Abstract

This paper studies the applicability of an automated non-destructive testing method to monitor the stiffness of asphalt concrete at low temperatures. A loudspeaker is used as a source of non-contact excitation of the axially symmetric fundamental resonant frequencies of a disc-shaped asphalt concrete specimen positioned inside an environmental chamber. Measured resonant frequencies are used to calculate the dynamic moduli of the specimen at different temperatures. The repeatability of the method as well as the effect of loudspeaker height above the sample are studied. Results show that the main advantage of the non-contact excitation method, compared to manually applied impact hammer excitation, is that repeatable automated measurements can be performed while the specimen is placed inside an environmental temperature chamber. This methodology enables to study the effect of only low temperature conditioning on the dynamic modulus of asphalt concrete without interference from mechanical loading.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The application of impact resonance and modal testing has been proven successful in determining the complex dynamic modulus of asphalt concrete samples [1,2,3,4,5]. The technique is based on excitation of samples and measurement of their corresponding resonant frequencies of different modes of vibration. This process leads to the determination of the viscoelastic properties of the samples. Researchers primarily use either an impact hammer or small steel balls to induce an excitation in impact resonance testing. Since the resonant frequency of any material is dependent on its geometry, density, boundary conditions, and viscoelastic material properties, one can back-calculate its viscoelastic properties from the measured resonant frequency.

This technique enables the study of a higher range of loading frequencies and small magnitudes of strains. With conventional methods that measure the complex dynamic modulus of asphalt concrete, the common practice is to apply cyclic loads of frequency range 0.01 to 25 Hz and a strain magnitude of about 50 micro-strains [6]. Resonant frequency tests performed on cylindrical samples of asphalt concrete using an impact method were successfully used to obtain a low-strain complex modulus at different frequencies and temperatures [7,8,9]. Beam-shaped asphalt concrete samples were also used to construct master curves using resonance acoustic spectroscopy (RAS) [1]. The impact resonance method has been used in an existing standard method, i.e., ASTM C 215, to determine the dynamic moduli of cylindrical concrete specimens. This standard method was also successfully used on cylindrical samples of asphalt concrete [2]. Agreements with conventional test methods have been obtained for the dynamic modulus of asphalt concrete within a wide range of mixture types [8, 9].

Resonance testing using a contact method based on manual excitation has its limitations. It is difficult to perform a manual impact resonance test in an environmental chamber, since it would require the chamber to be kept open while applying the tap. This may cause variations in the actual measurement temperatures. Since asphalt concrete is sensitive to changes in temperature due to its viscoelastic behavior, there is a need for a more accurate method of performing this test. A non-contact method of excitation can address this problem. A low-distortion speaker has been used to excite samples of roofing tiles in an investigation of damage using non-linear resonance ultrasound spectroscopy (NRUS) [10]. A long-range acoustic device has also been used to excite a flexural mode of vibration in cement concrete with an internal defect [11, 12]. Initial tests of a non-contact method using a loudspeaker were conducted to measure the axially symmetric fundamental resonant frequencies of disc-shaped PVC, cement concrete, and asphalt concrete [13]. The study in [13] focused on the measurement of possible non-linear elastic responses in building materials. It was also shown that this non-contact method can give the same results as those obtained through excitation with an impact hammer. These findings are further investigated in the current study, along with further fine tuning of a completely automated experimental set-up inside an environmental chamber.

It is not uncommon for asphalt pavements to reach extremely low temperatures, especially in Scandinavian countries, but also in North America. When asphalt is cooled down to low temperatures, it undergoes changes in its mechanical properties due to hardening that is associated with free volume shrinkage [14,15,16,17]. Since the conventional test methods utilized for these studies are susceptible to thermal contaminations due to prolonged mechanical contact, it has been a difficult task to be able to single out the soul effect of these isothermal conditioning. Additionally, since asphalt pavements are commonly exposed to extreme low temperatures prior to or in the absence of traffic, it is essential to gain a better understanding of the behavior of asphalt pavements under these conditions. Hence, an enhanced testing methodology of obtaining more accurate outcomes regarding the sole effects of cold temperature conditioning on asphalt concrete is required.

