Abstract

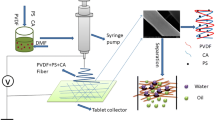

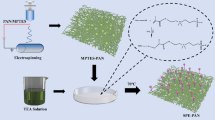

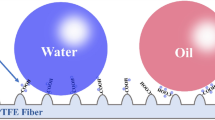

Polytetrafluoroethylene (PTFE)/polyvinyl alcohol (PVA)/ZnO composite fiber membranes were prepared by electrospinning, and PTFE/ZnO composite films were obtained after removing PVA. Considering that the spinning solution has good spinning performance, the PTFE/ZnO composite film has good flexibility and durability. The zinc oxide powder is evenly fixed on the surface of PTFE fibers, so that the film’s flexibility will not be affected during high-temperature calcination. The scanning electron micrograph shows that the morphology of the film is similar to the surface of the lotus leaf. The properties of PTFE/ZnO composite films were investigated by hydrophobic angle test and oil–water separation experiments. Results show that the PTFE/ZnO composite film has good hydrophobicity and oil–water separation performance. With the decrease in ZnO, the contact angle of the PTFE/ZnO composite film increased, and the oil–water separation performance improved. When the amount of ZnO added was 0.025 g, the contact angle was 160.9°, and the oil–water separation performance was the best.

Similar content being viewed by others

References

A. Pala, E. Tokat, Color removal from cotton textile industry wastewater in an activated sludge system with various additives. Water Res. 36(11), 2920–2925 (2002)

S.D. Richardson, T.A. Ternes, Water analysis: emerging contaminants and current issues. Anal. Chem. 83(12), 4614–4648 (2011)

J. Li, D. Li, Y. Yang et al., A prewetting induced underwater superoleophobic or underoil (super) hydrophobic waste potato residue-coated mesh for selective efficient oil/water separation. Green Chem. 18(2), 541–549 (2016)

A. Asatekin, A.M. Mayes, Oil industry wastewater treatment with fouling resistant membranes containing amphiphilic comb copolymers. Environ. Sci. Technol. 43(12), 4487–4492 (2009)

Z.X. Wang, C.H. Lau, N.Q. Zhang et al., Mussel-inspired tailoring of membrane wettability for harsh water treatment. J. Mater. Chem. A 3(6), 2650–2657 (2015)

S. Sabir, Approach of cost-effective adsorbents for oil removal from oily water. Crit. Rev. Environ. Sci. Technol. 45(17), 1916–1945 (2015)

Z. Chu, Y. Feng, S. Seeger, Oil/water separation with selective superantiwetting/superwetting surface materials. Angew. Chem. Int. Ed. 54(8), 2328–2338 (2015)

W.T. Cao, Y.J. Liu, M.G. Ma et al., Facile preparation of robust and superhydrophobic materials for self-cleaning and oil/water separation. Colloids Surf. A 529, 18–25 (2017)

M. Liu, S. Wang, L. Jiang, Nature-inspired superwettability systems. Nat. Rev. Mater. 2(7), 17036 (2017)

B. Wang, W. Liang, Z. Guo et al., Biomimetic super-lyophobic and super-lyophilic materials applied for oil/water separation: a new strategy beyond nature. Chem. Soc. Rev. 44(1), 336–361 (2015)

Z. Xue, S. Wang, L. Lin et al., A novel superhydrophilic and underwater superoleophobic hydrogel-coated mesh for oil/water separation. Adv. Mater. 23(37), 4270–4273 (2011)

Z. Xue, Y. Cao, N. Liu et al., Special wettable materials for oil/water separation. J. Mater. Chem. A 2(8), 2445–2460 (2014)

Y. Huang, C. Xiao, Q. Huang et al., Robust preparation of tubular PTFE/FEP ultrafine fibers-covered porous membrane by electrospinning for continuous highly effective oil/water separation. J. Membr. Sci. 568, 87–96 (2018)

D. Zou, M. Qiu, X. Chen et al., One step co-sintering process for low-cost fly ash based ceramic microfiltration membrane in oil-in-water emulsion treatment. Sep. Purif. Technol. 210, 511–520 (2019)

