Abstract

Ultrasonic pulse-echo non-destructive testing, combined with Distance Gain Size (DGS) analysis, is still the main method used for the inspection of forgings such as shafts or discs. This method allows the inspection to be carried out, assuring in turns the necessary sensitivity and defect detection capability in most of the cases. However, when testing large or highly attenuating samples with standard pulse-echo, the maximum achievable signal-to-noise ratio is limited by both the beam energy physical attenuation during the propagation and by the inherent divergence of any ultrasound beam emitted by a finite geometrical aperture. To face this issue, the application of the pulse-compression technique to the ultrasonic inspection of forgings was proposed by some of the present authors, in combination with the use of broadband ultrasonic transducers and broadband chirp excitation signals. Here, the method is extended by applying DGS analysis to the pulse-compression output signal. Both standard single-frequency/narrowband DGS and multi-frequency/broadband DGS analyses applied on pulse-compression data acquired on a forging with known defects are tested and compared. It is shown that the DGS analysis works properly with pulse-compression data collected by using a separate transmitter and receiver transducers. Narrowband analysis and broadband analyses provide almost identical results, but the latter exhibits advantages over the traditional method: it allows the inspection frequency to be optimized by using a single pair of transducers and with a single measurement. In addition, the range resolution achieved is higher than the one achievable for the narrowband case.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ultrasonic NDT is the only technique that allows the inspection of the whole volume of large forgings. Pulse-echo (PuE) is a widespread method—all the Standards and evaluation procedures have been developed around it. Among these, the analysis based on the DGS diagrams is the standard method allowing the sizing of defects in large structures where the use of Distance Amplitude Curve (DAC) is not feasible [1,2,3]. Various probes at different incidence angles and with different central frequencies are used to guarantee the inspection of the whole sample’s volume with an adequate sensitivity for each possible type of embedded defect.

Despite DGS analysis with PuE is effective in most of the situations, two main critical points emerge: (1) the increasing need of automatic inspection procedures, makes the use of many different probes inconvenient; (2) in the presence of high attenuation and/or large dimensions of the forgings, PuE could not guarantee an enough SNR level and sensitivity. To face the former point, phased-array systems have been introduced, making the automatic inspection easier. In fact, a single phased-array probe can replace several standard probes. Moreover, the sensitivity can be increased where needed to address also the latter issue, as it is possible to vary the focusing of the ultrasonic beam. However, this is not enough in some critical applications, especially when a high sensitivity is required with very weak signals or high noise level.

Some of the present authors proposed to exploit pulse-compression (PuC) technique in combination with the use of two separate transducers, one transmitter (Tx) and one receiver (Rx), and chirp signals to increase the SNR of the measurement, and in turns to increase the defect detection sensitivity [4, 5].

In the present work, the method is improved by developing a numerical simulation tool for calculating DGS curves for an arbitrary Tx–Rx configuration working with both single-element and phased-array probes. The resulting DGS diagrams are used to evaluate the size of known flat bottom hole defects realized on a steel forging. Two different DGS analysis procedures are implemented and compared: one makes use of a narrowband excitation chirp signal and of a single-frequency DGS analysis, so replicating the conditions of a standard single-frequency DGS analysis made in PuE with a single narrowband probe, the other makes use of a broadband chirp signal and a simultaneous multi-frequency DGS analysis.

The paper is organized as follows: the basic theory of PuC is summarized in Sect. 2; in Sect. 3, the multi-frequency DGS analysis is introduced; in Sect. 4, experimental results and a comparison between single-frequency and multi-frequency DGS analysis are reported. In Sect. 5, some conclusions and perspectives are drawn.

2 Pulse Compression Basic Theory

Flaws detection through ultrasonic inspection consists in measuring the impulse response \( h\left( t \right) \) of the sample under test (SUT) with respect to a mechanical wave excitation. In standard PuE method, the impulse response \( h\left( t \right) \) of the system under inspection is estimated by exciting the SUT with a short pulse \( \widetilde{\delta }\left( t \right) \) and then recording the system’s response \( \widetilde{h}\left( t \right) = \widetilde{\delta }\left( t \right)*h\left( t \right) \), where “*” is the convolution operator. If \( \widetilde{\delta }\left( t \right) \) is short enough to cover uniformly the whole bandwidth of the transducers, the approximation can be considered very close to the true expected signals.

