Abstract

This work aimed at conversion of worthless indurtial wastes to valuable product. Herein, bioactive composites based on bacterial cellulose (BC) and eggshell or eggshell-derived hydroxyapatite (HAp) were prepared by a green method using Gluconacetobacter xylinum bacteria. The effect of addition of eggshell (BC/Eg) and eggshell-derived HAp (BC/HAp-Eg) on the bacterial cellulose yield, biodegradation and biocompatibility was studied. For comparison, HAp derived from chemical precursors was synthesized (BC/HAp-ch). The resultant composites were characterized by XRD, FTIR, and SEM/EDX. Furthermore, the biodegradation and bioactivity were assessed in SBF, and the cell viability was studied against oral normal cells. The results showed that the productivity of BC applied HAp-derived eggshell (1.83 g/L) was higher than that of using (1.37 g/L). Interestingly, the eggshell was converted to Ca3(PO4)2 during incubation in the bacterial culture medium, while Ca3(PO4)2 was formed as a secondary phase when using either eggshell-derived HAp or chemically-derived. The in vitro bioactivity test in SBF showed that all composites were induced the formation of a bone-like apatite layer on their surface with Ca/P ratio, 1.49, 1.35, and 1.41 for BC/Eg, BC/HAp-ch, and BC/HAp-Eg, respectively, near to the ratio in the natural HAp. Finally, the in vitro cell viability test was confirmed good biocompatibility against the composites. However, at high sample concentration (250 µg/mL), BC/HA-Eg showed the higher cell viability (95.2%) than that of BC/Eg (80.5%) and BC/HA-ch (86.2%). In conclusion, eggshell waste could be used directly with bacterial cellulose to produce bioactive composites without the need to convert it to HAp which reduced the cost of production and thus has a higher economic return. Obiviously, eggshell waste can act as calcium, organic matter source, pH preservation, nuterilizing agent along with potential instead of costly buffering agent in the BC culture medium and further for increased the BC production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The use of innovative methods of waste disposal is of interest to the scientists. Each year huge amounts of the eggs are consumed into foods such as cakes, mayonnaise, and fast foods [1]. about 150,000 tons of eggshell waste is generated from the US only every year [2]. The eggshell waste can be reused as fertilizer, animal feed constituents, and others [3]. If high amounts of this kind of waste are kept in landfills they will attract rats and vermin due to the organic membrane attached to the shells [4], therefore, most landfill owners do not like to dispose of eggshell wastes. Consequently, the complete recycling of eggshell waste is considered the best choice to solve this environmental and economic problem.

The eggshells are considered a cheap, abundant, and natural source of CaCO3 compound which can be utilized in the synthesis of hydroxyapatite (HAp) which is one kind of bioceramic material. It has been reported that HAp is mostly preferred bioceramics, especially for fabrication of bone engineering scaffolds, due to their similarity of composition with the inorganic part of human bone [5, 6]. The natural precursors for the preparation of HAp are considered a versatile approach to obtaining pure final products free from toxic impurities and they give more advantageous properties, such as the pore structure carbonated constituent. Coral [7], bovine bone [8], and fishbone [9] are examples of natural raw materials for HAp synthesis. However, the mean problems of those materials are changeability in their physical and chemical properties [8]. Eggshell is considered the most natural raw material of the invariable chemical composition. Therefore, there have been numerous previous works that prepared HAp from eggshells as a natural source [10,11,12,13,14,15,16,17,18].

Biopolymers are a large group of polymers that are produced from living organisms. Cellulose is one of the most abundant polysaccharide polymer on the earth produced by a member of living organisms such as plant, microorganisms, and animals [19, 20]. Although its production is mostly by higher plants, an alternative route that used to prepared by another low-cost, rapid resource, such as bacterial systems, due to the extraction of cellulose from other components found naturally in the plants has many drawbacks because hazardous chemicals are used in this process [20,21,22,23]. Bacterial cellulose (BC) is fine cellulose produced naturally by Gram-negative bacteria in several forms with a high purity degree. Therefore, the BC is preferred due to the easily extraction and lower purification steps. In this way, the synthetic culture medium which widely used in the BC production like Hestrin– Schramm HS culture medium is correlated with the lower productivity and higher in cost [24]. Thus, cost-effectiveness of the cultural medium is considered as an important factor in the production process economics. [20,21,22,23]. Some kinds of bacteria can produce cellulose with the same as cellulose produced by higher plants and algae, but overall, it exhibits extra chemical pure. Commonly, BC was isolated from Gram-negative bacteria, which has an efficient ability to biosynthesis of cellulose from the standard substrate, glucose. The major bacterial genera secretion BC in the culture surface includes Achromobacter, Agrobacterium, Azotobacter, Pseudomonas, Acetobacter, and Gluconacetobacter. The most potent model strain Gluconacetobacter xylinus was extensively used for basic and applied studies on BC. Due to its unique physical, chemical, and mechanical properties that involve high crystallinity, high water holding capacity, large surface area, elasticity, mechanical strength, and biocompatibility, thus BC has potential applications in edible packing as a food contact packaging material. In medicine, as wound dressing materials, artificial skin, vascular grafts, scaffolds for tissue engineering, artificial blood vessels, medical pads, dental implants [25]. In other industries products, such as sponges to collect leaking oil in drug delivery agents, capsule shells, oil spill cleanup sponge; mineral and oil recovery; leather products, sports items; ultra-filters for water purification; audio speaker diaphragm; plywood laminates; specialty papers and polyesters; automotive and aircraft bodies and materials for absorbing toxins and optoelectronics materials (liquid crystal displays) [26].

