Abstract

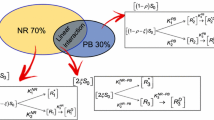

The paper presents a novel efficient closed form approach to determine the degree of vulcanization of natural rubber (NR) vulcanized with sulphur in presence of different accelerators. The general reaction scheme proposed by Han and co-workers for vulcanized sulphur NR is re-adapted and suitably modified taking into account the single contributions of the different accelerators, focusing in particular on some experimental data, where NR was vulcanized at different temperatures (from 150 to \(180\, ^{\circ }\hbox {C}\)) and concentrations of sulphur, using TBBS and DPG in the mixture as co-agents at variable concentrations. In the model, chain reactions initiated by the formation of macro-compounds responsible for the formation of the unmatured crosslinked polymer are accounted for. It is assumed that such reactions depend on the reciprocal concentrations of all components and their chemical nature. In presence of two accelerators, reactions are assumed to proceed in parallel, making the assumption that there is no interaction between the two accelerators. Despite there is experimental evidence that a weak process by which each accelerator affects the other, the reaction chemistry is still not well understood and therefore its effect cannot be translated into any mathematical model. In any case, even disregarding such interaction, good approximations of the rheometer curves are obtained. From the simplified kinetic scheme adopted, a closed form solution is found for the crosslink density, with the only limitation that the induction period is excluded from computations. The main capability of the model stands however in the closed form determination of kinetic constants representing the velocities of single reactions in the kinetic scheme adopted, which allows avoiding a numerically demanding least-squares best fitting on rheometer experimental data. Two series of experiments available, relying into rheometer curves at different temperatures and different concentrations of sulphur and accelerators, are utilized to evaluate the fitting capabilities of the mathematical model. Very good agreement between numerical output and experimental data is experienced in all cases analyzed.

Similar content being viewed by others

References

Y. Tanaka, Rubber Chem. Technol. 64, 325 (1991)

G. Wolfman, Hasenhidl, S. Wolf, Kautsch. Gummi Kunstst. 44(2), 118 (1991)

A.Y. Coran, Science and Technology of Rubber, Chapter 7 (Academic Press, New York, 1978)

K.D.O. Jackson, M.J.R. Loadman, C.H. Jones, G. Ellis, Spectrochim. Acta 46(2A), 217 (1990)

G. Ellis, P.J. Hendra, M.J.R. Loadman, Kautsch. Gummi Kunstst. 43(2), 118 (1990)

D.J.P. Harrison, W.R. Yates, J. Macromol. Sci. C 25, 481 (1985)

A.M. Zaper, J.L. Koenig, Rubber Chem. Technol. 60, 252 (1987)

R. Orza, P.C.M.M. Magusin, V.M. Litvinov, M. van Duin, M.A.J. Michels, Macromolecules 42, 8914–8924 (2009)

H.G. Dikland, M. van Duin, Crosslinking of EPDM and polydiene rubbers studied by optical spectroscopy, in Spectroscopy of Rubbers and Rubbery Materials, ed. by V.M. Litvinov, P.P. De (Rapra Technology Ltd., Shawbury, 2002). 207

T. Kemperman, Kautsch. Gummi Kunstst. 40, 820 (1987)

E. Leroy, Souid, R. Deterre, Polym. Test. 32, 575–582 (2013)

G. Milani, F. Milani, J. Appl. Polym. Sci. 119, 419–437 (2011)

G. Milani, F. Milani, Polym. Test. 33, 1–15 (2014)

R. Ding, I. Leonov, J. Appl. Polym. Sci. 61, 455 (1996)

R. Ding, I. Leonov, A.Y. Coran, Rubber Chem. Technol. 69, 81 (1996)

I.S. Han, C.B. Chung, S.J. Kang, S.J. Kim, H.C. Chung, Polymer (Korea) 22, 223–230 (1998)

X. Colin, L. Audouin, J. Verdu, Polym. Degrad. Stab. 92(5), 906–914 (2007)

M.R. Kamal, S. Sourour, Polym. Eng. Sci. 13, 59–64 (1973)

G. Milani, E. Leroy, F. Milani, R. Deterre, Polym. Testing 32, 1052–1063 (2013)

T. Hanel, Technical Report, Vulcanization behavior of immiscible elastomer blends. (Pirelli Tyre SpA, 2013)

X. Sun, A.I. Isayev, Rubber Chem. Technol. 82(2), 149–169 (2009)

R.P. Quirk, Prog. Rubber Plast. Technol. 4(1), 31 (1988)

Matlab User’s Guide. http://www.mathworks.com/products/matlab/ (2007)

G. Milani, F. Milani, J. Math. Chem. 52(2), 464–488 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Milani, G., Hanel, T., Donetti, R. et al. A closed form solution for the vulcanization prediction of NR cured with sulphur and different accelerators. J Math Chem 53, 975–997 (2015). https://doi.org/10.1007/s10910-014-0456-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10910-014-0456-4