On the contrary, in a PuC measurement scheme an estimate \( \widehat{h}\left( t \right) \) of \( h\left( t \right) \) is retrieved by: (I) exciting the system with a coded signal \( s\left( t \right) \); (II) measuring the output of the coded excitation \( y\left( t \right) = s\left( t \right)*h\left( t \right) \); (III) applying the so-called matched filter \( \psi \left( t \right) \) to the output [6]. The result obtained at the end of the PuC procedure is mathematically described in Eq. (1):

where the “pulse-compression condition” \( \psi \left( t \right)*s\left( t \right) = \widehat{\delta }\left( t \right) \approx \delta \left( t \right) \) has been exploited. As in most of the applications, in the present paper the matched filter is defined as the time-reversed replica of \( s\left( t \right), \psi \left( t \right) = s\left( { - t} \right) \), so that \( \widehat{\delta }\left( t \right) \) turns out to be the autocorrelation function of \( s\left( t \right) \).

The PuC condition can be therefore assured by every waveform having a δ-like autocorrelation function. An extended literature is available on this topic (see for example [4, 7,8,9]) even if, as a matter of fact, two main classes of coded excitations are of practical interest and used for various applications, among which NDT: (a) frequency modulated “chirp” signals and (b) phase-modulated “binary” signals. Chirp signals are sinusoidal signals characterized by a time-varying istantaneous frequency \( f_{ist} \left( t \right) \). Chirps can be either linear, i.e. with a linearly varying instantaneous frequency, and non-linear. A notable example of non-linear chirp is the exponential one in which the istantanesous frequency changes exponentially with the time and that is used in combination of pulse-compression to characterize a large class of non-linear systems [10]. More generally, a non-linear chirp can be defined to reproduce any arbitrary continuous spectrum depending on the application [11]. Phase-modulated coded excitations are instead derived by binary sequences having peculiar mathematical properties, e.g. Barker codes, maximum-length sequences (MLS), Golay codes, etc. [7,8,9, 12, 13]. In general such codes have a base-band spectrum but they can be modulated by a single frequency signal to obtain a bandpass one. Nevertheless, phase-modulated signals have not the same flexibility in shaping the excitation spectrum of the chirp signals. On the other hand, PuC measurement schemes based on binary phase-modulated coded signals can reach a perfect “pulse-compression condition”, as in the case of Golay [12], or an almost perfect one, as in the case of MLS [13], whereas the chirp-based ones are characterized by the sidelobes of the \( \widehat{\delta }\left( t \right) \) [14].

Unfortunately, in many NDT applications, and in the case of ultrasonic inspection of large reverberating structures as in the present case, nor the Golay-based neither the MLS-based PuC schemes are suitable. The former needs to combine two measurements for obtaining a single impulse response estimate \( \widehat{h}\left( t \right) \). In the case of large forgings, the ultrasound energy can reverberate into the SUT for a long time, so a longer pause must be placed between the two measurements to avoid any echo from the first excitation being collected, and wrongly interpreted, during the second measurement. MLS-based PuC scheme instead requires a single measurement, but in which a periodic excitation (at least two periods) must be used [8, 9, 14]. Under this condition, the reconstructed \( \widehat{h}\left( t \right) \) is very close to \( h\left( t \right) \), provided that the excitation period is longer than \( h\left( t \right). \) Also in this case, the fact that the ultrasound energy can last for long times inside forgings, and hence \( h\left( t \right) \) as well, makes the use of MLS-based PuC not suitable for forging inspection. On the other hand, PuC schemes relying on chirp signals have not these issues, and the worsening of the “pulse-compression condition” is largely counterbalanced by an extreme easiness and flexibility in the application.

Further, most of the NDT tests operate in linear regime and use band-pass transducers and measurement systems. In these cases, the use of non-linear chirps can provide few advantages with respect to the use on linear ones. For these reasons, the most used waveform in NDT applications of PuC is the Linear Chirp (LC), that is the signal employed also for the present application.

