Abstract

This paper presents a review of the possible methods for testing the fire performance properties of reused timber through non-destructive techniques, focusing on structural elements. Evaluating the fire performance of old wooden specimen is necessary to facilitate reuse, in the support of the transition to a circular economy. The use of non-destructive methods minimizes damages to the pieces during the evaluation process. Three angles are reviewed: (1) The properties of wood influencing fire performance, (2) the change of wood properties over time, and (3) the known non-destructive tests. Some properties of wood are known to influence the fire performance, e.g., the density. Of these, there is no evidence of irreversible changes due to the passage of time only. The many different non- and semi- destructive techniques that can be applied to wood seldom relate to these properties, but rather to mechanical properties or geometry. Additionally, accurate measurements are often difficult, while some are only done in laboratories. This review concludes that currently there is no known non-destructive method that permits to estimate the fire performance of a reused timber element compared to a new one. There is a gap of knowledge on the evolution of the fire properties of timber during the use phase of the building, and there are no established methods to test for these properties without destroying a significant portion of the element. Development of non-destructive test methodologies to assess fire properties of timber will expand the market for reused timber to include load carrying timber.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The European Union adopted in 2020 the Circular Economy Action Plan [1] as part of the Green Deal [2] for a more sustainable economy and the reduction of the impact of human activities on the environment. According to the European commission “[The built environment] requires vast amounts of resources and accounts for about 50% of all extracted material. The construction sector is responsible for over 35% of the EU’s total waste generation” [1]. The Circular Economy Action Plan intends to revise the Construction Product Regulation to address sustainability, with “the possible introduction of recycled content requirements for certain construction products, taking into account their safety and functionality” [1].

In the case of timber extracted from the demolition of buildings, also called waste timber, there are different ways to approach circularity, from reuse in new buildings to the production of wood pellets to be used as fuel in generation of heating [3]. Comparisons of these methods show that the reuse of waste timber has more benefits than other end-of-life solutions [4], by reducing the primary production in forestry systems among other effects [3]. The European Union in fact places reuse second only to prevention as a waste management practice [5]. Though there is no standard practice [6], there are many methods allowing to rate reused timber for the construction sector, from its appearance to its mechanical properties, including potential damages it might have accrued during its lifetime.

But there are also challenges to the reuse of timber. Lack of knowledge in the construction industry is reported to be the main obstacles for reuse [7], and there is a responsibility vacuum when it comes to the guarantee of the quality of the product [8]. Wood is a combustible material, for which the fire performance needs to be carefully documented. Thus, there is a need to establish a methodology of documenting timber elements’ fire performance for reuse. This methodology should include minimal fire tests. Their highly destructive nature, the length of the procedures, and their cost all are obstacles to the profitable reuse of timber.

This paper aims to explore whether there exist techniques for testing timber for fire performance without having to destroy a part of the element. It will focus on load bearing timber and will not explore the specificities of wooden facades and floorings. The ideal methodology would be non-destructive, fast, and able to be used on site, and could reliably be linked to the fire performance of wood. As exact results can be difficult to predict with a material as inhomogeneous as wood, a classification of the fire performance is the most likely outcome of such methodology.

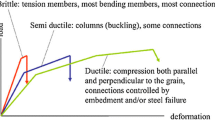

2 Structural Fire Performance

For the purpose of this paper, and for the sake of brevity, structural timber will be referred to as simply “timber”, though façades and floorings will not be investigated. Questions of fire impregnation and surface treatments will be ignored, as they are not generally applied to load bearing timber and add high uncertainty to the topic of reuse. Questions of ageing of wood glue will also not be explored in this review.

In this review, the focus will be on the aspects of fire performance that could cause issues of safety for people and structures in fire. There are many such aspects: how fast the wood burns, how much energy is produced during combustion, how fast the fire spreads on the surface, and how easy it is to ignite. For this review, the focus is on the charring rate.

Charring rate is one of the key parameters dictating how long the element can sustain a load in case of fire. It is critical to design methods for structural fire safety in many countries. Measured in millimetres per minute, it is a measure of the speed at which the interface between fully charred material and material maintaining some structural strength advances. It is usually determined either visually, or through the progression of the 300 °C isotherm with thermocouples inserted in the sample [9].

It is important to point out the difference between mass loss rate and charring rate. While the two are correlated when the moisture content is constant [9], a higher mass loss rate does not always correspond to a higher charring rate when comparing different timber pieces. Denser and moister timber pieces may have higher mass loss rates during exposure, but their charring rate may be equal or lower than that of lighter and drier pieces.

The charring rate is a major element in the design of wooden structures, used to calculate a residual cross-section after exposure to fire. It is used in the European Eurocode 5 [10], the Australian Standards [11], and the National Design Specification of the USA [12]. It is to be noted that these documents approach the subject in different manners. While the European and Australian standards associate different charring rates to different categories of timber, the National Design Specification defines one charring rate with adjustments for time elapsed and lamination thickness for cross-laminated timber. Only the Eurocode 5 considers the geometry of the beam, with an increase in charring rate for exposed fissures and corners.

This study is aiming to determine how to detect a lower performance of reused timber compared to new elements. There are multiple factors influencing performance metrics, among which the construction details around the piece, the exposure conditions, and the material properties of the timber. The construction and exposure conditions depend on the end-use of the timber in a building, and these may be determined through the design process in the same way as for ‘new’ timber elements. The missing information for re-used timber is, therefore, the material properties and how these influence the fire performance.

3 Properties of Timber Linked to Fire Performance

The main properties of wood linked to its fire performance are density [10, 11, 13,14,15,16,17,18,19,20,21,22], moisture content [9, 13, 17, 21, 23,24,25], permeability [13, 26], and species [13, 15, 19]. The chemical composition of wood has some effect on the pyrolysis [15, 21, 27,28,29,30], however, the charring rate and mass loss rate above the microscale cannot be explained through these differences alone [30].

Aside from the inherent properties of the wood, the overall geometry of the timber also influences the fire performance. Cracks and surface irregularities have some impact on the charring rate [31,32,33,34], but the evidence is mainly qualitative. The thickness of the element also has an influence on the charring rate [16, 35].

The following sections will detail how these properties affect the fire performance of wood, finishing with how the most common regulations cover fire safety for timber. An overview of all the papers reviewed is available in the Appendix.

4 Density

Bartlett et al. [13] provided a review of factors affecting the fire performance of wood. They report many studies showing that higher density decreases the charring rate of wood [36,37,38] and multiple charring models using it as a key variable. Some studies failed to find a correlation between density and charring rate, especially when the difference in density ranged lower than 150 kg/m3, but overall charring rates increased with decreasing density, while studies which covered mass loss rates reported a slight increase for denser samples.

Many other studies show this relationship between density and charring rate. A study by Gilka-Bötzow et al. [14] on Norway spruce (Picea abies), balsa (Ochroma pyramidale), and compressed laminated wood (genus and species not indicated), found an exponential decrease of the charring rate with increasing density, until the value of 800 kg/m3 is reached, at which the charring rate becomes independent of the density. This study did not attribute the differences found to the different species.

Pánek et al. [15] studied the burning behaviour of Scots pine (Pinus sylvestris), European larch (Larix decidua), Norway spruce and Douglas fir (Pseudotsuga menziesii), after different durations of weathering. They saw a clear correlation between the charring rate and the density for spruce, Douglas fir and larch, but for pine the density and charring rate seemed uncorrelated.

Harada [16] found in a study of 13 Japanese softwoods and hardwoods a weak correlation between mass loss rate and density, which he increased by correcting the density of the hardwoods, accounting for the presence of the vessels which carry sap. These vessels contribute to the local gas and water vapor flow and do not exist in softwoods. The species studied can be found in appendix.

Adetayo and Dahunsi [17] compared different Nigerian timber species (Terminalia superba, Milicia excelsa, Khaya ivorensis, Mansonia altissima, Nauclea diderrichii and Tectona grandis), at different moisture content, and found they could somewhat predict the charring rate through a combination of wood density, moisture content and a char contraction factor.

Hugi and Weber [39] studied European and tropical woods, among which Norway spruce, Oak (Quercus robur/petraea) and Maple (Acer pseudoplatanus). A full list of species can be found in appendix. The density and charring rates reported in this study do not show any correlation, but when compared with other values in literature, as in Fig. 1, they tend to agree with a weak correlation.

