Abstract

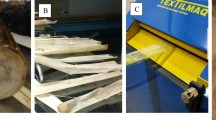

The objective of this work was to improve the impact and thermal properties of polylactic acid (PLA)-based biocomposite by appropriate application of cellulosic fiber and a bioelastomer. Biocomposites formulations with fiber contents of up to 20% in combination with a bioelastomer were extrusion-compounded in a twin-screw extruder followed by molding in an injection molding system. Fibers used in the formulations included three types of cellulosic fiber; namely, raw fiber from oat hull biomass (RF), hydrolysis byproduct (ATF) which was the solid fraction obtained from an acid-catalyzed hydrolysis of RF, and delignified fibers (AD30, AD65, AD100) which were the products of delignification of ATF. Formulated biocomposites were characterized for thermal (glass transition and melting temperatures, and enthalpy of melting) and physico-mechanical (tensile and bending strengths, stiffness, impact energy, and water absorption) properties. Among all types of biofibers, RF resulted in poor properties in the biocomposites due to the high hemicellulose content in the structure. On the other hand, the ratio of lignin to cellulose (in the absence of hemicellulose) in the modified fibers did not significantly affect the physico-mechanical and thermal properties of the biocomposites. The elastomer applied in the formulations improved the impact energy, thermal properties, and elongation at break of the composites. However, it adversely affected the strength and water resistance of biocomposites, especially in the presence of hemicellulose. The results indicated that, depending on the application, a wide range of PLA green composites with different physico-mechanical properties can be achieved.

Similar content being viewed by others

References

Zini E, Scandola M (2011) Polym Compos 32:1905

Mohanty AK, Misra M, Drzal LT(2002) J Polym Environ 10:19

Mohanty AK, Drzal LT, Misra M(2002) J Adhesion Sci Technol 16:999.

Soleimani M, Tabil LG (2015) Biochem Eng J 82:166

Nishino T, Hirao K, Kotera M, Nakamae K, Inagaki H (2003) Compos Sci Technol 63:1281

Taib RM, Ramarad S, Ishak ZAM, Todo M (2010) Polym Compos 31:1213

Gurunathan T, Mohanty S, Nayak SK (2015) Composites. Part A 77:1

Shalwan A, Yousif BF (2013) Mater Des 48:14

Tábi T, Tamás P, Kovács JG (2013) Express Polym Lett 7:107

Soleimani M, Tabil LG, Niu C (2015) AIChE J 61:1783

ASTM D638-14 (2014) Standard test method for tensile properties of plastics, ASTM International, West Conshohocken, PA

ASTM D790-10 (2010) Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials, ASTM International, West Conshohocken, PA,

ISO 179-1 (2010), Determination of Charpy impact properties European Committee for Standardization, Brussels

ASTM D570-98 (2010), Standard test method for water absorption of plastics (ASTM International, West Conshohocken, PA

AOAC (2005), AOAC Method 2002.04-Amylase-treated neutral detergent fiber in feeds, AOAC International

AOAC (1997), AOAC Method 973.18-Fiber (acid detergent) and lignin in animal feeds AOAC International

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass laboratory analytical procedure, National Renewable Energy Laboratory, Golden

Oksman K, Skrifvars M, Selin JF (2003) Compos Sci Technol 63:1317

Oksman K, Mathew AP, Bondeson D, Kvien I (2006) Compos Sci Technol 66:2776

Le Digabel F, Averous L (2006) Carbohydr Polym 66:537

Qiang T, Yu D, Gao H (2012) J Appl Polym Sci 124:1831

Soleimani M, Tabil LG, Panigrahi S, Opoku A (2008) J Polym Environ 16:74

Khoo RZ, Chow WS (2014)J Thermoplast Compos Mater. doi:10.1177/0892705715616857.

Chow WS, Leu YY, Ishak ZAM (2014) Polym Plast Technol Eng 53:858

Tham WL, Poh BT, Ishak M, Arifin Z, Chow WS (2016) J Appl Polym Sci. doi:10.1002/APP.42850

Balakrishnan H, Hassan A, Imran M, Wahit MU (2011), J Polym Environ 19:863.

Sajna VP, Mohanty S, Nayak SK (2015) J Thermoplast Compos Mater. doi:10.1177/0892705715604679.

Reddya N, Yang Y (2005) Polymer 46:5494

Reddya N, Yang Y (2005) Green Chem 7:190.

Rahman A, Panigrahi S, Kushwaha RL, Alam MM (2013) Int J Comp Mater 3:122

Awal A, Rana M, Sain M (2015) Mech Mater 80:87

Anuar H, Zuraida A (2011) Malaysia Polym J 6:51.

Cheung HY, Lau KT, Tao XM, Hui D (2008) Compos 39:1026.

Qian S, Sheng K, Yao W, Yu H (2015) Appl Polym Sci. doi:10.1002/app.43425

Liu T, Yu F, Yu X, Zhao X, Lu A, Wang J (2012) J Appl Polym Sci 125:1292

Johari AP, Mohanty S, Kurmvanshi SK, Nayak SK (2016) ACS Sustain Chem Eng 4:1619

Yaacab ND, Ismail H, Ting SS (2016) Procedia Chem 19:757.

Abdulkhani A, Hosseinzadeh J, Dadashi S, Mousavi M (2015) Cellul Chem Technol 49:597.

Dogu B, Kaynak C (2016) Cellulose 23:611

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Soleimani, M., Tabil, L.G., Oguocha, I. et al. Interactive Influence of Biofiber Composition and Elastomer on Physico-Mechanical Properties of PLA Green Composites. J Polym Environ 26, 532–542 (2018). https://doi.org/10.1007/s10924-017-0967-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-0967-8