Abstract

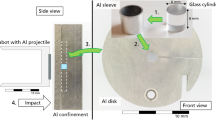

With a view to gaining an in-depth assessment of the response of particleboards (PBs) to different in-service loading conditions, samples of high-density homogeneous PBs of sugarcane bagasse and castor oil polyurethane resin were manufactured and subjected to low velocity impacts using an instrumented drop weight impact tower and four different energy levels, namely 5, 10, 20 and 30 J. The prediction of the damage modes was assessed using Comsol Multiphysics\(^\circledR .\) In particular, the random distribution of the fibres and their lengths were reproduced through a robust model. The experimentally obtained dent depths due to the impactor were compared with the ones numerically simulated showing good agreement. The post-impact damage was evaluated by a simultaneous system of image acquisitions coming from two different sensors. In particular, thermograms were recorded during the heating up and cooling down phases, while the specklegrams were gathered one at room temperature (as reference) and the remaining during the cooling down phase. On one hand, the specklegrams were processed via a new software package named Ncorr v.1.2, which is an open-source subset-based 2D digital image correlation (DIC) package that combines modern DIC algorithms proposed in the literature with additional enhancements. On the other hand, the thermographic results linked to a square pulse were compared with those coming from the laser line thermography technique that heats a line-region on the surface of the sample instead of a spot. Surprisingly, both the vibrothermography and the line scanning thermography methods coupled with a robotized system show substantial advantages in the defect detection around the impacted zone.

Similar content being viewed by others

Abbreviations

- ABNT:

-

Associacao Brasileira de Normas Tecnicas

- ANSI:

-

American National Standards Institute

- BD:

-

Bulk density

- CIS:

-

Cold image subtraction

- CMOS:

-

Complementary metal-oxide-semiconductor

- CV:

-

Coefficient of variation

- DIC:

-

Digital image correlation

- EOF:

-

Empirical orthogonal function

- FEM:

-

Finite element method

- FOV:

-

Field of view

- FPAs:

-

Focal plane arrays

- FT:

-

Flash thermography

- GUI:

-

Graphical user interface

- HD:

-

Hardness

- IRT:

-

Infrared thermography

- LLT:

-

Laser line thermography

- LSgT:

-

Line scanning thermography

- LStT:

-

Laser spot thermography

- MDFs:

-

Medium-density fiberboards

- MDI:

-

Methylenediphenyl isocyanate

- MOE:

-

Modulus of elasticity

- MOR:

-

Modulus of rupture

- Nd:YAG:

-

Neodymium-doped yttrium–aluminium–garnet

- NDT:

-

Non-destructive testing

- NETD:

-

Noise equivalent temperature difference

- PBs:

-

Particleboards

- PCT:

-

Principal component thermography

- PDE:

-

Partial differential equation

- PT:

-

Pulsed thermography

- ROI:

-

Region of interest

- SCB:

-

Sugarcane bagasse

- SH:

-

Screw-holding

- SPT:

-

Square pulse thermography

- \(\mathrm{t}_\mathrm{obs}\) :

-

Time of observation

- THz:

-

Terahertz

- TS:

-

Thickness swelling

- VT:

-

Vibrothermography

- WA:

-

Water absorption

References

Tabarsi, E., Kozak, R., Cohen, D., Gaston, C.: A market assessment of the potential for OSB products in the North American office furniture and door manufacturing industries. For. Prod. J. 53(7–8), 19–27 (2003)

Madurwar, M., Ralegaonkar, R.V., Mandavgane, S.A.: Application of agro-waste for sustainable construction materials: a review. Constr. Build. Mater. 38, 872–878 (2013)

Buyuksari, U., Ayrilmis, N., Avci, E., Koc, E.: Evaluation of the physical, mechanical properties and formaldehyde emission of particleboard manufactured from waste stone pine (Pinus pinea L.) cones. Bioresour. Technol. 101, 255–259 (2009)

