Abstract

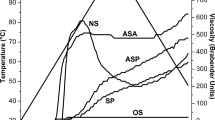

The common biodegradable properties of polymer make them an excellent pair for blending, and the water solubility of polyvinyl alcohol (PVA) makes it easy to mix evenly with the starch. In this study, PVAs with different molecular weights were blended with various compositions of cross-linked starch (CLS) to explore the effects of molecular weight of PVA on the biodegradable characteristics of the PVA/starch blends. Comparing the biodegradability of all the various PVA/starch blends, a PVA was singled out from the PVA/starch blends of higher biodegradability. Further, the chosen PVA was then blended with the acid-modified starch (AMS) to systematically investigate the effects of the modified processing of starch on the biodegradable characteristics of the PVA/starch blends. Differential scanning calorimetry (DSC) analysis of PVA and PVA/starch specimens reveal that the Tm values of PVA/starch specimens reduce gradually as their CLS or AMS contents increase. After the CLS is blended in PVAs of different molecular weights, the tensile strength (σf) and elongation at break (εf) values of (P100S0)G20M1 specimen increase and simultaneously reduce, respectively, as their molecular weights of PVA increase from about 80,000 (PVABF-17) to 120,000 (PVABF-26). The σf and εf values of the PVA/modified-starch blends decrease with an increase in the modified starch contents. The σf values of the PVA/AMS specimens decrease with an increase in the concentrations of hydrochloric acid. Comparing the σf values of the PVA/CLS specimens with those of the PVA/AMS specimens, the σf values of the PVA/CLS specimens are better than those of the PVA/AMS specimens. On the contrary, the εf values of the PVA/AMS specimens are better than those of the PVA/CLS specimens. According to the biodegradability of all the PVA/starch blends, PVA with higher molecular weights displays higher biodegradability. The biodegradability of the PVA/modified-starch blends increase as the modified starch contents of the PVA/modified-starch blends increase. As evidenced by the results of the biodegradability test, the biodegradability of the PVA/modified-starch blends, therein PVA is blended with 1N AMS, shows better biodegradability. The result of bio-reaction kinetics experiment can evaluate the decomposition tendency of the PVA/starch blends up to any biodegradable rate under ambient environment. Using the kinetic model of the first order reaction, it is estimated that 16.20 years and 12.47 years will be needed for the PVABF-17/starch blends, containing 20 and 40% of CLS respectively, to be degraded up to 70% under ambient environment. In addition, it is 1.68 years for the PVABF-26 blends with the 40% 2N AMS under decomposition environment while it is 1.94 years for the 40% 1N AMS. Overall, the decomposition potential of PVA/AMS specimens is better than PVA/CLS specimens. Furthermore, the 1N(26P60AS40)100G20M1 specimen is coincidence the biodegradable material criteria of Environmental Protection Administration (EPA) of Taiwan.

Similar content being viewed by others

References

Gould JM, Gordon SH, Dexter LB, Swanson CL (1990) Biodegradation of starch—containing plastics. ACS Symp Ser Am Chem Soc 433:66

Griffin GJL (1974) Fillers and reinforcements for plastics. ACS Symp Ser Am Chem Soc 134:159

Griffin GJL (1975) Biodegradable fillers in thermoplastics. ACS Adv Chem 134:12

Bhatnagar S, Hanna MA (1995) Physical, mechanical, and thermal properties of starch-based plastic foams. Trans ASAE 38:567

Godbole S, Gote S, Latkar M, Chakrabarti K (2003) Preparation and characterization of biodegradable poly-3-hydroxybutyrate-starch blend films. Bioresour Technol 86:33

Kim HS, Yang HS, Kim HJ, Lee YK, Park HJ (2004) Thermal properties of maize starch filled biodegradable polymer bio-composites. J Korean Wood Sci Tech 32:29

Villar MA, Thomas EL, Armstrong RC (1995) Rheological properties of thermoplastic starch and starch/poly(ethylene-co-vinyl alcohol) blends. Polymer 36:1869

Jiang W, Qiao X, Sun K (2006) Mechanical and thermal properties of thermoplastic acetylated starch/poly(ethylene-co-vinyl alcohol) blends. Carbohydr Polym 65:139

Demirgöz D, Elvira C, Mano JF, Cunha AM, Piskin E, Reis RL (2000) Chemical modification of starch based biodegradable polymeric blends: effects on water uptake, degradation behaviour and mechanical properties. Polym Degrad Stab 70:161

Araújo MA, Vaz CM, Cunha AM, Mota M (2001) In vitro degradation behaviour of starch/EVOH biomaterials. Polym Degrad Stab 73:237

Koeing MF, Huang SJ (1995) Biodegradable blends and composites of polycaprolactone and starch derivatives. Polymer 36:1877

Pranamuda H, Tokiwa Y, Tanaka H (1996) Physical properties and biodegradability of blends containing poly(ε-caprolactone) and tropical starches. J Environ Polym Degrad 4:1

Mani R, Tang J, Bhattacharya M (1998) Synthesis and characterization of starch-graft-polycaprolactone as compatibilizer for starch/polycarprolactone blends. Macromol Rapid Commun 19:283

