Abstract

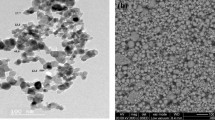

One of the important challenges in food industries is to achieve sufficient gas barrier properties for packaging films. Films made of polyvinyl alcohol (PVA) are commonly used for food packaging and are sometimes used with embedded nanoparticles. In this investigation, PVA nanocomposite films were prepared using solution-casting method with different concentrations of montmorillonite (MMT) and titanium oxide (TiO2) nanoparticles. A response surface methodology (RSM), based on three-level factorial design, was implemented to model and optimize the effect of the concentrations of the nanofillers on the barrier properties of thin nanocomposite films. The viscosity of the polymer-forming solution increased when nanoparticles were incorporated in the polymer matrix. SEM micrographs showed a good distribution of nanofillers at low concentration whereas some aggregation was observed at higher nanofiller loadings. Transparency of PVA-based thin films decreased with an increase of TiO2/MMT loading. A significant increase in the Young ̓s modulus occurred with an increase in the loading of nanoparticles whereas the tensile strength and elongation at the breakpoint both decreased. Results for PVA/MMT/TiO2 nanocomposite films showed a decrease in the oxygen transmission rate and water vapor permeability compared to a neat PVA membrane. The particle loading leading to optimum barrier properties for nanocomposite films was a combined loading of 1 wt% TiO2 and 4 wt% MMT.

Graphic Abstract

Similar content being viewed by others

References

Kumar S, Nehra M, Dilbaghi N, Tankeshwar K, Kim KH (2018) Recent advances and remaining challenges for polymeric nanocomposites in healthcare applications. Prog Polym Sci 80:1–38. https://doi.org/10.1016/j.progpolymsci.2018.03.001

Selke SE, Culter JD (2016) Plastics packaging: properties, processing, applications, and regulations Carl Hanser Verlag GmbH Co KG.

Silvério HA, Neto WPF, Pasquini D (2013) Effect of incorporating cellulose nanocrystals from corncob on the tensile, thermal and barrier properties of poly (vinyl alcohol) nanocomposites. J Nanomater 2013:74. https://doi.org/10.1155/2013/289641

Molki B, Heidarian P, Aframehr WM, Nasri-Nasrabadi B, Bahrami B, Ahmadi M, Bagheri R (2019) Properties investigation of polyvinyl alcohol barrier films reinforced by calcium carbonate nanoparticles. Mater Res Express 6(5):055311. https://doi.org/10.1088/2053-1591/ab0315

Pelissari FM, Grossmann MV, Yamashita F, Pineda EAG (2009) Antimicrobial, mechanical, and barrier properties of cassava starch− chitosan films incorporated with oregano essential oil. J Agric Food Chem 57(16):7499–7504. https://doi.org/10.1021/jf9002363

Tang X, Kumar P, Alavi S, Sandeep K (2012) Recent advances in biopolymers and biopolymer-based nanocomposites for food packaging materials. Crit Rev Food Sci Nutr 52(5):426–442. https://doi.org/10.1080/10408398.2010.500508

Liu W, Misra M, Askeland P, Drzal LT, Mohanty AK (2005) ‘Green’composites from soy based plastic and pineapple leaf fiber: fabrication and properties evaluation. Polymer 46(8):2710–2721. https://doi.org/10.1016/j.polymer.2005.01.027

Muratore G, Nobile D, Buonocore G, Lanza C, Asmundo N (2005) The influence of using biodegradable packaging films on the quality decay kinetic of plum tomato (PomodorinoDatterino®). J Food Eng 67(4):393–399. https://doi.org/10.1016/j.jfoodeng.2004.05.006

Sundaram J, Pant J, Goudie MJ, Mani S, Handa H (2016) Antimicrobial and physicochemical characterization of biodegradable, nitric oxide-releasing nanocellulose–chitosan packaging membranes. J Agric Food Chem 64(25):5260–5266. https://doi.org/10.1021/acs.jafc.6b01936

Abdollahi M, Rezaei M, Farzi G (2012) A novel active bionanocomposite film incorporating rosemary essential oil and nanoclay into chitosan. J Food Eng 111(2):343–350. https://doi.org/10.1016/j.jfoodeng.2012.02.012