LC is described by the expression [11]:

where T is the duration of the chirp signal, f1 is the start frequency, f2 is the stop frequency, \( F_{c} = \left( {f_{1} + f_{2} } \right)/2 \) is the centre frequency and \( B_{\% } = \left( {f_{2} - f_{1} } \right)/F_{c} \) is the percentage bandwidth of the chirp. Note that T and \( B \) are not constrained by each other, so that the duration of the LC can be increased arbitrarily. \( A\left( t \right) \) is a time-windowing function that modulates the amplitude of the chirp and \( \varPhi \left( t \right) = 2\pi F_{c} \left( {\left( {1 - \frac{{B_{\% } }}{2}} \right)t + \frac{{B_{\% } }}{2T}t^{2} } \right) \) is the chirp phase function that determines the instantaneous frequency of the signal accordingly with \( f_{ist} \left( t \right) \) = \( {\raise0.7ex\hbox{${\varPhi^{\prime}\left( t \right)}$} \!\mathord{\left/ {\vphantom {{\varPhi^{\prime}\left( t \right)} {2\pi }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${2\pi }$}} \).

In the case of a rectangular window, i.e. \( A\left( t \right) = A \) for \( t \in \left[ {0,T} \right] \), LC has a constant envelope and an almost flat power spectrum in the spanned frequency range \( f \in \left[ { f_{1} ,f_{2} } \right] \). However, a non-constant and usually symmetric \( A\left( t \right) \) is used to reduce sidelobes of \( \widehat{\delta }\left( t \right) \) and in the present work the Tukey-Elliptical window it is used [15].

Experimentally, while PuE requires only one transducer that acts both as Tx and Rx, PuC based schemes usually employ two separated Tx and Rx transducers in pitch-catch configuration to allow the excitation signal duration to be extended arbitrarily. The increased complexity of the PuC procedure is justified by the benefits provided in terms of both resolution and SNR enhancement. Indeed, by using two distinct transducers, the excitation signal can be long as the typical inspection time (few milliseconds for steel forgings) and therefore thousands of times longer than typical pulses used in PuE, which duration is inversely proportional to the transducer bandwidth. This allows more energy to be delivered to the system, increasing in turns the SNR. Moreover, it was found that PuC is optimal to reduce both environmental and quantization noise, the latter introduced by the Analog-to-Digital Converter [12, 13].

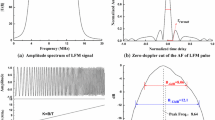

Figure 1 summarizes the PuC procedure adopted in this work, while Fig. 2 reports an example of the PuC procedure applied to a benchmark forging sample, on which a flat bottom hole was realized and filled afterward with soldering, so as to simulate a small void close to the backwall surface.

Block diagram of the PuC measurement procedure implemented. A windowed linear chirp is used as coded excitation signal. The sample output signal, \( y\left( t \right), \) at which is superimposed an Additive White Gaussian Noise, is then filtered with the matched filter, corresponding in the present case to the time reversed replica of the input signal. After the application of the PuC, an estimate \( \widehat{h}\left( t \right) \) of the impulse response, i.e. the reflectogram, is retrieved

Generated signal—a windowed linear chirp of duration equal to 33 μs, at central frequency of 5 MHz and bandwidth of 180% was used for the inspection of 300 mm long and 70 mm of diameter, a steel cylinder shown in the picture. The acquired signal, combined with additive noise, is passed through the matched filter (implementing the pulse-compression procedure) to retrieve the \( \widehat{h}\left( t \right) \) of the sample. The SNR of the measurement process at the backwall echo and the defect locations can be estimated from the Envelope of the retrieved \( \widehat{h}\left( t \right) \)

3 Multifrequency DGS Analysis

As previously mentioned, the standard procedure for forgings inspection relies on two pillars: the PuE method and the DGS diagrams analysis. In the previous Section, a measurement procedure based on PuC, an alternative to PuE, has been introduced to increase the SNR of the measurement and hence the sensitivity of the inspection. In this section, the procedure for applying DGS analysis in combination with PuC is shown, together with a thorough explanation on how to implement a multi-frequency DGS analysis that can be beneficial when: (1) the optimal inspection frequency is not known, (2) the effect of the inspection frequency on the defect sizing must be considered and (3) an accurate analysis of the defect sizing capability is of interest.

