Abstract

Candida antarctica: lipase B (CALB) is the most widely studied enzyme, due to its high selectivity and catalytic activity in organic and polymer synthesis. To avoid organometallic catalysts in the synthesis of biodegradable polyesters, the enzymatic ring-opening polymerization of cyclic esters can be carried out with CALB as a biocatalyst. This paper reviews selected examples of the application of lipases in polymer chemistry covering the synthesis of cyclic ester monomers, linear and star oligomers, as well as well-defined high molar mass polymers with improved mechanical properties. It is shown that by the selection of appropriate conditions of temperature and solvent assortment, CALB effectively catalyzes the polymerization of large size lactones obtaining polyesters with Mn up to 80 kg mol−1. The chemical structure and main applications of described materials are also discussed. As the polymer recycling is an important topic from environmental point of view, we also described the potential applications of CALB in degradation process of aliphatic polyesters.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Enzymes are non-toxic, recyclable and eco-friendly biocatalysts applied in various chemical reactions; in particular lipases are the most frequently used in organic synthesis. In biological systems lipases (EC.3.1.1.3) catalyse fats hydrolysis, but in the media of low water content they can be used not only for the synthesis of acylglycerols but also for different esters or amides. Their activity is affected by solvent type, pH, temperature and the presence of inhibitors and/or activators. Lipases do not require co-factors and they are sufficiently selective to limit the occurrence of side reactions. They are powerful biocatalysts for many industrial applications (food industry, flavor synthesis, pharmacy and biodiesel production) and for this purpose lipases of microbial origin are often used due to their relative stability, ease production and simplicity of genetic manipulation [1].

Lipases, became attractive catalysts also in polymer chemistry, where are involved in the preparation of well-defined functional polymers [2]. By enzymatic catalysis, the reaction is carried out in mild conditions (low temperature and pressure), giving polymers with high molar mass and specific structure [3]. Lipases have been shown to catalyze ring opening polymerization (ROP) and copolymerization of various cyclic monomers, mainly cyclic esters. In particular, lipases are able to catalyze the polymerization of large ring size lactones, which is not achievable by non-enzymatic methods [4]. Biodegradable polyesters, obtained in this clean process, are used in biomedical applications as scaffolds and in drug delivery systems. Enzymatic ring-opening polymerization (eROP) of lactones can be conducted in the presence of different lipases derived from microorganisms such as: bacteria (Pseudomonas fluorescens [5], Burkholderia cepacia [6, 7]), yeast species (Yarrowia lipolytica [8]), lipases of animal origin (porcine pancreas [9]), as well as thermophilic lipase/esterase family enzyme from the archaeon Archaeoglobus fulgidus [10, 11], nevertheless during last decades the most intensively studied for this purpose was lipase B from yeast Candida antarctica (CALB). CALB exhibits high polymerization catalytic activity of lactones containing from 4 to 17 membered rings [12], but in the case of lactide, only low molar mass oligomers were achieved [13].

In this paper, we present the actual studies on the eROP of cyclic esters in the presence of CALB or its immobilized form - Novozyme 435 (N-435) (Sigma-Aldrich, USA). Besides, some examples of recent CALB applications in the synthesis of cyclic esters—monomers and in degradation of aliphatic polyesters will be given.

Candida antarctica Lipase B

Candida sp. is the most prominent lipase producer among yeast reported in the literature [14]. The species C. antarctica produces two different lipases: lipase A and B. CALB is probably the mostly employed hydrolase in the biocatalysis field, meanwhile the use of the lipase A (CALA) has been rather scarce [15].

In 1994 the research group of Uppenberg [16] for the first time described the amino acid and genic sequence of CALB. It was proved that lipase B derived from C. antarctica yeast consists of 317 amino acid residues giving molar mass 33 kDa [17]. The active site is composed of a nucleophilic serine residue activated by a hydrogen bond in relay with histidine and aspartate or glutamate (“catalytic triad”) [18]. Moreover, the majority of lipases have a common pattern G-X1-S-X2-G for the nucleophilic serine S and the oxyanion hole residue X2, but CALB is characterized by the pattern T-W-S-Q-G [19]. Another difference which distinguishes CALB is the fact, that the active site of the enzyme is not covered by a lid, but the binding site for hydrophobic substrate is directly exposed to the solvent [20].

CALB is highly enantioselective and efficient biocatalyst used in the wide range of organic reactions including kinetic resolutions [21], aminolysis [22], esterification conducted in solventless media [23] and in polar organic solvents [24]. Its activity is higher in water than in organic media, therefore numerous studies were performed in order to improve the properties of CALB as a catalyst in other solution. One of the method is immobilization by different techniques such as non-covalent adsorption, deposition, single covalent attachment, multiple covalent attachments, entrapment in a polymeric gel in membrane or capsule, cross-linking of an enzyme and enzyme crystals [25]. Immobilized enzymes show better catalytic efficiency than the corresponding free enzymes and are able to withstand high temperatures [26]. Furthermore, immobilization allows ease removal of the catalyst from reaction mixture which can be reuse even up to ten times. N-435, the most extensively studied immobilized lipase B from C. antarctica, (immobilized on acrylic resin), shows significant thermal stability, specially under elevated temperatures, even up to 100 °C [27].

CALB in Cyclic Esters Synthesis

Cyclic esters, in particular lactones, are well known not only for their fragrance properties and a variety of biological effects. Optically active lactones are important building blocks in fine organic synthesis and are applied in the preparation of biodegradable polymers for biomedical applications. In this field enzymes are unique catalysts due to theirs stereoselectivity [28].

In the past two decades, several research groups reported synthesis of cyclic esters in the presence of CALB [29]. The optically active lactones can be obtained in enzymatic reaction via kinetic resolution or dynamic kinetic resolution of racemates [30]. In the second case, a single enantiomer can be theoretically formed from the racemate with a yield of 100% because of the racemization of the unreacted enantiomer [31]. Some examples of those lactones are presented in Fig. 1.

Shimotori research group [32] proved that high enantiomeric excess (ee) value, close to 100%, can be obtained for both enantiomers of γ-lactone (Fig. 1a), synthesized from succinic anhydride in 4-step reaction, completed with enzymatic resolution and lactonization process (Scheme 1). Based on the same method, both enantiomers of δ-lactone (Fig. 1b) with 80% ee were achieved, by enzymatic resolution of rac-N-methyl-5-hydroxyalkylamides catalyzed by N-435 [33].