In this paper, an automated non-contact resonance excitation and measurement system is established and its applicability is investigated by assembling a test set-up inside an environmental chamber. This proposed methodology study is particularly carried out with reference to the effect of low temperatures on asphalt. It focuses on exciting a cylindrical asphalt concrete sample in the fundamental free axially symmetric mode of vibration. The technique enables automated measurements of resonant frequencies in a controlled environment, as the excitation is triggered remotely by computer. A comparison with an impact resonance method is also carried out to show the advantages of this method regarding the control of measurement temperatures. The potential of the proposed technique with regards to its significant relevance to the study of the sole effect of low temperature conditioning on asphalt is illustrated. In order to illustrate the effect of low temperature conditioning, the stiffness moduli of an asphalt concrete specimen are calculated based on the theory of free vibration of cylindrical plates using the measured resonant frequencies.

2 Methodology

This study investigates the measurement of the fundamental symmetric resonant frequency after non-contact excitation by loudspeaker. It also illustrates its comparison with measurements from excitation by impact hammer. The moderate airborne sound intensity of 90 dB (from specification) radiated by a commercial loudspeaker is sufficient to generate resonance in our sample. The technique primarily monitors the frequency response analysis of a single resonance mode, i.e., the axially symmetric mode. Since the frequencies are less than 20 kHz, we refer to the measurements as resonant acoustic spectroscopy (RAS). The experimental setup is explained in detail in the following sections.

2.1 Materials

Cylindrical shaped asphalt concrete and cement concrete specimens with 100 mm diameter and 20 mm thickness are used in this study. The geometry of the specimens was decided based on the general recommendation of length to nominal maximum aggregate size ratio of 1.5 [18].The cement concrete sample is only used for additional verification of the experimental test set-up, since it is not as sensitive to temperature changes. The asphalt concrete specimen has a nominal aggregate size of 11 mm. It is referred to as ABT 11 70/100, according to the Swedish standard for asphalt mixtures. It is a dense graded mix with a nominal maximum aggregate size of 11 mm. Table 1 shows the measured values of the different parameters of the specimen. The gradation of the aggregates used for the mix of the asphalt concrete specimen is shown in Table 2.

2.2 Acoustic Excitation

Non-contact acoustic excitation is one method of inducing resonance in an object by means of air coupling, which can be used to perform a frequency response analysis. Its effective use has been proven in modal experiments that require small but measurable displacements [19,20,21,22]. This method has specific advantages compared to impact and shaker excitations. Its non-contact nature helps avoid coupling effects which may cause nonlinearity-related problems. It also makes the choice of excitation signal arbitrary, which permits the selection of a bandwidth according to specific requirements. In this study, a sinusoidal signal is generated and sent to a loudspeaker from a computer. The emitted sound wave, which lies within the acoustic frequency range, causes resonance as a result of the fundamental axially symmetric mode of vibration. Physically, resonance is achieved when the sound wave on the upper surface of the specimen excites the symmetric mode. Air coupling can be applied to this mode where the direct displacement is normal to the specimen’s surface.

Figure 1 shows a schematic of the fundamental axially symmetric mode shape after the speaker excitation. It should be noted that the radiated sound field from the diameter of this speaker approximately matches the mode shape in the sample. It should be noted that the complete setup is designed to measure this specific type of mode and is not suitable for other axially anti-symmetric flexural modes of vibration. An impact resonance method is also used to verify the mode of vibration.

The applied linear chirp for the sweep of excitation frequencies in this experiment is represented by the spectrogram in Fig. 2a. An example of a resulting output spectrogram from the measured data is shown in Fig. 2b. The measured resonant frequency can be identified at the maximum measured amplitude in Fig. 2b. At this time the input sweep signal passes through the resonant frequency of the sample, which is about 10 kHz in this example.

3 Experimental Setup

The experimental setup includes a loudspeaker (Seas Prestige 17TDFC/TV H1210). The chirp function in MATLAB is used to send a 10 s long chirp. By increasing the frequency of the signal from 8 kHz to 12 kHz, a sweep is applied to the specimen. The test frequency range is selected based on typical results from a similar trial test by using impact hammer on specimens of similar geometry. The output channel of a National Instruments data acquisition device (NI USB-6251M series) is used to transmit the signals to the loudspeaker. A signal conditioner (PCB model 480B21) is used to condition the accelerometer signals. The sampling frequency of the signal sweep is 100 kHz. An accelerometer (PCB model 352B10) with an operating temperature range of − 54 °C to 121 °C is attached to the samples and its data are acquired through the data acquisition device and output to a computer. Figure 3 shows the schematic representation of the experimental setup.