Charring rate versus density plot for standard temperature, from the data gathered by Adetayo and Dahunsi [17], Collier [36], Gilka-Bötzow et al. [14], Njankouo et al. [37], Fahrni et al. [18], Hugi et al. [38] and Hugi and Weber [39]. As the density provided by Collier was for oven-dry wood, which is not the case for the other data sets, the Collier density was corrected for the moisture content reported in their study

There is also a relationship between density and charring rate for glue-laminated timber. In the study by Fahrni et al. [18], which researched spruce glulam (species not indicated), the results were highly scattered, which they assign to the measuring resolution of the charring rate and the density variations in a single piece.

Haurie et al. [19] studied seven tropical hardwoods included other fire parameters. The species can be found in appendix. They showed that time to ignition could reliably be correlated to density but could not relate it to other metrics. Similarly, Chorlton and Gale [20] compare spruce glulam and spruce and pine historical timber (species not indicated). They find faster time to ignition in the historical timber, which is 100 kg/m3 less dense than the modern glulam. They also report slightly higher charring rates. Finally, time to ignition could also be related somewhat to density in a study by Wiesner et al. [40] of various Australian wood species. The quality of their regression increased when taking into account the extractive content of the samples. The species can be found in appendix.

The relationship between density and charring rate is illustrated in Fig. 1, with data from Adetayo and Dahunsi [17], Collier [36], Gilka-Bötzow et al. [14], Njankouo et al. [37], Fahrni et al. [18], Hugi et al. [38] and Hugi and Weber [39]. All densities were measured on wet wood, except for Collier, who measured the density oven dry. For this reason, the density data from Collier was corrected for the moisture content of the wood reported in their study. All data are for standard fire exposure (ISO 834 [41]), except for that of Adetayo and Dahunsi which uses an electric furnace.

Figure 1 shows that the density of wood is affecting the charring rate, even when mixing different species. For the purpose of wood reuse, this is an indicator that lighter pieces might cause issues for fire safety, with higher charring rates that would lead to earlier failure of the structure, and earlier ignition at the start of the fire.

4.1 Moisture Content

As wood must first dry before charring can occur, a high moisture content in wood is expected to lead to slower charring, as it takes longer to evaporate the water contained in the wood, though this effect is not always observable in experiments. Many models of fire performance include the humidity of the wood, such as the ones developed by Pečenko et al. [24], Mindykowski et al. [23], or Galgano and Di Blasi [25]. The problem of moisture is also very relevant to the reuse of wood. Pieces taken from demolition sites need to be properly conditioned before installation, so that their moisture content falls within acceptable ranges.

The review by Bartlett et al. [13] found that higher moisture content was linked to lower charring rates [36, 37], but it also points out that the exact relationship is not agreed upon, as it is often masked by other parameters such as density or species. Adetayo and Dahunsi [17] also found they could somewhat predict the charring rate through a combination of moisture content, density and a char contraction factor, in a study comparing different Nigerian timber species at 9, 12 and 15% moisture content. The species can be found in appendix.

Hugi and Weber [39] studied European and tropical woods, among which Norway spruce, Oak and Maple. The moisture contents and charring rates reported in this study do not show any correlation, but when compared with other values in literature, as in Fig. 2, they tend to agree with a weak correlation. A full list of the species can be found in appendix.

Figure 2 shows the data from Adetayo and Dahunsi [17], along with that of Njankouo et al. [37], Collier [36], Hugi and Weber [39] and Hugi et al. [38]. Though most of these data groups approach different species, and do not show correlations on their own, the combination of the four shows that the moisture content is a weak predictor of the charring rate (R2 < 0.3). All data are for standard fire exposure (ISO 834 [41]), except for that of Adetayo and Dahunsi which uses an electric furnace.

Bartlett et al. [13] also found longer ignition times with higher moisture content. Supporting this review, Mindykowski et al. [23] studied “Nordic Spruce” (sic., most likely Piceas abies, Norway spruce) wood, wet and dry, finding that with higher moisture contents come longer ignition times, and reporting that the difference becoming negligible at external heat fluxes higher than 25 kW/m2.

4.2 Permeability and Grain Direction

Wood permeability, which is the ability of fluids to pass through the material, is dependent on grain direction, as fluids can more easily flow along the grain than across it.

Of the three studies reviewed in Bartlett et al. [13], two reported that charring rates increased with increasing permeability [38, 42]. The correlation is explained by the increased permeability causing an increased flow of volatiles during combustion, facilitating pyrolysis. Accordingly, the charring rate parallel to the grain was higher than the charring rate perpendicular to the grain, attributed to the difference in permeability between the two orientations [13]. The third study did not find any trend between permeability and charring rate [29].

It is to be noted that two of the three studies use the penetration depth of copper chrome arsenate [29, 42] in wood as a measure of permeability, while the remaining study uses gaseous oxygen to calculate a permeability coefficient [38]. Copper arsenate is used as a treatment against insect and is applied as a water-based mixture. But the permeability of materials to water mixtures is generally smaller than to gaseous oxygen, because of the polarity of water as well as molecule sizes. This difference makes direct comparisons between studies less clear.

Hugi et al.’s experiment [38] was repeated in a subsequent study on tropical and European wood (species in appendix) by Hugi and Weber [39], where they found a similar correlation between the permeability to oxygen and the charring rate of the samples studied, as shown in Fig. 3. The oxygen permeability index in Figs. 3 and 4b is the negative logarithm of the coefficient of permeability and is lower for higher permeability of the material. In Fig. 3, the combination of the data from both studies shows the oxygen permeability index as a weak predictor of the charring rate (R2 < 0.5).

In his study of softwoods and hardwoods (species in appendix), Harada [16] found that adjusting the density of hardwoods to account for the sap carrying vessels brings the correlation coefficient between density and mass loss rate for his data to 0.96. This can be explained by the increased gas flow in these vessels, facilitating the pyrolysis reaction, and supports the theory that gas permeability plays an important role in the fire performance of wood.

Another study by Spearpoint and Quintiere [26] on Douglas fir, Redwood (unspecified), Red oak and Maple (unspecified) showed that the minimum heat flux required to ignite wood is lower if the exposed surface is cut across the grain, where permeability is highest. They also calculated the temperature of ignition from acquired data on redwood, which was approximately 200 °C for the highest permeability, whereas it became 375 °C for the lowest permeability. This shows that high permeability is correlated with “easier” ignition.

These studies give insight into the potential reusability of wood, as permeability is one of the characteristics of wood that can change as wood ages. Degradation of the cells increase the gas flow through the material, which would then increase the charring rate of the specimen, and ignition at lower temperatures. Permeability is thus an important factor to keep in mind for the reuse of timber.

4.3 Cross Correlation of Parameters

Density, moisture content and permeability are not independent parameters. Specifically, if not measured oven dry, the density is higher for higher moisture contents. The permeability of wood is dependent on the presence of voids in the wood structure, which lowers the density. When studying the relationship between these parameters and fire performance, it is important to consider whether any information is gained, or whether the relationships observed are a reiteration of some other relationship. It is then necessary to compare moisture content, permeability, and density.

A linear relationship between oxygen permeability and charring rate was already shown in Fig. 3 through data from Hugi et al. [38] and Hugi and Weber [39]. Figure 4 shows data from the same sources, in two additional configurations. The charring rate against the density shows a linear trend with a coefficient of determination R2 of 0.48 (Fig. 4a), similar to that obtained in Fig. 3. But when representing the charring rate against both density and permeability, in Fig. 4b, the charring rate appears to follow a surface along both parameters. The coefficient of determination for the linear regression of this surface becomes 0.63. This indicates that though the density and the permeability are not independent from each other, there is still an improvement of the model by incorporating both in prediction models. For the different predictive models, the coefficients of regression and their p-values are available in Table 1.

The same analysis was done for density and moisture content, with the data from Njankouo et al. [33], Adetayo and Dahunsi [20], Collier [32], Hugi and Weber [35] and Hugi et al. [34]. In this case, the coefficient of determination was 0.52 between density and charring rate, and 0.21 between moisture content and charring rate. Combining both density and moisture content, as shown in Fig. 5, brings the determination coefficient to 0.57, showing a 5% improvement of the prediction when moisture is added to density. For the different predictive models, the coefficients of regression and their p-values are available in Table 2.

