Abstract

The thermal and electrical conductivity of a single-crystal \(\hbox {Cd}_{0.22}\hbox {Hg}_{0.78}\hbox {Te}\) was studied in the temperature range of practical applications (77–300 K). The sample has impurity conductivity, which is limited by the scattering of charge carriers by phonons. Heat in the sample is transferred by phonons and thermal conductivity is limited by phonon–phonon scattering. The electron contribution to the thermal conductivity can be neglected.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The publication of Lawson et al. [1] caused the development of intense studies of \(\hbox {Cd}_{x} \hbox {Hg}_{1-{x}} \hbox {Te}\) compounds (cadmium mercury telluride—CMT), a semiconductor with variable band gap. At almost the same time, this compound was synthesized in the Lviv Pedagogical Institute in Ukraine [2]. CMT is a pseudo-binary alloy that crystallizes in the zinc blende structure. When the molar fraction of Cd varies within the limits \(0< x < 1\), the width of the forbidden band varies from a negative value (\({\sim }- 0.08 \, \hbox {eV}\)) that is characteristic for a semimetal, to a positive value (\({\sim }1.5 \, \hbox {eV}\)). In the interval \(0.15< x < 0.3\), the compound is a narrow-gap semiconductor, which is presently a widely used material for creating infrared (IR) detectors in the whole Earth’s atmosphere transparency spectrum (range): short waves (1.5–2.5 \(\upmu \hbox {m}\)), medium waves (3–5 \( \upmu \hbox {m}\)) and long waves (8–14 \(\upmu \hbox {m}\)) using the whole range of temperatures, from liquid helium (4.2 K) to room temperature. In the long-wave range, there is no alternative material to the CMT for detectors, which determines both the purely scientific and the applied interest in this compound. The direct energy gap, the possibility of obtaining samples with a low and high carriers’ concentration, the excessively high electron mobility, the low dielectric constant, an extremely small change in the lattice constant for variations of x (less than 0.3%), which makes possible to grow high-quality single crystals and thin-film heterostructures based on CMT, are some of the advantageous properties of CMT.

The main difficulties in the use of CMT are related to the technological drawbacks of this material. One of them is the weak Hg–Te bonds, which leads to volumetric, surface and interphase instability. However, these disadvantages are compensated by the unconditional advantages of this material. The contemporary research and technology state in using this compound are summarized in a collective monograph [3]. Taking into account these advantages of CMT, it is important to determine the parameters of CMT samples in the temperature range of their application.

2 Experimental techniques

For the X-ray studies, a sample was prepared from several fragments of a \(\hbox {Cd}_{x} \hbox {Hg}_{1-{x}} \hbox {Te}\) crystal by mechanical grinding in a mortar. A cylindrical sample with a diameter of 7 mm and a height of 3 mm in a steel mold at a pressure of 100 MPa was pressed from the resulting powder. X-ray diffraction patterns from the investigated sample were obtained using a X-ray diffractometer in copper (\(K_{\alpha }\)) radiation at a 30 kV accelerating voltage in the diffraction angle range (\(2 \theta ): 20{^{\circ }}{-}90{^{\circ }}\) with an angular scan rate of \(0.5 \, {^{\circ }}{/}\hbox {min}\). Phase analysis was performed by comparing the X-ray diffraction patterns of the sample and standard samples from the ICDD X-ray diffraction database [4]. The calculation was carried out using the program Windicvol 06 from the software package FullProf Suite [5].

Figure 1 shows the X-ray diffraction pattern of the sample. According to the results of qualitative X-ray phase analysis (Fig. 1), all the diffraction lines on the X-ray diffraction pattern of the sample belong to the same phase, having a structure close to \(\hbox {Cd}_{0.2} \hbox {Hg}_{0.8} \hbox {Te}\) (PDF No. 51-1122) [4]. At the same time, the results of calculating the X-ray diffraction pattern from the sample \(\hbox {Cd}_{x} \hbox {Hg}_{1-{x}} \hbox {Te}\) (Table 1) show that the lattice parameter is \(a = 6.4641 \pm 0.00005\,{\AA }\).

