Abstract

Photocrosslinked silicone acrylates are used for a wide variety of applications, such as photocurable coatings, printing inks and adhesives. Their production requires the use of a photoinitiator (PI), such as Darocur 1173 (2-hydroxy-2-methyl-1-phenyl-propan-1-one). Even if PI represents a minor part of the formulation, residual amounts may remain in the polymerized products and possibly migrate into the environment during the use of the end products and/or at their end-of-life stage. To assess its possible fate under different environmental conditions, the release of Darocur 1173 from photocrosslinked silicone acrylates and its biodegradation were investigated. Leaching tests in water were conducted on thick coating and thin coated plastic films. Results showed that approximately 90% of the amount of Darocur 1173 used to synthesize thick coatings was released within 8 days of experiment. Biodegration assays were also done to assess the biodegradation of silicone coatings and PI under experimental conditions simulating the products’ end-of-life in sewage treatment plants (aerobic conditions) or in domestic waste landfills (anaerobic conditions). Results showed no biodegradation of thick coatings and PI under anaerobic conditions. An inhibitory effect was even observed on the biodegradation of glucose used as a reference biodegradable molecule. Under aerobic conditions however, PI was totally biodegraded and used as a carbon source, unlike the silicone coating which was not biodegraded.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

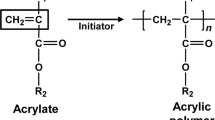

National and European regulations such as REACH (Registration, Evaluation and Autorisation of Chemicals) encourage industries to progressively replace potentially hazardous substances they might use by environmentally friendly substances. In coatings and ink industries, photo-induced crosslinking has become a mainstream technology for many applications because it provides products with better properties, sush as glossness, durability and abrasion resistance [1]. This technology is considered as a “green” one [2, 3] because it allows instant curing with low energy consumption and low emissions of volatile organic compounds. One of the application fields for UV curing is silicone release coatings. These ones are commonly obtained by photopolymerization of silicone acrylate monomers in the presence of a radical photoinitiator such as Darocur 1173 (2-hydroxy-2-methyl-1-phenylpropan-1-one) [4–7].

During the UV curing process at industrial scale in this field application, photoinitiator is generally applied in excess in order to favour its reactivity, usually at concentrations ranging from 2 to 10% (by weight of the total photocured formulation). Consequently only part of the photoinitiator is actually consumed in the reactional process [7, 8]. In the case of Darocur 1173, it is considered that only about 10% of the amounts applied are converted. The coated products therefore retain most of the amounts of Darocur initially added [8–10]. Due to the small size and molecular weight (164.2 g mol−1) of the molecule and its hydrosolubility, its migration within the coatings and transfer from the film surface into an aqueous phase seems quite possible. Green (2010) has reported that Darocur 1173 can be readily extracted from cured coatings with various solvents in Soxhlet extraction [8]. Unless the coated products are liberally washed, the residual amounts of Darocur remaining within the cured coatings are therefore available for potential release into environmental media if the products are contacted with water during their use and/or at their end-of-life stages.

Regarding the products’ end-of-life, little is known on the fate and behavior of solid polymers, and especially silicone coatings in the different waste treatment processes like wastewater treatment plants or landfills [11]. The fate of silicone in the environment has been extensively studied in the 1990s until the early 2000s by Dow Corning Company. Indeed, following a very strong market development of these products, producers have widely communicated to reassure consumers about the non-toxicity of the degradation products for themselves and for the environment. Since those years, very few studies on their end-of-life have been published [11] and to our knowledge no work has been yet published on silicone acrylates or Darocur 1173. Thus, special care has to be paid to potential emissions of photoinitiator and acrylate monomers and the fate of these substances in the environment. Although data are available from the safety data sheet of Darocur 1173 on its biodegradability under aerobic conditions (Table 1), no data have been reported yet under anaerobic conditions. In fact, the disposal of solid silicone waste varies from one country to another, but in most cases they are landfilled or incinerated. When photocrosslinked silicone materials are present in landfills, they may be degraded by chemical and/or biological processes under anaerobic conditions. Biotic and abiotic factors are interconnected. Microbial activities can have direct effets on the materials but undirect alterations are also possible through the production of aggressive metabolites and / or the changes induced in physico-chemical conditions [12, 13]. For example, microbial production of organic acids under anaerobic conditions can induce acidification of the medium [12].