It is to be noted that in most cases, adding more variables will increase the value of R2. Correcting for the addition of variables is possible. The corrected R2 for the models with only two variables are 0.56 for moisture content and density, and 0.62 for permeability and density. When combining all three variables (density, moisture content and permeability), the base R2 value of the model is 0.63, while the corrected value becomes 0.60. This indicates that adding the moisture content is not an improvement to the density and permeability model.

4.4 Species

Species identification can be a challenge for the reuse of timber, as often spruce, pine, and fir are sold in the same batch, but different wood species are known to have different fire performances. This is linked to differences in the properties mentioned above. The review [13] showed that after excluding moisture content and density, there was still an overall difference in behaviour between different wood species [13]. The differences were mostly attributed to chemical composition and anatomy of the wood [13].

Supporting the influence of the wood species on the fire performance is the work by Pánek et al. [15], who studied Scots pine, Norway spruce, Douglas fir and European larch after different durations of weathering. Considering the density of the samples, they found a distinctly different behaviour in the relative mass loss rate in percent of pine compared to the other three species, which they attribute to pine’s higher flammable extractive content, as shown in Fig. 6.

Dependence on density of maximum burn-off (mass loss) rate of Scots pine (♦), Norway spruce (●), Douglas fir (▲) and European larch (■) samples during burn-off.—reproduced from Pánek et al. [15]

4.5 Chemical Composition

The heat released by burning wood depends on the relative lignin, holo-cellulose and extractive content, though woods with similar compositions can have very different heat release rates, independent even of density [29].

Hemicelluloses, lignin and cellulose are considered to pyrolyze in the ranges 200–300, 225–450, and 300–450 °C respectively [28], and a study by Gerandi et al. [27] found that they could predict some of the fire performance of oak and eucalyptus (Quercus alba and Eucalyptus globulus) using known parameters from these polymers. Additionally, a study by Di Blasi et al. [43] related the difference between the fire performances of European beech (Fagus sylvatica L.), chestnut (Castanea sativa), Douglas fir, redwood (Sequoia sempervirens), and Stone pine (Pinus pinea) with the difference in the composition of their lignin.

On the other hand, a study by Richter et al. [30] compared the fire performance of biomass samples with their cellulose, hemicellulose and lignin content and found no relation at the mesoscale. In a subsequent study, Richter and Rein [35] confirm this result with a new model, offering that chemistry is an important mechanism at low heat fluxes and for thin char layers, but that the physics of heat transfer are dominant in other situations. This would indicate that changes in wood chemistry could affect the early stages of a fire but would most likely not create significant changes once the fire is fully developed.

A last element of the chemical composition is the extractive content, which has been linked to earlier ignition and degradation at lower temperatures by the Di Blasi et al. study [43]. This is corroborated by a study by Wiesner et al. [40], in which they show that the density and extractive content is a good predictor of time to ignition for different Australian wood species. The study by Pánek et al. [15] also attributed higher charring rates in Scots pine to a higher extractive content. This might be the source of a challenge for wood reuse. In a review by Routa et al. [44], it is shown that a 100 year old Scots pine tree stem contains more extractives than that of a 25 year old tree of the same species. As very old trees are becoming rarer in Europe [45], the standard modern timber piece is likely to contain less extractives than a piece harvested in the nineteenth century, which might have grown longer before being cut. The higher extractive content of that nineteenth century piece might then cause high charring rates which would disqualify it for reuse.

4.6 Damages, Defects, and Changes in Geometry

In this category are considered geometrical characteristics of a timber element such as cracks and surface damages, which are only local. Global geometry, such as cross-section and length, does affect the fire performance, but is considered in design whether the piece is modern or reused. Knots, due to their higher density, tend to char slower than clear wood [13].

Higher charring rates have been reported around cracks in the wood in three studies [31,32,33], with one by Cimer et al. indicating that wider cracks lead to deeper charring [31]. This study also reported no increased charring around holes due to insect attacks. They did not indicate the type of wood investigated. The study by Sandanus et al. [32] observed that for sawn slits in C24 timber (species not indicated), the difference between sound wood and damaged wood charring gets lower with longer burning times. The third study by Harun et al. [33] studied “heritage” pine (unspecified) beams from a construction built in 1905. They found that cracks expanded in the full-scale tests, but not in the cone calorimeter tests, which they assigned to the mechanics of moisture in the samples. None of these studies have investigated whether the local increase of charring had consequences on the global performance of timber, or whether it could have an impact on the design of timber structures using cracked pieces.

Reused timber will often show cracks due to shrinkage [46], but these can also appear early in the service life of a piece of timber. There is then little evidence that significant shrinkage cracks would disqualify a piece for reuse from the point of view of fire safety. Nonetheless, further research is necessary on the subject.

Finally, Wang et al. [34] studied ancient wood samples (species in appendix) from Chinese temples (400–1400 years old) through a cone calorimeter. They compared the damages to the surface of the wood, for example from insect attacks, to the ignition time and heat release. They found that the more damaged samples ignited earlier and had higher peak of heat release. This could cause concern for the reuse of wood, but only in the case of damaged pieces.

4.7 Discussion

Of all parameters generally measured in wood samples, four have a definite effect on the fire performance. Three of them, density, moisture content, and species of the wood have well accepted and reported effects. Some studies attribute the difference between species to their different chemical composition. In construction standards in the EU and Australia/New Zealand, only the density and the species are sometimes considered for design. The US standard only considers a flat charring rate.

The last of the four, permeability, is recognized and included in many models, but rarely studied independently. The method of measurement is also not uniform, complicating the analysis. Though permeability and density are not independent of each other, combining them in a model is still beneficial. The inclusion of moisture content did not appear to be beneficial for the data set considered.

Geometry is a property of timber that can affect the fire performance, but no studies have reported on whether a local geometrical change (e.g. cracks) would affect the global fire performance, which would cause a lower fire performance for the timber. The EU standard takes geometry into account when designing timber structures for fire.

For the reuse of timber, these six parameters (density, moisture content, species, permeability, chemical composition, local geometry) are the most likely to allow a classification of the fire performance without fire tests, especially when combined. The next step is determining how those properties evolve when the timber is in use.

5 Reused Wood: Irreversible Aging of Timber

There is hardly any agreement on how the properties of timber evolve as it ages. Some studies do not report changes, others do, but one aspect remains constant: it is extremely difficult to have clear links between the passage of time and the properties of wood, as many different mechanisms can influence the result. When studying samples, even when the origin and age is precisely known, there is a high level of uncertainty regarding loads and environmental conditions [47]. Some forms of deteriorations are due, or exacerbated by, inadequate moisture and temperature during the service life. Decay can happen quite fast if the wrong conditions are applied. Despite its importance, the history of the sample cannot reliably be measured for reused wood and might need to be considered a black box.

As wood is a plant that is grown and harvested, there is also the problem of human intervention. Modern timber has been selected with criterions that are different than that of the 19th and even early twentieth century. Reused timber could have been harvested 200 years ago, and it is impossible to know whether a lower performance (for example an unexpectedly high charring rate) is due to ageing, or if the result would have been the same if the test had been performed when the timber was new. Nonetheless, no change is overall observed in the modulus of elasticity (MoE) [48,49,50]. A loss of strength is common [47,48,49,50,51,52] but not always observed [53, 54], especially for timber that has only experienced low loads. And though there are reports on the evolution of the chemical composition with time [22, 55, 56], the changes observed vary greatly between studies.

Three of the studies found have looked at the age of wood as an indicator of fire performance [15, 20, 34], though other factors such as density and original quality of the wood were usually not excluded, leading to unclear applicability of their results to other scenarios.

Indirectly linked to aging, changes to the geometry of the piece are expected when the wood is exposed to changing environmental conditions. The slow adaptation of wood to changes in atmospheric humidity causes moisture gradients, and moisture-induced stresses [57, 58], which can cause cracking in the direction parallel to the grain, or loss of flatness of the piece [59]. In certain cases, biotic attacks may occur, which include fungi or insect attacks. Wood is particularly vulnerable to fungi if its moisture content is higher than 20%, and its temperature above 20 °C, while the conditions for insect attacks vary between wood and insect species.