To accomplish these aims, first of all it is worth to note that after the application of the PuC procedure, the signals \( \widehat{h}\left( t \right) \) are very similar to those provided by PuE, i.e. \( \widehat{h}\left( t \right) \), so the standard DGS analysis can be applied on the \( \widehat{h}\left( t \right) \) provided that: (i) the DGS diagrams for the Tx-Rx configuration are known, (ii) the overall measuring system composed of a linear chirp excitation signal and the Tx-Rx probes exhibits a narrowband nature, centred around the frequency \( F_{c} \) of the employed DGS diagrams and with relative bandwidth \( B_{\% } \sim 40. \)

Regarding point (i), a numerical tool was implemented that calculated the DGS diagrams by exploiting the Rayleigh–Sommerfeld Integral Model. The two probes were modelled both as piston transducers and full interference in the path Tx-defect–Rx was considered [16,17,18].

Regarding point (ii), usually the narrowband characteristic of the measurement system is guaranteed utilizing narrowband transducers. This is because the control over the excitation power spectrum is little when using single pulse or short burst excitation. Note that 40% is the typical \( B_{\% } \) value of narrowband probes used for DGS analysis in PuE, e.g. GE Krautkamer B2S. Indeed, even if DGS are calculated by considering a single frequency value, in practical applications \( B_{\% } < 40 \) implies a low range resolution that could hamper the defect detection.

Conversely, the excited bandwidth can be shaped with great accuracy and almost arbitrarily by employing a LC as input signal, provided that the so-called time-bandwidth product of the chirp \( T \cdot B \) is large enough, and this is the usual case for forgings inspection. This means that the transducers can also be broadband, \( B_{\% } > 100, \) but the ultrasonic generated spectrum is determined by the chirp signal.

DGS diagrams were developed so far for PuE inspections, i.e. for single probe UT measurement setups. Hence, they cannot be applied to the PuC UT inspections, due to unique geometry of the dual probe measurement setup. In the following sections, the results of the numerical tools proposed here for DGS calculation are compared to the standard DGS diagrams, and the procedure of multifrequency DGS analysis is described as well.

3.1 Field Simulation and DGS Calculation

A numerical tool was developed to compute the DGS diagrams for arbitrary shapes and positions of both the transducers and the defects, thus allowing the DGS method to be applied in PuC procedures employing pitch-catch configuration. The numerical tool solves the Rayleigh Summerfield integral model of wave propagation by considering the “full-interference” case and piston transducers model [16]. The Tx, Rx and defects are discretized, and the amplitude of the echo due to a defect is calculated by coherently summing up the contributions of all possible paths Tx-defect–Rx, i.e. considering amplitude and phase of each contribution. The defect is assumed to behave as a perfect reflector and the surfaces of the transducers are considered perfectly rigids.

In Fig. 3, the DGS diagrams produced by using the numerical tool for a GE Krautkrämer’s B2S probe in PuE configuration are compared with those reported in the probe data sheet. The diagram obtained for the infinite reflector and the DGS diagrams for various disk reflectors in the far field matched perfectly with the vendor DGS curves. Instead, in the near field, the numerical DGS curves exhibits a series of local minima and maxima while the standard DGS diagrams are more regular.

a Standard AVG diagram for B2S transducer, taken from the official Krautkrämer’s datasheets. b AVG diagram obtained from the developed numerical tools. The evaluated diagram gives identical amplitude of both the backwall and disk reflectors at different locations in the far field, while deviates slightly in the nearfield in case of the small reflectors

This phenomenon is well known, and it was first discussed by Krautkrämer brothers [1, 18]: in numerical curves calculated at a single frequency, constructive and destructive interference is considered, and interference has a high impact especially for small defects in the near field. In practical applications, although sometimes visible, interference phenomena are less relevant due to the finite but non-null bandwidth of the transducers, which implies different interference locations for each frequency value leading to a resultant averaging effect. Moreover, it must be considered that real defects are not perfect reflectors as well as the propagating medium is not perfectly homogeneous. Increasingly, as a matter of fact, the equivalent defect size evaluation is made by considering not a single measurement point but a finite area of inspection. So, to remove the interference effects in probes’ datasheet, the DGS diagrams in the near field are usually established by experiment or by performing frequency and spatial averaging over the theoretical single-frequency calculated curves.