The objective of the present study was therefore to develop and apply an exploratory experimental approach to assess the potential physico-chemical and biological degradation of silicone acrylates under the effect of factors which they may be exposed to during the use of the coated products or at their end-of-life stages. Leaching and hydrolysis of the silicone acrylate polymers was assessed by following the release of photoinitiator Darocur 1173 from thick coatings and thin coated plastic films at different pH. The biodegradability of these films and Darocur 1173 was also studied under aerobic and anaerobic conditions. Furthermore, the effects of these phenomena on the biodegradation of a reference biodegradable molecule (glucose) were monitored under aerobic and anaerobic conditions in order to assess a potential inhibition of microbial activity.

Elaboration and Characteristics of Test Materials

Thick UV Silicone Coating

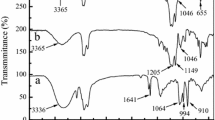

Silicone coatings supplied by Bluestar Silicones were synthesized by mixing 98% (w/w) silicone acrylate oil provided by Bluestar Silicones company (700–800 cPs at 25 °C, Mn = 8000, Mw = 20,000 g mol−1, Đ = 2.4) and 2% (w/w) photo-initiator 2-Hydroxy-2-methyl-1-phenylpropane-1-one (Darocur 1173, 97%, MW = 164.2 g mol−1, CAS N° 7473-98-5) (Fig. 1a) purchased from BASF. The mixture was stirred for 5 min, purged with nitrogen (N2) gas for 1 min to deoxygenate the system and deposited to synthesize solid films of 800 µm-thick and 2 mm-thick on Teflon plate. The conditions used for UV curing are optimized conditions, thus photocrosslinking was performed by exposing the formulation for 3 s to UV light at a wavelength of 280 nm and room temperature in a Labcure UV tunnel, consisting in a medium pressure mercury lamp operated at 300 W (Heraeus-Bulb) and a conveyor belt moving at a speed of 10 m min−1. UV exposure was done under inert atmosphere (100% N2) to avoid reaction with oxygen. A mass of 20 mg of Darocur 1173 was used in the initial formulation for the production of 1 g of thick coating.

The chemical structure of silicone acrylate oil is MD85D*M7.5 (with D* motif = SiMe (CH2)3OCH2CHOHCH2OCOCHCH2) (Fig. 1b).

M motifs = Me3SiO.

D motifs = Me2SiO2.

Thin UV Silicone Acrylate Coating on Plastic Films

The formulation prepared as explained above was deposited as a 1 µm-thick coating on 86 µm-thick LDPE film (low density polyethylene) at a load of 2.57 g m−2.

The coated films were placed on a conveyor moving at 100 m min−1 (wich corresponds to a residance time of about 0.2 s) and cured on a pilot machine equipped with a solvant headless five cylinders (Rotomec Brand) by exposing to UV light at 280 nm using a mercury lamp (UV HONLE Princoncept) set at 100 W cm−2. Coated films were taken immediately at the exit of the machine and the amount of coating deposited mentioned above (g m−2) was measured by X-ray fluorescence. A mass of 3 mg of Darocur 1173 was used in the initial formulation for the production of 5.21 g thin-film coated LDPE test samples (see section below).

The Rigaku NEX QC is a Benchtop Energy Dispersive X-ray Fluorescence (EDXRF) spectrometer which was used for elemental analysis of silicon in film coatings on solid substrates.

In EDXRF, low energy “soft” X-rays (1-50 keV) are emitted from an X-ray tube. These source X-rays enter the sample and cause the atoms in the sample to fluoresce their own characteristic low energy “soft” Xrays. These fluorescent X-rays are captured by the detector and counted by a multi-channel analyzer. The NEX QC software then calculates the concentration of each element present in the sample.

The X-ray analysis gives a signal proportional to the Si-atoms concentration in the coating. Calibration curves in X-ray units are used to calculate the actual silicone coat.

Leaching Tests’ Protocol

Aliquote masses of 1 g of thick-films and 5.21 g of thin-film coated LDPE were separately cut into small pieces of 1 cm2 and introduced into 150 mL high-density polyethylene flasks (HDPE) containing 50 mL of de-ionized water (pH = 6.5; 18 MΩ cm−1, Veolia water STI) for thick films and in 50 mL high-density polyethylene flasks (HDPE) containing 20 mL of de-ionized water for thin films. The flasks were placed in an orbital shaker operated at 9 rpm and room temperature (25 °C) for 15–20 days. All experiments were performed in triplicates. Several types of blanks were also performed in triplicates in which flasks containing (i) de-ionized water alone or (ii) a solution of Darocur 1173 at a known concentration in de-ionized water at different pH, or (iii) uncoated LDPE pieces and de-ionized water, were treated in the same manner as the assays. The solutions were sampled at different times and analyzed for Darocur 1173 by UV spectrophotometry. The main possible products from Darocur photo-degradation (benzaldehyde and benzoic acid [4]) were analysed by U-HPLC (Ultra-High Performance Liquid Chromatography).