Composites based on organic and inorganic phases gives materials with exceptional properties, because they combine the advantages of both phases. Therefore, incorporation of eggshell or eggshell-derived HAp into BC is consider a versatile method to produce bioactive composites from worthless materials. There have several studies conducted to prepare BC with eggshell or Ca-phosphates. Ummartyotin et al. prepared composite membranes of eggshell and bacterial cellulose as absorbent material in food active packaging by physical mixing of eggshell and bacterial cellulose [27]. Núñez et al., synthesized BC/HAp composites to remove lead from water, where they prepared BC separately by Komagataeibacter oboediens bacteria isolated from apple artisanal vinegar, and then included it in the solution medium used to prepare HAp by wet chemical precipitation method to get HAp nanocrystals dispersed in an ultrafine BC [28]. Another study synthesized BC/CaCO3 composites by precipitation of CaCO3 from CaCl2 and Na2CO3 aqueous solutions using microwave irradiation [29]. Similarly, Busuio, et al. prepared Ca-phosphates scaffolds using BC as a template by successive immersiong of BC in calcium- and phosphrous-reach solutions under ultrasonic irradiation. These allowed the required cations to form calcium phosphates on the surface of BC [30]. Athukorala, et al. prepared a cost-effective 3D cell culture platform based on HAp incorporated in [31]. Not only that, in an interesting study Liu et al. were used bacterial cellulose hydrogel matrix and egg white as a new mimetic method for biomineralization of CaCO3, and they obtained it with different morpholpgies according to changing of experimental parameters [32].

However, most of previous studies did not embedded eggshell or HAp in the BC culture medium to prepare composites, although this can achieve a high degree of homogeneity. Also, these studies did not determine the effect of eggshell or HAp addition to the bacterial medium on the production of BC. In this work an in-situ preparation of new bioactive composites based on BC synthesized by G. xylinum by using agricultural residues as an alternative culture media without any supplementation and eggshell or eggshell-derived HAp added directly to the culture medium for comparison. The culturing settings also studied carefully to determine the optimum conditions to obtain BC with high yield.

2 Materials and methods

2.1 Materials

Eggshell and membranes resulting from egg processing were collected from the disposal of free markets. The collected eggshell waste without disease symptoms was selected and washed thoroughly with distilled water to remove additional residues from its surface and then heated at 105 °C for 72 h to dry, sieved, and used as a template in the BC culture medium.

2.2 Methods

2.2.1 Synthesis of hydroxyapatite (HAp)

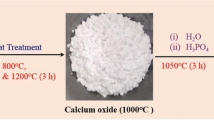

Hydroxyapatite powder was prepared from eggshell waste. Figure 1 presents schematic representation of synthesis process of different composites based on BC and eggshell or eggshell-derived HAp. Briefly, collected hen eggshells were cleaned in hot distilled water and left to dry in the air. And then, they heat treated up to 900 °C to give CaO. The calcined eggshell was dispersed in the water with a concentration of 0.5 M for 3 h, and 0.3 M of phosphoric acid (Sigma-Aldrich, Germany) was added dropwise on the calcium solution under stirring. After complete reaction, the solution was left for aging for 1 day and then washed and filtered. The precipitate was dried and sintered at different temperatures ranging from 600 to 900 °C. For comparison, HAp was prepared from CaCO3 chemical (Sigma-Aldrich, Germany) following the same previous steps. The prepared powders were suspended in the bacterial cellulose growth media to prepare in situ composite materials. Moreover, the collected eggshell waste was also used in the in situ preparation of composite material. The composites based on bacterial cellulose (BC)/eggshell, BC/HAp synthesized from CaCO3 chemical, and BC/HAp synthesized from eggshell herein encoded as BC/Eg, BC/HA-ch, and BC/HA-Eg, respectively.

2.2.2 Preparation of pure bacterial cellulose

Preparation of bacterial cellulose was achieved by the standard strain Gluconacetobacter xylinum ATCC 10,245 that was purchased from ATCC (American Type Culture Collection, Manassas, VA, USA). Preliminary activation of G. xylinum was carried out by cultivating it in Mannitol broth medium as described by Abdelraof, et al. [33] for 24 h. at 30 °C under shaking conditions. Subsequently, the activated strain was transferred to the standard HS culture medium for preparation of pure cellulose under standard culture optimization according to our previous report [34]. At the end of the incubation period, the cellulose pellicles were separated from the culture medium under centrifugation at 5000 rpm for 10 min. Then, the cellulose pellicles were subjected to purification protocol as mentioned by Abdelraof, et al. [34].

