Abstract

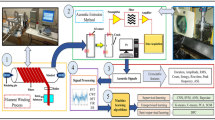

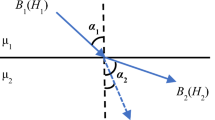

Resin fiber composites reinforcement is used to recover the original mechanical properties of steel tubes subjected to corrosion wall thinning. Pulsed Eddy Current (PEC) technique can perform nondestructive evaluation of this kind of component, due to its capability to penetrate nonmagnetic insulation. Despite the evaluation capability, distinguishing inner surface from outer surface defects is not an easy task for time-domain PEC technique. In this paper, Fast Fourier transform (FFT) in combination with multilayer perceptron (MLP) neural network classifiers are applied to PEC signals and used to detect defects (wall thinning) and also to indicate their position. The tested sample is a carbon steel tube, with 17 mm of composite reinforcement, where two defects were manufactured, one at the inner and another at the outer surface. An automated scanner system is used to obtain C-scan maps, showing the thinning areas. Two feature extraction methods are used to produce the input features for the neural network classifier: the coefficients of the FFT; and the parameters of an exponential curve fitted to the FFT coefficients. The results indicate that the MLP neural network correctly recognized the presence of wall thinning and its location with detection efficiencies of 97.4 and 97.0%, respectively. The PEC technique analysis in frequency-domain associated with a neural network classifier seems to be a promising alternative to identify the position of defects in composite reinforced steel tubes.

Similar content being viewed by others

References

Rohem, N.R.F., Pacheco, L.J., Budhe, S., Banea, M.D., Sampaio, E.M., Barros, S.: Development and qualification of a new polymeric matrix laminated composite for pipe repair. Compos. Struct. 152, 737–745 (2016). https://doi.org/10.1016/j.compstruct.2016.05.091

Duell, J.M., Wilson, J.M., Kessler, M.R.: Analysis of a carbon composite overwrap pipeline repair system. Int. J. Press. Vessel. Pip. 85, 782–788 (2008). https://doi.org/10.1016/j.ijpvp.2008.08.001

Keller, M.W., Jellison, B.D., Ellison, T.: Moisture effects on the thermal and creep performance of carbon fiber/epoxy composites for structural pipeline repair. Composites 45, 1173–1180 (2013). https://doi.org/10.1016/j.compositesb.2012.07.046

Winnik, S.: Corrosion Under Insulation (CUI) Guidelines, Revised edn. Woodhead Publishing Limited, Cambridge (2016)

Ahmed, W.H.: Evaluation of the proximity effect on flow-accelerated corrosion. Ann. Nucl. Energy 37, 598–605 (2010). https://doi.org/10.1016/j.anucene.2009.12.020

He, Y., Tian, G., Zang, H., Alamin, M., Simm, A., Jackson, P.: Steel corrosion characterization using Pulsed Eddy Current systems. IEEE Sens. J. 12, 2113–2119 (2012). https://doi.org/10.1109/JSEN.2012.2184280

Yu, Y., Yan, Y., Wang, F., Tian, G., Zhang, D.: An approach to reduce lift-off noise in Pulsed Eddy Current nondestructive technology. NDT E Int. 63, 1–6 (2014). https://doi.org/10.1016/j.ndteint.2013.12.012

Rourke, M., Li, Y., Roberts, G.: Multi-Tubular Corrosion Inspection Using a Pulsed Eddy Current Logging Tool. In: IPTC 2013, International Petroleum Technology Conference. https://doi.org/10.2523/16645-MS

Tian, G.Y., Sophian, A., Taylor, D., Rudlin, J.: Multiple sensors on Pulsed Eddy Current detection for 3d subsurface crack assessment. IEEE Sens. J. 5, 90–96 (2005). https://doi.org/10.1109/JSEN.2004.839129

Huang, S., Wang, S.: New Technologies in Electromagnetic Non-destructive Testing, pp 41–79. Springer, Singapore (2016). https://doi.org/10.1007/978-981-10-0578-7_2

Park, D.J., Angani, C.S., Kishore, M.B., Vértesy, G., Lee, D.H.: Application of the Pulsed Eddy Current technique to inspect pipelines of nuclear plants. J. Magn. 18, 342–347 (2013). https://doi.org/10.4283/JMAG.2013.18.3.342

Renken, C.J.: The use of personal computer to extract information from Pulsed Eddy Current. Mater. Eval. 59, 356–360 (2001)

Majidnia, S., Rudlin, J., Nilavalan, R.: Investigations on a Pulsed Eddy Current system for flaw detection using an encircling coil on a steel pipe. Insight—Non-Destr. Test. Cond. Monit. 56, 560–565 (2014)

Zeng, Z., Li, Y., Huang, L., Luo, M.: Frequency-domain defect characterization in Pulsed Eddy Current testing. Int. J. Appl. Electromagn. Mech. 45, 621–625 (2014). https://doi.org/10.3233/JAE-141885

Chen, X., Hou, D., Zhao, L., Huang, P., Zhang, G.: Study on defect classification in multi-layer structures based on fisher linear discriminate analysis by using Pulsed Eddy Current technique. NDT E Int. 67, 46–54 (2014). https://doi.org/10.1016/j.ndteint.2014.07.003