Leaching tests with thin-film coated on LDPE were also performed following the same protocol but using acidic (pH 2 with HCl Chimie-Plus Laboratories, 37%) or alkaline solutions (pH 12 with NaOH Chimie-Plus Laboratories, 98%) instead of de-ionized water as a leachant.

Analytical Methods

Darocur 1173 was analyzed using a Jasco V 630 Spectrophotometer set at a wavelength of 247 nm. Quartz cells of 1 cm path length were used, with de-ionized water as a reference. A calibration range of Darocur 1173 was prepared in de-ionized water from 1.56 to 20 mg L−1. The calibration curve was linear with optical density ranging from 0 to 0.89. Leaching solutions were diluted before analysis, if necessary, to be within this range of absorbance.

U-HPLC was used to separate Darocur 1173 from its possible photo-products before specific analysis. Benzaldehyde and Darocur were analysed using a ThermoFisher Scientific series instrument equipped with a C18 column operated at 20 °C (X-Bridge BEH, 2,5 µm, 4.6 × 75 mm) and a DAD detector set at 247 nm. The mobile phase was a water/acetonitrile solution with 0.1% formic acid pumped at a flow rate of 0.8 L min−1, which composition was varied as follows: 85:15 w:ac (v/v) to 60:40 w:ac (v/v) for the first 12 min, then 85:15 (v/v) w:ac for 3 min followed by 5 min of stabilisation, where w = water and ac = Acetonitrile. Calibration was performed between 1 and 10 mg L−1 with Darocur 1173 and from 0.1 to 0.5 mg L−1 for benzaldehyde. The LOQ (Limite of quantification) for both benzaldehyde and Darocur 1173 was 100 µg L−1.

Benzoic acid was analyzed in the same manner, but the mobile phase was a 50:50 (v/v) water/acetonitrile solution with 0.1% formic acid pumped and UV detection was set at 234 nm. Retention time was 2 min. Calibration was done between 0.5 and 2 mg L−1 and the LOQ was 100 µg L−1.

Microbiological Degradation

Aerobic Biodegradation

Aerobic biodegradability was assessed using OxiTop systems (WTW Ltd) at 30 °C according to OECD 301F guidelines [14]. The device used is illustrated in Fig. 2a. Glass bottles of 500 mL were used in which were introduced 88 mL of de-ionized water, 2 mL of activated sludge taken from the municipal wastewater treatment plant of La Feyssine (Villeurbanne, France) and previously starved for 2 weeks, and 10 mL of minimal medium (KH2PO4 = 28.25 g L−1, K2HPO4 = 146.08 g L−1, CaCl2, 2H2O = 3.66 g L−1, NH4Cl = 28.64 g L−1, MgSO4, 7H2O = 3.66 g L−1, FeSO4, 7H2O = 0.70 g L−1, ZnSO4, 7 H2O = 0.40 g L−1).

Four types of samples were tested as substrates: (a) 800 µm thick-films (30 mg) ; (b) pure silicone oil (50 mg) or (c) pure Darocur 1173 (50 and 100 mg) and (d) thin-film coated LDPE (5.21 g). LDPE films were cut into pieces of 1 cm2 prior to incubation. Some bottles were spiked with 100 mg of glucose used as a readily biodegradable reference cosubstrate to assess possible inhibitory effect of tested materials.