Another way, to obtain γ-lactone (a building block in the synthesis of anti-HCV agent) was proposed by Zhang et al. [34]. In their experiment, 2,3-O-isopropylidene-d-glyceraldehyde condensed with ethyl 2-fluoropropionate getting a mixture of three isomeric products. In the next step, N-435 was used in the enzymatic resolution process of a crude product and γ-lactone with 23% overall yield was obtained (Fig. 1f).

The influence of solvent, type of lipase and different alkyl lactates as substrates on the synthesis of (R,R)-lactide were investigated by Jeon [35]. It turned out, that N-435 was the most effective catalyst in the synthesis of (R,R)-lactide from methyl (R)-lactate in the presence of methyl tert-butyl ether. The product was obtained with 59% yield, and ee value equal to 99% (Fig. 1c).

Recently, Pyo et al. [36] described the synthesis of six membered functional cyclic carbonate (Fig. 1d) achieved with 63% yield, starting from transesterification reaction of trimethylolpropane (TMP) with methacrylate esters, followed by carbonation process and thermal cyclization. First two steps were conducted at the same temperature of 60 °C for 24 and 36 h, respectively, meanwhile the cyclization process was carried out at 90 °C. The amount of the N-435, added to the reaction system, was 10 wt% for functionalization step and 20 wt% for carbonation process (Scheme 2).

N-435 promoted also the formation of macrocyclic lactones (Fig. 1e), obtained from ω-hydroxycarboxylic acid [37]. It was found that in the case of hexadecanolide, the reaction always yielded a mixture of oligomers of both cyclic and non-cyclic esters and the 16-hydroxyhexanoic acid was completely converted to ester products. However, the yield of the hexadecanolide was fairly small and never exceeded 41%.

Linear and Star Ester Oligomers

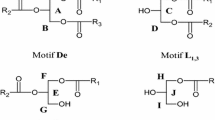

In enzymatic polymerization of cyclic esters, the catalytic site of lipase, which is –CH2OH group derived from serine residue, attacks the carbonyl carbon of the lactone monomer leading to the formation of acyl-enzyme intermediate (enzyme activated monomer, EAM). In the next step, EAM reacts with hydroxyl co-initiators present in the reaction system. The propagation step, the nucleophilic attack of the terminal hydroxyl group of hydroxycarboxylic acid on the EAM leads to the formation of one-unit more elongated polymer chain (Scheme 3). The polymerization rate mainly depends on the formation of the EAM or on the rate of the reaction of EAM with monomer. When the propagating hydroxyl end is sterically overcrowded, the deacylation step becomes more important [38].

Most of the polyesters obtained by enzymatic polymerization in the presence of C. antarctica lipase are characterized by a low molar mass and are predominantly designed for biomedical applications (especially in drug delivery systems [39]). Almost all polymerization reactions were conducted in organic solvents, such as: toluene [40], 1,4-dioxane [41], isopropyl ether [42], isooctane [43], diphenyl ether [44], cyclohexane [45]. The reaction was also carried out in supercritical carbon dioxide [46, 47], ionic liquids [48–50], and recently, in aqueous dispersion [51]. The best solvent for eROP with CALB seems to be toluene [52].

A four-membered (R,S)-β-butyrolactone was polymerized in bulk at 100 °C with 5 wt% of the CALB lipase [53]. The highest Mn about 1.0 kg mol−1 was obtained after 5 days of polymerization which was only twice higher than for the product synthesized without any catalyst. The higher polymerizability was reached during enantioselective copolymerization of β-BL with ε-CL or 12-dodecanolide, where the final product was characterized by Mn about 1.7 and 2.3 kg mol−1, respectively. Moreover, it was proved, that the (S)-isomer of β-BL is more readily polymerizable than the (R)-isomer to give the copolymer with relatively high optical purity in the (S)-enriched form [43].

It is well known that five-membered lactones (γ-BL) exhibit poor polymerizability due to positive reaction enthalpy. He group [54] showed, that N-435 is able to catalyze the copolymerization of γ-butyrolactone and ε-CL, getting products with Mn in the range of 10–16 kg mol−1 and γ-BL contents in the precipitated copolymers varied from 3 to 15 mol% (depending on the feed ratio) (Scheme 4a). They also proved, that the higher content of BL units in the product, the lower degradation rate was observed.

Surprisingly, there are only few reports regarding lactide polymerization in the presence of CALB lipase. The reason of this, is poor catalytic activity of free CALB or N-435 in ROP of LA [55], while the high molar mass PLA can be obtained using Pseudomonas cepacia lipase PS [50]. Recently, Avérous et al. [13] described results of l-, d- and d,l-lactide polymerization using CALB and N-435. All reactions were conducted in toluene solution at 70 °C for 48 h. It was found that the free CALB as well as N-435 catalysts showed higher activity for d-lactide compared with the other lactide isomers leading to higher molar mass PDLAs (1000–2600 g mol−1). The polymerization of l- and d,l-lactide gave only oligomers with Mn in the range of 0.2–0.5 kg mol−1. These experiments confirmed clearly the enantioselectivity of the N-435, which was discussed several times in the literature [57–59]. In addition, in 2009 Moeller et al. [60] studied eROP of d-lactide at 60 °C in the presence of 10, 15 and 25 wt% of N-435 used as a catalyst. In those conditions (with 15 wt% of lipase) PDLA characterized by Mn = 12 kg mol−1 and Đ = 1.1 was obtained. With the increase of the lipase content in the feed, the conversion also increased but Mn decreased. It was also found that up to a certain conversion, the polymerization followed first order kinetics and after that moment deactivation and denaturation of the enzyme were observed. A wide overview of LA ROP catalyzed by N-435 can be found in Idris [25] review.

Copolymerization of D-LA with ε-CL using 5 wt% of N-435 has also been investigated [13]. Two-step reaction, included 2 h homopolymerization of ε-CL and 48 h copolymerization with D-LA resulted in random copolymer with Mn = 7.5 kg mol−1 and Đ = 2.6. With twice lower Mn and polydispersity could be obtain copolymer of rac-LA and glycolide (GL) at 80 °C after 14 days of reaction initiated by poly(glycol ethylene) (Mn,PEG = 400 g mol−1) (Scheme 4b) [61].

