Abstract

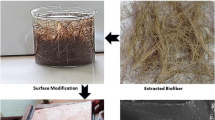

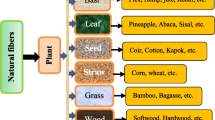

This study focuses on the development of needle-punched nonwoven composites reinforced with a Triumfetta cordifolia (TC) bast fiber based on a polylactide (PLA) matrix. Flax and hemp fibers, already known for their use in automotive applications, are used as a reference for comparison purposes. TC bast fibers from the equatorial region of Cameroon were extracted by a water retting process. Nonwoven felts were obtained by mixing TC fibers with PLA (50:50 weight ratio) through carding-napping process. The composite materials were obtained by thermocompression of the nonwoven felts with two thickness ranges (2 and 3 mm). The results obtained in tensile and flexural tests showed that composite materials with an optimal thickness of 2 mm displayed better mechanical performances. The anisotropy of the mechanical properties in traction and flexion of these composites was highlighted. It was found that the tensile and flexural mechanical properties in the transverse direction are always superior to those in the machine direction. Compared to flax or hemp nonwoven-reinforced biocomposites, TC fibers-based nonwoven biocomposites showed slightly lower maximum tensile and flexural stiffness values of 2882.7 MPa and 3908.6 MPa respectively. Thermogravimetric analysis revealed that the addition of the plant fibers increased the thermal stability of PLA and the ash content to 8%.

Graphical Abstract

Similar content being viewed by others

Data Availability

Data will be made available on request.

References

Lee, B.-H., Kim, H.-S., Lee, S., Kim, H.-J., Dorgan, J.R.: Bio-composites of kenaf fibers in polylactide: role of improved interfacial adhesion in the carding process. Compos. Sci. Technol. 69(15–16), 2573–2579 (2009). https://doi.org/10.1016/j.compscitech.2009.07.015

Alves, C., Ferrão, P.M.C., Silva, A.J., Reis, L.G., Freitas, M., Rodrigues, L.B., Alves, D.E.: Ecodesign of automotive components making use of natural jute fiber composites. J. Clean. Prod. 18(4), 313–327 (2010). https://doi.org/10.1016/j.jclepro.2009.10.022

Merotte, A., Le, D., Bourmaud, A., Behlouli, K., Baley, C.: Mechanical and acoustic behaviour of porosity controlled randomly dispersed flax/PP biocomposite. Polym. Test. 51, 174–180 (2016). https://doi.org/10.1016/j.polymertesting.2016.03.002

Carus, M., Partanen, A.: Bioverbundwerkstoffe: naturfaserverstärkte kunststoffe (NFK) und holz-polymer-werkstoff (WPC) [Biocomposites: natural fiber reinforced (NFK) and wood-polymer materials (WPC)], fachagentur nachwachsende Rohstoffe e.V. Gülzow-Prüzen, Germany (2017)

Ishikawa, T., Amaoka, K., Masubuchi, Y., Yamamoto, T., Yamanaka, A., Arai, M., Takahashi, J.: Overview of automotive structural composites technology developments in Japan. Compos. Sci. Technol. 155, 221–246 (2018)

Hadiji, H., Assarar, M., Zouari, W., Pierre, F., Behlouli, K., Zouari, B., Ayad, R.: Damping analysis of nonwoven natural fibre-reinforced polypropylene composites used in automotive interior parts. Polym. Test. 89, 106692 (2020). https://doi.org/10.1016/j.polymertesting.2020.106692

Elseify, L.A., Midani, M., El-Badawy, A.A., Seyam, A.F.M., Jawaid, M.: Benchmarking automotive nonwoven composites from date palm midrib and spadix fibers in comparison to commercial leaf fibers. Biomass Convers. Biorefinery (2023). https://doi.org/10.1007/s13399-023-03910-w

Segovia, C., Sauget, A., Besserer, A., Kueny, R., Pizzi, A.: Evaluating mold growth in tannin-resin and flax fiber biocomposites. Ind. Crops Prod. 83, 438–443 (2016). https://doi.org/10.1016/j.indcrop.2015.12.088

Komal, U.K., Lila, M.K., Singh, I.: PLA/banana fiber based sustainable biocomposites: a manufacturing perspective. Compos. Part B: Eng. (2019). https://doi.org/10.1016/j.compositesb.2019.107535

Manaii, R., Terekhina, S., Guillaumat, L., Duriatti, D.: Durabilité des bio-composites à matrice thermoplastique. In: 21ème Journées Nationales sur les Composites. (2019), July

Jawaid, M., Asim, M., Tahir, P.M., Nasir, M.: Pineapple leaf fibers. Green Energy Technol. (2020). https://doi.org/10.1007/978-981-15-1416-6