2.2.3 In situ preparation of BC/Eg, BC/HA-ch, and BC/HA-Eg

In this regard, various concentrations of each of Eg, HA-ch, and HA-Eg (0.025–0.75 g/ 100 ml) were incorporated into the standard culture medium of G. xylinum for examined their ability to use it as a template to produce cellulose, and thus evaluation the formed composite. Investigation of different parameters such as pH value, and glucose consumption and the relationship between them during cultivation time of each concentration of these materials was carried out. Regarding the pH value, HS culture medium was adjusted at 6.0 and the variation in the pH value after the addition of Eg, HA-ch, or HA-Eg was recorded before inoculation. The sugar consumption was expressed by calculating the total reducing sugar concentration via DNS reagent [35] using D-glucose as standard. After the fermentation process, BC/Eg, BC/HA-ch, and BC/HA-Eg composites were collected from the top of the culture medium and then purified like that of prepared pure BC [34]. Consequently, pure composites were dried at 70 °C for 24 h to evaluate the yield concentration in g/L. The influence of these materials on the cellulose yield can also be determined after purification of the composite [33] by estimating the cellulose amount in the composite after subtracting the Eg, HA-ch, or HA-Eg concentration from the total weight of the composite. The increase or decrease of cellulose yield (%) after treatment can be calculated as follows:

where A displayed the cellulose production without any treatment, while B is the cellulose producing after treatment.

2.2.4 Composite characterization

The XRD analysis of the composite samples was conducted by Philips PW1390 X-ray diffractometer (U.S.D.) in the 2θ range from 20 to 70° in 0.02° steps at λ = 1.5418 Å using CuKα radiation. Moreover, FTIR was performed for the samples using infrared absorption spectra at room temperature in the wavenumber range of 4000–400 cm−1 using Fourier transform infrared (BRUKER). The prepared samples each of 2 mg were mixed with 200 mg KBr in an agate mortar and pressed into a pellet. For each sample, the FTIR spectrum was normalized with a blank KBr pellet. Furthermore, the sample surfaces were coated with a thin layer of gold for SEM and EDX analyses to study the morphology microstructure of the prepared composites.

2.2.5 In vitro biodegradation and bioactivity test

The bone-forming activity in vitro was tested in simulated body fluid (SBF) to monitor the formation of hydroxyl-carbonated apatite (HCA) on the surface of composites samples over time. The samples were placed into a vessel containing SBF and incubated at 37 °C under pH 7.4 for periods 1, 3, 7, and d. At the predetermined periods, the ions’ concentrations released from the samples into the incubating medium was measured by colorimetric kits (SPECTRUM, Egypt), and they were characterized by scanning electron microscope coupled with energy dispersive X-ray analysis (SEM/EDX), to investigate the hydroxyapatite layer formed on coatings surfaces.

2.2.6 Evaluation of the cytotoxicity by MTT assay

MTT assay was applied to reveal the viability of (OEC) normal oral epithelial cells under the effect of BC/Eg, BC/HA-ch, and BC/HA-Eg. Briefly, OEC cells were plated in 96-well culture plates and exposed to various concentrations (15.63, 31.25, 62.5, 125 and 250 μg/ml). In addition to controlling untreated cells. All cultures were incubated for 24 h at 37 °C using a 5% CO2 incubator. At the end of the incubation period, the MTT solution (5 mg/mL) was added to each well and incubated at 37 °C for 4 h. The absorbance was measured in triplicates at 570 nm using the ELISA Reader system (SunRise TECAN, Inc., USA). The morphological changes of normal oral epithelial cells under the effect of BC/Eg, BC/HA-ch, and BC/HA-Eg of 250 and 125 μg/mL concentrations were captured using an inverted microscope (Leica, Germany) equipped with the digital microscopy camera [36].

3 Results and Discussion

3.1 Evaluations of BC yield in the presence of eggshell, chemically-derived HAp, and eggshell-derived HAp

Eggshell is a zero value waste, as well as the contaminant, have drawback against the environment which mainly consisted of sufficient quantities of calcium carbonate (94%), magnesium carbonate (1%), calcium phosphate (1%), and organic matter (4%) [18]. The management of large amounts of eggshell waste annually produced in the world is problematic as generally this material is only disposed of at landfills with odor production and microbial growth [37]. Table 1 shows a preliminary evaluation of bacterial cellulose production in the presence of each eggshell, eggshell-derived HAp, and chemically-derived HAp, while Table 2 shows detailed data of evaluation of bacterial cellulose production.

As shown in Table 2 it was evident that the BC production in the presence of Eg, HA-ch, or HA-Eg at a concentration of 0.1% to the culture medium before inoculation of G. xylinum does not cause any change in the pH level. Meanwhile, at the end of the cultivation period,, the pH values were significantly increased by more than 7 and that could be attributed to the fact that the redox reactions occurred among the metabolic components in the HS culture medium, which consumed the H+ and led to the increase in the pH value of the cultivated culture medium.

During the cultivation period, it was noted that the addition of HA-Eg and HA-ch at 0.05% exhibited the maximum BC production with 59% and 75% when compared with the standard HS culture medium (i.e. without any addition). In contrast, the incorporation of Eggshell to the culture medium was found to be insignificant in terms of the BC productivity, in which the BC production was increased by 12% at 0.1% Eggshell concentration. Releasing of Phosphorus caused a decrease in the pH value only when it was from inorganic P. and there was a significant correlation between the culture pH and P mineralization.