Arfat YA, Benjakul S, Prodpran T, Sumpavapol P, Songtipya P (2014) Properties and antimicrobial activity of fish protein isolate/fish skin gelatin film containing basil leaf essential oil and zinc oxide nanoparticles. Food Hydrocolloids 41:265–273. https://doi.org/10.1016/j.foodhyd.2014.04.023

López-Carballo G, Higueras L, Gavara R, Hernández-Muñoz P (2013) Silver ions release from antibacterial chitosan films containing in situ generated silver nanoparticles. J Agric Food Chem 61(1):260–267. https://doi.org/10.1021/jf304006y

Muppalaneni S, Omidian H (2013) Polyvinyl alcohol in medicine and pharmacy: a perspective. J Dev Drugs. https://doi.org/10.4172/2329-6631.1000112

Yun X, Dong T (2017) Fabrication of high-barrier plastics and its application in food packaging, In Food packaging, Elsevier. pp. 147–184. https://doi.org/https://doi.org/10.1016/B978-0-12-804302-8.00005-4.

Kaler V, Pandel U, Duchaniya R (2018) Development of TiO2/PVA nanocomposites for application in solar cells. Mater Today 5(2):6279–6287. https://doi.org/10.1016/j.matpr.2017.12.237

Akindoyo JO, Ismail NH, Mariatti M (2019) Performance of poly (vinyl alcohol) nanocomposite reinforced with hybrid TEMPO mediated cellulose-graphene filler. Polym Test 80:106140. https://doi.org/10.1016/j.polymertesting.2019.106140

Baker MI, Walsh SP, Schwartz Z, Boyan BD (2012) A review of polyvinyl alcohol and its uses in cartilage and orthopedic applications. J Biomed Mater Res B 100(5):1451–1457. https://doi.org/10.1002/jbm.b.32694

Guirguis OW, Moselhey MT (2012) Thermal and structural studies of poly (vinyl alcohol) and hydroxypropyl cellulose blends. Nat Sci 4(1):57. https://doi.org/10.4236/ns.2012.41009

Yu Z, Li B, Chu J, Zhang P (2018) Silica in situ enhanced PVA/chitosan biodegradable films for food packages. Carbohydr Polym 184:214–220. https://doi.org/10.1016/j.carbpol.2017.12.043

Youssef HF, El-Naggar ME, Fouda FK, Youssef AM (2019a) Antimicrobial packaging film based on biodegradable CMC/PVA-zeolite doped with noble metal cations. Food Packag Shelf Life 22:100378. https://doi.org/10.1016/j.fpsl.2019.100378

Woo JY, Shin EJ, Lee YH (2010) Effect of boric acid treatment on the crystallinity and drawability of poly (vinyl alcohol)–iodine complex films. Polym Bull 65(2):169–180. https://doi.org/10.1007/s00289-010-0279-9

Manikandan K, Yelilarasi A, Senthamaraikannan P, Saravanakumar S, Khan A, Asiri AM (2019) A green-nanocomposite film based on poly (vinyl alcohol)/Eleusine coracana: structural, thermal, and morphological properties. Int J Polym Anal Charact. https://doi.org/10.1080/1023666X.2019.1567087

Wagner Jr JR (2016) Blown film, cast film, and lamination processes multilayer flexible packaging, 137–145 William Andrew Publishing. https://doi.org/https://doi.org/10.1016/B978-0-323-37100-1.00010-7.

Ding J, Zhao C, Zhao L, Li Y, Xiang D (2018) Synergistic effect of α-ZrP and graphene oxide nanofillers on the gas barrier properties of PVA films. J Appl Polym Sci 135(27):46455. https://doi.org/10.1002/app.46455

Yu HY, Qin ZY, Sun B, Yang XG, Yao JM (2014) Reinforcement of transparent poly (3-hydroxybutyrate-co-3-hydroxyvalerate) by incorporation of functionalized carbon nanotubes as a novel bionanocomposite for food packaging. Compos Sci Technol 94:96–104. https://doi.org/10.1016/j.compscitech.2014.01.018

Arora R, Mandal UK, Sharma P, Srivastav A (2015) Synthesis and thermal properties of polyaniline-TiO2 nanocomposites PVA based film. Mater Today 2(4–5):2215–2225. https://doi.org/10.1016/j.matpr.2015.07.241