An overview of the different studies reviewed, by property investigated, method, and findings, is available in the appendix.

5.1 Mechanical Properties

Mechanical properties are not directly linked to fire performance metrics such as charring rate and heat release. There are two reasons the subject is not dismissed in this review. First, the resistance of timber to load cannot be dismissed when studying load-bearing timber exposed to fire. Assuming that there are no mechanical changes in reused wood compared to new could lead to failure in case of fire, even if the piece can sustain common loads.

Additionally, the mechanical properties and the fire performance of wood can both be traced back to similar wood properties, such as its density. A study by Dömény et al. [60] also showed that damages to the micro-structure of European beech led to increased permeability and decreased compression strength.

A loss of strength is expected from timber through its use. Machado et al. [48] studied Scots and maritime pine (Pinus pinaster) members from a building constructed after the 1755 Lisbon earthquake. The specimens experienced a significant loss of tensile strength compared to the modern made control group, while the density was equivalent between old and new.

Another study by Llana et al. [49] manufactured CLT pieces from 200-year-old recovered European oak (Quercus robur L.) and compared them to modern CLT of the same species. They found a lower bending strength in the CLT made with recovered wood, which they attributed to both the load history and the original quality of the timber, as shown in Fig. 7b). Bending strength was also found to decrease by Wu et al. [51] in a study of Canadian spruce-pine-fir, but only for pieces exposed to long durations of loading above 55% of their capacity. This is attributed to the creep effect, in which the deformation of timber to its load increases with time. This will eventually lead to the failure of the piece [61], but in the shorter term reduces the ultimate mechanical strength.

Average result for: a Modulus of elasticity (MOE, global, for 12% moisture content), b Modulus of rupture, for new cross-laminated timber (CLT, three layers; NNN and NRN) and three layers CLT made of reclaimed wood (RRR and RNR). R indicates a layer or reused wood, N a layer of New wood—reproduced from Llana et al. [49]

Hoffmeyer and Sørensen [52] studied the combined effect of moisture content and the duration of time spent under design load on Norway spruce boards over a 13-year period. Higher moisture content (MC) (20%) led to an increased failure rate of the specimens during testing, with worst rates for varying moisture content, showing that the creep effect depends on the environmental conditions, and not only the load and its duration. The ratio of applied stress to stress capacity that causes failure after 50 years was extrapolated to be 0.60 for MC = 11%, 0.50 for MC = 20%, and 0.44 if the MC cycles between 11 and 20%. The mechanosorptive effect explains the failure at lower stresses when the moisture content has high variations, which is the phenomena of long-lasting mechanical changes in wood through simultaneous loading and high humidity.

Loss of bending strength due to environmental conditions was also found by Uwizeyimana et al. [50] in a study of Douglas fir Glulam before and after seventeen cycles of wetting and drying, creating artificial aging of the wood. On the other hand, two studies by Falk et al. [53] studied recovered Douglas fir from 55-year old columns. They did not find any loss of strength in the loading direction compared to the expected value for modern pieces. Additionally, they did not find any loss of compressive strength in the pieces presenting shrinkage cracks compared to their uncracked counterparts.

Yokoyama et al. [54] studied Hinoki wood (Chamaecyparis obtusa) from historical buildings compared to modern. They found no change in rigidity nor longitudinal strength when accounting for differences in density and moisture content but noted an increased brittleness especially in the radial direction.

When it comes to the modulus of elasticity, none of the studies which tested it found any loss in timber recovered from old buildings [48, 49], or in timber artificially aged through wetting and drying [50]. An example of this is shown in Fig. 7a).

Overall, these studies show that the mechanical strength of timber does degrade over its use, but that it is highly dependent on its loading and environmental conditions. There is also the question of whether wood harvested 200 years ago was of comparable strength grade as wood harvested in the last 20 years.

5.2 Chemical Composition

Kránitz [55] reviewed 16 studies on the chemical composition of aged wood of different species, from 60 up to 4400 years old. Though results varied, some general trends were established. Hemicellulose and crystallinity of cellulose decreased over time, while lignin and cellulose content remained overall constant. Aseeva et al. [22] also reviewed multiple articles and concluded that the chemical composition in archeological timber is different from modern samples, with a general increase of the proportion of lignin and ashy substances.

Both studies attribute the changes found to the ageing process, and not to differences in growth conditions. These differences could lead to changes in the fire performance of wood, as higher lignin contents in natural fibers was linked by Dorez et al. [62] to higher charring and higher calorific values. It is to be noted that this link has not yet been studied for wood.

5.3 Age as an Indicator of Fire Performance

The fire performance of older wood elements is a concern when it comes to the conservation of historical buildings [63,64,65]. The study by Pánek et al. [15] found no significant change in fire performance in Scots pine, Douglas fir, European Larch or Norway Spruce after 24 months of weathering, as shown in Fig. 8. On the other hand, two studies were found indicating that there is a degradation of the fire performance after a period of use [20, 34].

Mass loss 240 s after starting the flame source exposure. The Tukey HSD test shows that the differences in the analysed values were statistically significant (p-value < 0.05) for Pine wood mass loss compared to other wood species.—reproduced from Pánek et al. [15]

Chorlton and Gales [20] studied the fire performance of timber removed from buildings constructed in the 1800s, compared to modern glulam. Both modern and historical wood were of unspecified spruce and pine. They observed lower performances for the older timber (higher char rates and lower time to ignition) but conceded to a higher density of the modern timber, and a marked difference in growth ring width. This would indicate that the difference observed is due to lower initial quality rather than a degradation of the performance over time.

In comparison, Wang et al. [34] studied a small number of wood samples from ancient Chinese temples through a cone calorimeter test. The species can be found in appendix. They found earlier ignition and higher peak heat release in the older samples compared to modern samples of the same species. They also found irregular heat release rate curves in the older samples, associated with high thermal conductivity, and early failing of the char layer. This was done on only a few samples, such that statistical analysis is impossible, probably due to the difficulty of sourcing wood as old as 1000 years old. These results might thus be considered anecdotal.

5.4 Discussion

None of the properties investigated in the reviewed papers have been definitively proven to change due to the passage of time only. The mechanical strength of wood is often reported as decreasing with age, but it appears to be due to environmental and/or loading conditions. No studies have been found relating the mechanical properties of timber at room temperature with its burning behaviour.

Though changes in the chemical composition of wood have been observed, there is no consensus on which changes occur, and the mechanisms driving these changes. Furthermore, the relationship between chemical composition and fire performance in wood in unclear. The local geometry of a piece can change due to environmental conditions or biotic attacks. This has been linked to the fire performance of wood, but the relationship requires further research.

After reviewing the properties of wood linked to fire performance and the way wood properties change with age, the question remains of whether these properties can reliably be measured without damaging the element. The non-destructive tests that are currently available to researchers are covered in the next section.

6 Non-Destructive Testing

To gain insight into properties of timber linked to fire performance, such as density, moisture content or permeability, and to maximize timber’s reusability in the construction sector, non-destructive testing is preferable, meaning techniques that do not damage the specimen. More specifically, the technique must be able to be repeated to infinity to be truly non-destructive. For techniques that can be repeated, but would eventually lead to degradation of the specimen, the term semi-destructive is used. These techniques can also be used, but must be carefully applied to not reduce the potential of the specimen for reuse.

The most common non-destructive techniques are presented here, as well as some newer methods that are considered promising.

Some methods only give limited information on the element tested, making them less attractive for commercial use. To differentiate the ways in which a method is limited, four categories are introduced:

-

L: the information is only applicable to part of the element (Local).

-

NQ: the information is Not Quantifiable.

-

UR: the technique is still Under Research.

-

E: the technique only provides an Estimate of the investigated property, with high error rates.

6.1 Visual Investigation

Historically, the first step when a wooden element is evaluated is a thorough visual investigation [66,67,68], supported by pictures and basic measurement tools such as callipers, feeler gauges, or rubber mallets. This is the case for wooden objects, furniture, construction beams and even trees.