Rosa DS, Lopes DR, Calil MR (2005) Thermal properties and enzymatic degradation of blends of poly(ε-caprolactone) with starches. Polym Testing 24:756

Park JW, Im SS (2002) Biodegradable polymer blends of poly (L-lactic acid) and gelatinized starch. Polym Eng Sci 40:2539

Pierre S, Gang L, William JO, Basil DF (2008) Binary and ternary blends of polylactide, polycaprolactone and thermoplastic starch. Polymer 49:599

Follain N, Joly C, Dole P, Bliard C (2005) Properties of starch based blends. Part 2. Influence of poly vinyl alcohol addition and photocrosslinking on starch based materials mechanical properties. Carbohydr Polym 60:185

Imam SH, Cinelli P, Gordon SH, Chiellini E (2005) Characterization of biodegradable composite films prepared from blends of poly(vinyl alcohol), cornstarch, and lignocellulosic fiber. J Polym Environ 13:47

Guohua Z, Ya L, Cuilan F, Min Z, Caiqiong Z, Zongdao C (2006) Water resistance, mechanical properties and biodegradability of methylated-cornstarch/poly(vinyl alcohol) blend film. Polym Degrad Stab 91:703

Landreau E, Tighzert BL, Bliard C, Berzin F, Lacoste C (2009) Morphologies and properties of plasticized starch/polyamide compatibilized blends. Eur Polym J 45:2609

Fang JM, Fowler PA, Tomkinson J, Hill CAS (2002) The preparation and characterisation of a series of chemically modified potato starches. Carbohydr Polym 47:245

Zhai M, Yoshii F, Kume T (2003) Radiation modification of starch-based plastic sheets. Carbohydr Polym 52:311

Kiatkamjornwong S, Chomsaksakul W, Sonsuk M (2000) Radiation modification of water absorption of cassava starch by acrylic acid/acrylamide. Radiat Phys Chem 59:413

Bikiarisa D, Prinosa J, Koutsopoulosa K, Vouroutzisb N, Pavlidoub E, Frangisb N, Panayiotou C (1998) LDPE/plasticized starch blends containing PE-g-MA copolymer as compatibilizer. Polym Degrad Stab 59:287

Rahmat AR, Rahman WA, Lee TS, Yussuf AA (2009) Approaches to improve compatibility of starch filled polymer system: a review. Maters Sci Eng C 29:2370

Lee WJ, Youn YN, Yun YH, Yoon SD (2007) Physical properties of chemically modified starch(RS4)/PVA blend films—part 1. J Polym Environ 15:35

Yin Y, Li J, Liu Y, Li Z (2005) Starch crosslinked with poly(vinyl alcohol) by boric acid. J Appl Polym Sci 96:1394

Yoon SD, Chough SH, Park HR (2007) Preparation of resistant starch/poly(vinyl alcohol) blend films with added plasticizer and crosslinking agents. J Appl Polym Sci 106:2485

Yoon SD, Chough SH, Park HR (2006) Properties of starch-based blend films using citric acid as additive. II. J Appl Polym Sci 100:2554

Park HR, Chough SH, Yun YH, Yoon SD (2005) Properties of starch/PVA blend films containing citric acid as additive. J Polym Environ 13:357

Ramaraj B (2007a) Crosslinked poly(vinyl alcohol) and starch composite films. II. Physicomechanical, thermal properties and swelling studies. J Appl Polym Sci 103:909

Woo K, Seib P (1997) Cross-linking of wheat starch and hydroxypropylated wheat starch in alkaline slurry with sodium trimetaphosphate. Carbohydr Polym 33:263

Beliakova MK, Aly AA, Abdel-Mohdy FA (2004) Grafting of poly(methacrylic acid) on starch and poly(vinyl alcohol). Starch/Stäke 56:407

Khan M, Bhattacharia S, Kader MA, Bahari K (2006) Preparation and characterization of ultra violet (UV) radiation cured bio-degradable films of sago starch/PVA blend. Carbohydr Polym 63:500

Jayasekara R, Harding I, Bowater I, Christie GBY, Lonergan GT (2004) Preparation, surface modification and characterisation of solution cast starch PVA blended films. Polym Testing 23:17

Chung YL, Lai HM (2006) Molecular and granular characteristics of corn starch modified by HCl-methanol at different temperatures. Carbohydr Polym 63:527

Nabar YU, Draybuck D, Narayan R (2006) Physicomechanical and hydrophobic properties of starch foams extruded with different biodegradable polymers. J Appl Polym Sci 102:58

Chai WL, Chow JD, Chen CC, Chuang FS, Lu WC (2009) Evaluation of the biodegradability of polyvinyl alcohol/starch blends: A methodological comparison of environmentally friendly materials. J Polym Environ 17:71

Conflict of interest

The authors declare that there are no competing financial interests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chai, WL., Chow, JD. & Chen, CC. Effects of Modified Starch and Different Molecular Weight Polyvinyl Alcohols on Biodegradable Characteristics of Polyvinyl Alcohol/Starch Blends. J Polym Environ 20, 550–564 (2012). https://doi.org/10.1007/s10924-012-0419-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-012-0419-4