Huang JY, Limqueco J, Chieng YY, Li X, Zhou W (2017) Performance evaluation of a novel food packaging material based on clay/polyvinyl alcohol nanocomposite. Innov Food Sci Emerg Technol 43:216–222. https://doi.org/10.1016/j.ifset.2017.08.012

Loste J, Lopez-Cuesta JM, Billon L, Garay H, Save M (2018) Transparent polymer nanocomposites: an overview on their synthesis and advanced properties. Prog Polym Sci. https://doi.org/10.1016/j.progpolymsci.2018.10.003

Youssef HF, El-Naggar ME, Fouda FK, Youssef AM (2019b) Efficient removal of pesticides and heavy metals from wastewater and the antimicrobial activity of f-MWCNTs/PVA nanocomposite film. J Clean Prod 206:315–325. https://doi.org/10.1016/j.fpsl.2019.100378

Ibrahim S, El-Naggar ME, Youssef AM, Abdel-Aziz MS (2019) Functionalization of polystyrene nanocomposite with excellent antimicrobial efficiency for food packaging application. J Clust Sci. https://doi.org/10.1007/s10876-019-01748-9

Oleyaei SA, Almasi H, Ghanbarzadeh B, Moayedi AA (2016) Synergistic reinforcing effect of TiO2 and montmorillonite on potato starch nanocomposite films: thermal, mechanical and barrier properties. Carbohydr Polym 152:253–262. https://doi.org/10.1016/j.carbpol.2016.07.040

Yousefi A, Savadkoohi B, Zahedi Y, Hatami M, Ako K (2019) Fabrication and characterization of hybrid sodium montmorillonite/TiO2 reinforced cross-linked wheat starch-based nanocomposites. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2019.03.083

Kubacka A, Serrano C, Ferrer M, Lünsdorf H, Bielecki P, Cerrada ML, Fernández-García M (2007) High-performance dual-action polymer− TiO2 nanocomposite films via melting processing. Nano Lett 7(8):2529–2534. https://doi.org/10.1021/nl0709569

Ali NA, Noori FTM (2014) Gas barrier properties of biodegradable polymer nanocomposites films. J Chem Mater Res 6(1):44–51.

Ren J, Wang S, Gao C, Chen X, Li W, Peng F (2015) TiO2-containing PVA/xylan composite films with enhanced mechanical properties, high hydrophobicity and UV shielding performance. Cellulose 22(1):593–602. https://doi.org/10.1007/s10570-014-0482-1

Farhoodi M, Mousavi M, Sotudeh GR, Emam DZ, Oromiehie A (2017) Effect of TiO2 nanoparticles on mechanical and transport properties of polyethylene terephthalate (PET) packages. Iranian J Food Sci Technol 13(60):187–197.

Nakayama N, Hayashi T (2007) Preparation and characterization of poly (L-lactic acid)/TiO2 nanoparticle nanocomposite films with high transparency and efficient photodegradability. Polym Degrad Stab 92(7):1255–1264. https://doi.org/10.1016/j.polymdegradstab.2007.03.026

Xiao-E L, Green AN, Haque SA, Mills A, Durrant JR (2004) Light-driven oxygen scavenging by titania/polymer nanocomposite films. J Photochem Photobiol, A 162(2–3):253–259. https://doi.org/10.1016/j.nainr.2003.08.010

Fathi N, Almasi H, Pirouzifard MK (2019) Sesame protein isolate based bionanocomposite films incorporated with TiO2 nanoparticles: study on morphological, physical and photocatalytic properties. Polym Test 77:105919. https://doi.org/10.1016/j.polymertesting.2019.105919

El-Naggar ME, Shaheen TI, Zaghloul S, El-Rafie MH, Hebeish A (2016) Antibacterial activities and UV protection of the in situ synthesized titanium oxide nanoparticles on cotton fabrics. Ind Eng Chem Res 55(10):2661–2668. https://doi.org/10.1021/acs.iecr.5b04315

Alboofetileh M, Rezaei M, Hosseini H, Abdollahi M (2013) Effect of montmorillonite clay and biopolymer concentration on the physical and mechanical properties of alginate nanocomposite films. J Food Eng 117(1):26–33. https://doi.org/10.1016/j.jfoodeng.2013.01.042

Ali SS, Tang X, Alavi S, Faubion J (2011) Structure and physical properties of starch/poly vinyl alcohol/sodium montmorillonite nanocomposite films. J Agric Food Chem 59(23):12384–12395. https://doi.org/10.1021/jf201119v