It is worth to mention, that in 2009 Bourissou et al. [62], reported the synthesis of PLA with relatively high molar mass using N-435 as a catalyst (Scheme 4c). In described experiment, the O-carboxylic anhydride derived from lactic acid (lacOCA) was used as a monomer, and the reaction was carried out with carbon dioxide liberation. 3 wt% of the lipase and 8 h of the reaction were sufficient to reach the PLLA with Mn = 28.5 kg mol−1 and Đ = 1.2 and high monomer conversion.

CALB is the most effective catalyst in the polymerization of ε-CL. Even 1 wt% of the catalyst was sufficient to synthesize PCL with Mn in the range of 3.0-3.4 kg mol−1, depending on the number of recycling cycles of the catalyst [63]. Bulk homopolymerization of ε-CL catalyzed by 2 wt% of CALB at 60 °C for 24 h led to a polymer mixture of 2 mol% of cyclic products (di-lactone, macrocycles) and linear PCL with Mw = 4.7 kg mol−1 [64]. Surprisingly, more cyclic oligomers were present in products of solution polymerization conducted in THF (28 mol%), dioxane (34 mol%) and acetonitrile (53 mol%) resulted in lower molar mass of PCL (1.9, 3.0 and 1.3 kg mol−1, respectively). Much higher Mw of the PCL can be achieved when to the polymerization system toluene and 10 wt% of N-435 lipase were introduced. During the first reaction cycle, Poojari et al. [65] obtained PCL characterized by Mw = 27 kg mol−1 and Đ = 1.59, meanwhile after next 9 cycles, the polymers with about Mw = 50 kg mol−1 and Đ = 1.44 were achieved. Increased catalytic activity may be attributed to the attainment of a new chemical equilibrium state resulting from the residual water content (or the water activity) in the organic medium. Unfortunately, during mechanical stirring, some of enzyme-immobilized resin particles found to be disintegrated.

Several groups reported a copolymerization reaction of ε-CL with other cyclic esters, such as δ-gluconolactone [41], PDL, macrolides, as well as oligodiols, to improve e.g. its thermal properties and increase biodegradation rate [66, 67]. Incorporating α,ω-(dihydroxy alkyl) terminated poly(dimethylsiloxane) (PDMS) to the PCL structure, slightly increase the thermal stability of PCL [68]. The reaction was carried out in toluene at 70 °C for 4 h catalyzed by 10 wt% of N-435, and the triblock copolymer PCL-PDMS-PCL with Mn about 10 kg mol−1 and Đ about 1.5 was achieved (Scheme 4d).

Moreover, immobilized CA lipase catalyzed ROP of ε-CL in the presence of low-molar mass telechelic hydroxylated poly[(R)-3-hydroxybutyrate] (PHB-diol) [69], and diblock polyester with hydroxyl group at both ends was produced. The product was characterized by Mn and Đ in the range of 4.2–8.9 kg mol−1 and 1.5–2.0, respectively. Random and triblock copolyester of ε-CL and vinyl sulfide-containing hydroxy acid was recently studied [70] in order to obtain hydrolytically stable materials with good thermal properties.

It should be emphasized that another route for production of block copolymers is chemoenzymatic polymerization, which has been intensely developed in the last five years [71, 72]. This combination allows to obtain new polymeric materials that are otherwise difficult to synthesize [73]. Block copolymers of ε-CL, were prepared using techniques such as chemoenzymatic ATRP [74, 75], combination of enzymatic polymerization with reversible addition-fragmentation chain transfer (RAFT) [76] and carbene chemistry [77].

To synthesize star- and dendrimer-like PCL, ROP of ε-CL was performed in the presence of glycerol [78], PHB [79, 80] and polyglycidol [67]. In first case, the three-arm PCL-triols were obtained in solution polymerization with 10 wt% of N-435 and two molar ratios of CL/GLY 10:1 and 30:1. Star oligomers with Mn in the range of 2.7–5.0 kg mol−1 and narrow polymer distribution were achieved and used to synthesize shape memory polymers by reaction with methylene diphenyl 4,4′-diisocyanate and 1,6-hexanediol. Prepared samples, exhibited good shape-memory properties, with shape recovery in 10 s, shape fixity rate of 91–92%, and shape recovery rate of 95–99%. Hyperbranched polymers with their unique chemical and physical properties [81] are promising materials for biomedical applications. In 2002, the research group of Frey [79] synthesized hyperbranched PCL by copolymerization of ε-CL with bis(hydroxymethyl)butyric acid (BHB) and 10 wt% of N-435, which was a combination of ROP and AB2 polycondensation. After 24 h at 85 °C hyperbranched PCL with high yield and high molar mass (Mn = 52.4 kg mol−1) was achieved. The MALDI-ToF mass spectra of the obtained products revealed that in all samples some minute linear and cyclic fractions were present but the major products were hyperbranched PCL. Based on the same reaction, hyperbranched PCL with lower Mn (8.8 kg/mol, DI = 1.33) was synthesized 5 years later by Ai [82]. In this case, obtained product was modified by esterification reaction of α-bromopropionyl bromide and used as macroinitiator in ATRP of styrene. The chemoenzymatic polymerization resulted in hyperbranched triblock copolymer characterized by Mn = 33.7 kg mol−1 and DI = 1.2.

Another example of multi-arm star polymers obtained in the presence of N-435 was proposed by Moeller [67]. In this case hyperbranched polyglycidol with Mn,NMR about 2.0 kg mol−1 was used as a macroinitiator of bulk ROP of ε-CL. The final product was characterized by Mn = 21.8 kg mol−1 and Đ = 1.7 after 24 h reaction at 70 °C. The presented results suggest that some of hydroxyl groups of the macroinitiator remained unreacted in the product mixture, which can be used for further modification, to obtain e.g. heterografted molecular bottle brushes [83].

