites. Appl Surf Sci 343(7):11–18

Han Y, Shi J, Mao L, Wang Z, Zhang L (2020) Improvement of compatibility and mechanical performances of PLA/PBAT composites with epoxidized soybean oil as compatibilizer. Ind Eng Chem Res 59(50):21779–21790

Zhang Q, Lu W, Zhou L, Zhang D, Cai H, Lin X (2019) Tensile and flammability characterizations of corn straw slagging/high-density polyethylene composites. J Thermoplast Compos Mater. https://doi.org/10.1177/0892705719830459

Todkar SS, Patil SA (2019) Review on mechanical properties evaluation of pineapple leaf fibre (PALF) reinforced polymer composites. Compos B Eng 174(10):1–16

Pickering KL, Efendy MGA, Le TM (2016) A review of recent developments in natural fibre composites and their mechanical performance. Compos A Appl Sci Manuf 83(4):98–112

Wu H, Xu D, Zhou Y, Gao C, Guo J, He W, Qin S (2020) Tung oil anhydride modified hemp fiber/polypropylene composites: the improved toughness, thermal stability and rheological property. Fibers and Polymers 21(10):2084–2091

Poletto M (2017) Polypropylene-based wood-plastic composites: Effect of using a coupling agent derived from a renewable resource. Maderas Ciencia y tecnología 19(3):265–272

Sommer, W. Plasticizer. In: Gachter, R & Muller, H. Plastics Additives Handbook. 2° edition, Hanser, Munich, 1985.

Luna CBB, Silva DF, Araújo EM, Mélo TJA, Oliveira AD (2016) Efeito dos agentes de compatibilização SBS e SEBS-MA no desempenho de misturas de poliestireno/resíduo de borracha de SBR. Matéria (Rio J) 21(3):632–646

Rusayyis MAB, Schiraldi DA, Maia J (2018) Property/morphology relationships in SEBS-compatibilized HDPE/poly(phenylene ether) blends. Macromolecules 51(16):6513–6523

Bezerra EB, França DC, Morais DDS, Silva IDS, Siqueira DD, Araújo EM, Wellen RMR (2019) Compatibility and characterization of Bio-PE/PCL blends. Polímeros 29(2):e2019022

Luna CBB, Ferreira ESB, Silva LJMD, Silva WA, Araújo EM, Melo JBCA (2019) Blends with technological potential of copolymer polypropylene with polypropylene from post-consumer industrial containers. Mater Res Express 6(12):125319

Firmino HCT, Chagas TF, Melo PMA, Silva LB (2017) Caracterização de compósitos particulados de polietileno de alta densidade/pó de concha de molusco. Matéria (Rio J) 22(4):1–12

Wolak JE, White JL (2005) Factors that allow polyolefins to form miscible blends: polyisobutylene and head-to-head polypropylene. Macromolecules 38:10466–10471

Bosenbecker MW, Croche S, Cholant G, Rosa P, Passador F, Marini J, Oliveira A (2018) Propriedades térmicas de compósitos de polietileno de alta densidade reforçados com celulose. Revista Brasileira de Engenharia e Sustentabilidade 5(1):7–12

Machado, M. L. C.; Pereira, N. C.; Miranda, L. F.; Terence, M. C.; Pradella, J. G. C. Estudo das propriedades mecânicas e térmicas do polímero poli-3-hidroxibutirato (PHB) e de compósitos PHB/Pó de madeira. Polímeros: Ciência e Tecnologia 2010, 20(1), 65–71.

Kaymakci A, Gulec T, Hosseinihashemi SK, Ayrilmis N (2017) Physical, mechanical and thermal properties of wood/zeolite/plastic hybrid composites. Maderas Ciencia y tecnología 19(3):339–348

Garcia DP, Caraschi JC, Ventorim G (2016) Decomposição térmica de pellets de madeira por TGA. HOLOS 32(1):327–339

Poletto M (2016) Effect of extractive content on the thermal stability of two wood species from Brazil. Maderas Ciencia y tecnología 18(3):435–442

Poletto M, Zattera AJ, Santana RMC (2014) Effect of natural oils on the thermal stability and degradation kinetics of recycled polypropylene wood flour composites. Polym Compos 35(10):1935–1942

Poletto M (2020) Natural oils as coupling agents in recycled polypropylene wood flour composites: Mechanical, thermal and morphological properties. Polym Polym Compos 28(7):443–450

Vijay R, Singaravelu DL, Vinod A, Sanjay MR, Siengchin S (2019) Characterization of alkali-treated and untreated natural fibers from the stem of parthenium hysterophorus. Journal of Natural Fibers. https://doi.org/10.1080/15440478.2019.1612308

Vijay, R.; Singaravelu, D. L.; Vinod. A.; Sanjay, M. R.; Siengchin, S.; Jawaid, Mand.; Parameswaranpillai, J. Characterization of raw and alkali treated new natural cellulosic fibers from Tridax procumbens. International Journal of Biological Macromolecules 2019, 125(15), 99–108.

Zahari WZW, Badri RNRL, Ardyananta H, Kurniawan D, Nor FM (2015) Mechanical properties and water absorption behavior of polypropylene/ljuk fiber composite by using silane treatment. Procedia Manufacturing 2(1):573–578

Bezerra AFC, Carvalho LH, Cavalcanti WS, Barbosa AG (2016) Mechanical behavior of composites reinforced with fibers caroa. Fibers and Polymers 17(1):1908–1915

Karim MRA, Tahir D, Hussain A, Haq EU, Khan KI (2020) Sodium carbonate treatment of fibres to improve mechanical and water absorption characteristics of short bamboo natural fibres reinforced polyester composite. Plast, Rubber Compos 49(10):425–433

Wang X, Guo C, Song K (2020) The effects of maleated polybutadiene-grafted polypropylene (MAPB-g-PP) content on the properties of wood flour/polypropylene composites. J Vinyl Add Tech 26(1):17–23

Acknowledgements

The authors thank UFCG for the infrastructure of the laboratories, National Council for Scientific and Technological Development—CNPq, Coordination for the Improvement of Higher Education Personnel (CAPES) for financial support and Addivant for the donation of the compatibilizer (PE-g-MA).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

da Silva, F.S., Luna, C.B.B., Siqueira, D.D. et al. From Waste to Reuse: Manufacture of Ecological Composites Based on Biopolyethylene/wood Powder with PE-g-MA and Macaíba Oil. J Polym Environ 30, 1028–1044 (2022). https://doi.org/10.1007/s10924-021-02256-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02256-6