Çöpür, Y., Güler, C., Taşçıoğlu, C., Tozluoğlu, A.: Incorporation of hazelnut shell and husk in MDF production. Bioresour. Technol. 99, 7402–7406 (2008)

Pirayesh, H., Khazaeian, A.: Using almond (Prunus amygdalus L.) shell as a biowaste resource in wood based composite. Composites B 43, 1475–1479 (2012)

Batalla, L., Nuñez, A.J., Marcovich, N.E.: Particleboards from peanut shell flour. J. Appl. Polym. Sci. 97, 916–923 (2005)

Guler, C., Copur, Y., Tascioglu, C.: The manufacture of particleboards using mixture of peanut hull (Arachis hypogaea L.) and European black pine (Pinus nigra Arnold) wood chips. Bioresour. Technol. 99, 2893–2897 (2008)

Wechsler, A., Zaharia, M., Crosky, A., Jones, H., Ramírez, M., Ballerini, A., Nuñez, V., Sahajwalla, M.: Macadamia (Macadamia integrifolia) shell and castor (Rícinos communis) oil based sustainable particleboard: a comparison of its properties with conventional wood based particleboard. Mater. Des. 50, 117–123 (2013)

Bektas, I., Guler, C., Kalaycioğlu, H., Mengeloglu, F., Nacar, M.: The manufacture of particleboards using sunflower stalks (Helianthus annuus L.) and poplar wood (Populus alba L.). J. Compos. Mater. 39, 467–473 (2005)

Guntekin, E., Karakus, B.: Feasibility of using eggplant (Solanum melongena) stalks in the production of experimental particleboard. Ind. Crops Prod. 27, 354–358 (2008)

Quintana, G.C., Velásquez Jiménez, J.A., Betancourt, S., Gañán, P.F.: Binderless fiberboard from steam exploded banana bunch. Ind. Crops Prod. 29(1), 60–66 (2009)

Sampathrajan, A., Vijayaraghavan, N.C., Swaminathan, K.R.: Mechanical and thermal properties of particle boards made from farm residues. Bioresour. Technol. 40, 249–251 (1992)

Kadam, V., Chattopadhyay, K., Bharimalla, A., Venugopal, B.: Mechanical characterization of brown and green coconut husk. J. Nat. Fibers 11(4), 322–332 (2014)

Xu, R., Sugawara, Y., Widyorini, R., Han, G.P., Kawai, S.: Manufacture and properties of low-density binderless particleboard from kenaf core. Wood Sci. 50, 62–67 (2004)

Machado Cravo, J.C., de Lucca Sartori, D., Màrmol, G., de Carvalho Balieiro, J.C., de Oliveira Machado, G., Fiorelli, J.: Manufacture of particleboard based on cement bag and castor oil polyurethane resin. Constr. Build. Mater. 87, 8–15 (2015)

Hernández-Salas, J.M., Villa-Ramírez, M.S., Veloz-Rendó, N.J.S., Rivera-Hernández, K.N., González-César, R.A., Plascencia-Espinosa, M.A., et al.: Comparative hydrolysis and fermentation of sugarcane and agave bagasse. Bioresour. Technol. 100, 1238–1245 (2009)

Pandey, A., Soccol, C.R., Nigam, P., Soccol, V.T.: Biotechnological potential of agro-industrial residues. I: sugarcane bagasse. Bioresour. Technol. 74, 69–80 (2000)

Loh, Y.R., Debnath, S., Ekhlasur Rahman, M., Das, C.A.: Sugarcane bagasse–the future composite material: a literature review. Resour. Conserv. Recycl. 75, 14–22 (2013)

Vilay, V., Jaafar, M., Mat Taib, R., Todo, M.: Effect of fiber surface treatment and fiber loading on the properties of bagasse fiber-reinforced unsaturated polyester composites. Compos. Sci. Technol. 68, 631–638 (2008)

de Sousa, M.V., Monteiro, S., d’Almeida, J.R.M.: Evaluation of pre-treatment, size and molding pressure on flexural mechanical behavior of chopped bagasse-polyester composites. Polym. Test. 23, 253–258 (2004)