3.1 Procedure for Computing the Dynamic Modulus from the Measured Resonant Frequency

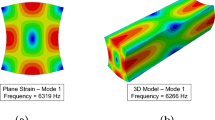

Measured fundamental natural frequencies of the axially symmetric mode can be used to determine the dynamic moduli of thick circular plates [23, 24]. This calculation is based on the theory of three-dimensional elasticity of a freely vibrating plate and considers the influence of shear deformation [25, 26]. According to this method, a dimensionless frequency parameter relates measured axially symmetric fundamental resonant frequencies to the corresponding shear moduli (G). Equation 1 shows how this non-dimensional frequency parameter (\( \varOmega_{n} \)) can be used to determine shear moduli from measured axially symmetric fundamental resonant frequencies.

In Eq. 1, \( f_{n} \) represents the axially symmetric fundamental natural frequency that is obtained from Eq. 2, Ro is the radius of the specimen, ρ is mass density, G is shear modulus, and \( \varOmega_{n} \) represents the dimensionless frequency parameter as described in [22]. For the geometry of the specimen used in this study, \( \varOmega_{n} \) is computed to be 1.403(for Poisson’s ratio of 0.25) and 1.346 (for Poisson’s ratio of 0.2).

The measured resonant frequencies from the procedures in this work are damped natural frequencies. Therefore, they must be converted to undamped natural frequencies before computing the moduli of the specimen. This is achieved using Eq. 2.

where \( f_{n} \) is the natural frequency, \( f_{d} \) is the measured damped natural frequency, and ξ is the damping ratio. The damping ratio is determined according to the half power bandwidth approach using Eq. 3.

where \( \Delta f \) is the width of the frequency response curve at 0.707 (half power) multiplied by the maximum amplitude. The damping ratio is also used to determine the phase angle (\( \phi \)) using Eq. 4, which is in turn used for determining loss modulus.

This approach can be used if the damping ratio is less than 0.5, the length of the recorded frequency response is greater than the inverse of the half-power width, and there are low temperatures.

Compressive dynamic modulus and shear modulus are related by Eq. 5, where \( v \) is Poisson’s ratio \( , G \) is shear modulus and E is dynamic modulus.

The computation of the damping ratio and phase angle can be used to determine the complex dynamic modulus using Eq. 6.

where \( E^{'} \) is storage modulus, \( E^{''} \) is loss modulus, and ξ is the damping ratio, as shown in Eq. 3.

4 Results and Discussion

4.1 Fine-Tuning and Verification of the Experimental Set-Up

In order to see the effect of air gap length between the speaker and the specimen, a cement concrete specimen of similar geometry to the asphalt concrete specimen is used to take measurements at room temperature. Cement concrete is chosen for this particular test since its elastic behavior makes it more convenient to adjust the air gap at room temperature. Figure 4 shows that there is no significant difference in resonant frequencies due to differences in air gap lengths, except at the shortest length (20 mm) considered where there is a slight deviation (13 Hz). This also means that the effect of air resonance does not affect the measurement results at the lengths shown in Fig. 4, since there is no major difference in the amplitudes. It can also be noted that only a decrease in amplitude can be evident at longer lengths. Based on these results, it is satisfactory to adjust the air gap to one of the closest distances in Fig. 4. For the measurements taken on the actual asphalt concrete specimen, an air gap length of 40 mm is chosen based on the above findings.

A similar measurement is also taken using an impact hammer to excite the axially symmetric fundamental mode of the cement concrete specimen. This helps verify that the frequency sweep of the loudspeaker goes through the fundamental axially symmetric mode of resonance of the specimen. Figure 5 illustrates that the non-contact method measures the resonant frequency of the same mode as the impact hammer method does. By varying the amplitudes of the sound signals, the possible effect of sound intensity is monitored as shown in Fig. 5b. Even though no major differences are encountered by varying sound intensity (amplitudes), it can be noted that there are slight shifts in resonant frequencies with increase in amplitudes. These slight shifts are smaller than 0.1% in resonant frequencies and can be a manifestation of non-linearity behavior that is associated with a possible presence of discontinuity or flaw in the specimen. These slight shifts are also observed in the results from the impact hammer test (Fig. 5a).