D. Ding, H. Mao, X. Chen et al., Underwater superoleophobic-underoil superhydrophobic Janus ceramic membrane with its switchable separation in oil/water emulsions. J. Membr. Sci. 565, 303–310 (2018)

J. Hong, Y. He, Polyvinylidene fluoride ultrafiltration membrane blended with nano-ZnO particle for photo-catalysis self-cleaning. Desalination 332(1), 67–75 (2014)

V.A. Ganesh, H.K. Raut, A.S. Nair et al., A review on self-cleaning coatings. J. Mater. Chem. 21(41), 16304–16322 (2011)

S. Laohaprapanon, A.D. Vanderlipe, B.T. Doma Jr. et al., Self-cleaning and antifouling properties of plasma-grafted poly (vinylidene fluoride) membrane coated with ZnO for water treatment. J. Taiwan Inst. Chem. Eng. 70, 15–22 (2017)

J. Shen, Y. Wu, L. Fu et al., Preparation of doped TiO2 nanofiber membranes through electrospinning and their application for photocatalytic degradation of malachite green. J. Mater. Sci. 49(5), 2303–2314 (2014)

A. Haider, S. Haider, I.K. Kang, A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arab. J. Chem. 11(8), 1165–1188 (2018)

F.E. Ahmed, B.S. Lalia, R. Hashaikeh, A review on electrospinning for membrane fabrication: challenges and applications. Desalination 356, 15–30 (2015)

M.J. Park, R.R. Gonzales, A. Abdel-Wahab et al., Hydrophilic polyvinyl alcohol coating on hydrophobic electrospun nanofiber membrane for high performance thin film composite forward osmosis membrane. Desalination 426, 50–59 (2018)

J.K.Y. Lee, N. Chen, S. Peng et al., Polymer-based composites by electrospinning: preparation & functionalization with nanocarbons. Prog. Polym. Sci. 2018

Q.L. Huang, Y. Huang, C.F. Xiao et al., Electrospun ultrafine fibrous PTFE-supported ZnO porous membrane with self-cleaning function for vacuum membrane distillation. J. Membr. Sci. 534, 73–82 (2017)

Y. Huang, Q. Huang, C. Xiao et al. Supported electrospun ultrafine fibrous poly (tetrafluoroethylene)/ZnO porous membranes and their photocatalytic applications. Chem. Eng. Technol. 41(3), 656–662 (2018)

W.M. Kang, H.H. Zhao, J.G. Ju et al., Electrospun Poly(tetrafluoroethylene) nanofiber membranes from PTFE-PVA-BA-H2O gel-spinning solutions. Fibers Polym. 17, 1403–1413 (2016)

P. Zhao, N. Soin, K. Prashanthi et al., Emulsion electrospinning of polytetrafluoroethylene (PTFE) nanofibrous membranes for high-performance triboelectric nanogenerators. ACS Appl. Mater. Interfaces 10(6), 5880–5891 (2018)

Z. Jahan, M.B.K. Niazi, ØW. Gregersen, Mechanical, thermal and swelling properties of cellulose nanocrystals/PVA nanocomposites membranes. J. Ind. Eng. Chem. 57, 113–124 (2018)

Y. Huang, Q.L. Huang, H. Liu et al., Preparation, characterization, and applications of electrospun ultrafine fibrous PTFE porous membranes. J. Membr. Sci. 523, 317–326 (2017)

R. Chen, Y. Wan, W. Wu et al., A lotus effect-inspired flexible and breathable membrane with hierarchical electrospinning micro/nanofibers and ZnO nanowires. Mater. Des. 162, 246–248 (2019)

H. Bai, L. Zhang, D. Gu, Micrometer-sized spherulites as building blocks for lotus leaf-like superhydrophobic coatings. Appl. Surf. Sci. 459, 54–62 (2018)

C.H. Xue, X.J. Guo, J.Z. Ma et al., Fabrication of robust and antifouling superhydrophobic surfaces via surface-initiated atom transfer radical polymerization. ACS Appl. Mater. Interfaces 7(15), 8251–8259 (2015)

L. Yan, Q. Li, H. Chi et al., One-pot synthesis of acrylate resin and ZnO nanowires composite for enhancing oil absorption capacity and oil-water separation. Adv. Compos. Hybrid Mater. 1(3), 567–576 (2018)