This method can identify many defects and problems with the wood (cracks, fungi, etc.), can generally identify wood genus (though precise species can be difficult to pinpoint) [69, 70], can sometimes identify the time period during which the piece was sawn [71], and has been historically, and is still to this day, used to grade the mechanical properties of timber [72,73,74]. An example of damages visible to the eye is shown in Fig. 9. Visual investigation can also be used to estimate the density of a specimen through its weight and apparent dimensions. The more irregular the piece, and the more damages it received, the less precise the method is.

This method is always going to be used, as it is relatively cheap and fast and requires little equipment. It has nonetheless some drawbacks, as it requires an experienced investigator and cannot accurately answer for the internal quality of the specimen [75]. As such, it is a Local (L) method for geometrical properties and provides only an Estimate (E) of the mechanical properties and the species identification.

6.2 Photometry

Photometry in the context of measurements of construction materials includes all methods of measurement of visible light that supplement visual investigation, such as pictures, 3D mapping, laser measurements, etc. They are used to obtain geometrical information such as shape, cracks, slope of grain or measurement of knots [76,77,78], or surface information on weathering [56, 79]. Since the information is limited to the surface of the element, photometry is categorized as Local (L). An example of 3D mapping is shown in Fig. 10.

3D mapping of the Pinus sylvestris piece shown in Fig. 9. The crack (arrow), the cut and the steel tube (red square) are visible (Color figure online)

6.3 Sound Waves

These methods study sound waves in the wooden element. Information about the wood is obtained by analysing a sound pulse through the element and/or its echo. It can be used as an imaging technique or for measuring the vibrational properties of the wood.

The use of sound waves as an imaging tool is limited, though rapidly progressing [80], but the results are Not Quantifiable (NQ) [81]. Sound waves can also be used to measure the time of flight of sound in the material, which is related to both the density and modulus of elasticity [73, 74, 76, 82,83,84]. These measurements have been shown to be dependent on both temperature and moisture content [85,86,87].

Vibrational analysis is the study of the resonance frequency of the element, usually calculated from an oscilloscope or accelerometer. It is related to the modulus of elasticity and the density [85]. The vibration frequency of wood is temperature and moisture content dependent. Riggio et al. [88] showed that vibrational analysis returns lower results than time of flight measurements for the modulus of elasticity of the same sample.

With these limitations of the technique in mind, the use of sound waves to calculate mechanical properties is here considered an Estimate (E).

6.4 X-Rays

This method is usually applied for imaging the internal structure of the element. The absorption of X-ray beams is measured, giving insight on the wood geometry and potential damages or inhomogeneities, such as hidden metal nails or dowels of a different wood species.

X-ray computer tomography has been shown to be used to map knots [89, 90] and detect damages inside wooden specimens [66, 69]. An example of the information which can be retrieved through this method is shown in Fig. 11. There is a clear difference in pore size and distribution, and rays are visible on the left sample but absent on the right. There is also a very strong correlation between the density of wood clear of knots and defects and its attenuation of X-rays [91,92,93].

X-Ray fluorescence spectroscopy has also been used by Shugar et al. [94] along with machine learning to identify wood species from samples. As this use of the technique is new, it is still Under Research (UR).

6.5 Microwave

As with X-rays, the absorption of microwaves can be used to infer wood properties, as well as for imaging [66]. This relies on the dielectric properties of the sample.

Aichholzer et al. [95] used this method to measure the density, moisture content and grain angle in spruce. They found good correlations for samples from 5 to 27% moisture content, but the technique has only been used in laboratory, on smaller samples. This method is considered Under Research (UR) for the purpose of this review.

Brodie et al. [96] showed that microwave measurements could be used to detect termite infestations in hardwood poles installed in Melbourne, Australia, in a qualitative detection scenario.

Ground penetrating radars use the same principle as microwave methods, measuring the dielectric properties of the sample to image its internal structure. Its main advantage is the speed of the application, though the interpretation of the results is oftentimes difficult, and requires an experienced operator [97]. This method is Not Quantifiable (NQ).

6.6 Infrared Spectroscopy

Infrared spectroscopy is the study of the spectrum of light created by a sample when excited with infrared light. When associated with machine learning, it has been shown to be able to discriminate wood species [98,99,100], wood origin [101], as well as trace individual trees through a production line [102]. It has also been associated with other methods to determine the chemical composition of wood and biomass [103,104,105,106], though the method is often only adapted to one species. Near-infrared spectroscopy has also shown promises for the determination of mechanical properties [46].

Pánek et al. [15] showed that the surface spectrum of wood changed significantly after weathering, indicating that the state of the surface could influence the results of IR spectroscopy. They attribute the changes in spectra to the changes in chemical composition of the wood surface after exposure to water and UV light, specifically degradation of lignin and hemicelluloses. Palanti et al. [107] used the near infrared spectrum of Italian cypress to determine its extractive content.

Infrared spectroscopy may also be used for density measurements, though the model needs to be calibrated for a specific species, and for the detection of defects such as knots, bark, and cracks [108]. The same study found a low correlation between the IR information and the modulus of elasticity of the wood.

Poletto et al. [103] used Fourier Transform Infrared spectroscopy combined with chemical analysis and thermogravimetry to evaluate differences wood chemistry and structure between different species.

All these uses of infrared spectroscopy are classified for this review as Under Research (UR).

6.7 Semi-Destructive Testing

Many different methods of measurement imply some damage to the sample. These damages may be minimal, as only a sample weighing a few micrograms may be needed, but are not infinitely repeatable. Nonetheless, they might be necessary to measure some wood properties. Aside from species identification, the results are always Local (L).

6.7.1 Sample Collection

Many properties of wood can be measured locally by collecting and testing a sample. In this case, the test can be fully destructive, as it only affects the sample, and not the full element. Such tests can measure:

-

Mechanical strength (bending, shear, tensile) [109]

-

Density [110]

-

Moisture content [110]

-

Permeability [38]

-

Chemical composition [111]

The identification of the wood species is also often done through the study of a sample under microscope, comparing the anatomy with a library [70]. These tests are negligibly destructive, as long as care is taken to document the specimen properly, since the sample taken is usually on the scale of micrograms.

Nuclear magnetic resonance (NMR), which measures the reaction of molecules to a magnetic field, can give insight into the chemical composition and porosity of wood [112,113,114]. Samples usually need to be taken, but some studies have been done with mobile probes [113, 115]. This is a well-documented semi-destructive method, but still under research as a non-destructive method.

For density specifically, drill residue collection leads to more accurate readings of the density [116], by collecting not only the core sample but also the sawdust residue created by the drilling.

Sample collection to investigate the properties of reused wood are not always problematic, particularly for small stocks. But in timber buildings, some properties of the wood are uncertain, such as the species and genus of the pieces, or how long ago they have been harvested. It is precarious to make assumptions about statistical distributions in the stock. Thus, nearly all specimens should be tested, which for large stocks is a lengthy and expensive process. The same reasoning explains the avoidance of fire tests.

6.7.2 Local Tests

Local tests are performed on the full element tested, but only damage the test area.

Resistivity measurements are the accepted method for measuring the moisture content of wood, with many different brands of moisture meter functioning on the measurement of the electrical resistivity of the wood. It consists of pushing two electrodes into the specimen and measuring the electrical resistance. This leaves two small holes in the wood. These measurements are limited to the range between 6% and the fibre saturation point [117].

Complex resistivity has also been shown to be able to measure both moisture content and the degradation of wood, for example due to fungi attacks [118]. This method is most commonly used on live trees.

In penetration tests, a probe usually made of steel is pushed into the element, and the resistance to penetration is measured. They are often used to give a measure of the density or hardness of the piece, as well as other mechanical properties [83].

Pin pushing [74, 109], needle penetration [119] and drill resistance [74, 120] tests are all examples of penetration tests. They are sometimes used to investigate the internal soundness of the wood, as a sudden drop in penetration resistance is reliably associated with a defect such as rot, insect damage or the presence of a void. Multiple measurements placed strategically on the piece can give information on the residual geometry of a heavily damaged piece, for example after exposure to fire [120].

Another form of penetration test is the hardness test, usually derived from the Janka test [121], in which the force needed to imbed a 1cm diameter steel hemisphere into the wood. This only gives surface information on the element but is well correlated with the modulus of rupture, the density, and the modulus of elasticity for sound wood [109, 122].

