Abstract

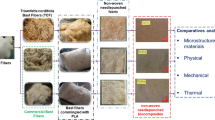

This work is aimed to study the suitability of the wooden backbone of Opuntia ficus indica cladodes as reinforcement for the production of bio-composites. The wooden backbone can be extracted from O. ficus indica cladodes, which constitute a very relevant agricultural scrap, and is characterized by a thick walled cellular structure. In view of its potential in poly-lactic acid (PLA) matrix bio-composite production, two different possible applications were examined. In the first alternative, the wooden backbone was used in replacement of flax fibers for the production of fully consolidated bio-composites. Results obtained have shown that, though being characterized by lower properties compared to those of flax fiber composites, the opuntia actually works as an efficient reinforcement for PLA/wood flour matrix, increasing the flexural strength and elongation at break. In the second alternative, the cellular structure was used for the production of a sandwich bio-composite with a PLA/wood flour skin. In this case, the very high interlaminar adhesion strength between the skin and the core was considered as an indication of the potentiality of this material for the production of high strength sandwich structures. As a confirmation of this, no interlaminar debonding was observed during short beam tests.

Similar content being viewed by others

References

Nabi Saheb D, Jog JP (1999) Adv Polym Technol 18(4):351–363

Gowda TM, Naidu ACB, Chhaya R (1999) Compos Part A-Appl S 30:277–284

Maffezzoli A, Calò E, Zurlo S, Mele G, Tarzia A, Stifani C (2004) Compos Sci Technol 64:839–845

Campaner P, D’Amico D, Ferri P, Longo L, Maffezzoli A, Stifani C, Tarzia A (2010) Macromole Symp 296:526–530

Li Y, Mai YW, Ye L (2000) Compos Sci Technol 60:2037–2055

Nunez AJ, Aranguren MI, Berglund LA (2006) J Appl Polym Sci 101:1982–1987

Okubo K, Fujii T, Yamamoto Y (2004) Compos Part A-Appl S 35:377–383

Joseph S, Sreekala MS, Oommen Z, Koshyc P, Thomas S (2002) Compos Sci Technol 62:1857–1868

Esmeraldo MA, Barreto AC, Freitas JEB, Fechine PBA, Sombra ASB, Corradini E, Mele G, Maffezzoli A, Mazzetto SE (2010) BioResour 5(4):2478–2501

Mehta G, Drzal LT, Mohanty AK, Misra M (2010) J Appl Polym Sci 99:1055–1068

Lee SH, Wang S (2006) Compos Part A-Appl S 37:80–91

Dweib MA, Hu B, O’Donnell A, Shenton HW, Wool RP (2004) Compos Struct 63:147–157

Osei-Antwi M, de Castro J, Vassilopoulos AP, Keller T (2013) Constr Build Mater 41:231–238

Sadler RL, Sharpe M, Panduranga R, Shivakumar K (2009) Compos Struct 90:330–336

Kepler JA (2011) Compos Sci Technol 71:46–51

Saenz C (2000) J Arid Environ 46:209–225

Malaininea ME, Dufresne A, Dupeyre D, Mahrouza M, Vuonga R, Vignon MR (2003) Carbohyd Polym 51:77–83

Malainine ME, Mahrouz M, Dufresne A (2004) Macromol Mater Eng 289:855–863

Colajanni S, De Vecchi A, Fiore V, Lanza Volpe A, Valenza A (2010) Materiale isolante a base di cactacee, pannello realizzato con detto materiale e relativo processo di produzione, Italian patent IT2010RM00355 20100630

Albamonte F (2008) Realizzazione di pannelli isolanti termico-acustici per l’edilizia a base di legno di opunzia, Italian Patent IT2008PA00023 20081016

Liu X, Zou Y, Li W, Cao G, Chen W (2006) Polym Degr Stab 91:3259–3265

Gibson LJ, Ashby MF (1997) Cellular Solids: Structure and Properties. Cambridge University Press, Cambridge

Greco A, Lionetto F (2009) Polym Eng Sci 49(6):1142–1150

Salomi A, Greco A, Pacifico T, Rametta R, Maffezzoli A (2011) Adv Polym Tech. doi: 10.1002/adv.20267

Gere JM, Timoshenko SP (1997) Mechanics of Materials, PWS Publishing Company, Boston. Hibbeler, R.C

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Greco, A., Gennaro, R., Timo, A. et al. A Comparative Study Between Bio-composites Obtained with Opuntia ficus indica Cladodes and Flax Fibers. J Polym Environ 21, 910–916 (2013). https://doi.org/10.1007/s10924-013-0595-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-013-0595-x