Ndengue, M.J., Ayissi, M.Z., Noah, P.M.A., Ebanda, F.B., Ateba, A.: Implementation and evaluation of certain properties of a polymer matrix composite material reinforced by fibrous residues of Saccharum officinarum in view of an applicability orientation. J. Miner. Mater. Charact. Eng. 9(02), 206 (2021). https://doi.org/10.4236/jmmce.2021.92015

Elseify, L.A., Midani, M., El-Badawy, A., Jawaid, M.: Natural fibers in the automotive industry. In: Manufacturing automotive components from sustainable natural fiber composites, pp. 1–10. Springer International Publishing, Cham (2021). https://doi.org/10.1007/978-3-030-83025-0_1

Senwitz, C., Kempe, A., Neinhuis, C., Mandombe, J.L., Branquima, M.F., Lautenschläger, T.: Almost forgotten resources–biomechanical properties of traditionally used bast fibers from Northern Angola. BioResources 11(3), 7595–7607 (2016)

Mewoli, A., Segovia, C., Ebanda, F., Ateba, A., Noah, P., Ndiwe, B., Njom, A.: Physical-chemical and mechanical characterization of the Bast fibers of Triumfetta cordifolia A. Rich. from the equatorial region of cameroon. J. Miner. Mater. Charact. Eng. 8, 163–176 (2020). https://doi.org/10.4236/jmmce.2020.84011

Grosser, P., Siegel, C., Neinhuis, C., Lautenschlaeger, T.: Triumfetta cordifolia: a valuable (African) source for biocomposites. BioResources 13(4), 7671–7682 (2018)

Njom, A.E., Mewoli, A., Ndengue, M.J., Ebanda, F.B., Nitidem, A.D., Otiti, S.B., Ateba, A.: Hybrid composite based on natural rubber reinforced with short fibers of the Triumfetta cordifolia/Saccharum officinarum L.: performance evaluation. J. Miner. Mater. Charact. Eng. 10, 385–399 (2022). https://doi.org/10.4236/jmmce.2022.105027

Behlouli, K., Mérotte, J., Le Bihan, J., Renouard, N., Kervoëlen, A., Fournet, M., Bourmaud, A.: Études des voies de revalorisation pour des Composites non tissés poly-(propylène)/fibre de Lin, p. 26. Revue des Composites et des Matériaux Avancés (2016)

Renouard, N., Mérotte, J., Kervoëlen, A., Behlouli, K., Baley, C., Bourmaud, A.: Exploring two innovative recycling ways for poly-(propylene)-flax non wovens wastes. Polym. Degrad. Stab. 142, 89–101 (2017). https://doi.org/10.1016/j.polymdegradstab.2017.05.031

Baley, C., Gomina, M., Breard, J., Bourmaud, A., Drapier, S., Ferreira, M., Davies, P.: Specific features of flax fibres used to manufacture composite materials. Int. J. Mater. Form. 12(6), 1023–1052 (2019). https://doi.org/10.1007/s12289-018-1455-y

Zhang, J., Khatibi, A.A., Castanet, E., Baum, T., Komeily-Nia, Z., Vroman, P., Wang, X.: Effect of natural fibre reinforcement on the sound and vibration damping properties of bio-biocomposites compression moulded by nonwoven mats. Biocompos. Commun. (2019). https://doi.org/10.1016/j.coco.2019.02.002

Thilagavathi, G., Muthukumar, N., Krishnanan, N.S., Senthilram, T.: Development and characterization of pineapple fibre nonwovens for thermal and sound insulation applications. J. Nat. Fibers (2019). https://doi.org/10.1080/15440478.2019.1569575

Chocinski-Arnault, L., Touchard, F., Martinez, G., Vroman, P., Vermeulen, B., Rault, F.: Biocomposites non tissés à fibres de lin: microstructure, comportement mécanique et endommagement. Comptes Rendus des JNC 18—ÉCOLE CENTRALE NANTES—12, 13, 14 Juin (2013)

Alimuzzaman, S., Gong, R.H., Akonda, M.: Nonwoven polylactic acid and flax biocomposites. Polym. Biocompos. 34(10), 1611–1619 (2013). https://doi.org/10.1002/pc.22561

Kandola, B.K., Mistik, S.I., Pornwannachai, W., Anand, S.C.: Natural fibre-reinforced thermoplastic biocomposites from woven-nonwoven textile preforms: mechanical and fire performance study. Biocompos. Part B: Eng. (2018). https://doi.org/10.1016/j.biocompositesb.2018.09.013

Tse, B., Yu, X., Gong, H., Soutis, C.: Flexural properties of wet-laid hybrid nonwoven recycled carbon and flax fibre biocomposites in poly-lactic acid matrix. Aerospace 5(4), 120 (2018). https://doi.org/10.3390/aerospace5040120