Moreover, it is more noticeable than the process of consuming glucose with 0.05% of HA-Eg and HA-ch was increased more than other concentrations. The pH level has been a slight change from 6 to 6.3 and at the end of the cultivation period (i. e. 7th day) and that could be related to the maximum BC productivity, which still maintains the buffering capacity of the culture medium and thus resistance the gluconic acid action [33, 34]. The vital role of HA-Eg and HA-ch on the BC productivity explains that the minerals such as calcium, magnesium, and phosphate group were greatly contributed to the processes of cell division and assisted in the various biological processes within it and the phosphate group was may be responsible for the buffering capacity of the culture medium through the cultivation period, and this, in turn, contributed to an increase in its growth, glucose uptake, and decrease the action of gluconic acid on the pH value and thus an increase in its BC production. While at concentrations of more than 0.25%, the culture medium becomes more turbidity and the level of BC production would be decreased, and this may be attributed to impeding the movement of the bacterium in the culture medium and the lack of ease to obtaining the nutrient elements for their growth [33, 38].

Studies that scoped in the exploitation of eggshell waste in the microbial culture medium was firstly require to dissolved by acid or alkli pretreatment in order to easily metabolized by microbial cells. In this way, utilization of eggshell waste for cellulase enzyme induction by Neurospora crassa under solid state fermentation was explored by Verma, et al. [39] which was firstly pretreated with 10% of HCl before incorporation to wheat bran solid culture medium. The major purpose of eggshell acid-hydrolysate supplementation was to enrichment the low-cost oganic matter, and calcium source for the Neurospora crassa culture medium.

Interstingly, eggshell waste in the BC production was exhibited via the high percentage of calcium carbonate content, which make as a natural buffering capacity acted as neutralizing agent of the cultural pH. The high exploitation of a zero-value eggshell waste in the BC production and at the same time preparation of BC/HAp composite in situe was achieved many advantages such as, cultural medium supplementation with oganic matter, and calcium source, regulate the pH and acted as CaO sorbent for enhanced CO2 deplation in the culture medium [4, 40]. Therefore, sustainable development of eggshell recycling for BC/HAp in-situ preparation was candidiated a promising low-cost green, and ecofriendly method.

3.2 XRD

Figure 2 represents XRD analysis of as-prepared BC/Eg, BC/HA-ch, and BC/HA-Eg composite samples. The diffraction peaks at 2θ around 15° and 20° are attributed to cellulose structure. These peaks are corresponding to the planes (1 0 0) and (1 1 0) of cellulose (cellulose produced by Gluconacetobacter xylinus strains ATCC 53524 and ATCC 23768: Pellicle formation, post-synthesis aggregation, and fiber density). Otherwise, the addition of inorganic materials (eggshell or HAp) to the in-situ production of BC led to the disappearance of BC peaks that referred to good incorporation of the BC with eggshell and HAp as resulting in modified BC production condition. It can be noticed from the figure that the eggshell powder (sample BC/Eg) was converted from CaCO3 (the main component of eggshell) to tricalcium phosphate (Ca3(PO4)2, Card # 00-151-7238) in the bacterial growth medium during the synthesis of cellulose by this bacteria. Whereas, the addition of chemically-derived HAp (sample BC/HA-ch) to the bacterial culture medium produced the composite based on bacterial cellulose and combined tricalcium phosphate (TCP) and HAp (Card # 00-901-3629), where TCP was the main crystalline phase. In contrast, incorporation of eggshell-derived HAp (sample BC/HA-Eg) in the culture medium also yielded bacterial cellulose and combined HAp and TCP, but, HAp was the main crystalline phase.

3.3 FT-IR

The main characteristic functional groups in the composites under investigation were determined using FT-IR analysis. Figure 3 shows the FT-IR of BC/Eg, BC/HA-ch, and BC/HA-Eg composites. The spectrum was operated in the wavenumber range of 4000–400 cm−1. The very weak and shallow peaks observed around 3274 and 2970 were assigned to (O–H) stretching vibration mode and stretching vibration of methylene (–CH2–), respectively, of BC. The peak allocated around 1642 cm−1 was attributed to the bending vibration mode of (O–H) group.

Moreover, the mean characteristic peaks of hydroxyapatite (HAp) can be detected from the figure. Where, the peaks observed in the range 900–1150 cm−1 were attributed to the asymmetric stretching vibration mode of PO4 group [41]. This peaks range was split into sharp peaks for BC/HA-ch and BC/HA-Eg composite samples, whereas, it was only one peak for weak shoulder for BC/Eg composite. This can be explained by the formation of poor-crystalline HAp during the in situ formation of bacterial cellulose with the eggshell waste by using phosphate ions presented already in the bacteria growth medium, while, splitting of this peak in case of the composites based on bacterial cellulose and HAp prepared from CaCO3 chemical or eggshell indicated to the well-crystallinity of HAp added to the bacteria medium. substitution, as identified by characteristic peaks of CO32− at around 875 and 1415 cm−1, which are attributed to the vibrational modes of the carbonate [42]. These peaks were stronger and sharper for BC/Eg composite than the other two composites, which is an acceptable result as the eggshell containing carbonate ions. The carbonated HAp is more favorable for implantation due to its more resorbability than the pure HAp [43]. In addition, the peaks at 561 and 600 cm−1 were assigned to P–O–P vibration mode [44, 45].