In recent years intensive research effort was directed on the synthesis of poly(pentadecalactone) (PPDL) catalyzed by N-435, because it is susceptible to biodegradation process and exhibits good mechanical properties comparable to low density polyethylene. Recently, oligomers of PPDL were obtained at 70 and 90 °C for 24 h [84]. PPDL can be also synthesized in the presence of HEMA initiator [85], in order to obtain methacrylated aliphatic polyester, which in further studies can be used for formation of macroporous matrices for tissue scaffolds [86]. Another difunctional poly(ω-PDL) designed for biomedical application was prepared by solvent free ROP of PDL in the presence of 4 wt% of N-435 and initiated by 6-mercapto-1-hexanol and terminated by γ-thiobutyrolactone or vinyl acrylate (Scheme 4e) [87]. After 44 h at 80 °C, the final product with thio–thiol or thiol–acrylate functional end groups was characterized by Mn = 1.5 kg mol−1 (Đ = 2.3) and Mn = 1.2 kg mol−1 (Đ = 2.9), respectively.

N-435 exhibited high catalytic activity in solution copolymerization of PDL with TMC [88]. With various molar ratios of monomers (PDL:TMC from 1:10 to 10:1), Gross research group obtained random copolymers with Mn in the range of 7.3–25.2 kg mol−1. The content of PDL units in the polymer structure was much higher in comparison with products obtained in the presence of chemical catalysts such as tin octanoate, aluminum ethylaluminoxane or aluminum isopropoxide. It turned out that immobilized C. antarctica lipase polymerized PDL more rapidly than TMC and exhibited the ability to catalyze the conversion of PDL/TMC from multiblock to random copolymers.

Summarizing the CALB assisted ROP lactone polymerization were successfully performed up to 16 membered rings with some limitations for five membered lactones. It should be noted that in this reaction the relative polymerization rates are much greater for macrolides than for small rings, unlike the chemical ring opening polymerizations. Docking and molecular dynamics studies revealed the difference between the binding modes of small/cisoid/lactones and the/transoid/conformation of macrolides during the formation of enzyme–substrate complex [89]. Based on the calculated docking energies for cisoid lactones, and comparing them with the ideal near attack conformation (NAC) it was proved, that the docking score was found to be 0.00, and indicating unfavorable positioning of these lactones in the enzyme active site. On the other hand, macrolides (DDL and PDL) with non-zero docking score, can readily react with CALB, as was observed from the high substrate specificity values experimentally determined by Veld.

High Molar Mass Polymers

There are only few reports of high molar mass polyesters obtained in the presence of CALB. In most cases, the Mn above 50 kg mol−1 was reached during ROP of large-size lactones such as PDL or its copolymerization with other cyclic esters. As it was previously mentioned, lipase catalyzed polymerization of macrolactones occurs with higher reaction rates and higher conversions compared to traditional chemical polymerization methods, and that is why the high molar mass polymers can be obtained [90]. Enzymatic polymerization of 12-, 13-, 16- and 17- membered macrolides in the presence of CALB has been extensively studied by Kobayashi during the period 1995–1999 [91–93] and since that moment, only few reports on this topic can be found.

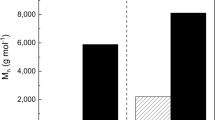

Recently, the most attention was focused on the ROP of 16-membered PDL. The optimum temperature for polymerization of PDL in toluene was established as 70 °C, and the reaction time in the range of 4–20 h. In those conditions the relatively high molar mass PPDL could be obtained [94]. The detailed correlation between amount of organic solvent used in the process and reaction temperature on monomer conversion and molar mass of the product was studied e.g. by Kumar et al. [95]. They proved, that the reduction of the polymerization temperature from 90 to 55 °C and toluene/monomer molar ratio from 10:1 to 1:1 gave PPDL with increased Mn (66 to 81 and 49 to 86 kg mol−1, respectively) and monomer conversion. The similar conclusion was presented by Korzhikov [86], although he found second optimum (between 100 and 110 °C) were the PPDL with high molar mass could be formed. The final product was characterized by Mw about 88 kg mol−1 and Đ = 1.65. In both cases, the monomer/enzyme ratio was equal to 10 wt/wt.

Focarete [44] et al. reported the synthesis of high molar mass PPDL obtained with 98% yield, Mn of 64.5 kg mol−1 and Ð of 2.0.The reaction was conducted at 70 °C for 4 h in toluene. Highly crystalline product exhibited good mechanical properties, comparable to low density polyethylene, and good thermal stability, with a main TGA weight loss centered at 425 °C. In addition, de Geus et al. also synthesized PPDL with high Mn about 80 kg mol−1 which was used to prepare high strength fibers with tensile strength up to 0.74 GPa [96].

Due to the good thermal and mechanical properties of PPDL, PDL was copolymerized several times [97] with p-dioxanone (DO) (ester-ether) in order to improve thermal stability of polydioxanone (PDO) and its tensile strength. PDO can be used in drug delivery, reconstructive surgery, cardiovascular and bone repair applications. It is also well known as a synthetic absorbable suture material for wound closure [98]. Poly(PDL-co-DO) with high molar mass (M w > 50 kg mol−1) was obtained by ROP in toluene, at 70 °C for 26 h, in the presence of 5 wt% of N-435. It was found that large ring PDL was more reactive than its smaller counterpart DO, resulting in higher PDL/DO unit ratios in polymer chains than the corresponding PDL/DO monomer ratios in the feed. On the other hand, homopolymerization of DO gave also the high molar mass polymer with Mw = 112 kg mol−1, synthesized in bulk polymerization with 10 wt% of CA lipase, at 60 °C for 4 h [99]. Interestingly, under the same conditions, polymerization of ε-CL (seven-member ring structure) was much slower than of DO. It suggests, that there is no strong correlation between polymerization rate and ring size of lacton. Recently, PCL homopolymer and its copolymer with methyl 3-((2-hydroxyethyl)thio)propanoate were synthesized by solution polymerization in diphenyl ether obtaining products with Mn = 70.2 kg mol−1 and Mn = 51 kg mol−1, respectively [66].

In 2010 Hodge et al. [100] reported enzymatic polymerization of mixture of cyclic monomers containing from 12 to 72 ring atoms as well as pure macromonomers (after isolation) at 70 °C in the presence of 7.5 wt% of polymer supported CALB. The highest Mn (about 60.0 kg mol−1) was reached for polymers synthesized from monomer mixture after 4 h, and during polymerization of 24-membered cyclic ester after 20 h. The correlation between number of ring atoms on the polymer molar mass is difficult to find, due to the fact that the monomer concentration was not stable in all experiments and varied from 6 to 118.