Ding F, Liu J, Zeng S, Xia Y, Wells KM, Nieh MP, Sun L (2017) Biomimetic nanocoatings with exceptional mechanical, barrier, and flame-retardant properties from large-scale one-step coassembly. Sci Adv 3(7):e1701212. https://doi.org/10.1126/sciadv.1701212

Rohini B, Ishwarya SP, Rajasekharan R, Kumar VA (2020) Ocimum basilicum seed mucilage reinforced with montmorillonite for preparation of bionanocomposite film for food packaging applications. Polym Test. https://doi.org/10.1016/j.polymertesting.2020.106465

Rehan M, El-Naggar ME, Mashaly HM, Wilken R (2018) Nanocomposites based on chitosan/silver/clay for durable multi-functional properties of cotton fabrics. Carbohydr Polym 182:29–41. https://doi.org/10.1016/j.carbpol.2017.11.007

Bodaghi H, Mostofi Y, Oromiehie A, Ghanbarzadeh B, Hagh ZG (2015) Synthesis of clay–TiO2 nanocomposite thin films with barrier and photocatalytic properties for food packaging application. J Appl Polym Sci 132(14):41764. https://doi.org/10.1002/app.41764

Yang CC, Lee YJ (2008) Preparation and characterization of the PVA/MMT composite polymer membrane for DMFC. ECS Trans 13(28):1–20. https://doi.org/10.1149/1.3055402

Marten F (2002) Vinyl alcohol polymers. Encyclopedia of polymer science and technology. Wiley, USA

Han JH, Floros JD (1997) Casting antimicrobial packaging films and measuring their physical properties and antimicrobial activity. J Plast Film Sheeting 13(4):287–298. https://doi.org/10.1177/875608799701300405

Standard A(2004) Annual book of ASTM standards. American Society for Testing and Materials Annual, Philadelphia, PA, USA 4(04.08).

International A. (2005) ASTM standards: standards test methods and definitions for mechanical testing of steel products (A370–02) ASTM.

Gao HW, Yang RJ, He JY, Yang L (2010) Rheological behaviors of PVA/H2O solutions of high-polymer concentration. J Appl Polym Sci 116(3):1459–1466. https://doi.org/10.1002/app.31677

El-Shamy AG, Attia W, Abd El-Kader KM (2014) The optical and mechanical properties of PVA-Ag nanocomposite films. J Alloy Compd 590:309–312. https://doi.org/10.1016/j.jallcom.2013.11.203

Ip KH, Stuart BH, Thomas PS, Ray A (2011) Characterisation of poly (vinyl alcohol)–montmorillonite composites with higher clay contents. Polym Test 30(7):732–736. https://doi.org/10.1016/j.polymertesting.2011.06.004

Kim SW (2008) Preparation and barrier property of poly (vinyl alcohol)/SiO2 hybrid coating films. Korean J Chem Eng 25(5):1195–1200. https://doi.org/10.1007/s11814-008-0197-9

Ali MH, Kahder MM, Al-Saad KA (2013) Al-Meer S (2013) Properties of nanoclay PVA composites materials. QScience Connect. https://doi.org/10.5339/connect.2013.1

Cao X, Chen Y, Chang PR, Stumborg M, Huneault MA (2008) Green composites reinforced with hemp nanocrystals in plasticized starch. J Appl Polym Sci 109(6):3804–3810. https://doi.org/10.1002/app.28418

Zolfi M, Khodaiyan F, Mousavi M, Hashemi M (2014) Development and characterization of the kefiran-whey protein isolate-TiO2 nanocomposite films. Int J Biol Macromol 65:340–345. https://doi.org/10.1016/j.ijbiomac.2014.01.010

Sapalidis AA, Katsaros FK, Kanellopoulos NK (2011) PVA/montmorillonite nanocomposites: development and properties. nanocomposites and polymers with analytical methods, 29–50.

Yun YH, Youn YN, Yoon SD, Lee JU (2012) Preparation and physical properties of starch-based nanocomposite films with the addition of titanium oxide nanoparticles addition of titanium oxide nanoparticles. J Ceram Process Res 13(1): 59–64.