A screw withdrawal test measures the force needed to remove a screw drilled into the wood. It provides information on density and mechanical properties [109, 123]. The compression strength can be measured in a pre-drilled hole [109], leading to better representation of the internal mechanical properties of the wood element.

6.8 Unsuitable Methods

There exist non- and semi-destructive techniques which are used for wood and wood products, but which have been found to be irrelevant for this review. Some examples will be mentioned here.

Acoustic emissions testing gives valuable insight into the stresses of timber in service [124], but it is unsuitable for timber out of service. Loading tests only measure the mechanical properties of timber, which at room temperature have not been linked to burning behaviour. Thermography can identify regions of damage [81] or unusually high moisture content, but only qualitatively. Magnetic resonance imaging, or MRI, is most suited for the imaging of specimen with high water content, like living tissues or waterlogged wood [66, 125], and cannot be used if there are any magnetic metals in the tested specimen.

7 Summary

Table 3 summarizes the different techniques explained in this review, with the associated measured properties and limitations of each method. The greyed-out cells correspond to techniques which are not readily available commercially. Table 3 shows that most methods are concerned with measuring geometrical properties (including biotic attacks and internal defects). There exists no non-destructive method to measure permeability of wood.

Of all available techniques, some stand out:

-

Acoustic emission measurements cannot be used to measure inherent properties of the wood.

-

The use of X-Rays is the only method which can observe reliably and quantifiably the geometry of the wood internal and external (voids, cracks, and biotic attacks). It is also the only non-destructive method which can measure the density of wood over a large volume.

-

Infrared spectroscopy is the only method which might identify wood species without having to collect a sample, inducing excessive costs, though the method requires heavy calibration. It is also the only non-destructive technique found to measure wood chemistry, though no study has been found applying it to construction grade timber.

Some techniques can report on the mechanical properties of wood (i.e., stress waves), while others cover properties that can be associated with fire performance (i.e., X-rays). Of the reported techniques in this study, only the study of samples and the use of (near-) infrared spectroscopy have been shown to do both, as shown in Fig. 12.

Table 4 compares the properties of wood and shows whether they change with time, whether they have been linked to the fire performance, and whether they can be measured by non-destructive methods. The best options for measuring non-destructively the fire performance of reused timber rely in the measurement of properties that are linked to fire.

It shows that there is potential in studying the density, moisture content, permeability, and species of wood when it comes to its fire performance. Permeability cannot yet be measured non-destructively, but the others can. And though the mechanical properties of wood are not directly linked to its fire performance, other properties of timber are linked to both, such as the density, or the species. An additional point of research could be to find a non-destructive technique linked to both fire reaction and mechanical properties.

8 Conclusion

The aim of this paper is to review whether non-destructive testing methods allow to estimate the fire performance of reused wood, reducing the need for expensive and extensive fire tests. For this purpose, three aspects were investigated in literature:

-

The properties of wood linked to its fire performance

-

The aging of wood properties

-

Which non-destructive testing methods are available

Many properties of wood have been agreed by researchers to factor into its fire performance. Density, moisture content, permeability and species all have an influence, but none can be said to dominate the burning process. Thus, the fire performance of reused wood cannot be reliably predicted by one or even a combination of these parameters.

Additionally, the relationship between fire performance and both local geometry and chemical composition is unclear for different reasons. The influence of local geometry is under researched, while there is contradicting literature on the influence of the chemical composition.

There were no studies found researching a relationship between mechanical properties at room temperature and fire performance metrics, though they are both linked to other wood properties, such as its density.

With those different factors in mind, this paper looked at which properties of wood change with ageing, and how. As the genus and species of the wood cannot change, the focus was on mechanical properties, geometry, moisture content, permeability, and density, of which none were found to irreversibly change through only the passage of time.

Mechanical and geometrical properties change depending on the environmental conditions and the loads during its use. There often is a degradation of the mechanical strength of the wood, and some loss of material can be seen due to biotic attacks, or human action. Cracks are also common in timber even after a short period of use.

Moreover, though the moisture content of the wood might change with time, it is not irreversible, and proper conditioning will bring the element to the desired level with time.

As for density and permeability, no research was found indicating whether changes can be observed over time, though there were indications of chemical changes, as the hemicelluloses decreased, while the lignin and celluloses content remained constant. It is to be noted that the results were not uniform over all studies.

Finally, non-destructive testing was investigated. Many uses were found, but most techniques focus on obtaining information on the geometrical defects of the wood, such as insect attacks or internal voids. Only four non-destructive tests were found which could measure wood properties accurately and over an entire piece while at the same time being well-researched and documented:

-

X-ray photography/tomography permits both the measurement of the density of the wood as well as the recording of the wood geometry.

-

Resistivity measurement is an accepted and commercially available method for the determination of the moisture content in timber.

-

Infrared spectroscopy has been reliably linked to the discrimination of different wood species.

-

Loading tests are the only method that can precisely measure some of the mechanical properties of timber, though these tests are not always non-destructive.

From the results of the reported studies, it is concluded that there is no currently available methodology to determine the fire performance of reused timber through non-destructive tests. There are nonetheless indications that density measurements, combined with moisture content and species identification, could answer broadly for the fire performance.

A clearer picture of the way fire performance of timber evolves with time is needed, through extensive comparative testing. But there are also more research opportunities revealed by this review.

Current technology does not permit to measure wood permeability non-destructively. Such a technique is available for the water absorption capabilities of concrete. The development of an equivalent for wood would encourage future researcher to consider permeability as a factor for fire performance, as well as for other parameters.

As a second opportunity, there is already a technique for the determination of the chemical composition of wood through NIR/IR spectrometry. Without having to content with expensive and time-consuming chemical tests, this technique permits a rapid answer, if the proper method is established for the type of sample. There is thus a need for a large-scale study of softwood chemical composition compared to NIR/IR spectrometry, which would open the door for many subsequent studies comparing wood chemical composition to other properties, among others the fire performance.

Lastly, the relationship between wood geometry and fire performance is still unclear. Cracks and biotic attacks can influence the depth of the char layer locally, but there is little information on whether this is a concern for global design.

Availability of Data and Materials

Data sharing not applicable to this article as no datasets were generated or analysed during the current study.

References

Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions—A new Circular Economy Action Plan—For a cleaner and more competitive Europe. (2020)

Delivering the European Green Deal. https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal/delivering-european-green-deal_en

Risse, M., Weber-Blaschke, G., Richter, K.: Resource efficiency of multifunctional wood cascade chains using LCA and exergy analysis, exemplified by a case study for Germany. Resour. Conserv. Recycl. 126, 141–152 (2017). https://doi.org/10.1016/j.resconrec.2017.07.045

Niu, Y., Rasi, K., Hughes, M., Halme, M., Fink, G.: Prolonging life cycles of construction materials and combating climate change by cascading: the case of reusing timber in Finland. Resour. Conserv. Recycl. 170, 105555 (2021). https://doi.org/10.1016/j.resconrec.2021.105555

Waste prevention and management—Environment—European Commission. https://ec.europa.eu/environment/green-growth/waste-prevention-and-management/index_en.htm

Benachio, G.L.F., Freitas, M.C.D., Tavares, S.F.: Circular economy in the construction industry: a systematic literature review. J. Clean. Prod. 260, 121046 (2020). https://doi.org/10.1016/j.jclepro.2020.121046

Knoth, K., Fufa, S.M., Seilskjær, E.: Barriers, success factors, and perspectives for the reuse of construction products in Norway. J. Clean. Prod. 337, 130494 (2022). https://doi.org/10.1016/j.jclepro.2022.130494

Bertelsen, S.E., Fogh Gustafsson, K., Hill-Hansen, D., Shoonhoven, J., Lysgaard Vind, D.: Drivers and demands for circular building materials. Lendager TCW (2020)

Mikkola, E.: Charring of wood based materials. Fire Saf. Sci. 3, 547–556 (1991). https://doi.org/10.3801/IAFSS.FSS.3-547

European Committee for Standardization: EN 1995 (2004) Eurocode 5: Design of timber structures

Standards Australia: AS/NZS 1720.4 Timber structures Fire resistance of timber elements (2019)

ANSI: National Design Specification for Wood Construction (2024)