Carvajal, O., Valdés, J.L., Puig, J.: Bagasse particleboards for building purpose. Holz als Roh- und Werkstoff 54(1), 61–63 (1996)

Nonaka, S., Umemura, K., Kawai, S.: Characterization of bagasse binderless particleboard manufactured in high-temperature range. J. Wood Sci. 59, 50–56 (2013)

Fiorelli, J., de Lucca Sartori, D., Machado Cravo, J.C.: Savastano Jr., H., Rossignolo, J.A., do Nascimento, M.F., Rocco Lahr, F.A.: Sugarcane bagasse and castor oil polyurethane adhesive-based particulate composite. Mater. Res. 16(2), 439–446 (2013)

Zike, S., Kalnins, K.: Enhanced impact absorption properties of plywood. In: Civil Engineering’11, 3rd International Scientific Conference Proceedings, Jelgava, Latvia, 2011, pp. 125–130

Sfarra, S., López, F., Sarasini, F., Tirillò, J., Ferrante, L., Perilli, S., Ibarra-Castanedo, C., Paoletti, D., Lampani, L., Barbero, E., Sánchez-Sáez, S., Maldague, X.: Analysis of damage in hybrid composites subjected to ballistic impacts: an integrated non-destructive approach. In: Thakur, V.K., Thakur, M.K., Kessler, M.R. (eds) Handbook of Composites from Renewable Materials. Physico-chemical and Mechanical Characterization, vol. 3, pp. 175–210. Wiley-Scrivener (2017). ISBN 978-1-119-22366-5

Tang, Z., Hang, C., Suo, T., Wang, Y., Dai, L., Zhang, Y.: Numerical and experimental investigation on hail impact on composite panels. Int. J. Impact Eng. (2016). https://doi.org/10.1016/j.ijimpeng.2016.05.016

Bendada, A., Sfarra, S., Genest, M., Paoletti, D., Rott, S., Talmy, E., Ibarra-Castanedo, C., Maldague, X.: How to reveal subsurface defects in Kevlar\(\textregistered \) composite materials after an impact loading using infrared vision and optical NDT techniques? Eng. Fract. Mech. 108, 195–208 (2013)

Meola, C., Carlomagno, G.M.: Infrared thermography to evaluate impact damage in glass/epoxy with manufacturing defects. Int. J. Impact Eng. 67, 1–11 (2014)

Shi, W., Wu, Y., Wu, L.: Quantitative analysis of the projectile impact on rock using infrared thermography. Int. J. Impact Eng. 34, 990–1002 (2007)

Prentice, H.J., Proud, W.G., Walley, S.M., Field, J.E.: Optical techniques for the investigation of the ballistic impact of thin plates. Int. J. Impact Eng. 38, 849–863 (2011)

Sfarra, S., Ibarra-Castanedo, C., Santulli, C., Sarasini, F., Ambrosini, D., Paoletti, D., Maldague, X.: Eco-friendly laminates: from the indentation to non-destructive evaluation by optical and infrared monitoring techniques. Strain 49, 175–189 (2013)

Sfarra, S., Ibarra-Castanedo, C., Santulli, C., Paoletti, A., Paoletti, D., Sarasini, F., Bendada, A., Maldague, X.: Falling weight impacted glass and basalt fibre woven composites inspected using non-destructive techniques. Composites B 45, 601–608 (2013)

Sfarra, S., Ibarra-Castanedo, C., Santulli, C., Paoletti, D., Maldague, X.: Monitoring of jute/hemp fiber hybrid laminates by nondestructive testing techniques. Sci. Eng. Compos. Mater. 23(3), 283–300 (2016)

