Abstract

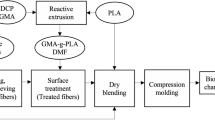

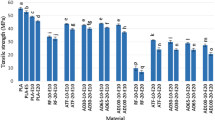

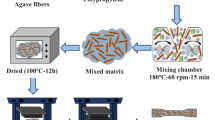

In this work, agave fibers were surface treated using maleated PLA (MAPLA) in order to increase the fiber content (from 10 up to 40% wt.) in polylactic acid (PLA) biocomposites produced by rotational molding and to study the effect of the agave fiber and its treatment on the physical, mechanical and thermal properties of the biocomposites. This chemical modification between agave fibers and MAPLA was evaluated by FTIR spectroscopy. In general the results indicate that MAPLA surface treatment produces a more homogeneous morphology with lower interfacial gaps and overall porosity, especially at higher agave contents. This improved compatibility promoted better stress transfer leading to increased mechanical properties. For example, the tensile strength and modulus of treated fiber composites increased by up to 68% (from 25 to 41 MPa) and 32% (from 1.30 to 1.74 GPa) respectively, in comparison with untreated fiber composites. Fiber surface treatment also decreases hydrophilicity, lowering water absorption and diffusion coefficient. From thermo–mechanical analyses, the damping behavior of the biocomposites decreased with MAPLA treatment since a stronger interface is able to sustain higher stresses and dissipates less energy. Finally, the thermal stability was also improved as a result of better interfacial chemical bonding leading to a 12 °C increase in thermal stability (from 254 to 266 °C).

Similar content being viewed by others

References

Kwon HJ, Sunthornvarabhas J, Park JW, Lee JH, Kim HJ, Piyachomkwan K, Sriroth K, Cho D (2014) Compos Part B 56:232

Tokiwa Y, Calabia BP (2006) Appl Microbiol Biotechnol 72:244

Baheti V, Militky J, Marsalkova M (2013) Polym Compos 34:2133

Awal A, Rana M, Sain M (2015) Mech Mater 80:87

Auras R, Harte B, Selke S (2004) Macromol Biosci 4:835

Pérez-Fonseca AA, Robledo-Ortíz JR, González-Núñez R, Rodrigue D (2016) J Appl Polym Sci 133:43750

Greco A, Maffezzoli A (2016) Polym Degrad Stab 132:213

Jiang L, Wolcott MP, Zhang J (2006) Biomacromolecules 7:199

Zhang M, Thomas N (2011) Adv Polym Technol 2:67

Hinchcliffe SA, Hess KM, Srubar WV (2016) Compos Part B 95:346

Harmaen AS, Khalina AK, Azowa I, Hassan MA, Tarmian A, Jawaid M (2015) Polym Compos 36:576

Le Moigne N, Longerey M, Taulemesse JM, Bénézet JC, Bergeret A (2014) Ind Crop Prod 52:481

Avella M, Martuscelli E, Raimo M (2000) J Mater Sci 35:523

Huda MS, Drzal LT, Mohanty AK, Misra M (2008) Compos Sci Tech 68:424

Yu T, Ren J, Li S, Yuan H, Li Y (2010) Compos Part A 41:499

Luo H, Zhang C, Xiong G, Wan Y (2016) Polym Compos 37:3499

Orue A, Jauregi A, Unsuain U, Labidi J, Eceiza A, Arbelaiz A (2016) Compos Part A 84:186

Cisneros-López EO, Pérez-Fonseca AA, Fuentes-Talavera FJ, Anzaldo J, González-Núñez R, Rodrigue D, Robledo-Ortíz JR (2016) Polym Eng Sci 56:856

Cisneros-López EO, González-López ME, Pérez-Fonseca AA, González Núñez R, Rodrigue D, Robledo-Ortíz JR (2017) Compos Interface 24:35

Gunning MA, Geever LM, Killion JA, Lyons JG, Higginbotham CL (2014) Polym Compos 35:1792