Bartlett, A.I., Hadden, R.M., Bisby, L.A.: A review of factors affecting the burning behaviour of wood for application to tall timber construction. Fire Technol. 55, 1–49 (2019). https://doi.org/10.1007/s10694-018-0787-y

Gilka-Bötzow, A., Heiduschke, A., Haller, P.: Zur Abbrandrate von Holz in Abhängigkeit der Rohdichte. Eur. J. Wood Wood Prod. 69, 159–162 (2011). https://doi.org/10.1007/s00107-010-0430-1

Pánek, M., Kubovský, I., Oberhofnerová, E., Štěrbová, I., Niemz, P., Osvald, A., Kačík, F.: Influence of natural weathering on the ignition and relative burning rate of selected softwoods. Constr. Build. Mater. 304, 124615 (2021). https://doi.org/10.1016/j.conbuildmat.2021.124615

Harada, T.: Charring of wood with thermal radiation, 2: charring rate calculated from mass loss rate. Mokuzai Gakkai-Shi. 42, 194–201 (1996)

Adetayo, O., Dahunsi, B.I.O.: Comparisons of predicted and experimental charring rates at various moisture contents of selected Southern Nigerian structural wood species. Eng. Technol. Appl. Sci. Res. 47, 93–102 (2020)

Fahrni, R., Klippel, M., Just, A., Ollino, A., Frangi, A.: Fire tests on glued-laminated timber beams with specific local material properties. Fire Saf. J. 107, 161–169 (2019). https://doi.org/10.1016/j.firesaf.2017.11.003

Haurie, L., Giraldo, M.P., Lacasta, A.M., Montón, J., Sonnier, R.: Influence of different parameters in the fire behaviour of seven hardwood species. Fire Saf. J. 107, 193–201 (2019). https://doi.org/10.1016/j.firesaf.2018.08.002

Chorlton, B., Gales, J.: Fire performance of cultural heritage and contemporary timbers. Eng. Struct. 201, 109739 (2019). https://doi.org/10.1016/j.engstruct.2019.109739

Friquin, K.L.: Material properties and external factors influencing the charring rate of solid wood and glue-laminated timber. Fire Mater. 35, 303–327 (2011). https://doi.org/10.1002/fam.1055

Aseeva, R., Serkov, B., Sivenkov, A.: Effect of natural aging of timber building structures on fire behavior and fire safety. In: Fire Behavior and Fire Protection in Timber Buildings, pp. 229–258. Springer Netherlands, Dordrecht (2014)

Mindykowski, P., Jørgensen, M., Svensson, S., Jomaas, G.: A simple correlation for monitoring the ignition propensity of wet nordic spruce wood. Fire Saf. J. 107, 186–192 (2019). https://doi.org/10.1016/j.firesaf.2018.08.001

Pečenko, R., Svensson, S., Hozjan, T.: Modelling heat and moisture transfer in timber exposed to fire. Int. J. Heat Mass Transf. 87, 598–605 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2015.04.024

Galgano, A., Di Blasi, C.: Modeling the propagation of drying and decomposition fronts in wood. Combust. Flame 139, 16–27 (2004). https://doi.org/10.1016/j.combustflame.2004.07.004

Spearpoint, M.J., Quintiere, J.G.: Predicting the piloted ignition of wood in the cone calorimeter using an integral model—effect of species, grain orientation and heat flux. Fire Saf. J. 36, 391–415 (2001). https://doi.org/10.1016/S0379-7112(00)00055-2

Gerandi, G., Tihay-Felicelli, V., Santoni, P.-A., Leroy-Cancellieri, V., Cancellieri, D.: Multi-scale modeling of the degradation of thermally thin wood plates. Fire Saf. J. 108, 102823 (2019). https://doi.org/10.1016/j.firesaf.2019.102823

Dietenberger, M., Hasburgh, L.: Wood products thermal degradation and fire. Ref. Module Mater. Sci. Mater. Eng. (2016). https://doi.org/10.1016/b978-0-12-803581-8.03338-5

Tran, H.C., White, R.H.: Burning rate of solid wood measured in a heat release rate calorimeter. Fire Mater. 16, 197–206 (1992). https://doi.org/10.1002/fam.810160406

Richter, F., Atreya, A., Kotsovinos, P., Rein, G.: The effect of chemical composition on the charring of wood across scales. Proc. Combust. Inst. 37, 4053–4061 (2019). https://doi.org/10.1016/j.proci.2018.06.080

Cimer, Z., Czoboly, O., Harmann, B., Lublóy, É.: The effect of the wood defects on fire resistance. Period. Polytech. Civ. Eng. 64, 60–64 (2020). https://doi.org/10.3311/PPci.14838

Sandanus, J., Kamenická, Z., Rantuch, P., Martinka, J., Balog, K.: Charring of timber with fissures in experimental and numerical simulations. In: Makovicka Osvaldova, L., Markert, F., Zelinka, S.L. (eds.) Wood & Fire Safety, pp. 159–165. Springer, Cham (2020)

Harun, G., Chorlton, B., Richter, F., Gales, J.: The effects of radial cracks on the fire performance of heritage timber. Fire Mater. 47, 386–399 (2023). https://doi.org/10.1002/fam.3104

Wang, Y., Wang, W., Zhou, H., Qi, F.: Burning characteristics of ancient wood from traditional buildings in Shanxi Province, China. Forests 13, 190 (2022). https://doi.org/10.3390/f13020190

Richter, F., Rein, G.: A multiscale model of wood pyrolysis in fire to study the roles of chemistry and heat transfer at the mesoscale. Combust. Flame 216, 316–325 (2020). https://doi.org/10.1016/j.combustflame.2020.02.029

Collier, PCR: SR42 Charring rates of timber. https://www.branz.co.nz/pubs/research-reports/sr42/ (1992)

Njankouo, J., Dotreppe, J.-C., Franssen, J.-M.: Experimental study of the charring rate of tropical hardwoods. Fire Mater. 28, 15–24 (2004). https://doi.org/10.1002/fam.831

Hugi, E., Wuersch, M., Risi, W., Wakili, K.G.: Correlation between charring rate and oxygen permeability for 12 different wood species. J. Wood Sci. 53, 71–75 (2007). https://doi.org/10.1007/s10086-006-0816-1

Hugi, E., Weber, R.: Fire behaviour of tropical and European wood and fire resistance of fire doors made of this wood. Fire Technol. 48, 679–698 (2012). https://doi.org/10.1007/s10694-010-0207-4

Wiesner, F., McGiveron, B., Liu, T., Hidalgo, J.P., Morrell, J.J.: Bushfire performance of native Australian wood species. Fire Saf. J. 140, 103884 (2023). https://doi.org/10.1016/j.firesaf.2023.103884

International Organization for Standardization: ISO 834-1:1999

White, R.H., Nordheim, E.V.: Charring rate of wood for ASTM E 119 exposure. Fire Technol. 28, 5–30 (1992). https://doi.org/10.1007/BF01858049

Di Blasi, C., Branca, C., Santoro, A., Gonzalez Hernandez, E.: Pyrolytic behavior and products of some wood varieties. Combust. Flame 124, 165–177 (2001). https://doi.org/10.1016/S0010-2180(00)00191-7

Routa, J., Brännström, H., Anttila, P., Mäkinen, M., Jänis, J., Asikainen, A.: Wood extractives of Finnish pine, spruce and birch—availability and optimal sources of compounds

O’Brien, L., Schuck, A., Fraccaroli, C., Pötzelsberger, E., Winkel, G., Lindner, M.: Protecting old-growth forests in Europe—a review of scientific evidence to inform policy implementation. European Forest Institute (2021)

Niemz, P., Sonderegger, W., Keplinger, T., Jiang, J., Lu, J.: Physical properties of wood and wood-based materials. In: Niemz, P., Teischinger, A., Sandberg, D. (eds.) Springer Handbook of Wood Science and Technology, pp. 281–353. Springer, Cham (2023)

Cavalli, A., Cibecchini, D., Togni, M., Sousa, H.S.: A review on the mechanical properties of aged wood and salvaged timber. Constr. Build. Mater. 114, 681–687 (2016). https://doi.org/10.1016/j.conbuildmat.2016.04.001