Anaerobic Biodegradation

Biochemical Methane Potential (BMP) was measured to assess anaerobic biodegradation following USEPA, OPPTS 835.5154 guidelines [15]. The device used is illustrated in Fig. 2b. Glass bottles of 250 mL were used, in which were introduced 75 mL of anaerobic sludge taken from the municipal wastewater treatment plant of La Feyssine (Villeurbanne, France) and previousely starved for 2 weeks, and 25 mL of mineral medium (KH2PO4 = 0.97 g L−1, Na2HPO4, 12H2O = 4.03 g L−1, NH4Cl = 1.91 g L−1, CaCl2, 2H2O = 0.27 g L−1, MgCl2, 6 H2O = 0.36 g L−1, H3BO3 = 0.005 g L−1, ZnCl2 = 0.005 g L−1, CuCl2 = 0.003 g L−1, CoCl2, 6H2O = 0.1 g L−1). Four types of samples were tested as substrates: (a) 800 µm thick-films (30 mg), (b) pure silicone oil (50 mg) or (c) pure Darocur 1173 (50 and 100 mg); (d) thin-film coated LDPE (5.21 g). LDPE films were cut into pieces of 1 cm2 prior to incubation. Some bottles were spiked with 900 mg of glucose used as a readily biodegradable reference cosubstrate to assess possible inhibitory effect of tested materials.

Biogas volumetric production was monitored by periodical manometric measurements (Digitron manometre) done at 35 °C, and the results expressed as cumulative volume of biogas under normal conditions of temperature and pressure (0 °C, 1 Atm).

Biogas was regularly analyzed for CH4, CO2, O2 and N2 using a portable Agilent G2890A-P200H gas chromatograph equipped with a microcatharometer detector. Gas samples were injected simultaneously in two parallel columns (PoraPlotU 8 m × 0.32 mm ID, 0.5 µdf and Molsieve 55 Å 10 m/PPU 3 m) and helium was used as a carrier gas. Standard mixtures (Spancan Calibration Gaz) of CO2 and CH4 at known concentrations diluted at 40 or 60% in air were used for calibration. Data acquisition was performed with Soprane (SRA Instruments) software. Methane contents in biogas between two sampling times were estimated by linear interpolation.

Blanks and Replicates

Blanks with no substrates nor glucose and blanks with glucose alone (100 mg and 900 mg for aerobic and anaerobic tests, respectively) were carried out following the same protocol to assess the endogenous activity of the sludge and its potential chemotrophic activity. Other blanks were followed by incubating uncoated LDPE pieces.

All assays and blanks were perfomed in triplicates. Assays using coated LDPE films were not carried out at the same time as with thick films, and therefore two series of blanks were performed (blanks with no substrates nor glucose and blanks with glucose).

Results and Discussion

The experimental methodology developed in this study aimed at evaluating the potential release of the residual amounts of Darocur 1173 from the silicone films into the environment via transfer into water. Leaching tests were done in that purpose. It was also considered necessary to evaluate the potential biotic and abiotic degradation of the films since these phenomena may accelerate the release of Darocur. Leaching tests were therefore done at different pH to estimated potential acidic or alkaline hydrolyses of the films, and biodegradation tests were conducted.

Leaching of Darocur 1173 from Thick and Thin Films

Results obtained with 2 mm-thick and 800 µm-thick coatings are shown in Fig. 3. It was observed that the photo-initiator used in the formulation (i.e. 20 mg g−1 of sample) was strongly released (up to 90%) from the two tested materials within about 8 days of leaching. This result suggested a recombination of the unreacted free radicals into the original molecule (Darocur 1173) during silicone acrylates photocrosslinking. It indicated that Darocur was not strongly trapped within or bound to the silicone matrix.

Figure 3 also showed that the kinetics of leaching was dependent upon the thickness of silicone thick coating. Leaching was faster when the thickness decreased. Close to 18 mg of Darocur were released in 30 min from the 800 µm-thick samples, as compared to about 5 mg observed from the 2 mm-thick samples. However, after 4 days the final quantity of photoinitiator released is quite similar and could be attributed to the time required to migrate out of the sample. According to Green, 2010 [8], migration of Darocur 1173 can be influenced by other factors, including above all the polymer matrix itself, the entanglement of free photoinitiator in the polymer, the degree of cross-linking and the nature of the medium in which it is used.

Results obtained with thin films are shown in Fig. 4. It can be seen that around 4.6 mg (corresponding to ca. 22% of the Darocur 1173 used in the formulation) was released into water in 15 days from silicone coated LDPE. The release of Darocur was therefore found to be much lower from thin coated films (Fig. 4) than from thick films (Fig. 3). This observation was explained by the fact that photocrosslinking could be more effective within a thin film than thick ones during UV exposure. Indeed, it has been demonstrated that highly cross-linked polymers reduce the extraction of the photoinitiator by entanglement [8]. The thick films provided by the manufacturer were used in the present study to optimize the analytical methodology. They were not meant to be representative of any industrial applications fields since their thickness (mm) is much higher than that of the films (µm) actually used in practice as release coatings for adhesives. Given the very different thicknesses of the two types of coatings, the degree of crosslinking in each film is very probably quite different.