Sfarra, S., Theodorakeas, P., Černecky, J., Pivarčiová, E., Perilli, S., Koui, M.: Inspecting marquetries at different wavelengths: the preliminary numerical approach as aid for a wide-range of non-destructive tests. J. Nondestruct. Eval. 36(6), 1–20 (2017)

Blaber, J., Adair, B., Antoniou, A.: Ncorr: open-source digital image correlation Matlab software. Exp. Mech. 55(6), 1105–1122 (2015a)

Blaber, J., Adair, B.S., Antoniou, A.: A methodology for high resolution digital image correlation in high temperature experiments. Rev. Sci. Instrum. 86, 035111-1–035111-6 (2015b)

Zhang, H., Hassler, U., Genest, M., Fernandes, H., Robitaille, F., Ibarra-Castanedo, C., Joncas, S., Maldague, X.: Comparative study on submillimeter flaws in stitched T-joint carbon fiber reinforced polymer by infrared thermography, microcomputed tomography, ultrasonic c-scan and microscopic inspection. Opt. Eng. 54(10), 104109 (2015)

Fernandes, H., Zhang, H., Ibarra-Castanedo, C., Maldague, X.: Fiber orientation assessment on randomly-oriented strand composites by means of infrared thermography. Compos. Sci. Technol. 121, 25–33 (2015)

Sham, F.C., Xu, W.T., Lo, T.: Application of flash thermography for crack identification in concrete materials. Insight 52(9), 494–497 (2010)

Arndt, R.W.: Square pulse thermography in frequency domain as adaptation of pulsed phase thermography for qualitative and quantitative applications in cultural heritage and civil engineering. Infrared Phys. Technol. 53(4), 246–253 (2010)

Renshaw, J., Chen, J.C., Holland, S.D., Thompson, R.B.: The sources of heat generation in vibrothermography. NDT&E Int. 44(8), 736–739 (2011)

Oswald-Tranta, B., Sorger, S.: Scanning pulse phase thermography with line heating. QIRT J. 9(2), 103–122 (2012)

Ibarra-Castanedo, C., Tarpani, J.R., Maldague, X.P.V.: Nondestructive testing with thermography. Eur. J. Phys. 34, S91–S109 (2013)

Rajic, N.: Principal component thermography for flaw contrast enhancement and flaw depth characterization in composite structures. Compos. Struct. 58(4), 521–528 (2002)

Zhang, H., Yu, L., Hassler, U., Fernandes, H., Genest, M., Robitaille, F., Joncas, S., Holub, W., Sheng, Y., Maldague, X.: An experimental and analytical study of micro-laser line thermography on micro-sized flaws in stitched carbon fiber reinforced polymer composites. Compos. Sci. Technol. 126, 17–26 (2016)

Zhang, H., Fernandes, H., Dizeu, F., Hassler, U., Fleuret, J., Genest, M., Ibarra-Castanedo, C., Robitaille, F., Joncas, S., Maldague, X.: Pulsed micro-laser line thermography on submillimeter porosity in carbon fiber reinforced polymer composites: experimental and numerical analyses for the capability of detection. Appl. Opt. 55(34), D1–D10 (2016)

Pawar, S.S., Vavilov, V.P.: Applying the heat conduction-based 3D normalization and thermal tomography to pulsed infrared thermography for defect characterization in composite materials. Int. J. Heat Mass Transf. 94, 56–65 (2016)

American Society for Testing and Materials (ASTM): D 1037: Standard Test Method for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials. ASTM, Philadelphia (1996)

Fiorelli, J., Curtolo, D.D., Barrero, N.G., Savastano Jr., H., Pallone, E.M.J.A., Johnson, R.: Particulate composite based on coconut fiber and castor oil polyurethane adhesive: an ecoefficient product. Ind. Crops Prod. 40, 69–75 (2012)