Degradation of Aliphatic Polyesters

Biodegradation is the process by which organic substances (e.g. polymers) are broken down into smaller compounds by living microorganisms such as fungi, bacteria or algae. The microbial organisms transform these substances through metabolic processes. Although individual processes vary greatly, as a final result microbial metabolic end-products such as water, carbon dioxide, methane (in the case of anaerobic degradation) and new biomass are produced [101]. Biodegradation of polymers usually concerns water insoluble materials which implies, that it is a heterogeneous process. Because of water insolubility and their macromolecular structure, polymers are unable to penetrate/permeate the cell walls of microorganisms and due to this microorganisms are not able to pick up the polymers directly into the cells where most of the biochemical processes take place. During biodegradation microorganisms produce some enzymes to degrade the polymers, and after the reduction of molar mass, molecules can be transported into their cells, introduced into the metabolic pathways and utilized as carbon and energy sources. It is generally known that polymers with ester bonds may be degraded by hydrolysis—chain scission of the polyesters requires only ester hydrolysis to form water soluble products. Therefore microorganisms producing hydrolases can be applied in their biodegradation [102].

Regarding polymers, apart from their biodegradability, it is necessary to consider the large scale recycling for efficient utilization. In the case of polyesters, the use of lipases which can catalyze the synthesis and the degradation of ester bond provides additionally the opportunity of recycling of polymers as a result of its depolymerisation into cyclic oligomers. This type of degradation can be particularly useful for recycling/reusing the polymer waste to prevent or reduce environmental pollution.

In this review we present some examples of two pathways of polyester degradation, which involve enzymatic polymer recycling in organic solvent (Scheme 5, path a) and biodegradation in aqueous solution (Scheme 5, path b) in the presence of CALB.

The first case (Scheme 5, path a) is concerned to the formation of cyclic oligomers and to use them as potential monomers in further polymerization reaction. So far, enzymatic polymer recycling in the presence of N-435 was conducted for: PLLA [103], PBA [104], PBS [104], PCL [105], PHB [106], poly(trimethylene carbonate) (PTMC) [107], PTCL [108], and in some cases the repolymerization step was also investigated [107].

The systematic studies of Matsumura research group [103], showed that cyclic oligomers of l-lactide with a molar mass of several hundred, can be obtained in o-xylene solvent at 100 °C with 500 wt% of N-435. Much lower temperature of degradation was applied for poly(R,S)-3-hydroxybutanoate [106] and PCL [109], which were transformed into a reactive cyclic products in toluene, to give oligomers with Mn less than 500 g mol−1. Both polymers were also depolymerized under continuous flow conditions in toluene solution, using enzyme column packed with N-435 [105, 110]. The cyclic oligomers were received at 40 °C with high yield in the range of 87–99%, depending on the flow rate and polymer concentration.

Polymer recycling of PTMC led to obtain mainly TMC monomer whereas the cyclic and linear oligomers were minute [111]. The reaction was carried out in acetonitrile with N-435 for 148 h with satisfactory high yield up to 80%. The resulting monomer was then polymerized by solvent ROP in the presence of lipase N-435, with monomer conversion close to 60% after 80 h.

In order to replace solvent degradation method of aliphatic polyesters, Jbilou et al. [112] proposed an easy recycling route based on reactive extrusion. Since the experiments were performed at 120 °C, the N-435 was chosen as the best catalyst for this process, as it is characterized by high thermal stability. Only 1 wt% of N-435 was sufficient for rapid degradation of PBS, which after 5 min decomposed to oligomers with Mn about 4.5 kg mol−1.

As it was previously mentioned, N-435 can be also used in enzymatic degradation of polyesters films in buffer solution (Scheme 5, path b). In majority, for this purpose the Rhizopus arrhizus, Rh. delemar and Fusarium sp. [113] lipases were applied, however some interesting examples of degradation in the presence of N-435 can be also found. For instance, it was proved that N-435 is able to degrade homopolymer poly(trimethylene carbonate) (PTMC) with 98% mass loss after 9 days [114]. The molar mass of the sample changed during the experiment, and decreased from 117 kg mol−1(Ð = 1.8) to 6.90 kg mol−1 (Ð = 16.7) after 5 days. The results of biodegradation analysis were different, when to the degradation test the copolymer of TMC and GL (PTGA) were chosen. In this case, mass loss of PTGA films did not exceed 5.8% and the Mn and Ð values remained almost constant. ESEM analysis and contact angle measurements revealed that both polymers were homogeneously eroded from the surface during enzymatic degradation and the degradation mechanism involves enzyme adsorption on the sample surface followed by enzyme-catalyzed chain cleavage.

The ability of carbonate segment to biodegradation was analyzed by Yang research group [115], who tried to accelerate degradation rate of poly(butylene succinate) (PBS) by incorporating carbonate m.u. into the PBS chains. The synthesis was realized by ROP of 5 kinds of six-membered cyclic carbonate monomers initiated by PBS macrodiol. The presented results showed, that N-435 is not able to degrade the PBS homopolymer, meanwhile for copolymers, enzymatic degradation rate increased, with increasing the carbonate block content of the copolymer. For all samples, the changes in Mn before and after degradation by N-435 were negligible and never exceeded more than 30%.

An interesting method, of PCL films degradation in the presence of CALB was proposed in 2009 by Gross et al. [116]. CALB, solubilized in toluene by surfactant pairing with sodium bis(2-ethylhexyl)sulfosuccinate, was mixed with PCL-toluene and casted into films. It turned out, that in the presence of surfactant-paired CALB, complete film degradation was reached after 19 days, when the concentrations of catalyst in the polymer matrix was equal 1.6%. A fourfold increase in CALB content resulted in acceleration of the biodegradation rate almost 17 times. Moreover, molar mass of PCL was changed from 120 to 24.7 kg mol−1 during 20 h of process. In contrast, when unmodified CALB was added externally to buffer solution, the Mn was stable as film weight loss proceeded, due to limitation of access to the internal part of the samples. In 2012, the same research group repeated experiments, but in this case the biodegradation process of PCL was performed under continuous flow conditions [117]. Using this technique, they have tried to avoid the autocatalysis caused by acidic degradation products accumulated in the films external media. Applied conditions allowed to increase biodegradation rate almost six times.