Figure 4 also showed that Darocur leaching from coated LDPE films was affected by the pH of the leaching solution. Over 15 days of leaching, 42% of Darocur 1173 was released at pH 2, 22% at pH 6 and 25% at pH 12. Blanks with uncoated LDPE films confirmed that under the conditions of the leaching tests these films did not release any compound which may have interferred with Darocur 1173 analysis. Moreover, the stability of Darocur 1173 in aqueous solutions at the different pH was also verified. In order to explain the differences of Darocur 1173 release at different pH, silicon released in solution from silicone coating was analysed by Inductively Coupled Plasma-Optical Emission Spectroscopy (ICP-OES) which gives the rate of silicone network hydrolysis (Fig. 4). Furthermore, after 15 days of leaching the basic solution became cloudy. This phenomenon could explain a possible significant release of Darocur 1173 after silicone layer hydrolysis but whose analysis was limited by silicon accumulation in solution or physico–chemical interactions (probably adsorption) between silicone byproducts and Darocur 1173. This could be also explained by the Polyacrylic acid (PAA) formation for which solubility increased with increasing pH (pH ≥8) [16].

Figure 4 shows that a significant amount of released silicon was not necessarily followed by a significant amount of released Darocur 1173. Indeed, a high rate of silicon at pH 12 was not linked with a large release of Darocur 1173. Similar results by using different silicone elastomers were obtained by Laubie, 2012, regarding catalyst concentrations, his findings are completely the opposite in all conditions (pH 2, pH 6, pH 12) with a very high Si concentration at pH 12 but a very high concentration of catalyst at pH 2 indicating that catalyst is not strongly trapped by the silicone matrix (no chemical or physical bonds) [11]. Other studies showed that the solubility of silica increases at high pH especially for pH >9 [17]. In fact in organic chemistry, acids or bases promoted hydrolysis reactions, proceeding through a nucleophilic substitution mechanism [18]. In base catalysed hydrolysis, an electrophilic carbon acts as a reaction site for nucleophilic attack. Silicon is much more electrophilic than carbon and, thus, more prone to undergo hydrolysis reactions [19]. Indeed, Goudie et al., 1998 show that hydrolytic degradation of silicone elastomers only becomes appreciable at pH values of the aqueous media smaller than 2.5 and greater than 11 [20].

The relatively strong release of PI into water observed in the leaching tests within a relatively short time (around 4 days or less) therefore revealed the mobility of the residual molecules of PI remaining in the silicone coating after its synthesis. In scenarios where coated materials would be contacted with water, eitheir during their use (for example exposure to rain in case of outdoors uses) or at their end-of-life stages (domestic wastewater treatment plants or municipal solid waste sanitary landfills), PI may migrate within the coating and be released into water and transported to environmental targets with potential impacts.

Biodegradability Under Aerobic Conditions

Results obtained with 800 µm thick silicone coatings containing Darocur 1173, silicone oil or Darocur 1173 are shown respectively in Figs. 5 and 6. Respiration of the blanks spiked with glucose indicated that the starved sludge was in a good state with around 70% glucose biodegradation. The assays with Darocur 1173 spiked with glucose showed that Darocur did not inhibit glucose biodegradation. Similarly, the assays with silicone coating or silicone oil spiked with glucose also showed no inhibitory effect on glucose biodegradation. Silicone coatings and silicone oil used as sole carbon sources were not biodegraded, unlike Darocur which induced a respiration proportional to its concentration. These results were consistent with those of [21], which showed that synthetic polymers (crosslinked ones in particular) were inert to microbial degradation compared with natural macromolecules since crosslinking limits the mobility of polymer chains and the accessibility of enzymes to the polymer.

Indeed, the biodegradation of silicon cross-linked polymers also depends on the hydrophobicity/hydrophilicity of the surface. This parameter influences both the swelling ability of the polymer in the polar water solvent as well as the ability of bacteria and enzymes to adhere to the surface, from which every biodegradation phenomenon starts.