To further illustrate the advantage of the proposed non-contact measurement setup over a similar measurement method using an impact hammer, two more measurements are performed on the asphalt concrete specimen at two measurement temperatures. The first measurement was taken 5 s after opening the thermal chamber and the second measurement was taken after 10 s. Figure 6 shows examples of comparisons at − 20 °C (Fig. 6a) and − 30 °C (Fig. 6b).

The results obtained using the impact hammer have lower measured resonant frequencies, since opening the temperature chamber disturbs the conditioning temperature. This effect is more pronounced at − 30 °C than at − 20 °C, since lower temperatures are even more sensitive to thermal disturbances by room temperature (~ 22 °C). The amount of time needed to take the measurement when using the impact hammer while the chamber is kept open has a significant effect on the results of the measurements at low temperatures.

The technique also helps to save good amount of time when there is a need to take repeated resonant frequency measurements at multiple low temperatures since it avoids the waiting time until temperature of specimens reaches the required value after its increase due to an opening of climate chambers, which is the case if we use manual impacting method as the climate chamber should be opened for every measurement.

4.2 Applicability of the Method to the Evaluation of Low Temperature Stiffness Modulus of Asphalt Concrete

To assess the repeatability of the measurement at low temperatures, 30 repetitions are performed at 60 s interval on a dummy asphalt concrete specimen of similar geometry. The results indicate high repeatability with standard deviations of 4.7 Hz and 2.4 Hz at − 20 °C and − 30 °C, respectively (Fig. 7). Even though the damping increases with increased measurement temperatures, the repeatability of the resonant frequencies is still satisfactory (4.9 Hz at − 10 °C and 5.1 Hz at 0 °C).

Low temperature measurements on asphalt concrete require a sample to be conditioned at the required temperatures. To set the conditioning time for a single measurement temperature, the resonance of the dummy asphalt specimen was monitored with time. The specimen is positioned in the thermal chamber at room temperature and then the temperature is set to − 20 °C. After waiting for 16 h, a continuously repeated resonant frequency measurement is taken until the values of the results have an average deviation of 0.08%. Then, the temperature is decreased to − 25 °C and repeated measurements are taken until the measured resonant frequency reaches a satisfactorily constant value (Fig. 8). It is to be noted that longer duration is chosen for conditioning the dummy specimen before decreasing the temperature to − 25 °C. This is done in order to obtain a satisfactorily constant reference measurement at − 20 °C.

The above procedure allows the conditioning time to be estimated before the respective measurements are taken on the actual specimen at each temperature. Figure 8 shows the measurements on the dummy sample for the conditioning period. As expected, the resonant frequency of the sample increases with a decrease in temperature due to the increase in the stiffness of the asphalt at lower temperatures. From the result of this measurement, it can be observed that an average deviation of 0.1% (for 5 °C difference) can be achieved within 3 h. Therefore, according to this result, 3 h is considered as an applicable conditioning period.

The measurements on the actual asphalt specimen are taken after the specimen is conditioned for 3 h at each measurement temperature (0 °C to − 40 °C) as per the above finding. With no other form of variation in the measurement, the temperature is decreased by 5 °C from a starting point of 0 °C. It should be noted that the entire test protocol is performed automatically with the temperature chamber kept closed during all measurements at each temperature. The change in resonant frequency is caused only by the reduction in temperature and not by any other modification. This is advantageous, since it is possible to avoid any effects caused by contact between the transducers and the specimen that would disturb the dynamics of the specimen.

It can be observed in Fig. 9 that the decrease in temperature affects the measured resonant frequencies of the specimen. This result shows the expected increase in resonant frequency as the asphalt mixture specimen becomes increasingly stiff with a decrease in temperature. It should be noted in this measurement protocol that the cumulative number of conditioning hours increases while the specimen is kept at these low temperatures. This may cause physical hardening to play a role by increasing the resonant frequencies. However, the temperature effect is considered to be dominant in the results obtained.

Studies on micro-damage associated with low temperature depict the presence of micro-cracks at the aggregate-mastic interfaces as well as within the mastic portion of asphalt concrete after it has been subjected to low temperatures [27]. Hence, it is possible that the measured resonant frequencies can be influenced by the presence of potential micro-damage. However, the main focus of our study is developing the methodology and the topic of micro-damage is out of its scope.