3.4 SEM/EDX

The morphology and the elemental analysis of the composites were examined using SEM/EDX. Figure 4 shows SEM micrographs of BC/Eg, BC/HA-ch, and BC/HA-Eg composites. From the figure, it can be observed that all samples were characterized by good homogeneity in the morphology and microstructure, and there was no significant difference among the composite samples in the morphology. Interestingly, EDX analysis showed a peak of phosphorus appeared in BC/Eg composite sample, where, the starting eggshell did not contain any phosphate ions. Likely, the calcium ions released from the eggshell particles were combined with the phosphate ions presented originally in bacterial growth medium to form nuclei of Ca-phosphate crystals. Therefore, the in-situ synthesis of BC/eggshell composite used in this study was superior to mechanically mixed methods used in previous study [27]. Where, the mechanical mixing of eggshell particles and BC gave a composite with the same chemical composition of the starting components, while, the in-situ synthesis was provided a sutiable environment for ion exchange to convert the eggshell to a kind of Ca-phosphate. This finding was confirmed from the Ca/P atomic ratio calculated from EDX analysis, where, this ratio was 1.35 (Table 3) which is close to the ratio in hydroxyapatite crystal (1.67). In contrast, this ratio was far from the ratio in HAp for BC/HA-ch, and BC/HA-Eg composites (0.56 and 0.83 respectively). This was mostly due to the precipitation of more phosphate ions presented in the growth medium on the composite surface.

3.5 In Vitro Bioactivity Test

The in vitro degradation and bioactivity of the prepared composites were studied by immersion of the samples in SBF. This method is widely used as a strategy for examining the ability of a material to adhere to the living tissue. The key mark of the material biocompatibility is its facility to induce the formation of bone-like apatite crystals on its surface upon soaking in the SBF. Figure 5 presents the SEM coupled with EDX analysis of the surface of BC/Eg, BC/HA-ch, and BC/HA-Eg composite samples after immersion in SBF for 30 days. As shown from SEM micrographs, new crystals of bone-like apatite layer were formed on all composite surfaces. The typical hydroxyapatite crystal shape can be observed on BC/HA-ch, and BC/HA-Eg samples, while, it was unobvious in the case of BC/Eg sample. The corresponding EDX spectra of the new crystals formed on the BC/HA-ch and BC/HA-Eg composite surfaces showed that the intensity of calcium atom was increased compared to EDX spectra of the samples before immersion in SBF (see Fig. 4). While there was no noticeable change in this ratio for BC/Eg sample. The Ca/P atomic ratio of the samples before and after immersion in SBF was calculated from the EDX results (Table 3). As it can be seen, the calculated ratio of BC/EG sample was closer value (1.49) to the ratio in hydroxyapatite crystals (Ca/P = 1.67) than the other two composites. Moreover, the change of Ca/P ratio of BC/Eg before and after immersion in SBF was small (1.35 and 1.49, respectively), but, there were big differences in this ratio for BC/HA-ch and BC/HA-Eg samples. This can be explained likely by the precipitation of phosphate ions presented in the bacteria growth medium.

The change of pH of the SBF incubated BC/Eg, BC/HA-ch, and BC/HA-Eg composite samples were tracked at different times. Figure 6a demonstrates a change of SBF with the time during immersion in SBF up to 14 d. It can be observed from the figure that the profile of pH change for all samples was nearly similar, and the differences between the samples were insignificant (P > 0.05), where the pH was progressively decreased from 7.40 to about 6.68, 6.83, and 6.90 for BC/Eg, BC/HA-ch, and BC/HA-Eg, respectively, till 7 days of incubation, followed by an increase up to the end of soaking time.

Calcium and phosphate ion concentrations in SBF were also measured as a sign of bone-like apatite layer formation on the composite surfaces. Figure 6b and c show the concentration of calcium and phosphate ions, in SBF solution. Likewise, the release profiles of all samples were similar. Where, for calcium ion, the concentration was decreased after 1 day of immersion to become 83.0, 84.6, and 87.0 ppm for BC/Eg, BC/HA-ch, and BC/HA-Eg, respectively. The calcium ion concentration fluctuated thereafter till the end of incubation time. On the other hand, the concentration of phosphate ions was abruptly decreased after 1 day of immersion to 57.1, 51.7, and 55.2 ppm, for BC/Eg, BC/HA-ch, and BC/HA-Eg, respectively, followed by a slight change up to the end of the immersion time. The decrease of calcium and phosphate ions in the initial soaking time was due to using of such ions in the precipitation of calcium phosphate layer on the composite surfaces. The fluctuation of ion concentrations can be explained from the repeating deposition and dissolution process of the newly formed bone-like apatite layer.