Gager, V., Le Duigou, A., Bourmaud, A., Pierre, F., Behlouli, K., Baley, C.: Understanding the effect of moisture variation on the hygromechanical properties of porosity-controlled nonwoven biocomposites. Polym. Test. 78, 105944 (2019). https://doi.org/10.1016/j.polymertesting.2019.105944

Mewoli, A., Segovia, C., Soppie, A.G., Ebanda, F.B., Njom, A.E., Ateba, A., Brosse, N.: Investigation of the performance of needle-punched nonwoven fabrics using Triumfetta cordifolia and thermoplastic fibers, compared to other commercial bast fibers used in preformed biosourced composites. Heliyon 9(7), e17888 (2023). https://doi.org/10.1016/j.heliyon.2023.e17888

Alimuzzaman, S.: Nonwoven flax fibre reinforced PLA biodegradable biocomposites (Doctoral dissertation, University of Manchester). (2014)

Akonda, M., Alimuzzaman, S., Shah, D.U., Rahman, A.N.M.: Physico-mechanical, thermal and biodegradation performance of random flax/polylactic acid and unidirectional flax/polylactic acid biocomposites. Fibers 6(4), 98 (2018). https://doi.org/10.3390/fib6040098

Martin, N.A.M.: Contribution à l’étude de paramètres influençant les propriétés mécaniques de fibres élémentaires de lin: Corrélation avec les propriétés de matériaux biocomposites (Doctoral dissertation, Université de Bretagne Sud). (2014)

Gager, V., Duigou, A.L., Bourmaud, A., Pierre, F., Behlouli, K., Baley, C.: Influence of the nonwoven biocomposite’s microstructure on its hygromechanical behaviour. Revue Biocompos. Matér. Avancés 29, 215–224 (2019)

Miao, M., Shan, M.: Highly aligned flax/polypropylene nonwoven preforms for thermoplastic composites. Compos. Sci. Technol. 71(15), 1713–1718 (2011)

Tejyan, S.: Effect of erosive parameters on solid particle erosion of cotton fiber–based nonwoven mat/wooden dust reinforced hybrid polymer composites. J. Ind. Text. 51, 2514S-2532S (2022)

Ornaghi Júnior, H.L., Zattera, A.J., Amico, S.C.: Thermal behavior and the compensation effect of vegetal fibers. Cellulose 21(1), 189–201 (2013). https://doi.org/10.1007/s10570-013-0126-x

Legrand, N.B.R., Pierre, O., Fabien, B.E., Marcel, N.P., Jean, A.A.: Physico-chemical and thermal characterization of a lignocellulosic fiber, extracted from the bast of cola lepidota stem. J. Miner. Mater. Charact. Eng. 8(5), 377–392 (2020). https://doi.org/10.4236/jmmce.2020.85024

Teixeira, F.P., Gomes, O.D.F.M., de Andrade Silva, F.: Degradation mechanisms of curaua, hemp, and sisal fibers exposed to elevated temperatures. BioResources 14, 1494–1511 (2019)

Ketata, N., Seantier, B., Guermazi, N., Grohens, Y.: On the development of a green composites based on poly (lactic acid)/poly (butylene succinate) blend matrix reinforced by long flax fibers. Mater. Today: Proc. (2021). https://doi.org/10.1016/j.matpr.2021.10.493

Hallila, T., Maijala, P., Vuorinen, J., Viikari, L.: Enzymatic pretreatment of seed flax-and polylactide-commingled nonwovens for composite processing. J. Thermoplast. Compos. Mater. 27(10), 1387–1398 (2014)

Öztürk, S.: The investigation of polylactic acid based natural fiber reinforced biocomposites for automotive applications. Kırklareli Üniversitesi Mühendislik Ve Fen Bilimleri Dergisi 6(1), 21–31 (2020)

FlexForm: FlexForm technologies: the leader in natural fiber composites (2013)

Acknowledgements

The authors would like to thank Dr. Floran Pierre of EcoTechnilin SAS, F-76190, Valliquerville, France for his contribution to the fabrication of the nonwoven composite by thermocompression.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

AM: Conceptualization, collection raw material (Triumfetta cordifolia fibers), Methodology investigation, Formal analysis, Bibliographic research and writing. CS: Conceptualization, Project administration, Procurement of raw material, Supervision, Review and editing. FBE: Conceptualization, Project administration, Supervision, Reading of the manuscript and validation; AA: Conceptualization, Project administration, Supervision and validation. PG: Thermal testing methodology and formal analysis; NB: Conceptualization, Project administration, Supervision, Reading of final manuscript and validation.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no known competing financial interests or personal relationships that might appear to influence the work reported in this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mewoli, A., Segovia, C., Ebanda, F.B. et al. Development of Novel Non-woven Triumfetta cordifolia Bast Fibers and Polylactide Fibers Biocomposites. Waste Biomass Valor 15, 3109–3121 (2024). https://doi.org/10.1007/s12649-023-02371-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02371-6