The procedure described in Sect. 2 is used to calculate the complex dynamic moduli of the specimen at each temperature. Poisson’s ratio is assumed to be 0.2 for temperatures below − 20 °C and 0.25 for those above − 20 °C [9]. Figure 10 shows the change in dynamic moduli resulting from an increase in stiffness with a decrease in asphalt temperature. This result shows that the proposed method can be applicable to the study of low temperature effects without any other form of mechanical stress involved.

Figure 11 shows the calculated damping ratios of the measurements according to the half-power bandwidth method (Eq. 3). It can be observed that, with the temperature decreasing, the damping of the measured frequencies becomes less significant. There is a stronger decrease in damping from 0 to − 10 °C, while a smooth and gentle drop is later observed in the measurement temperatures. This shows that the viscous behavior of the specimen is more pronounced above a temperature of − 10 °C. The lower rate of decrease in damping ratio below − 10 °C can be an indication that the specimen becomes more consistently elastic below − 10 °C. The result also indicates the potential use of the proposed testing method to study the viscoelastic behaviors of asphalt concrete with a decrease in temperature.

5 Conclusions

The applicability of an automated non-contact technique for measuring the fundamental resonant frequencies of a cylindrical asphalt concrete was investigated. The method enables automatic measurements in a controlled environment as the excitation is triggered remotely by computer. The flexibility of the measurement set up is also studied by varying the air gap between the specimen and the loud speaker. A comparison with the impact resonance method has revealed the method’s advantage regarding the control of measurement temperatures, particularly for asphalt concrete. The proposed technique has a significant relevance to studying the sole effects of low temperature conditioning on asphalt by avoiding thermal contamination, which is associated with the impact resonance method and conventional mechanical testing. Based on the findings of this study, the following conclusions can be drawn:

-

A loud speaker can be utilized to excite cylindrical asphalt concrete specimens at low temperatures in order to induce their axially symmetric fundamental mode of vibration so that their resonant frequencies can be measured.

-

An automated non-contact method for measuring resonant frequencies of asphalt concrete can be set up in a thermal chamber. This automated technique can eliminate thermal disturbances as the measurement is controlled by computer while the specimen is inside thermal chamber.

-

The measured resonant frequencies showed good agreements with results obtained from a recognized methodology in which impact hammer is used. The verifications show that accuracy of measurement can be improved at low temperatures by using the proposed non-contact method.

-

The repeatability of results and reproducibility of the method are monitored to be satisfactory. The lower the measurement temperature the more precise the measurement becomes.

-

No significant variation has been observed on measured resonant frequencies by varying air gap length between the speaker and the specimen.

-

The testing technique developed in this work can be utilized to carry out a study regarding effects of low temperature conditioning on asphalt pavements without involving any other form of stress. This can help to obtain a better understanding of the changes that asphalt undergoes when it is exposed to long period of low temperatures under no traffic.

References

Gudmarsson, A., Ryden, N., Birgisson, B.: Application of resonant acoustic spectroscopy to asphalt concrete beams for determination of the dynamic modulus. Mater. Struct. 45(12), 1903–1913 (2012)

Kweon, G., Kim, Y.R.: Determination of asphalt concrete complex modulus with impact resonance test. J. Transp. Res. Board Natl. Acad. 1, 151–160 (2014)

Kim, D., Kim, Y.R.: Determination of dynamic modulus values of asphalt mixtures using impact resonance testing of thin disk specimens. J. Test. Eval. 45(2), 20150076 (2015)

Gudmarsson, A., Ryden, N., Birgisson, B.: Characterizing the low strain complex modulus of asphalt concrete specimens through optimization of frequency response functions. J. Acoust. Soc. Am. 132(4), 2304–2312 (2012)

Gudmarsson, A., Ryden, N., Birgisson, B., Benedetto, H.D.I., Sauzéat, C.: Characterizing the complex modulus and Poisson’ s ratio of asphalt concrete specimens through modal testing. In: Int. Symp. Non-Dest Testing in Civil Engineering (2015)

Brown, E.R., Kandhal, P.S., Roberts, F.L., Kim, Y.R., Lee, D.Y., Kennedy, T. W.: Hot mix asphalt materials, mixture design and construction (NAPA Research and Education Foundation) (2009)

Boz, I., Tavassoti-Kheiry, P., Solaimanian, M.: The advantages of using impact resonance test in dynamic modulus master curve construction through the abbreviated test protocol. Mater. Struct. 50(3), 1–12 (2017)