Figure 4 reports an example of this last approach and the related effect on destructive and constructive interference—it is shown that the averaged diagrams are very close to the experimental calculated ones in the near field.

Once having verified the robustness of the tool for the calculation of DGS diagrams in PuE configuration, the DGS diagrams for two probes in pitch-catch used in the PuC procedures were evaluated. Figure 5 compares the single probe DGS diagrams of B2S probes with the DGS curves obtained for a pair of two B2S probes placed side-by-side. Note that here the probes’ case dimensions (45 mm of diameter) have been considered. In the near field, the DGS diagrams for pitch-catch configuration exhibit a lower sensitivity in PuC configuration than in PuE, meaning that the backwall echo or a defect echo gives a signal of less amplitude in the PuC case. However, the PuC and PuE sensitivity values become closer and closer as long as the distance of backwall or defects increases, almost coinciding in the far field.

Numerically evaluated AVG diagrams of single probe (PuE inspection method) and dual probes (PuC inspection method). The two methods exhibit the same pattern of amplitude values for both the infinite and the disk reflectors in the far field. In the near field, PuC sensitivity and hence the DGS diagrams’ amplitudes is lower due to the partial superposition of the Tx and Rx beams

In the case considered here, the sensitivity difference in the near field is very large. This is because the case of the probes is approximately twice the element size. Thus, the ultrasonic beam of the Tx and those of the Rx superimpose significantly only at a certain distance, and the Tx and Rx beams superposition is strictly related to the DGS diagrams values. Only beam’s sidelobes can superimpose at a very small distances for a pair of probes which elements are separated by some gap. This is depicted by the two-dimensional images reported in Fig. 6, which shows the sensitivity for both PuE and PuC cases for X–Z and Y–Z planes, wherein the sensitivity map is formed by visualizing pixelwise the amplitude of the echo signal due to a defect of 1 mm placed at the pixel position. For PuE, the Tx and Rx fields coincide, thus the sensitivity is proportional to the beam energy. In addition, for circular probes as the B2S here considered, the sensitivity on the X–Z and Y–Z planes is the same.

On the other hand, in pitch-catch configuration, the superposition of the Tx and Rx field patterns is not symmetrical and so is the sensitivity. By using fingertips type probes, the centre–centre distance for the Tx–Rx pair can be minimized, yielding to an increased sensitivity in the near field. Please note that the experimental results reported later were obtained by using finger-type probes.

3.2 Multi-frequency DGS Analysis Procedure

In this Section the multi-frequency DGS analysis procedure is introduced and quantitatively compared with the standard single-frequency one. Please note that the single-frequency DGS analysis must be more properly defined as narrowband analysis, meaning that when the standard single-frequency analysis is considered, it is referred to the use of a narrowband signals, \( B_{\% } = 40 \) or \( 60 \) exciting broadband transducers (VIDEOSCAN Tx-Rx- pairs from Olympus).

Which are the main reasons for introducing the multi-frequency DGS analysis? One is the possibility to implement DGS defect sizing at different frequencies simultaneously, so as to increase reliability and accuracy; the second one is related to the fact that broadband signals exhibit a higher spatial/range resolution than narrowband one, and this helps the defect detection by reducing grain noise and possible pile-up of different echoes. In addition, the use of broadband signals is dual beneficial in PuC, since the largest is the bandwidth, the higher is the SNR increment, and the higher is the bandwidth, the smaller are the \( \widehat{\delta }\left( t \right) \)’s sidelobes [14].

At the same time, the use of broadband signals conflicts with the direct application of the standard DGS procedure, even though this has been recently proposed [19]. We therefore investigated if the DGS analysis could be extended to the use of broadband signals and transducers. In this paper we propose and test the following procedure:

-

1.

A broadband LC signal and a broadband Tx-Rx transducers pair are used;

-

2.

The PuC output \( \widehat{h}\left( t \right) \) undergoes to a bank of digital filters that produce the set of narrowband signals \( \left\{ {\widehat{h}_{{f_{j} }} \left( t \right)} \right\} \), centred at \( f_{j} \) with \( B_{\% } \sim 40 \);

-

3.