He, Y., Luo, F., Pan, M., Hu, X., Gao, J., Liu, B.: Defect classification based on rectangular Pulsed Eddy Current sensor in different directions. Sens Actuators A 157, 26–31 (2010). https://doi.org/10.1016/j.sna.2009.11.012

Tian, G.Y., Sophian, A.: Defect classification using a new feature for Pulsed Eddy Current sensors. NDT E Int. 38, 77–82 (2005). https://doi.org/10.1016/j.ndteint.2004.06.001

Tian, G.Y., He, Y., Adewale, I., Simm, A.: Research on spectral response of Pulsed Eddy Current and NDE applications. Sens. Actuators A 189, 313–320 (2013). https://doi.org/10.1016/j.sna.2012.10.011

Cheng, W.: Pulsed Eddy Current testing of carbon steel pipes, wall-thinning through insulation and cladding. J. Nondestruct. Eval. 31, 215–224 (2012). https://doi.org/10.1007/s10921-012-0137-9

Qiu, X., Zhang, P., Wei, J., Cui, X., Wei, C., Liu, L.: Defect classification by Pulsed Eddy Current technique in con-casting slabs based on spectrum analysis and wavelet decomposition. Sens. Actuators A 203, 272–81 (2013). https://doi.org/10.1016/j.sna.2013.09.004

Pan, M., He, Y., Tian, G., Chen, D., Luo, F.: PEC frequency band selection for locating defects in two-layer aircraft structures with air gap variations. IEEE Trans. Instrum. Meas. 62, 2849–2856 (2013). https://doi.org/10.1109/TIM.2013.2239892

Peng, Y., Qiu, X., Wei, J., Li, C., Cui, X.: Defect classification using PEC responses based on power spectral density analysis combined with EMD and EEMD. NDT E Int. 78, 37–5 (2016). https://doi.org/10.1016/j.ndt&eint.2015.11.003

Kiwa, T., Kawata, T., Yamada, H., Tsukada, K.: Fourier-transformed eddy current technique to visualize cross-sections of conductive materials. NDT E Int. 40, 363–367 (2007). https://doi.org/10.1016/j.ndteint.2007.01.006

Buck, J., Underhill, P.R., Morelli, J.E., Krause, T.W.: Simultaneous multiparameter measurement in Pulsed Eddy Current steam generator data using artificial neural networks. IEEE Trans. Instrum. Meas. 65, 672–679 (2016). https://doi.org/10.1109/TIM.2016.2514778

Dolapchiev, I., Brandisky, K.: Crack sizing by using Pulsed Eddy Current technique and neural network. Facta Univ. 19, 371–377 (2006). https://doi.org/10.2298/FUEE0603371D

Xie, S., Chen, Z., Chen, H., Wang, X., Takagi, T., Uchimoto, T.: Sizing of wall thinning defects using Pulsed Eddy Current testing signals based on a hybrid inverse analysis method. IEEE Trans. Instrum. Meas. 49, 1653–1656 (2013). https://doi.org/10.1109/TMAG.2012.2236827

Liu, Z., Forsyth, D.S., Lepine, B.A., Hammad, I., Farahbakhsh, B.: Investigation into classifying 3D Pulsed Eddy Current signals with neural network. Insight—Non-Destruct. Test. Cond. Monit. 45, 608–614 (2003). https://doi.org/10.1784/insi.45.9.608.52940

Arjun, V., Sasi, B., Rao, B.C.P., Mukhopadhyay, C.K., Jayakumar, T.: Optimisation of Pulsed Eddy Current probe for detection of sub-surface defects in stainless steel plates. Sens. Actuators A 226, 69–75 (2015). https://doi.org/10.1016/j.sna.2015.02.018

Sophian, A., Tian, G.Y., Taylor D Rudlin, J.: A feature extraction technique based on principal component analysis for Pulsed Eddy Current NDT. NDT E Int. 36, 37–41 (2003). https://doi.org/10.1016/S0963-8695(02)00069-5

Haykin, S.: Neural Networks and Learning Machines, 3rd edn. Pearson Education, New Jersey (2009)

Diniz, P.S.R., Silva, E.A.B., Netto, S,L.: Digital Signal Processing: System Analysis and Design, 2nd edn. Cambridge University Press, Cambridge (2010)

Tian, L., Yin, C., Cheng, Y., Bai, L.: Successive approximation method for the measurement of thickness using Pulsed Eddy Current. IEEE Int. Instrum. Meas. Technol. Conf. 2015, 848–852 (2015). https://doi.org/10.1109/I2MTC.2015.7151379

Fletcher, R., Reeves, C.M.: Function minimization by conjugate gradients. Comput. J. 7, 149–154 (1964). https://doi.org/10.1093/comjnl/7.2.149

Simas Filho, E.F., Silva Junior, M.M., Farias, P.C.M.A., Albuquerque, M.C.S., Silva, I.C., Farias, C.T.T.: Flexible decision support system for ultrasound evaluation of fiber-metal laminates implemented in a DSP. NDT E Int. 79, 38–45 (2016). https://doi.org/10.1016/j.ndteint.2015.12.001

Acknowledgements

The authors thank FAPESB for funding this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Larocca, C.B., Farias, C.T.T., Simas Filho, E.F. et al. Wall Thinning Characterization of Composite Reinforced Steel Tube Using Frequency-Domain PEC Technique and Neural Networks. J Nondestruct Eval 37, 44 (2018). https://doi.org/10.1007/s10921-018-0477-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-018-0477-1