According to the standards of PDF No. 51-1122 [4], the lattice parameter of the sample \(\hbox {Cd}_{0.2} \hbox {Hg}_{0.8} \hbox {Te}\) is 6.46544 Å. According to Eq. (1), the dependence of the lattice parameter \(\hbox {Cd}_{x} \hbox {Hg}_{1-{x}} \hbox {Te}\) from the coefficient x has the following form [6]:

where x is the concentration of Cd atoms. The solution of Eq. (1) for the value of the lattice parameter obtained in this paper gives the value \(x = 0.22\), and the structural formula acquires the following form: \(\hbox {Cd}_{0.22} \hbox {Hg}_{0.78} \hbox {Te}\).

The temperature dependence of the electrical conductivity was obtained by a standard four-contact method at direct current. The temperature was measured by a platinum resistance thermometer with an accuracy of 0.1 K. The thermal conductivity was measured by the method of stationary heat flow on a sample with dimensions: measuring \(13 \times 8 \times 1 \, \hbox {mm}^{3}\) at a temperature gradient of \({\approx } 0.05 \, \hbox {K}/\hbox {mm}\). From the Hall effect measured in a field of 0.15 T at 293 K, it can be deduced that the samples represent an n-type material with carrier concentration at room temperature \(n = 3 \times 10^{21} \, \hbox {m}^{-3}\) (Hall constant \(R_\mathrm{H} = 2 \times 10^{-3} \, \hbox {m}^{3} /\hbox {C}\)).

3 Results and discussion

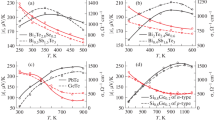

The temperature dependence of the conductivity of the sample \(\hbox {Cd}_{0.22} \hbox {Hg}_{0.78} \hbox {Te}\) in the interval 77–300 K is shown in Fig. 2. This dependence reflects the fact that at sufficiently high temperatures, intrinsic conductivity with exponential temperature variation prevails in semiconductors, \(\sigma \propto \hbox {exp}(-\Delta E_\mathrm{g}/(2 {\textit{kT}}))\) [7]. The exponential decrease in intrinsic conductivity with decreasing temperature leads to the predominance of impurity conduction at intermediate temperatures, which depends weakly on the temperature. The temperature dependence of the impurity conductivity is determined by the mobility of the charge carriers, which in the present study decreases with increasing temperature (see Fig. 2, \(T < 120 \, \hbox {K}\)), indicating the scattering of these carriers by phonons [7].

The plot of the temperature dependence of the conductivity of the sample \(\hbox {Cd}_{0.22} \hbox {Hg}_{0.78} \hbox {Te}\). Symbols: square box—experiment, solid line—approximation in accordance to (2). The inset shows the dependence of the band-gap width for Cd–Hg–Te compound from the Cd content: solid line—calculation by formula (2) [8]; square box—experimental data from Table 1 in [8]; circle—data [9]; filled triangle—our data

In a first approximation, the conductivity of a sample can be described in the following form:

where the first term is the impurity conductivity, and the second is the intrinsic conductivity [7]. Here, \(b_{0} \approx 3800 \, (\Omega \, \hbox {cm})^{-1}\,\hbox {K}^{3/2}\), \(\sigma _{0} \approx 0.0234 \, (\Omega \,\hbox {cm})^{-1}\), \(\Delta E_\mathrm{g}/2 k \approx 400 \, \hbox {K}\) (see Fig. 2). The value of the energy gap, \(\Delta E_\mathrm{g}\), is close to the data from the bibliography [8, 9], as it is shown in the inset to Fig. 2.

Figure 3 represents the temperature dependence of the thermal conductivity of the sample \(\hbox {Cd}_{0.22} \hbox {Hg}_{0.78} \hbox {Te}\) in the temperature range 77–180 K. It is observed that the thermal conductivity decreases by increasing the temperature as \(T^{-1}\). This behavior is in agreement with reference data, although the value of the thermal conductivity is somewhat lower than previously reported [10].