3.6 Biocompatibility Assay

The in vitro biocompatibility of BC/HA-Eg, BC/HA-ch and BC/Eg was evaluated against the normal oral epithelial cells (OEC) (Fig. 7). The cytotoxic effect of the prepared composites, given in different concentrations of 15.63 to 250 μg/mL, showed more than 50% of viable cells and exhibited all concentrations of BC/Eg, BC/HA-ch, and BC/HA-Eg caused no toxic effect against OEC cells. Also, inverted microscopy (Fig. 8) revealed no morphological variations in the OEC cells treated with different composites from 125 to 250 µg/mL compared with the untreated cells. However, at high sample concentration (250 µg/ml), BC/HA-Eg showed a higher cell viability (95.2%) than that of BC/Eg (80.5%) and BC/HA-ch (86.2%). According to the SEM/EDX analysis, the BC/HA-Eg, BC/HA-ch, and BC/Eg improved the precipitation of hydroxyapatite. Hydroxyapatite made from natural bases or waste such as eggshells [11, 46] is an excellent Ca and P source [47]. In our study, The high Ca/P ratio of hydroxyapatite supports the growth and survival of normal oral cells due to the increase in the expression of the calcium canal. In addition, calcium-sensing receptor (CaSR) could notice any change in the external concentration of Ca2+ and increase Ca2+ entry (6–9). Also, the XRD pattern displayed that the composites (BC/Eg, BC/HA-ch and BC/HA-Eg) were mainly constituted of bacterial cellulose and combined tricalcium phosphate (TCP) and Hap. The phosphate group in both tricalcium phosphate (TCP) and Hap act as a buffering system to maintain the culture medium at neutral pH, which is the best for cell proliferation and differentiating [36, 48,49,50,51]. In dental orthopedics, tricalcium phosphate and Hydroxyapatite have been used to coat the implant; the coating materials stimulate new bone formation and increase protein adsorption on the interior surfaces, leading to enhanced cell adhesion [52, 53].

Morphological characteristics of OEC cells treated with BC/Eg, BC/HA-ch, and BC/HA-Eg observed under an inverted microscope after 24 h. The OEC normal cells stained with a crystal violet stain. a Control OEC cells at 24 h, b Cells treated with (250 µg/mL) of BC/Eg, c Cells treated with (250 µg/mL) of BC/HA-ch, d Cells treated with (250 µg/mL) of the sample BC/HA-Eg, e Cells treated with (125 µg/mL) of BC/Eg, f Cells treated with (125 µg/mL) of BC/HA-ch, and g Cells treated with (125 µg/mL) of the sample BC/HA-Eg Magnification: × 40

4 Conclusion

The bioactive composites based on eggshell wastes, hydroxyapatite (HAp) synthesized from eggshell, or HAp synthesized from chemicals and bacterial cellulose (BC) were successfully prepared in situ by G. xylinum by using agricultural residues as an alternative culture media without any supplementation. The benefite of eggshell waste as buffering agent and also as low-cost source of HAp was exploited in the first time for BC/HAp composite production without any chemical pretreatments. FTIR analysis showed the main functional groups of BC and the ceramic fillers. Furthermore, SEM/EDX analysis presented that the produced composites were characterized by good homogeneity, and the in vitro bioactivity test in SBF demonstrated that the composites under investigation were induced the formation of a bon-like apatite layer on their surface. Finally, the in vitro cell viability test was confirmed good biocompatibility against the composites which expectedly are as pure as to be used safely in different biomedical applications.

In the future work, based on good biocompatibility results of BC/eggshell composite, we`ll emphasize the possibility to prepare composites based on bacterial cellulose and eggshell directly without converting the last one to HAp. This approach will save extra costs for the industrial scale production.

References

C. Sonenklar, Famous for egg waste. Res Penn State News 20, 1–2 (1999)

J. Hecht, Eggshells Break into Collagen Market (New Scientist Publ Expediting Inc, Elmont, 1999)

W. Daengprok, W. Garnjanagoonchorn, Y. Mine, Fermented pork sausage fortified with commercial or hen eggshell calcium lactate. Meat Sci. 62, 199–204 (2002)

Z. Wei, C. Xu, B. Li, Application of waste eggshell as low-cost solid catalyst for biodiesel production. Biores. Technol. 100, 2883–2885 (2009)

S. Best, A. Porter, E. Thian, J. Huang, Bioceramics: past, present and for the future. J. Eur. Ceram. Soc. 28, 1319–1327 (2008)

C. Tan, A. Yaghoubi, S. Ramesh, S. Adzila, J. Purbolaksono, M. Hassan et al., Sintering and mechanical properties of MgO-doped nanocrystalline hydroxyapatite. Ceram. Int. 39, 8979–8983 (2013)

M. Sivakumar, T.S. Kumar, K. Shantha, K.P. Rao, Development of hydroxyapatite derived from Indian coral. Biomaterials 17, 1709–1714 (1996)

L.S. Ozyegin, F.N. Oktar, G. Goller, E.S. Kayali, T. Yazici, Plasma-sprayed bovine hydroxyapatite coatings. Mater. Lett. 58, 2605–2609 (2004)

M. Ozawa, S. Suzuki, Microstructural development of natural hydroxyapatite originated from fish-bone waste through heat treatment. J. Am. Ceram. Soc. 85, 1315–1317 (2002)

G. Gergely, F. Wéber, I. Lukács, A.L. Tóth, Z.E. Horváth, J. Mihály et al., Preparation and characterization of hydroxyapatite from eggshell. Ceram. Int. 36, 803–806 (2010)

Goloshchapov D, Kashkarov V, Rumyantseva N, Seredin P, Lenshin A, Agapov B, et al (2013) Synthesis of nanocrystalline hydroxyapatite by precipitation using hen's eggshell. Ceram Int 39:4539–4549

D.S.R. Krishna, A. Siddharthan, S. Seshadri, T.S. Kumar, A novel route for synthesis of nanocrystalline hydroxyapatite from eggshell waste. J. Mater. Sci. 18, 1735–1743 (2007)