Goudarzi V, Shahabi-Ghahfarrokhi I, Babaei-Ghazvini A (2017) Preparation of ecofriendly UV-protective food packaging material by starch/TiO2 bio-nanocomposite: characterization. Int J Biol Macromol 95:306–313. https://doi.org/10.1016/j.ijbiomac.2016.11.065

Pereda M, Amica G, Rácz I, Marcovich NE (2011) Structure and properties of nanocomposite films based on sodium caseinate and nanocellulose fibers. J Food Eng 103(1):76–83. https://doi.org/10.1016/j.jfoodeng.2010.10.001

Zamanian M, Sadrnia H, Khojastehpour M, Thibault J, Hosseini F (2020) Effect of TiO2 nanoparticles on barrier and mechanical properties of PVA films. J Membr Sci Res. https://doi.org/10.22079/jmsr.2020.112911.1283

de Moraes CT, de Oliveira RA, Alves VD, Bandarra N, Moldão-Martins M, Flores SH (2018) Active food packaging prepared with chitosan and olive pomace. Food Hydrocolloids 74:139–150. https://doi.org/10.1016/j.foodhyd.2017.08.007

Liu S, Cai P, Li X, Chen L, Li L, Li B (2016) Effect of film multi-scale structure on the water vapor permeability in hydroxypropyl starch (HPS)/Na-MMT nanocomposites. Carbohydr Polym 154:186–193. https://doi.org/10.1016/j.carbpol.2016.08.006

Chen C, Chen Y, Xie J, Xu Z, Tang Z, Yang F, Fu K (2017) Effects of montmorillonite on the properties of cross-linked poly (vinyl alcohol)/boric acid films. Prog Org Coat 112:66–74. https://doi.org/10.1016/j.porgcoat.2017.06.003

Achachlouei BF, Zahedi Y (2018) Fabrication and characterization of CMC-based nanocomposites reinforced with sodium montmorillonite and TiO2 nanomaterials. Carbohydr Polym 199:415–425. https://doi.org/10.1016/j.carbpol.2018.07.031

Oleyaei SA, Zahedi Y, Ghanbarzadeh B, Moayedi AA (2016) Modification of physicochemical and thermal properties of starch films by incorporation of TiO2 nanoparticles. Int J Biol Macromol 89:256–264. https://doi.org/10.1016/j.ijbiomac.2016.04.078

Venkatesan R, Rajeswari N (2017) TiO2 nanoparticles/poly (butylene adipate-co-terephthalate) bionanocomposite films for packaging applications. Polym Adv Technol 28(12):1699–1706. https://doi.org/10.1002/pat.4042

Nasiri A, Shariaty-Niasar M, Akbari Z (2012) Synthesis of LDPE/Nano TiO2 nanocomposite for packaging applications. Int J Nanosci Nanotechnol 8(3):165–170

Khalaj MJ, Ahmadi H, Lesankhosh R, Khalaj G (2016) Study of physical and mechanical properties of polypropylene nanocomposites for food packaging application: Nano-clay modified with iron nanoparticles. Trends Food Sci Technol 51:41–48. https://doi.org/10.1016/j.tifs.2016.03.007

Bhatia A, Gupta RK, Bhattacharya SN, Choi HJ (2012) Analysis of gas permeability characteristics of poly (lactic acid)/poly (butylene succinate) nanocomposites. J Nanomater 2012:6. https://doi.org/10.1155/2012/249094

Mondal D, Mollick MMR, Bhowmick B, Maity D, Bain MK, Rana D, Chattopadhyay D (2013) Effect of poly (vinyl pyrrolidone) on the morphology and physical properties of poly (vinyl alcohol)/sodium montmorillonite nanocomposite films. Prog Nat Sci 23(6):579–587. https://doi.org/10.1016/j.pnsc.2013.11.009

Li Y, Tian H, Jia Q, Niu P, Xiang A, Liu D, Qin Y (2015) Development of polyvinyl alcohol/intercalated MMT composite foams fabricated by melt extrusion. J Appl Polym Sci 132(43):42706. https://doi.org/10.1002/app.42706

Acknowledgements

The authors gratefully acknowledge the financial support provided by the Ferdowsi University of Mashhad (Grant No. 44023).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zamanian, M., Sadrnia, H., Khojastehpour, M. et al. Barrier Properties of PVA/TiO2/MMT Mixed-Matrix Membranes for Food Packaging. J Polym Environ 29, 1396–1411 (2021). https://doi.org/10.1007/s10924-020-01965-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01965-8