Machado, J.S., Pereira, F., Quilhó, T.: Assessment of old timber members: importance of wood species identification and direct tensile test information. Constr. Build. Mater. 207, 651–660 (2019). https://doi.org/10.1016/j.conbuildmat.2019.02.168

Llana, D.F., González-Alegre, V., Portela, M., Íñiguez-González, G.: Cross Laminated Timber (CLT) manufactured with European oak recovered from demolition: structural properties and non-destructive evaluation. Constr. Build. Mater. 339, 127635 (2022). https://doi.org/10.1016/j.conbuildmat.2022.127635

Uwizeyimana, P., Perrin, M., Laügt, E., Eyma, F.: Durability study of glulam timber under cyclic moisture loading. Constr. Build. Mater. 315, 125715 (2022). https://doi.org/10.1016/j.conbuildmat.2021.125715

Wu, Q., Huo, L., Zhu, E., Niu, S., Wang, H.: An investigation of the duration of load of structural timber and the clear wood. Forests 12, 1148 (2021). https://doi.org/10.3390/f12091148

Hoffmeyer, P., Sørensen, J.D.: Duration of load revisited. Wood Sci. Technol. 41, 687–711 (2007). https://doi.org/10.1007/s00226-007-0154-5

Falk, R.H., Green, D., Rammer, D., Lantz, S.F.: Engineering evaluation of 55-year-old timber columns recycled from an industrial military building. For. Prod. J. 50, 71–76 (2000)

Yokoyama, M., Gril, J., Matsuo, M., Yano, H., Sugiyama, J., Clair, B., Kubodera, S., Mistutani, T., Sakamoto, M., Ozaki, H., Imamura, M., Kawai, S.: Mechanical characteristics of aged Hinoki wood from Japanese historical buildings. Comptes Rendus Phys. 10, 601–611 (2009). https://doi.org/10.1016/j.crhy.2009.08.009

Kránitz, K.: Effect of natural aging on wood. http://hdl.handle.net/20.500.11850/98764 (2014)

Pandey, K.K.: Study of the effect of photo-irradiation on the surface chemistry of wood. Polym. Degrad. Stab. 90, 9–20 (2005). https://doi.org/10.1016/j.polymdegradstab.2005.02.009

Ranta-Maunus, A.: Effects of climate and climate variations on strength. In: Thelandersson, S., Larsen, H.J. (eds.) Timber Engineering, pp. 153–168. Wiley (2003)

Fragiacomo, M., Fortino, S., Tononi, D., Usardi, I., Toratti, T.: Moisture-induced stresses perpendicular to grain in cross-sections of timber members exposed to different climates. Eng. Struct. 33, 3071–3078 (2011). https://doi.org/10.1016/j.engstruct.2011.06.018

Shirmohammadi, M., Leggate, W., Redman, A.: Effects of moisture ingress and egress on the performance and service life of mass timber products in buildings: a review. Constr. Build. Mater. 290, 123176 (2021). https://doi.org/10.1016/j.conbuildmat.2021.123176

Dömény, J., Koiš, V., Dejmal, A.: Microwave radiation effect on axial fluid permeability in false heartwood of beech (Fagus sylvatica L.). BioResources 9 (2013). https://doi.org/10.15376/biores.9.1.372-380

Granello, G., Palermo, A.: Creep in timber: research overview and comparison between code provisions. 27, 6–22 (2019)

Dorez, G., Ferry, L., Sonnier, R., Taguet, A., Lopez-Cuesta, J.-M.: Effect of cellulose, hemicellulose and lignin contents on pyrolysis and combustion of natural fibers. J. Anal. Appl. Pyrolysis 107, 323–331 (2014). https://doi.org/10.1016/j.jaap.2014.03.017

Garcia-Castillo, E., Paya-Zaforteza, I., Hospitaler, A.: Analysis of the fire resistance of timber jack arch flooring systems used in historical buildings. Eng. Struct. 243, 112679 (2021). https://doi.org/10.1016/j.engstruct.2021.112679

Guibaud, A., Mindeguia, J.-C., Albuerne, A., Parent, T., Torero, J.: Notre-Dame de Paris as a validation case to improve fire safety modelling in historic buildings. J. Cult. Herit. (2023). https://doi.org/10.1016/j.culher.2023.05.008

Garcia-Castillo, E., Paya-Zaforteza, I., Hospitaler, A.: Fire in heritage and historic buildings, a major challenge for the 21st century. Dev. Built Environ. 13, 100102 (2023). https://doi.org/10.1016/j.dibe.2022.100102

Bucur, V.: Nondestructive Characterization and Imaging of Wood. Springer, Berlin (2003)

Feio, A., Machado, J.S.: In-situ assessment of timber structural members: combining information from visual strength grading and NDT/SDT methods—a review. Constr. Build. Mater. 101, 1157–1165 (2015). https://doi.org/10.1016/j.conbuildmat.2015.05.123

Cruz, H., Yeomans, D., Tsakanika, E., Macchioni, N., Jorissen, A., Touza, M., Mannucci, M., Lourenço, P.B.: Guidelines for on-site assessment of historic timber structures. Int. J. Archit. Herit. 9, 277–289 (2015). https://doi.org/10.1080/15583058.2013.774070

Kasal, B., Anthony, R.W.: Advances in in situ evaluation of timber structures. Prog. Struct. Eng. Mater. 6, 94–103 (2004). https://doi.org/10.1002/pse.170

Wheeler, E.A., Baas, P.: Wood identification—a review. IAWA J. 19, 241–264 (1998). https://doi.org/10.1163/22941932-90001528

Williams, D.: “Reading” tool marks on furniture. Chron. Early Am. Ind. Assoc. 61 (2008)

Derikvand, M., Kotlarewski, N., Lee, M., Jiao, H., Chan, A., Nolan, G.: Visual stress grading of fibre-managed plantation Eucalypt timber for structural building applications. Constr. Build. Mater. 167, 688–699 (2018). https://doi.org/10.1016/j.conbuildmat.2018.02.090

Wang, S.-Y., Chen, J.-H., Tsai, M.-J., Lin, C.-J., Yang, T.-H.: Grading of softwood lumber using non-destructive techniques. J. Mater. Process. Technol. 208, 149–158 (2008). https://doi.org/10.1016/j.jmatprotec.2007.12.105

Branco, J.M., Sousa, H.S., Tsakanika, E.: Non-destructive assessment, full-scale load-carrying tests and local interventions on two historic timber collar roof trusses. Eng. Struct. 140, 209–224 (2017). https://doi.org/10.1016/j.engstruct.2017.02.053

Dietsch, P., Tannert, T.: Assessing the integrity of glued-laminated timber elements. Constr. Build. Mater. 101, 1259–1270 (2015). https://doi.org/10.1016/j.conbuildmat.2015.06.064

Palma, P., Steiger, R.: Structural health monitoring of timber structures—review of available methods and case studies. Constr. Build. Mater. 248, 118528 (2020). https://doi.org/10.1016/j.conbuildmat.2020.118528

Thomas, R.E.: Laser scanning of logs and lumber. In: Nondestructive Evaluation of Wood, 2nd edn. (2015)

Ross, R.J.: Nondestructive Evaluation of Wood: Second Edition. U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, WI (2015)

Esteves, B., Velez Marques, A., Domingos, I., Pereira, H.: Heat-induced colour changes of pine (Pinus pinaster) and eucalypt (Eucalyptus globulus) wood. Wood Sci. Technol. 42, 369–384 (2008). https://doi.org/10.1007/s00226-007-0157-2

Drinkwater, B.W., Wilcox, P.D.: Ultrasonic arrays for non-destructive evaluation: a review. NDT E Int. 39, 525–541 (2006). https://doi.org/10.1016/j.ndteint.2006.03.006

Riggio, M., Sandak, J., Franke, S.: Application of imaging techniques for detection of defects, damage and decay in timber structures on-site. Constr. Build. Mater. 101, 1241–1252 (2015). https://doi.org/10.1016/j.conbuildmat.2015.06.065

Osuna-Sequera, C., Llana, D.F., Hermoso, E., Arriaga, F.: Acoustic wave velocity in long pieces of Salzmann pine for in-situ structural assessment. Constr. Build. Mater. 269, 121256 (2021). https://doi.org/10.1016/j.conbuildmat.2020.121256