For each frequency \( f_{j} \), the standard DGS analysis is applied (the physical attenuation is calculated and counterbalanced numerically, the echo envelope is compared with the DGS diagrams).

The process of standard single frequency and multifrequency DGS analysis is further explained in the flow chart in Fig. 7. Moreover, an example of the procedure is depicted in Fig. 8 while in the following Section, some results obtained with both narrowband and broadband LC are reported.

Example of application of the multi-frequency DGS analysis to data collected with broadband probes centred at 5 MHz (Olympus V108 Videoscan). The broadband signal passes to several narrowband filters and the outputs of these filters undergo to a standard single-frequency DGS analysis. The defect detection capability depends on the frequency of the analysis. In this case, it is found to be maximised at 3 MHz

In perspective, this method could be further developed considering only a unique broadband DGS diagram. This can be done by considering the spectrum of the input signal and the frequency-dependent attenuation within the sample, thus providing the estimation of the defects size as well as the defect detection sensitivity by exploiting the SNR values and the range resolution of broadband data. It is worth to note that a similar approach has been already considered in calculating standard narrowband DGS to deal with the real bandwidth of the transducers [19].

4 Experimental Results

To test and compare the single- and the multi-frequency DGS analysis, experimental data were collected on two samples containing reference defects, see Fig. 9. The first sample, (a), was a cylindrical forging of diameter ~ 600 mm and length ~ 1450 mm with a flat bottom bore defect (FBB) of diameter D = 3 mm, length L = 20 mm and depth 1430 mm realized on the back flat surface. The second sample, (b), was a section of a disk sample with outer radius ~ 873 mm and the inner radius ~ 147 mm, in which there was a FBB defect of D = 1 mm and L = 20 mm drilled on one of the cross-section radial flat surfaces so that the normal incidence condition on its flat surface is attained by using a beam oriented at 45° with respect the normal of the curved outer surface.

Sample (a) was inspected with a pair of Olympus fingertips V109 VIDEOSCAN probes (active element diameter = 0.5 in, central frequency = 5 MHz, with centre–centre distance in pitch catch of 17 mm), and with a pair of Olympus, V108 VIDEOSCAN probes (active element diameter = 0.75 in, central frequency = 5 MHz, with centre–centre distance in pitch catch of 35 mm). Both pairs were used without any wedge so that longitudinal waves were generated within the sample and the beam axis had a 0° angle with respect the normal of the inspection surface. Sample (b) was inspected with the same pair of Olympus fingertips V109 VIDEOSCAN probes and with a pair of Olympus C106 CENTERSCAN probes (active element diameter = 0.5 in, central frequency = 2.25 MHz, with centre–centre distance in pitch catch of 17 mm). To assure an orientation of the UT beam axis of 45° with respect the curved inspection surface normal, a 30° wedge was used. This allowed share waves being solely generated into the sample.

For both cases, and for all Tx-Rx pairs, the DGS diagrams were calculated for various central frequencies by means of the numerical simulation tool discussed in the previous Section. Figures 10, 11, 12, 13, 14, 15, 16 and 17 report the results of the DGS analyses implemented.

Results of multi-frequency DGS analysis calculated at the same frequencies of Fig. 10 (4, 5 and 6 MHz respectively from the top to the bottom), with the same pair of probes (OlympusV108) and defect (3 mm diameter flat bottom bore), but this time using a single broadband chirp excitation signal

Results of multi-frequency DGS analysis calculated at the same frequencies of Fig. 12, but using a single broadband chirp excitation signal, employing a pair of Olympus V109-fingertips Probes on a 3 mm diameter flat bottom bore defect

Comparison of the narrowband and broadband PuC procedures based on the evaluation of the equivalent defect diameter. (Left) The outcome of the multifrequency DGS analysis employing a broadband (B% = 180) chirp signal and the single frequency DGS analysis employing a narrowband excitation pulse (B% = 40, 60). (Right) Results of the multifrequency AVG analysis employing broadband chirp signals at different central frequencies