Conclusions

Biodegradable polyesters offer the prospective applications in a number of biomedical fields like drug delivery system, orthopedics and pharmaceuticals. For this purpose it is required to use non-toxic and eco-friendly catalysts for which there is no need for complete removal from the polymerization product. With this in mind, enzymes can be good alternative for the heavy metal based catalysts commonly used in ROP, which residues in the biomedical products are highly dangerous for human body. In the presented review we showed the wide application range of CALB as a catalyst in the synthesis of monomers, oligomers and polymers conducted with high yield at the mild reaction conditions. The polymerization in the presence of CALB can be carried out in bulk or in solution, however, the second one is more favorable, due to the higher molar mass of synthesized polymers obtained in the process. On the other hand, bulk polymerization is more acceptable from an industrial point of view. Polyesters obtained in the presence of CALB are suitable for preparation of scaffolds and wound closure. They are also applicable in diagnostic field and in cancer therapy [118]. Moreover, they are playing an important role as effective and safe drug delivery platforms [119] for e.g. camptothecin [120], daunorubicin [121] and ibuprofen [122]. In the presented article, it was also demonstrated that CALB is an efficient catalyst in (bio)degradation process, which provides to reduce environmental pollution.

Through this review, we highlighted several recent themes which involve the unique properties of CALB. The main attention was focused on the synthesis of new polymeric materials with novel structures and properties e.g. block, brush, comb and graft copolymers, and hyperbranched polymers. In addition, we believe that further studies on the ROP of lactones in the presence of CALB will bring better understanding of the enzyme kinetics in relation to varying lacton substrate.

Abbreviations

- ATRP:

-

Atom transfer radical polymerization

- BHB:

-

Bis(hydroxymethyl)butyric acid

- BL:

-

Butyrolactone

- CALA:

-

Candida antarctica lipase A

- CALB:

-

Candida antarctica lipase B

- Ð:

-

Polydispersity

- DO:

-

p-Dioxanone

- EAM:

-

Enzyme activated monomer

- ε-CL:

-

ε-Caprolactone

- eROP:

-

Enzymatic ring-opening polymerization

- ESEM:

-

Environmental scanning electron microscope

- GL:

-

Glycolide

- GLY:

-

Glycerol

- HEMA:

-

Hydroxyethyl methacrylate

- LA:

-

Lactide

- Lac(OCA):

-

O-carboxylic anhydride derived from lactic acid

- Mn :

-

Number average molecular weight

- Mw :

-

Weight average molecular weight

- N-435:

-

Novozym 435

- PBA:

-

Poly(butylene adipate)

- PBS:

-

Poly(butylene succinate)

- PCL:

-

Polycaprolactone

- PDL:

-

Pentadecalactone

- PDLA:

-

Poly(d-lactide)

- PDMS:

-

Poly(dimethylsiloxane)

- PEG:

-

Poly(glycol ethylene)

- PHB:

-

Polyhydroxybutyrate

- PLA:

-

Polylactide

- PLLA:

-

Poly(l-lactide)

- PPDL:

-

Poly(pentadecalactone)

- PTCL:

-

Polythiocaprolactone

- PTGA:

-

Poly(glycolide-co-trimethylene carbonate)

- PTMC:

-

Poly(trimethylene carbonate)

- ROP:

-

Ring opening polymerization

- TGA:

-

Thermogravimetric analysis

- TMC:

-

Trimethylene carbonate

- TMP:

-

Trimethylolpropane

References

Gupta R, Kumari A, Syal P, Singh Y (2015) Progr Lipid Res 57:40–54

Uyama H, Kobayashi S (2006) Adv Polym Sci 194:133–158

Taresco V, Creasey RG, Kennon J, Mantovani G, Alexander C, Burley JC, Garnett MC (2016) Polymer 89:41–49

Albertsson AC, Varma IK, Srivasta RK (2009) Polyesters from large lactones In: Dubois P, Coulembier O, Raquez JM (eds) Handbook of ring-opening polymerization, Wiley, Belgium, p 287–306

Numata K, Srivastava RK, Finne-Wistrand A, Albertsson AC, Doi Y, Abe H (2007) Biomacromolecules 8:3115–3125

Malberg S, Finne-Wistrand A, Albertsson AC (2010) Polymer 51(23):5318–5322

Duchiron SW, Pollet E, Givry S, Avérous L (2015) RSC Adv 5:84627–84635

Barrera-Rivera KA, Flores-Carreón A, Martínez-Richa A (2008) J Appl Polym Sci 109:708–719

Henderson LA, Svirkin YY, Gross RA (1996) Macromolecules 29(24):7759–7766

Cao H, Han H, Li G, Yang J, Zhang L, Yang Y, Fang X, Li Q (2012) Int J Mol Sci 13:12232–12241

Ma J, Li Q, Song B, Liu D, Zheng B, Zhang Z, Feng Y (2009) J Mol Catal B 56(2–3):151–157

Ates Z, Thornton PD, Heise A (2011) Polym Chem 2:309–312

Öztürk Düskünkorur H, Bégué A, Pollet E, Phalip V, Güvenilir Y, Avérous L (2015) J Mol Catal B 115: 20–28

Treichel H, de Oliveira D, Mazutti MA, Di Luccio M, Oliveira JV (2010) Food Bioprocess Technol 3(2):182–196

Domínguez de María P, Carboni-Oerlemans C, Tuin B, Bargeman G, van der Meer A, van Gemert R (2005) J Mol Catal B 37(1–6):36–46

Uppenberg J, Patkar S, Bergfors T, Jones TA (1994) J Mol Biol 235(2):790–792

Strzelczyk P, Bujacz GD, Kiełbasiński P, Błaszczyk J (2016) Acta Biochim Pol 63(1):103–109

Li C, Tan T, Zhang H, Feng W (2010) J Biol Chem 285(37):28434–28441

Pleiss J, Fischer M, Peiker M, Thiele C, Schmid RD (2000) J Mol Catal B 10(5):491–508