Yu T, Jiang N, Li Y (2014) Compos Part A 64:139

Arias A, Heuzey MC, Huneault MA (2013) Cellulose 20:439

Nyambo C, Mohanty AK, Misra M (2011) Macromol Mater Eng 296:710

Lv S, Gu J, Tan H, Zhang Y (2016) J Appl Polym Sci 133:43295

Jiang A, Xu X, Wu H (2016) Polym Compos 37:802

Greco A, Maffezzoli M (2015) Adv Polym Technol 34:21505

Lu T, Liu S, Jiang M, Xu X, Wang Y, Wang Z, Gou J, Hui D, Zhou Z (2014) Compos Part B 62:191

Brewer CE, Chuang VJ, Masiello CA, Gonnermann H, Gao X, Dugan B, Driver LE, Panzacchi P, Zygourakis K, Davies CA (2014) Biomass Bioenerg 66:176

Martynenko A (2014) Dry Technol 32:1319

Xu H, Zhou J, Dong Q, Tan Y (2017) Mater Des 124:108

Carter HG, Kibler KG (1978) J Compos Mater 12:118

Orozco VH, Brostow W, Chonkaew W, López BL (2009) Macromol Symp 277:69

Verdaguer A, Rodrigue D (2014) Effect of surface treatment on the mechanical properties of wood-plastics composites produced by dry-blending. In: 72th annual technical conference & exhibition, Society of Plastics Engineers, Las Vegas, NV, USA

Korotkova E, Pranovich A, Wärnå J, Salmi T, Murzin DY, Willför S (2015) Green Chem 17:5058

Melo JDD, Carvalho LFM, Medeiros AM, Souto CRO, Paskocimas CA (2012) Compos Part B 43:2827

Jandas PJ, Mohanty S, Nayak SK (2011) Polym Compos 32:1689

Csikós Á, Faludi G, Domján A, Renner K, Móczó J, Pukánszky B (2015) Eur Polym J 68:592

Raymond A, Rodrigue D (2014) Effect of surface treatment on the properties of wood-plastics composites produced by rotomolding. In: 72th annual technical conference & exhibition, Society of Plastics Engineers, Las Vegas, NV, USA

Mahfoudh A, Cloutier A, Rodrigue D (2013) Polym Compos 34:510

Kaynak C, Meyva Y (2014) Polym Adv Technol 25:1622

Teymoorzadeh H, Rodrigue D (2015) J Bio Mater Bio 9:1

Kaymakci A, Ayrılmis N, Gülec T (2013) Bioresources 8:592

Bax B, Müssig J (2008) Compos Sci Technol 68:1601

Bledzki AK, Jaszkiewicz A, Scherzer D (2009) Compos Part A 40:404

Ning N, Fu S, Zhang W, Chen F, Wang K, Deng H, Zhang Q, Fu Q (2012) Prog Polym Sci 37:1425

Rajesh G, Prasad AR, Gupta A (2015) J Reinf Plast Compos 34:951

Orue A, Eceiza A, Peña-Rodriguez C, Arbelaiz A (2016) Materials 9:400

Arbelaiz A, Fernandez B, Ramos JA, Regegi A, Llano-Ponte R, Mondragon I (2005) Compos Sci Technol 65:1582

Acknowledgements

This research was supported by the Secretaría de Educación Pública PRODEP-NPTC Mexican program (#195010). One of the authors (M.E. González-López) thanks the Mexican National Council for Science and Technology (CONACyT) for a scholarship (#587384) and the Academic Secretariat of the University of Guadalajara (CUCEI) for the complementary financial support for a research internship at Université Laval. The technical support of D. Chimeni and Y. Giroux is also highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

González-López, M.E., Pérez-Fonseca, A.A., Cisneros-López, E.O. et al. Effect of Maleated PLA on the Properties of Rotomolded PLA-Agave Fiber Biocomposites. J Polym Environ 27, 61–73 (2019). https://doi.org/10.1007/s10924-018-1308-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-018-1308-2