Figure 7 showed that uncoated LDPE films (blanks) were almost not biodegraded since the recorded cumulated oxygen consumption was very low. The respiration observed with coated LDPE films was 16.1 ± 2.1 mg O2, possibly due to the biodegradation of Darocur 1173 released from the coating. The assays with coated and uncoated LDPE films spiked with glucose revealed no inhibitory effect on glucose biodegradation, as already observed above with thick silicone, silicon oil and Darocur itself.

Biodegradability Under Anaerobic Conditions

Results are shown in Figs. 8 and 9. The blanks with glucose as sole carbon source showed the good activity of the microbial inoculum used with about 60% glucose degradation achieved after 40 days. However, when the coatings, silicon oil or Darocur were used as sole carbon sources, almost no biogas production was observed, indicating that these substrates were almost not biodegraded under anaerobic conditions. This result confirmed the information from previously published studies [11, 22, 23]. It could be explained by the possible need of O2 in the initial steps of biodegradation, as described for example in the biodegradation of lignin [24] or poly-aromatic hydrocarbons studies [25] where aerobic bacteria and fungi were mostly responsible of biodegradation. It was also shown that the initial intracellular attack of organic pollutants was an oxidative process with activation and introduction of oxygen as key enzymatic reactions catalyzed by oxygenases and peroxidases [26]. This result could be also explained by the lack of adapted microorganisms in the inoculum used. The relatively slow growth rate of anaerobic microorganisms makes any adaptation significantly longer than for aerobic microorganisms.

The assays performed with silicon oil spiked with glucose (Fig. 9a) revealed no significant inhibition on glucose biodegradation. However, a slight inhibition of glucose degradation was observed with the 800 µm thick silicone coating, and to a lower extent the 2 mm thick silicone coating, and with Darocur 1173 (Fig. 9b). This result confirmed that the inhibitory effect on glucose biodegradation was mostly attributed to Darocur 1173 and not to the silicon matrix, as observed under aerobic conditions.

Figure 10 showed that uncoated LDPE films (blanks) were almost not biodegraded since the recorded cumulated biogas production was very low. Biogas production observed with coated LDPE films was similar to blank samples. The assays with coated and uncoated LDPE films spiked with glucose revealed no inhibitory effect on glucose biodegradation compared to inhibitory observed above with thick silicone coatings and Darocur 1173 itself. This result could be explained either by a very low amount of Darocur 1173 initially used to synthesize silicone coating (5 mg). Indeed, leaching test at pH 6 which is close to sludge pH (pH 8) has shown that 22% of Darocur 1173 was released from coated LDPE films. This low amount could be released in sludge without any effect on biogas production.

Conclusion

The present study provides experimental data and information which contribute to the assessment of the possible fate and environmental impacts of photocrosslinked silicone acrylates during their use as coatings on various types of materials, and at the end-of-life stages of the coated materials.

The potential release of the residual amounts of photo-initiator (PI) Darocur 1173 remaining within silicone coating after its synthesis was evaluated by conducting agitated batch leaching tests in water on small pieces of thick coatings and thin coated plastic films. Results showed that depending on the thickness of the films and the pH of the leaching solutions, approximately 20 to 90% of the amount of Darocur 1173 used to synthesize the coatings was released within 8 days of leaching with a liquid to solid ratio of 10 mL g−1. These results revealed that the residual molecules of PI were not strongly trapped within or bound to the silicone matrix. Therefore, in scenarios where coated materials would be contacted with water during their use or at their end-of-life stages, PI may migrate within the coating and be released into water with potential environnmental impacts. Under the experimental conditions used here, the leaching process was found to be relatively rapid (equilibrium reached within a few days), favored by acidic pH and faster with thin films.

Biodegration assays were also done to assess the potential fate of silicone coatings and PI under the effects of biotic factors simulating the environmental conditions of the products’ end-of-life stages in sewage treatment plants (aerobic conditions) or municipal solid waste sanitary landfills (anaerobic conditions). Results revealed no biodegradation of silicone coatings and PI under anaerobic conditions, where an inhibitory effect was even observed on the biodegradation of glucose used as a reference biodegradable molecule. Under aerobic conditions however, PI was totally biodegraded and used as a carbon source by the microorganisms, unlike the silicone coating which was not biodegraded. The recalcitrance of silicone coating to biodegradation under both aerobic and anaerobic conditions was attributed to the cross-linked domains which provided a certain rigidity to the films and limited the access of water and microorganisms to the polymeric network and therefore their biodegradation.