Associação Brasileira de Normas Técnicas (ABNT): NBR 14810: Chip Panel Sheets—Part 3: Testing Methods, Terminology. ABNT, Rio de Janeiro (2006)

Lopresto, V., Caprino, G., Leone, C., Langella, A.: A damage index of indentation sensitivity in low velocity impact conditions. Polym. Compos. 36, 987–991 (2015)

Caprino, G., Lopresto, V.: The significance of indentation in the inspection of carbon fibre-reinforced plastic panels damaged by low-velocity impact. Compos. Sci. Technol. 60(7), 1003–1012 (2000)

Belingardi, G., Vadori, R.: Low velocity impact tests of laminate glass-fiber-epoxy matrix composite material plates. Int. J. Impact Eng. 27(2), 213–229 (2002)

Wos, P., Michalcki, J.: Effect of initial cylinder liner honing surface roughness on aircraft piston engine performances. Tribol. Lett. 41, 555–567 (2011)

Schönauer, W., Adolph, T.: How we solve PDEs. J. Comput. Appl. Math. 131(1–2), 473–492 (2001)

Introduction to Comsol Multiphysics\(\textregistered .\) http://cdn.comsol.com/documentation/5.0.1.276/IntroductionToCOMSOLMultiphysics.pdf. Accessed 1 May 2016

Constitutive Equation. http://web.mit.edu/16.20/homepage/3_Constitutive/Constitutive_files/module_3_with_solutions.pdf. Accessed 26 May 2016

Javier, J., Majano-Majano, A., Fernandez-Cabo, J.: On the identifiability of stiffness components of clear wood from a 3D off-axes prismatic specimen: angle orientation and friction effects. Eur. J. Wood Wood Prod. 74(3), 285–290 (2016)

Rasul, M.G., Rudolph, V., Carsky, J.M.: Physical properties of bagasse. Fuel 78(8), 905–910 (1999)

Han, Y.W., Catalano, E.A., Ciegler, A.: Chemical and physical properties of sugarcane bagasse irradiated with gamma rays. J. Agric. Food Chem. 31(1), 34–38 (1983)

Fiorelli, J., Gomide, C.A.: Lahr, F.A.R., do Nascimento, M.F., de Lucca Sartori, D., Mejia Ballesteros, J.E., Bonila Bueno, S., Belini, U.L.: Physico-chemical and anatomical characterization of residual lignocellulosic fibers. Cellulose 21(5), 3269–3277 (2014)

Öchsner, A.: Elasto-plasticity of Frame Structure Elements Modeling and Simulation of Rods and Beams. Springer, Berlin (2014). ISBN 978-3-662-44224-1

Maldague, X.P.: Theory and Practice of Infrared Technology for Nondestructive Testing. Wiley Interscience, New York (2001)

Zhang, H., Fernandes, H., Hassler, U., Ibarra-Castanedo, C., Genest, M., Robitaille, F., Joncas, S., Maldague, X.: Comparative study of microlaser excitation thermography and microultrasonic excitation thermography on submillimeter porosity in carbon fiber reinforced polymer composites. Opt. Eng. 56(4), 041304 (2016)

Ibarra-Castanedo, C., Genest, M., Guibert, S., Piau, J.-M., Maldague, X.P.V., Bendada, A.: Inspection of aerospace materials by pulsed thermography, lock-in thermography, and vibrothermography: a comparative study. In: Knettel, K.M., Vavilov, V.P., Miles, J.J. (eds) Proceedings of SPIE, Thermosense XXIX, vol. 6541, 2007

Zhang, H., Sfarra, S., Saluja, K., Peeters, J., Fleuret, J., Duan, Y., Fernandes, H., Avdelidis, N., Ibarra-Castanedo, C., Maldague, X.: Non-destructive investigation of paintings on canvas by continuous wave terahertz imaging and flash thermography. J. Nondestruct. Eval. 36(2), 1–12 (2017)