Mun, S.: Determining the dynamic modulus of a viscoelastic asphalt mixture using an impact resonance test with damping effect. Res. Nondestruct. Eval. 26(4), 189–207 (2015)

Gudmarsson, A., Ryden, N., Di Benedetto, H., Sauzéat, C., Tapsoba, N., Birgisson, B.: Comparing linear viscoelastic properties of asphalt concrete measured by laboratory seismic and tension-compression tests. J. Nondestruct. Eval. 33(4), 571–582 (2014)

Van Den Abeele, K.E., Sutin, A., Carmeliet, J., Johnson, P.A.: Micro-damage diagnostics using nonlinear elastic wave spectroscopy (NEWS). NDT E Int. 34(4), 239–248 (2001)

Sugimoto, T., Sugimoto, K., Utagawa, N.: Study on the long distance non-contact acoustic inspection method using a strong ultrasonic sound source. In: World Conference on Non-Destructive Testing, pp. 1–8 (2016)

Sugimoto, T., Uechi, I., Sugimoto, K., Utagawa, N., Katakura, K.: Study on the non-contact acoustic inspection method for concrete structures by using strong ultrasonic sound source. Phys. Procedia 70, 398–401 (2015)

Gudmarsson, A., Ryden, N., Birgisson, B.: Non-contact excitation of fundamental resonance frequencies of an asphalt concrete specimen. AIP Conf. Proc. 1650(2015), 1401–1408 (2015)

Bahia, H.U., Anderson, D.A.: Physical hardening of paving grade asphalts as related to compositional characteristics. Prepr. ACS Div. Fuel 37(3), 1397–1407 (1992)

Dollimore, D.: Physical aging in amorphous polymers and other materials. Thermochim. Acta 54(1–2), 242–243 (1982)

Paul Togunde, O., Hesp, S.A.M.: Physical hardening in asphalt mixtures. Int. J. Pavement Res. Technol. 5(1), 46–53 (2012)

Kriz, P., Stastna, J., Zanzotto, L., Materials, B.: Temperature dependence and thermo-reversibility of physical hardening of asphalt binders. In: EAPA (2008)

Zhang, L., Li, T.S., Tan, Y.Q.: The potential of using impact resonance test method evaluating the anti-freeze-thaw performance of asphalt mixture. Constr. Build. Mater. 115, 54–61 (2016)

Luukkala, M., Heikkila, P., Surakka, J.: Plate wave resonance—a contactless test method. Ultrasonics 9(4), 201–208 (1971)

Brigante, M., Sumbatyan, M.A.: Acoustic methods in nondestructive testing of concrete: review of foreign publications in the field of theoretical studies. Russ. J. Nondestruct. Test. 49(4), 185–195 (2013)

Kaczmarek, M., Piwakowski, B., Drelich, R.: Noncontact ultrasonic nondestructive techniques: state of the art and their use in civil engineering. J. Infrastruct. Syst. 23(1), B4016003 (2016)

Solodov, I., Pfleiderer, K., Gerhard, H., Predak, S., Busse, G.: New opportunities for NDE with air-coupled ultrasound. NDT E Int. 39(3), 176–183 (2006)

Kolluru, S., Popovics, J., Shah, S.: Determining elastic properties of concrete using vibrational resonance frequencies of standard test cylinders. Cem. Concr. Aggreg. 22, 81–89 (2016)

Martinček, G.: The determination of poisson’s ratio and the dynamic modulus of elasticity from the frequencies of natural vibration in thick circular plates. J. Sound Vib. 2(2), 116–127 (1965)

So, J., Leissa, A.W.: Three-dimensional vibrations of thick circular and annular plates. J. Sound Vib. 209(1), 15–41 (1998)

So, J., Leissa, A.: Free vibrations of thick hollow circular cylinders fromthree-dimensional analysis. J. Vib. Acoust. 119, 89–95 (1997)

Behnia, B., Buttlar, W.G.: Cooling cycle effects on low temperature cracking characteristics of asphalt concrete mixture. Mater. Struct. 47, 1359 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Bekele, A., Ryden, N., Gudmarsson, A. et al. Automated Non-contact Resonance Excitation Method to Assess Low Temperature Dynamic Modulus of Asphalt Concrete. J Nondestruct Eval 38, 43 (2019). https://doi.org/10.1007/s10921-019-0584-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-019-0584-7