Martinelle M, Holmquist M, Hult K (1995) Biochim Biophys Acta 1258(3):272–276

Lund IT, Bøckmann PL, Jacobsen EE (2016) Tetrahedron. doi:10.1016/j.tet.2016.02.018

Mouada AM, Taupin D, Lehr L, Yvergnaux F, Porto AL (2016) J Mol Catal B 126:64–68

Ravelo M, Fuente E, Blanco A, Ladero M, García-Ochoa F (2015) Biochem Eng J 101:228–236

Hasegawa S, Azuma M, Takahashi K (2008) J Chem Technol Biotechnol 83:1503–1510

Idris A, Bukhari A (2012) Biotechnol Adv 30:550–563

Mateo C, Palomo JM, Fernandez-Lorente G, Guisan JM, Fernandez-Lafuente R (2007) Enzyme Microb Technol 40:1451–1463

Mei Y, Kumar A, Gross RA (2002) Macromolecules 35(14):5444–5448

Kataoka M, Miyakawa T, Shimizu S, Tanokura M (2016) Appl Microbiol Biotechnol 100:5747–5757

Yang Y, Yu Y, Zhang Y, Liu C, Shi W, Li Q (2011) Process Biochem 46:1900–1908

Kobayashi S (2010) Proc Jpn Acad Ser B Phys Biol Sci 86:338–365

De Miranda AS, Miranda LSM, de Souza ROMA (2015) Biotechnol Adv 33:372–393

Shimotori Y, Nakahachi Y, Inoue K, Miyakoshi T (2007) Flavour Fragr J 22:421–429

Shimotori Y, Sekine K, Miyakoshi T (2007) Flavour Fragr J 22:531–539

Zhang P, Iding H, Cedilote M, Brunner S, Williamson T, Cleary TP (2009) Tetrahedron 20:305–312

Jeon BW, Lee J, Kim HS, Cho DH, Lee H, Chang R, Kim YH (2013) J Biotechnol 168:201–207

Sayed M, Gaber Y, Bornadel A, Pyo SH (2016) Biotechnol Prog 32(1):83–88

Morén AK, Kumar A, Stenhagen G, Holmberg HK (2003) J Dispers Sci Technol 24(1):79–87

Kobayashi S (2006) Macromol Symp 240:178–185

Kaihara S, Fisher JP, Matsumura S (2009) Macromol Biosci 9:613–621

Kumar A, Gross RA (2000) Biomacromolecules 1:133–138

Todea A, Badea V, Nagy L, Kéki S, Boeriu CG, Péter F (2014) Acta Biochim Pol 61(2):205–210

Arumugasamy SK, Ahmad Z (2011) Asia-Pac J Chem Eng 6(3):398–405

Kikuchi H, Uyama H, Kobayashi S (2000) Macromolecules 33(24):8971–8975

Focarete MF, Scandola M, Kumar A, Gross RA (2001) J Polym Sci Part B 39:1721–1729

Yang Y, Ge Y, Zhao H, Shi W, Li Q (2011) Biocatal Biotransform 29(6):337–343

Loeker FC, Duxbury CJ, Kumar R, Gao W, Gross RA, Howdle SM (2004) Macromolecules 37(7):2450–2453

Takamoto T, Uyama H, Kobayashi S (2001) e-Polymers 4:1–6

Gorke JT, Okrasa K, Louwagie A, Kazlauskas RJ, Srienc F (2007) J Biotechnol 132(3):306–313

Piotrowska U, Sobczak M, Oledzka E, Combes C (2016) J Appl Polym Sci. doi:10.1002/APP.43728

Wu C, Zhang Z, Chen C, He F, Zhuo R (2013) Biotechnol Lett 35(10):1623–1630

Inprakhon P, Panlawan P, Pongtharankul T, Marie E, Wiemann LO, Durand A, Sieberb V (2014) Colloids Surf B 113:254–260

He F, Li S, Vert M, Zhuo R (2003) Polymer 44:5145–5151

Matsumura S, Suzuki Y, Tsukada K, Toshima K (1998) Macromolecules 31:6444–6449

He F, Li S, Garreau H, Vert M, Zhuo R (2005) Polymer 46:12682–12688

Shoda S, Uyama H, Kadokawa J, Kimura S, Kobayashi S (2016) Chem Rev 116:2307–2413

Matsumura M, Mabuchi K, Toshima K (1998) Macromol Symp 130(1):285–304

Zhou J, Wang W, Thurecht KJ, Villarroya S, Howdle SM (2006) Macromolecules 39:7302–7305

Hæffner F, Norin T, Hult K (1998) Biophys J 74:1251–1262

Kadokawa J, Kobayashi S (2010) Curr Opin Chem Biol 14:145–153

Hans M, Keul H, Moeller M (2009) Macromol Biosci 9:239–247

Sobczak M (2012) J Appl Polym Sci 125:3602–3609

Bonduelle C, Martin-Vaca B, Bourissou D (2009) Biomacromolecules 10:3069–3073

Kobayashi S, Takeya K, Sudu S, Uyama H (1998) Macromol Chem Phys 199:1729–1736

Cordova A, Iversen T, Hult K, Martinelle M (1998) Polymer 39(25):6519–6524

Poojari Y, Beemat JS, Clarson SJ (2013) Polym Bull 70:1543–1552

Wu WX, Qu L, Liu BY, Zhang WW, Wang N, Yu XQ (2015) Polymer 59:187–193

Hans M, Keul H, Moeller M (2008) Biomacromolecules 9:2954–2962

Poojari Y, Clarson SJ (2009) Silicon 1:165–172

Dai S, Li Z (2008) Biomacromolecules 9:1883–1893

Beyazkilic Z, Lligadas G, Ronda JC, Galià M, Cádiz V (2014) Macromol Chem Phys 215:2248–2259

Yang Y, Zhang J, Wu D, Xing Z, Zhou Y, Shi W, Li Q (2014) Biotech Adv 32:642–651

Kobayashi S, Makino A (2009) Chem Rev 109:5288–5353

Zhang J, Shi H, Wu D, Xing Z, Zhang A, Yang Y, Li Q (2014) Process Biochem 49:797–806

De Geus M, Peeters J, Wolffs M, Hermans T, Palmans ARA, Koning CE, Heise A (2005) Macromolecules 38:4220–4225

