Abstract

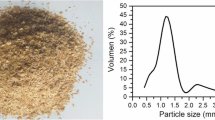

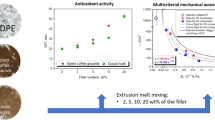

The utilization of the coffee husk fiber (CHF) from the coffee industry as a reinforcing filler in the preparation of a cost-effective thermoplastic based composite was explored in this study. The chemical composition and thermal properties of the CHF were investigated and compared with those of wood fiber (WF). CHF proved to be mainly composed of cellulose, hemicellulose and lignin, and exhibited similar thermal behavior to WF. High density polyethylene (HDPE) composites with CHF loadings of from 40 to 70% were prepared using melt processing and extrusion. The processing properties, mechanical behavior, water absorption and thermal performance of these composites were investigated. The effect of maleated polyethylene (MAPE) used as a coupling agent on the composite was explored. The experimental results showed that increasing the CHF loading in the HDPE matrix resulted in an increase in the modulus and thermal properties of the composites, but resulted in poor water resistance. The addition of a 4% MAPE significantly improved the interfacial behavior of the hydrophilic lignocellulosic fiber and the hydrophobic polymer matrix.

Similar content being viewed by others

References

Daglia M, Papetti A, Gregotti C, Bertè F, Gazzani G (2000) In vitro antioxidant and ex vivo protective activities of green and roasted coffee. J Agric Food Chem 48:1449–1454

Ponte S (2002) The ‘latte revolution’? Regulation, markets and consumption in the global coffee chain. World Dev 30:1099–1122

Oliveira LS, Franca AS (2015) An overview of the potential uses for coffee husks. Coffee Health Dis Prev 31:283–291

Adams M, Dougan J (1981) Biological management of coffee processing wastes. Trop Sci 23:177–195

Murthy PS, Naidu MM (2012) Sustainable management of coffee industry by-products and value addition—a review. Resour Conserv Recycl 66:45–58

Mussatto SI, Machado EMS, Martins S, Teixeira JA (2011) Production, composition, and application of coffee and its industrial residues. Food Bioprocess Technol 4:661–672

Givens DI, Barber WP (1986) In vivo evaluation of spent coffee grounds as a ruminant feed. Agric Waste 18:69–72

Adi AJ, Noor ZM (2009) Waste recycling: utilization of coffee grounds and kitchen waste in vermicomposting. Bioresour Technol 100:1027–1030

Kondamudi N, Mohapatra SK, Misra M (2008) Spent coffee grounds as a versatile source of green energy. J Agric Food Chem 56:11757–11760

Kante K (2012) Spent coffee-based activated carbon: Specific surface features and their importance for H2S separation process. J Hazard Mater 201–202:141–147

Panusa A, Zuorro A, Lavecchia R, Marrosu G, Petrucci R (2013) Recovery of natural antioxidants from spent coffee grounds. J Agric Food Chem 61:4162–4168

Caetano NS, Silva VnFM, Melo AC, Martins AA, Mata TM (2014) Spent coffee grounds for biodiesel production and other applications. Clean Technol Environ 16:1423–1430

Ismail H, Nizam J, Abdul Khalil H (2001) White rice husk ash filled natural rubber/linear low density polyethylene blends. Int J Polym Mater 48:461–475

Sreekala M, Kumaran M, Thomas S (2001) Stress relaxation behaviour in oil palm fibres. Mater Lett 50:263–273

Luz S, Gonçalves A, Del’Arco A (2007) Mechanical behavior and microstructural analysis of sugarcane bagasse fibers reinforced polypropylene composites. Compos Part A 38:1455–1461

Faruk O, Bledzki AK, Fink H-P, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37:1552–1596

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33

Keener T, Stuart R, Brown T (2004) Maleated coupling agents for natural fibre composites. Compos Part A 35:357–362

García-García D, Carbonell A, Samper M, García-Sanoguera D, Balart R (2015) Green composites based on polypropylene matrix and hydrophobized spend coffee ground (SCG) powder. Compos Part B 78:256–265