The value of the electron contribution to the thermal conductivity calculated from the Wiedemann–Franz law, \(\lambda _{e} = L_{0} T \sigma (T)\), is of the order of \(10^{-2}\,\hbox {W}/(\hbox {m}\,\hbox {K})\), which is much lower as compared to the experimental value of the thermal conductivity (see Fig. 3). Therefore, the thermal conductivity measured experimentally in the temperature range of the possible use of single crystals as a material for radiation detectors is phonon, and the \(\lambda \propto T^{-1}\) dependence is related to the phonon–phonon scattering (see the inset to Fig. 3 and, for example, [11]). A certain role in this is played by the presence of structural and kinematic anisotropy in the system [12,13,14,15].

4 Conclusions

The X-ray pattern analysis showed that the sample has the structure \(\hbox {Cd}_{0.22} \hbox {Hg}_{0.78} \hbox {Te}\). It is shown that in the temperature range of the possible use of the material (77–120 K), the electrical and thermal conductivity of the \(\hbox {Cd}_{0.22} \hbox {Hg}_{0.78} \hbox {Te}\) is limited by the scattering on phonons of the charge carriers for the case of electrical conductivity, or of the heat carriers—phonons—for the case of thermal conductivity.

References

W.D. Lawson et al., J. Phys. Chem. Solids 9, 325 (1959)

A.D. Schneider, I.V. Gavrischak, Solid State Phys. 2, 2079 (1960)

P. Capper, J. Garland, Mercury Cadmium Telluride: Growth, Properties, and Applications (Wiley, Hoboken, 2011), p. 540

J. Faber, T. Fawcett, Acta Crystallogr. B58, 325 (2002)

A. Boultif, D. Louer, J. Appl. Cryst. 37, 724 (2004)

J.C. Wooley, B. Ray, J. Phys. Chem. Solids 13, 151 (1960)

P.S. Kireyev, Physics of Semiconductors, 2nd edn. (Moscow High School, Moscow, 1975), p. 586

A. Rogalski, Institute of physics publishing. Rep. Prog. Phys. 68, 2267–2336 (2005)

S.G. Gasan-zade, V.V. Bogoboyashchiy, I.P. Zhadko, E.A. Zinchenko, G.A. Shepelsky, Phys. Technol. Semicond. 27, 1508 (1993)

A.S. Okhotinin (ed.), Thermal Conductivity of Solids: Handbook (Energoatomizdat, Moscow, 1984), pp. 123–320

R. Berman, Thermal Conduction in Solids (Clarendon Press, Oxford, 1976), p. 286

S.V. Savich, A.V. Samoylov, S.N. Kamchatnaya, I.L. Goulatis, R.V. Vovk, A. Chroneos, A.L. Solovjov, L.V. Omelchenko, J. Low Temp. Phys. 186, 285–293 (2017)

P.G. Curran, V.V. Khotkevych, S.J. Bending, A.S. Gibbs, S.L. Lee, A.P. Mackenzie, Phys. Rev. B 84, 104507 (2011)

V.M. Apalkov, M.E. Portnoi, Phys. Rev. B 65, 125310 (2002)

I.N. Adamenko, K.E. Nemchenko, V.I. Tsyganok, A.I. Chervanev, Low Temp. Phys. 20, 498 (1994)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Bessmolniy, Y.V., Khadzhaj, G.Y., Beletskii, V.I. et al. Electro- and Heat Transfer in \(\mathbf{Cd}_{\mathbf{0.22}}\mathbf{\hbox {Hg}}_{\mathbf{0.78}}{} \mathbf{Te}\) Single Crystals in the Temperature Range of Their Practical Applications. J Low Temp Phys 190, 39–44 (2018). https://doi.org/10.1007/s10909-017-1810-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10909-017-1810-2