Zhang B, Li Y, Wang W, Wang J, Chen X (2011) Polym Bull 67(8):1507–1518

Thurecht KJ, Gregory AM, Villarroya S, Zhou J, Heise A, Howdle SM (2006) Chem Commun 42:4383–4385

Xiao Y, Coulembier O, Koning CE, Heise A, Dubois P (2009) Chem Commun 18:2472–2474

Xue L, Dai S, Li Z (2009) Macromolecules 42:964–972

Skaria S, Smet M, Frey H (2002) Macromol Rapid Commun 23:292–296

Ursu M, Frey H, Neuner I, Thomann R, Rusu M (2004) Rom Rep Phys 56(3):445–452

Kundys A, Plichta A, Florjańczyk F, Zychewicz A, Lisowska P, Parzuchowski P, Wawrzyńska E (2016) Polym Int 65(8):927–937

Ai P, Chen L, Hu D, Chen Y, Li D, Zhang B, Sha K, Wang J (2006) Chin Sci Bull 51(22):2706–2709

Hans M, Keul H, Heise A, Moeller M (2007) Macromolecules 40:8872–8880

Herrera-Kao W, Cervantes-Uc JM, Lara-Ceniceros T, Aguilar-Vega M (2015) Polym Bull 72:441–452

Takwa M, Xiao Y, Simpson N, Malmström E, Hult K, Koning CE, Heise A, Martinelle M (2008) Biomacromolecules 9:704–710

Korzhikov VA, Gusevskaya KV, Litvinchuk EN, Vlakh EG, Tennikova TB (2013) Int J Polym Sci. doi:10.1155/2013/476748

Takwa M, Simpson N, Malmström E, Hult K, Martinelle M (2006) Macromol Rapid Commun 27:1932–1936

Kumar A, Garg K, Gross RA (2001) Macromolecules 34:3527–3533

Veld MAJ, Fransson L, Palmans ARA, Meijer EW, Hult K (2009) Chem Bio Chem 10:1330–1334

Mee L, Helmich F, De Bruijn R, Vekemans JAJM, Palmans ARA, Meijer EW (2006) Macromolecules 39:5021–5027

Uyama H, Kikuchi H, Takeya K, Kobayashi S (1996) Acta Polym 47:357–360

Uyama H, Takeya K, Hoshi N, Kobayashi S (1995) Macromolecules 28(21):7046–7050

Namekawa S, Uyama H, Kobayashi S (1998) Proc Jpn Acad Ser B 74:65–68

Cai J, Hsiao BS, Gross RA (2009) Polym Int 58:944–953

Kumar A, Kalra B, Dekhterman A, Gross RA (2000) Macromolecules 33:6303–6309

De Geus M, Meulen I, Goderis B, Van Hecke K, Dorschu M, Van der Werff H, Koning CE, Heise A (2010) Polym Chem 1:525–533

Jiang Z, Azim H, Gross RA (2007) Biomacromolecules 8:2262–2269

Banerjee A, Chatterjee K, Madras G (2014) Polym Degrad Stab 110:284–289

Srivastava RK, Albertsson AC (2005) J Polym Sci A 43:4206–4216

Manzini B, Hodge P, Ben-Haida A (2010) Polym Chem 1:339–346

Eubeler JP, Bernhard M, Knepper TP (2010) Trends Anal Chem 29(1):84–100

Lucas N, Bienaime C, Belloy C, Queneudec M, Silvestre F, Nava-Saucedo JE (2008) Chemosphere 73(4):429–442

Takahashi Y, Okajima S, Toshima K, Matsumura S (2004) Macromol Biosci 4:346–353

Okajima S, Kondo R, Toshima K, Matsumura S (2003) Biomacromolecules 4:1514–1519

Osanai Y, Toshima K, Matsumura S (2004) Macromol Biosci 4:936–942

Osanai Y, Toshima K, Yoshie N, Inoue Y, Matsumura S (2002) Macromol Biosci 2:88–94

Matsumura S (2002) Japanese Patent JP2002017384 A

Shimokawa K, Kato M, Matsumura S (2011) Macromol Chem Phys 212:150–158

Kobayashi S, Uyama H, Takamoto T (2000) Biomacromolecules 1:3–5

Osanai Y, Toshima K, Matsumura S (2003) Green Chem 5:567–570

Matsumura S, Harai S, Toshima K (2001) Macromol Rapid Commun 22:215–218

Jbilou F, Dole P, Degraeve P, Ladavière C, Joly C (2015) Eur Polym J 68:207–215

Kim DY, Rhee YH (2003) Appl Microbiol Biotechnol 61:300–308

Liu F, Yang J, Fan Z, Li S, Kasperczyk J, Dobrzynski P (2012) J Biomater Sci 23:1355–1368

Yang J, Tian W, Li Q, Li Y, Cao A (2004) Biomacromolecules 5:2258–2268

Ganesh M, Dave RN, L’Amoreaux W, Gross RA (2009) Macromolecules 42:6836–6839

Ganesh M, Gross RA (2012) Polymer 53:3454–3461

Khan A, Sharma SK, Kumar A, Watterson AC, Kumar J, Parmar VS (2014) Chem Sus Chem 7:379–390

Liu J, Jiang Z, Zhang S, Liu C, Gross RA, Kyriakides TR, Saltzman WM (2011) Biomaterials 32(27):6646–6654

Liu J, Jiang Z, Zhang S, Saltzman WM (2009) Biomaterials 30(29):5707–5719

Liu J, Qiu Z, Wang S, Zhou L, Zhang S (2010) Biomed Mater 5(6):065002

Stebbins ND, Yu W, Uhrich KE (2015) Macromol Biosci 15(8):1115–1124

Acknowledgements

A. Kundys acknowledges the support of the Warsaw University of Life Sciences-SGGW within the internal project “Application of lipolytic enzymes of microbial origin in degradation of polylactide films designed for food packaging industry”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kundys, A., Białecka-Florjańczyk, E., Fabiszewska, A. et al. Candida antarctica Lipase B as Catalyst for Cyclic Esters Synthesis, Their Polymerization and Degradation of Aliphatic Polyesters. J Polym Environ 26, 396–407 (2018). https://doi.org/10.1007/s10924-017-0945-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-0945-1