Wise LE, Murphy M, D ADIECO A (1946) A chlorite holocellulose, its fractionation and bearing on summative wood analysis and studies on the hemicelluloses. Paper 122:35–43

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Jonoobi M, Niska KO, Harun J, Misra M (2009) Chemical composition, crystallinity, and thermal degradation of bleached and unbleached kenaf bast (Hibiscus cannabinus) pulp and nanofibers. BioResources 4:626–639

Vallo C, Kenny JM, Vazquez A, Cyras VP (2004) Effect of chemical treatment on the mechanical properties of starch-based blends reinforced with sisal fibre. J Compos Mater 38:1387–1399

Liu D, Han G, Huang J, Zhang Y (2009) Composition and structure study of natural Nelumbo nucifera fiber. Carbohydr Polym 75:39–43

Bekalo SA, Reinhardt HW (2010) Fibers of coffee husk and hulls for the production of particleboard. Mater Struct 43:1049–1060

Liu W, Mohanty A, Drzal L, Askel P, Misra M (2004) Effects of alkali treatment on the structure, morphology and thermal properties of native grass fibers as reinforcements for polymer matrix composites. J Mater Sci 39:1051–1054

Li T, Wolcott M (2005) Rheology of wood plastics melt. Part 1. Capillary rheometry of HDPE filled with maple. Polym Eng Sci 45:549–559

López J, Boufi S, El Mansouri N, Mutjé P, Vilaseca F (2012) PP composites based on mechanical pulp, deinked newspaper and jute strands: a comparative study. Compos Part B 43:3453–3461

Dányádi L, Janecska T, Szabó Z, Nagy G, Móczó J, Pukánszky B (2007) Wood flour filled PP composites: compatibilization and adhesion. Compos Sci Technol 67:2838–2846

Yang HS, Kim HJ, Park HJ, Lee BJ, Hwang TS (2007) Effect of compatibilizing agents on rice-husk flour reinforced polypropylene composites. Compos Struct 77:45–55

Sannigrahi P, Ragauskas AJ, Tuskan GA (2010) Poplar as a feedstock for biofuels: a review of compositional characteristics. Biofuel Bioprod Biorefin 4:209–226

Li Q, Matuana LM (2003) Effectiveness of maleated and acrylic acid-functionalized polyolefin coupling agents for HDPE-wood-flour composites. J Thermoplast Compos 16:551–564

Aithal US, Aminabhavi TM, Cassidy PE (1990) Sorption and diffusion of monocyclic aromatic compounds through polyurethane membranes. Acs Symp Ser 423:351–376

Espert A, Vilaplana F, Karlsson S (2004) Comparison of water absorption in natural cellulosic fibres from wood and one-year crops in polypropylene composites and its influence on their mechanical properties. Compos Part A 35:1267–1276

George J, Bhagawan S, Thomas S (1998) Effects of environment on the properties of low-density polyethylene composites reinforced with pineapple-leaf fibre. Compos Sci Technol 58:1471–1485

Thwe MM, Liao K (2003) Durability of bamboo-glass fiber reinforced polymer matrix hybrid composites. Compos Sci Technol 63:375–387

Rozman H, Peng G (1998) The effect of compounding techniques on the mechanical properties of oil palm empty fruit bunch–polypropylene composites. J Appl Polym Sci 70:2647–2655

Arbelaiz A, Fernandez B, Ramos J, Retegi A, Llano-Ponte R, Mondragon I (2005) Mechanical properties of short flax fibre bundle/polypropylene composites: influence of matrix/fibre modification, fibre content, water uptake and recycling. Compos Sci Technol 65:1582–1592

Acknowledgements

The authors are thankful to the financial support from National Key Technologies R&D Program of China (No. 2012BAD32B04) and Fundamental Research Funds for the Central Universities (2572015AB07).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, L., Mu, B., Yi, X. et al. Sustainable Use of Coffee Husks For Reinforcing Polyethylene Composites. J Polym Environ 26, 48–58 (2018). https://doi.org/10.1007/s10924-016-0917-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0917-x