The methodology followed here may be used to evaluate alternative photoinitiators in the objective to substitute potentially toxic photoinitiators such as Darocur 1173 by more environmentally friendly formulations. In parallel, further studies would be needed in order to reduce the dosage of photoinitiator currently used in excess in photocrosslinked formulations.

References

Dietliker K, Husler R, Birbaum J-L, Ilg S, Villeneuve S (2007) J Prog Org Coat 58:146–157

Phillips R (1978) J Oil Colour Chem Assoc 61:233–240

Eichler J, Herz CP, Naito I, Schnabel W (1980) J Photochem 12:225–234

Seidl B, Liska R, Grabner G (2006) J. Photochem Photobiol 1(180):109–117

Kaczmarek H, Vukovic-Kwiatkowsk I (2012) J Express Polym Lett 1(6):78–94

Belaidi O, Bouchaour T, Maschke U (2013) J Struct 2013:1–9

Gruber H-F (1992) Prog Polym Sci 17:953–1044

Green WA (2010) Industrial photoinitiators: A technical guide. Taylor and Francis Group, Boca Raton.

Jang SC, Yi SC, Hong JW (2005) Ind Eng Chem 11(6):964–970

WIPO GREEN Databe (2015) Nanoparticle Photoinitiators for UV Curing Printing Inks, Varnishes and Glues, Germany. Accessed https://www3.wipo.int/wipogreen-database/SearchDetailPage.htm?query=Darocur%201173&type=all&showLi=Chemi&id=TGREEN17806

Laubie B, Ohannessian A, Desjardin V, Germain P (2012) J Polym Environ 20: 1019–1026

Mata-Alvarez J, Macé S, Llabrés P (2000) Bioresour Technol 74:3

Iglesias Jimenez E, Perez Garcia V (1991) Resour Conserv Recycl 6:45

OECD (1993) OECD Guidelines for testing of chemicals, OECD 301 A: Doc die-away-test; OECD 301 B: CO2 evolution test; OECD 301 C: modified MITI test (1); OECD 301 D: closed bottle test; OECD 301 E: modified OECD screening test; OECD 301 F: manometric respirometry test; OECD 302 B: Zahn-Wellens/EMPA test

US Environmental Protection Agency (1996) Prevention, pesticides and toxic substances guidelines, “public drafts” for guidelines OPPTS 835. 3110, 835. 3120, 835. 3170, 835. 3180, 835. 3200, 835. 3210, 835. 5045, 835.5154 and 835.3400

Mori H, Muller AHE (2003) J Top Curr Chem 228:1–37

Alexander GB, Heston WM, Iler RK (1954) J Phys Chem 58(6):453–455

Bruice PY (1998) Organic chemistry, 2 edn. Prentice Hall, Upper Saddle River

Hamilton R (2001) Hydrolysis of silicone polymers in aqueous systems. Lakehead University. Faculty of graduate studies. Department of Chemistry. Thunder Bay, Ontario

Goudie JL, Owen MJ, Orbeck (1998) Dow corning corporation. Midland

Huang SJ (1989) Biodegradable polymers. In: Eastmond G, Ledwith A, Russo S, Sigwalt P Comprensive polymer science, vol 6.(Pergamon Press, Oxford, 597–607

Watts RJ, Kong S, Haling C-S, Gearhart L, Frye CL, Vigon BW (1995) Water Res 29(10):2405–2411

Smith DM, Lehmann R-G, Nayaran R, Kozerski G-E, Miller J-R (1998) Compost Sci Util 6:6–12

Crestini C, Argyropoulos DS (1998) J Bioorg Med Chem 6:2161–2169

Haritash AK, Kaushik CP (2009) J Hazard Mater 169:1–15

Fritsche W, Hofrichter M (2000) In: Rehm H-J, Reed G, Puhler A, Stadler P (eds). Biotechnology, Wiley, Weinheim, pp. 146–155

Acknowledgements

This project was carried out thanks to FUI-ECOSILAC funding (Unique Interministerial Fund-ECOconception of new SILicones ACrylates). The authors acknowledge the analytical department of the DEEP laboratory for contributions in this study. The authors would also thank Bluestar Silicones Company, for supplying silicone coatings.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Ouali, S., Louis, Y., Germain, P. et al. Leaching and Biodegradation of Darocur 1173 used as a Photo-Initiator in the Production of Photocrosslinked Silicone Acrylates. J Polym Environ 26, 244–253 (2018). https://doi.org/10.1007/s10924-017-0939-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-0939-z