Spatial width of echoes from a 3 mm defect (FBB). A smaller value of full width at half maximum (FWHM) of the envelopes obtained in case of the broadband excitation chirps is an indication of better spatial resolution as compared to the narrowband excitation signals. Here \( f_{r} \) is the frequency bandwidth of the filter, applied in the multifrequency analysis

Results of PuC, shear wave UT inspection of the disk sample with known defect, a flate bottom hole of 1 mm diameter. Probe used were V109 and a wedge of 30° creating an incident angle of 45° at the circular surface of inspection. A broadband linear chirp at central frequncy of 3.5 MHz was employed. Echograms were obtained using the multifrequncy AVG analysis approach

Same Multifrequency AVG diagrams of the disk sample as Fig. 15, but in this case using a pair of the Probes C106 and the broadband chirp signal centred at 2.25 MHz

On sample (a), both single-frequency and multi-frequency DGS analyses were done. Figures 10 and 12 depict the results obtained using a narrow-band linear chirp, \( B_{\% } = 40 \), exploiting several measurements at different central frequencies. For multi-frequency case instead, Figs. 11 and 13, the analysis was carried out by acquiring a single broadband signal and then applying the procedure illustrated in Fig. 7-bottom. The results obtained by using multi-frequency DGS are almost identical to those achieved by standard narrowband DGS, even more precise in some cases.

This is illustrated in Fig. 14, which summarizes the values of the equivalent defect diameter estimated at various frequency, by using both narrowband and wideband excitation signals.

In subplot (a), the diameter values, \( D_{est} \), estimated for the 3 mm defect by using a broadband excitation together with the multi-frequency DGS analysis are compared with the \( D_{est} \) values retrieved by using narrowband chirp signals with \( B_{\% } = 40 \) and \( B_{\% } = 60 \) respectively. It emerges that the results of multifrequency analysis applied to a broadband signal at different central frequencies are more precise and accurate than those attained by using a narrowband signal for each frequency.

The \( D_{est} \) values estimated for the 3 mm defect at various frequencies by using \( B_{\% } = 180 \) broadband chirps with different \( F_{C} \)’s are compared and showed in subplot (b). The results are almost identical in the three cases demonstrating that the procedure is robust and does not depends from the effective bandwidth of the excitation, provided that the frequency range of the multiple DGS analysis is covered.

The two aspects evidenced by Fig. 14 show that the proposed method provides precise results at different frequencies and a reduction of the inspection time.

In addition, a better spatial resolution was also obtained employing the broadband excitation signal with respect to the narrowband one. This is shown in Fig. 15 where a zoom of the defect signal echo envelope and of the backwall echo, that were at 20 mm of distance, is depicted. The spatial width of the measured defect echoes is smaller by using broadband excitation. Moreover, broadband signals allow reducing the sidelobes of the backwall echo, which can hide possible defects located at a very short distance from the backwall.

For sample (b), only results attained by using broadband excitation are reported. Figure 16 illustrates the results of the pair of V109 probes placed on a 30° wedge; Fig. 17 illustrates the results attained with the pair of C106 probes placed on a 30° wedge.

The defect is clearly detected, and its diameter is well estimated, except for the smaller frequency of analysis corresponding to 1.5 MHz.

5 Conclusions

An application of the pulse-compression technique to the ultrasonic inspection of forgings is presented. By using broadband probes and broadband excitations, the standard DGS analysis of echograms was extended to perform multi-frequency DGS analysis on a single measurement. The procedure was compared with the use of narrowband signals, even in combination of pulse-compression. Results showed that the defect sizing capability is left unaltered by using broadband signals and then applying filters before DGS analysis, but this approach can increase the precision and accuracy of the defect sizing and the spatial resolution, while lowering the inspection time. In addition, such procedure allows the optimal inspection frequency being established for a given measurement point. The results open space for further developments in terms of inspection frequency optimization and for the development of a broadband DGS defect estimation procedure, which should benefit from the pulse-compression in terms of both SNR gain and spatial resolution. Moreover, the use of such procedure in combination with 3D imaging protocols (see for instance [20]) could further improve the defect characterization, while providing its location within the sample, which is also relevant in the evaluation of defect impact.