E.M. Rivera, M. Araiza, W. Brostow, V.M. Castano, J. Dıaz-Estrada, R. Hernández et al., Synthesis of hydroxyapatite from eggshells. Mater. Lett. 41, 128–134 (1999)

K. Sanosh, M.-C. Chu, A. Balakrishnan, T. Kim, S.-J. Cho, Utilization of biowaste eggshells to synthesize nanocrystalline hydroxyapatite powders. Mater. Lett. 63, 2100–2102 (2009)

A. Toibah, F. Misran, A. Shaaban, Z. Mustafa, Effect of pH condition during hydrothermal synthesis on the properties of hydroxyapatite from eggshell waste. J Mech Eng Sci. 13, 4958–4969 (2019)

V. Trakoolwannachai, P. Kheolamai, S. Ummartyotin, Development of hydroxyapatite from eggshell waste and a chitosan-based composite: in vitro behavior of human osteoblast-like cell (Saos-2) cultures. Int. J. Biol. Macromol. 134, 557–564 (2019)

S.-C. Wu, H.-C. Hsu, S.-K. Hsu, Y.-C. Chang, W.-F. Ho, Effects of heat treatment on the synthesis of hydroxyapatite from eggshell powders. Ceram. Int. 41, 10718–10724 (2015)

S.-C. Wu, H.-C. Hsu, S.-K. Hsu, Y.-C. Chang, W.-F. Ho, Synthesis of hydroxyapatite from eggshell powders through ball milling and heat treatment. J. Asian Ceram. Soc. 4, 85–90 (2016)

D. Klemm, D. Schumann, U. Udhardt, S. Marsch, Bacterial synthesized cellulose—artificial blood vessels for microsurgery. Prog. Polym. Sci. 26, 1561–1603 (2001)

S. Sheykhnazari, T. Tabarsa, A. Ashori, A. Shakeri, M. Golalipour, Bacterial synthesized cellulose nanofibers; Effects of growth times and culture mediums on the structural characteristics. Carbohyd. Polym. 86, 1187–1191 (2011)

R.M. Brown Jr., A.C. Millard, P.J. Campagnola, Macromolecular structure of cellulose studied by second-harmonic generation imaging microscopy. Opt. Lett. 28, 2207–2209 (2003)

C. Castro, R. Zuluaga, C. Álvarez, J.-L. Putaux, G. Caro, O.J. Rojas et al., Bacterial cellulose produced by a new acid-resistant strain of Gluconacetobacter genus. Carbohyd. Polym. 89, 1033–1037 (2012)

W.-C. Lin, C.-C. Lien, H.-J. Yeh, C.-M. Yu, S.-H. Hsu, Bacterial cellulose and bacterial cellulose–chitosan membranes for wound dressing applications. Carbohyd. Polym. 94, 603–611 (2013)

A.H. Hashem, A.M. Khattab, M. Abdelraof, A facile one-pot bioconversion of frying oil waste to single cell oils and related products using fungi via response surface methodology. Biomass. Conv. Bioref. (2022). https://doi.org/10.1007/s13399-021-02165-7

F. Esa, S.M. Tasirin, N.A. Rahman, Overview of bacterial cellulose production and application. Agric. Agric. Sci. Procedia. 2, 113–119 (2014)

A.F. Jozala, L.C. de Lencastre-Novaes, A.M. Lopes, S.-E. de Carvalho, P.G. Mazzola, A. Pessoa-Jr et al., Bacterial nanocellulose production and application: a 10-year overview. Appl. Microbiol. Biotechnol. 100, 2063–2072 (2016)

S. Ummartyotin, P. Pisitsak, C. Pechyen, Eggshell and bacterial cellulose composite membrane as absorbent material in active packaging. Int. J. Polym. Sci. 2016, 1047606 (2016)

D. Núñez, R. Cáceres, W. Ide, K. Varaprasad, P. Oyarzún, An ecofriendly nanocomposite of bacterial cellulose and hydroxyapatite efficiently removes lead from water. Int. J. Biol. Macromol. 165, 2711–2720 (2020)

A. Stoica-Guzun, M. Stroescu, S.I. Jinga, I.M. Jipa, T. Dobre, Microwave assisted synthesis of bacterial cellulose-calcium carbonate composites. Ind. Crops Prod. 50, 414–422 (2013)

C. Busuioc, M. Stroescu, A. Stoica-Guzun, G. Voicu, S.-I. Jinga, Fabrication of 3D calcium phosphates based scaffolds using bacterial cellulose as template. Ceram. Int. 42, 15449–15458 (2016)

S.S. Athukorala, C.J. Liyanage, A.C.A. Jayasundera, Hydroxyapatite incorporated bacterial cellulose hydrogels as a cost-effective 3D cell culture platform. Soft Mater. 20, 183–192 (2022)

X. Liu, Y. Zhou, C. Pei, Mimetic biomineralization matrix using bacterial cellulose hydrogel and egg white to prepare various morphologies of CaCO3. CrystEngComm 20, 4536–4540 (2018)

M. Abdelraof, M.S. Hasanin, H. El-Saied, Ecofriendly green conversion of potato peel wastes to high productivity bacterial cellulose. Carbohyd. Polym. 211, 75–83 (2019)