Gruss, C., Balageas, D.: Theoretical and experimental applications of the flying spot camera. In: EETI (ed) Proceedings of QIRT 1992—The International Conference on Quantitative Infrared Thermography—Eurotherm Series 27, 1992

Deonna Woolard, F., Elliott Cramer, K.: Line scan versus flash thermography: comparative study on reinforced carbon–carbon. In: Raymond Peacock, G., Burleigh, D.D., Miles, J.J. (eds) Proceedings of SPIE, Thermosense XXVII, vol. 5782, pp. 315–323, 2005

Ibarra-Castanedo, C., Servais, P., Ziadi, A., Klein, M., Maldague, X.: RITA—robotized inspection by thermography and advanced processing for the inspection of aeronautical components. In: Batsale, J.-C., Balageas, D., Battaglia, J.-L., et al. (eds) Proceedings of QIRT 2014—The 12th International Conference on Quantitative Infrared Thermography, vol. XXII (2014). http://www.ndt.net/article/qirt2014/papers/QIRT-2014-164.pdf

Aindow, J., Markham, M., Puttick, K., Rider, J., Rudman, M.: Fibre orientation detection in injection-moulded carbon fibre reinforced components by thermography and ultrasonics. NDT&E Int. 19(1), 24–29 (1986)

Ball, R.J., Almond, D.P.: Detection and measurements of impact damage in thick carbon fibre reinforced laminates by transient thermography. NDT&E Int. 31, 165–173 (1998)

Avdelidis, N.P., Almond, D.P., Dobbinson, A., Hawtin, B.C.: Pulsed thermography: philosophy, qualitative and quantitative analysis on certain aircraft applications. Insight 48(5), 286–289 (2006)

Zhang, H., Sfarra, S., Sarasini, F., Ibarra-Castanedo, C., Perilli, S., Fernandes, H., Duan, Y., Peeters, J., Avdelidis, N.P., Maldague, M.: Optical and mechanical excitation thermography for impact response in basalt-carbon hybrid fiber-reinforced composite laminates. IEEE Trans. Ind. Inform. (2017). https://doi.org/10.1109/TIII.2017.2744179

Balageas, D., Maldague, X., Burleigh, D., Vavilov, V.P., Oswald-Tranta, B., Roche, J.-M., Pradere, C., Carlomagno, G.M.: Thermal (IR) and other NDT techniques for improved material inspection. J. Nondestruct. Eval. 35, 1–17 (2016)

Fernandes, H., Ibarra-Castanedo, C., Zhang, H., Maldague, X.P.V.: Thermographic non-destructive evaluation of carbon fiber-reinforced polymer plates after tensile testing. J. Nondestruct. Eval. 34, 35–45 (2015)

Vavilov, V.P.: Modeling and characterizing impact damage in carbon fiber composites by thermal/infrared non-destructive testing. Composites B 61, 1–10 (2014)

Ahi, K.: Mathematical modeling of THz point spread function and simulation of THz imaging systems. IEEE Trans. Terahertz Sci. Technol. 7(6), 747–754 (2017). https://doi.org/10.1109/TTHZ.2017.2750690

Acknowledgements

The research leading to these results has received funding from The Research Fund: Flanders FWO Travel Grant V4.010.16N and the University of Antwerp (Belgium). In addition, this study was supported by Russian Foundation Grant #17-19-01047 and in part by Tomsk Polytechnic University Competitiveness Enhancement Program Grant. Finally, the authors want to thank both the Canada Research Chair in Multipolar Infrared Vision (MIVIM) and the FAPESP-Brazil (Proc. 2012/13881-2 and 2013/1985-8) for supporting this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, H., Sfarra, S., Sarasini, F. et al. Impact Modelling and A Posteriori Non-destructive Evaluation of Homogeneous Particleboards of Sugarcane Bagasse. J Nondestruct Eval 37, 6 (2018). https://doi.org/10.1007/s10921-018-0461-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-018-0461-9