Change history

02 March 2021

A Correction to this paper has been published: https://doi.org/10.1007/s10921-021-00753-1

References

Krautkramer, J.: Determination of the size of defects by the ultrasonic impulse echo method. Br. J. Appl. Phys. 10, 240–245 (1959)

Krautkrämer, J., Krautkrämer, H.: Detection and classification of defects. In: Ultrasonic Testing of Materials, pp. 312–329. Springer, Berlin (1990)

Distance Gain Sizing Technique, European Standard DIN EN583-2:2001

Ricci, M., Senni, L., Burrascano, P., Borgna, R., Neri, S., Calderini, M.: Pulse-compression ultrasonic technique for the inspection of forged steel with high attenuation. Insight-Non-Destr. Test. Cond. Monit. 54(2), 91–95 (2012)

Mohamed, I., Hutchins, D., Davis, L., Laureti, S., Ricci, M.: Ultrasonic NDE of thick polyurethane flexible riser stiffener material. Nondestr. Test. Eval. 32(4), 343–362 (2017)

Turin, G.L.: An introduction to matched filters. IRE Trans. on Inf. Theory 6(3), 311–329 (1960)

Misaridis, T., Jensen, J.A.: Use of modulated excitation signals in medical ultrasound. Part I: basic concepts and expected benefits. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 52(2), 177–191 (2005)

Burrascano, P., Callegari, S., Montisci, A., Ricci, M., Versaci, M. (eds.): Ultrasonic Nondestructive Evaluation Systems: Industrial Application Issues. Springer, New York (2014)

Hutchins, D., Burrascano, P., Davis, L., Laureti, S., Ricci, M.: Coded waveforms for optimised air-coupled ultrasonic nondestructive evaluation. Ultrasonics 54(7), 1745–1759 (2014)

Novak, A., Simon, L., Kadlec, F., Lotton, P.: Nonlinear system identification using exponential swept-sine signal. IEEE Trans. Instrum. Meas. 59(8), 2220–2229 (2010)

Pollakowski, M., Ermert, H.: Chirp signal matching and signal power optimization in pulse-echo mode ultrasonic nondestructive testing. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 41(5), 655–659 (1994)

Challis, R.E., Ivchenko, V.G.: Sub-threshold sampling in a correlation-based ultrasonic spectrometer. Meas. Sci. Technol. 22(2), 025902 (2011)

Ricci, M., Senni, L., Burrascano, P.: Exploiting pseudorandom sequences to enhance noise immunity for air-coupled ultrasonic nondestructive testing. IEEE Trans. Instrum. Meas. 61(11), 2905–2915 (2012)

Burrascano, P., Laureti, S., Senni, L., Ricci, M.: Pulse compression in nondestructive testing applications: reduction of near sidelobes exploiting reactance transformation. IEEE Trans. Circuits Syst. I Regul. Pap. 99, 1–11 (2018)

Pallav, P., Gan, T.H., Hutchins, D.: Elliptical-Tukey chirp signal for high-resolution, air-coupled ultrasonic imaging. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 54(8), 1530–1540 (2007)

Schmerr, L., Song, J.S.: Ultrasonic Nondestructive Evaluation Systems. Springer, New York (2007)

Certo, M., Nardoni, G., Nardoni, P., Feroldi, M., Nardoni, D.: DGS curve evaluation applied to ultrasonic phased array testing. Insight-Non-destr. Test. Cond. Monit. 52(4), 192–194 (2010)

Krautkrämer, J., Krautkrämer, H.: Ultrasonic Testing of Materials. Springer, New York (2013)

Kleinert, W.: Defect Sizing Using Non-destructive Ultrasonic Testing: Applying Bandwidth-dependent Dac and Dgs Curves. Springer, New York (2016)

Fendt, K.T., Mooshofer, H., Rupitsch, S.J., Ermert, H.: Ultrasonic defect characterization in heavy rotor forgings by means of the synthetic aperture focusing technique and optimization methods. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 63(6), 874–885 (2016)

Acknowledgements

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No 722134—NDTonAIR.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Rizwan, M.K., Senni, L., Burrascano, P. et al. Contextual Application of Pulse-Compression and Multi-frequency Distance-Gain Size Analysis in Ultrasonic Inspection of Forging. J Nondestruct Eval 38, 72 (2019). https://doi.org/10.1007/s10921-019-0612-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-019-0612-7