Abstract

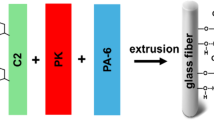

Blends of PA6 and ionomer scraps, with compositions ranging from 5 to 30 wt% ionomer without incorporation of compatibilizer, and blends with 10 and 20 wt% ionomer compatibilized with 2 wt% maleic anhydride grafted polyethylene copolymer (PEgMA) were obtained by extrusion. Their morphology (SEM), mechanical (tensile, flexural and impact tests) and thermal properties (HDT, DSC and TGA tests) were analyzed. The incorporation of ionomer in PA6 promoted an increase in strain at break and impact strength. PEgMA acted positively on these properties, increasing the interaction between the ionomer and PA6 phases. Tensile and flexural strength, tensile and flexural modulus decreased with increasing ionomer concentration. The compatibilizer acted significantly, reducing these properties. The crystallinity and melting temperature of PA6 were not influenced by the incorporation of ionomer and compatibilizer in the blends.

Similar content being viewed by others

References

Eisenberg A (1970) Macromolecules 3(2):147

Poulakis JG, Papaspyrides CD (2000) Adv Polym Technol 19(3):203

Datta P, Guha C, Sarkhel G (2015) Polym Eng Sci 55(7):1571

Momtaz M, Barikani M, Razavi-Nouri M (2015) Iran Polym J 24:505

Gómez GH, Gasparini TM, Canevarolo SV (2019) Mater Res 22(4):e20180592

DuPont. Material Safety Data Sheet Surlyn PC2000DUPONT. USA (2007)

Maris J, Bourdon S, Brossard JM, Cauret L, Fontaine L, Montembault V (2018) Polym Degrad Stabil 147:245

Araújo EM, Hage E Jr, Carvalho AJF (2004) Polímeros 14(1):205

Saiwari S, Yusoh B, Thitithammawong A (2019) J Polym Environ 27:1141

Datta J, Błażek K, Włoch M, Bukowski R (2018) J Polym Environ 26:4415

Willis JM, Favis BD (1988) Polym Eng Sci 28(21):1416

Kuphal JA, Sperling LH, Robeson LM (1991) J Appl Polym Sci 42(6):1525

Choudhury A, Mukherjee M, Adhikari B (2006) Indian J Chem Technol 13(3):233

Macknight WJ, Lenz RW, Musto PV, Somani RJ (1985) Polym Eng Sci 25(18):1124

Fairley G, Prud’Homme RE (1987) Polym Eng Sci 27(20):1495

Deanin RD, Orroth SA, Bhagat RI (2006) Polymer Plast Technol Eng 29(3):289

Jaklewicz M, Litak A, Ostoja-Starzewski M (2004) J Appl Polym Sci 91(6):3866

Basf. Technical Data Sheet – Ultramid B27 E01-Polyamide 6 (2014)

Tachino H, Hara H, Hirasawa E, Kutsumizu S, Yano S (1995) J Appl Polym Sci 55(1):131

Armat R, Moet A (1993) Polymer 34(5):977

Tadano K, Hirasawa E, Yamamoto H, Yano S (1989) Macromolecules 22(1):226

Miwa Y, Kondo T, Kutsumizu S (2013) Macromolecules 46(13):5232

Loo YL, Wakabayashi K, Huang YE, Register RA, Hsiao BS (2005) Polymer 46(14):5118

Sessini V, Broxa D, López AJ, Ureña A, Peponi L (2018) Nanocomposites 4(2):19

Acknowledgements

The authors would like to thank Albea Packaging by donating ionomer Surlyn® scraps and FEI for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Almeida, L.J., de Souza, A.M.C. Reusing Ionomer Scraps as Impact Modifier in Polyamide 6. J Polym Environ 28, 3129–3138 (2020). https://doi.org/10.1007/s10924-020-01836-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01836-2