M. Abdelraof, M.S. Hasanin, M.M. Farag, H.Y. Ahmed, Green synthesis of bacterial cellulose/bioactive glass nanocomposites: effect of glass nanoparticles on cellulose yield, biocompatibility and antimicrobial activity. Int. J. Biol. Macromol. 138, 975–985 (2019)

G.L. Miller, Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959)

H.Y. Ahmed, N. Safwat, R. Shehata, E.H. Althubaiti, S. Kareem, A. Atef et al., Synthesis of natural nano-hydroxyapatite from snail shells and its biological activity: antimicrobial, antibiofilm, and biocompatibility. Membranes 12, 408 (2022)

S. Mignardi, L. Archilletti, L. Medeghini, C. De Vito, Valorization of eggshell biowaste for sustainable environmental remediation. Sci. Rep. 10, 2436 (2020)

E. Bilgi, E. Bayir, A. Sendemir-Urkmez, E.E. Hames, Optimization of bacterial cellulose production by Gluconacetobacter xylinus using carob and haricot bean. Int. J. Biol. Macromol. 90, 2–10 (2016)

N. Verma, V. Kumar, M.C. Bansal, Utilization of Egg Shell Waste in Cellulase Production by Neurospora crassa under Wheat Bran-Based Solid State Fermentation. Pol. J. Environ. Studies. 21(2), 491–497 (2012)

X. Meng, D. Deng, Trash to treasure: waste eggshells used as reactor and template for synthesis of Co9S8 nanorod arrays on carbon fibers for energy storage. Chem. Mater. 28, 3897–3904 (2016)

J. Rocha, A. Lemos, S. Kannan, S. Agathopoulos, J. Ferreira, Hydroxyapatite scaffolds hydrothermally grown from aragonitic cuttlefish bones. J. Mater. Chem. 15, 5007–5011 (2005)

R. Murugan, S. Ramakrishna, Production of ultra-fine bioresorbable carbonated hydroxyapatite. Acta Biomater. 2, 201–206 (2006)

C. Rodrigues, P. Serricella, A. Linhares, R. Guerdes, R. Borojevic, M. Rossi et al., Characterization of a bovine collagen–hydroxyapatite composite scaffold for bone tissue engineering. Biomaterials 24, 4987–4997 (2003)

M.M. Farag, M.M. Ahmed, N.M. Abdallah, W. Swieszkowski, A.M. Shehabeldine, The combined antibacterial and anticancer properties of nano Ce-containing Mg-phosphate ceramic. Life Sci. 257, 117999 (2020)

P. Tamilselvi, A. Yelilarasi, M. Hema, R.J.N.B. Anbarasan, Synthesis of hierarchical structured MgO by sol-gel method. Nano Bull. 2, 130106 (2013)

Ummartyotin S, Manuspiya H. Eggshell waste: An effective source of hydroxyapatite for photocatalyst. J. Met. Mater. Min. 2018;28.

M. Akram, R. Ahmed, I. Shakir, W.A.W. Ibrahim, R. Hussain, Extracting hydroxyapatite and its precursors from natural resources. J. Mater. Sci. 49, 1461–1475 (2014)

M.M. Farag, Z.M. Al-Rashidy, M.M. Ahmed, In vitro drug release behavior of Ce-doped nano-bioactive glass carriers under oxidative stress. J. Mater. Sci. 30, 1–15 (2019)

T. Numata, Y. Okada, Molecular determinants of sensitivity and conductivity of human TRPM7 to Mg2+ and Ca2+. Channels 2, 283–286 (2008)

E.S. Day, L. Osborn, A. Whitty, Effect of divalent cations on the affinity and selectivity of α4 integrins towards the integrin ligands vascular cell adhesion molecule-1 and mucosal addressin cell adhesion molecule-1: Ca2+ activation of integrin α4β1 confers a distinct ligand specificity. Cell Commun. Adhes. 9, 205–219 (2002)

M. Goldberg, P. Krohicheva, A. Fomin, D. Khairutdinova, O. Antonova, A. Baikin et al., In situ magnesium calcium phosphate cements formation: from one pot powders precursors synthesis to in vitro investigations. Bioact. Mater.. 5, 644–658 (2020)

H.W. Kim, J.C. Knowles, H.E. Kim, Hydroxyapatite and gelatin composite foams processed via novel freeze-drying and crosslinking for use as temporary hard tissue scaffolds. J. Biomed. Mater, Research Part A 72, 136–145 (2005)

S.V. Dorozhkin, Dental applications of calcium orthophosphates (CaPO4). J Dent Res. 1, 1007 (2019)

Acknowledgements

We would like to thank the National Research Centre for funding this work under the Project No. E120105. As well as, we would like to thank Faculty of Science, Al-Azhar University (Girls), Egypt for the possibility to use their facilities.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest.

Research Involving Human and Animal Rights

The research does not involve human participants and in vivo animals tests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abdelraof, M., Farag, M.M., Al-Rashidy, Z.M. et al. Green Synthesis of Bioactive Hydroxyapatite/Cellulose Composites from Food Industrial Wastes. J Inorg Organomet Polym 32, 4614–4626 (2022). https://doi.org/10.1007/s10904-022-02462-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-022-02462-2