A. Rajaa, S. Ashokkumar, R.P. Marthandamc et al., Eco-friendly preparation of zinc oxide nanoparticles using Tabernaemontana divaricata and its photocatalytic and antimicrobial activity. J. Photochemis. Photobiol. B 181, 53–58 (2018)

J. Hao, C. Liu, Y. Li et al., Preparation nano-structure polytetrafluoroethylene (PTFE) Functional film on the cellulose insulation polymer and its effect on the breakdown voltage and hydrophobicity properties. Materials 11.5, 851 (2018)

M. Pirhashemi, A. Habibi-Yangjeh, Ultrasonic-assisted preparation of plasmonic ZnO/Ag/Ag2WO4 nanocomposites with high visible-light photocatalytic performance for degradation of organic pollutants. J. Colloid Interface Sci. 491, 216–229 (2017)

L. Nejati-Moghadam, A. Esmaeili Bafghi-Karimabad, M. Salavati-Niasari et al., Synthesis and characterization of SnO2 nanostructures prepared by a facile precipitation method. J. Nanostruct. 5(1), 47–53 (2015)

Y. Guo, L. Kang, M. Zhu et al., A strategy toward air-stable and high-performance ZnO-based perovskite solar cells fabricated under ambient conditions. Chem. Eng. J. 336, 732–740 (2018)

K.L. Harris, A.A. Pitenis, W.G. Sawyer et al., PTFE tribology and the role of mechanochemistry in the development of protective surface films. Macromolecules 48(11), 3739–3745 (2015)

X. Yu, P. Yang, M.G. Moloney et al., Electrospun gelatin membrane cross-linked by a bis (diarylcarbene) for oil/water separation: a new strategy to prepare porous organic polymers. ACS Omega 3(4), 3928–3935 (2018)

N.P. Khumalo, L.N. Nthunya, E. Canck, De et al., Congo red dye removal by direct membrane distillation using PVDF/PTFE membrane. Sep. Purif. Technol. 211, 578–586 (2019)

X. Gu, C. Tong, C. Lai et al., A porous nitrogen and phosphorous dual doped graphene blocking layer for high performance Li–S batteries. J. Mater. Chem. A 3(32), 16670–16678 (2015)

H. Tang, L. Hao, J. Chen et al., Surface modification to fabricate superhydrophobic and superoleophilic alumina membranes for oil/water separation. Energy Fuels 32(3), 3627–3636 (2018)

H. Ke, E. Feldman, P. Guzman et al., Electrospun polystyrene nanofibrous membranes for direct contact membrane distillation. J. Membr. Sci. 515, 86–97 (2016)

S.S. Latthe, C. Terashima, K. Nakata et al., Superhydrophobic surfaces developed by mimicking hierarchical surface morphology of lotus leaf. Molecules 19(4), 4256–4283 (2014)

P. Liu, Y. Gao, F. Wang et al., Superhydrophobic and self-cleaning behavior of Portland cement with lotus-leaf-like microstructure. J. Clean. Prod. 156, 775–785 (2017)

S. Dai, Y. Zhu, Y. Gu et al., Biomimetic fabrication and photoelectric properties of superhydrophobic ZnO nanostructures on flexible PDMS substrates replicated from rose petal. Appl. Phys. A 125(2), 138 (2019)

J.J. Li, Y.N. Zhou, Z.H. Luo, Smart fiber membrane for pH-induced oil/water separation. ACS Appl. Mater. Interfaces 7(35), 19643–19650 (2015)

R.H. Kollarigowda, S. Abraham, C.D. Montemagno, Antifouling cellulose hybrid biomembrane for effective oil/water separation. ACS Appl. Mater. Interfaces 9(35), 29812–29819 (2017)

Acknowledgements

This work was financially supported by National Natural Science Foundation of China (21505097); Jiangsu Collaborative Innovation Center of Technology and Material for Water Treatment; Science and Technology Development Project of Suzhou (SYG201742), Science and technology development plan of Xiangcheng District-special science and technology for people’s livelihood (201708).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, M., Chen, F., Liu, C. et al. Electrospun Fibrous PTFE Supported ZnO for Oil–Water Separation. J Inorg Organomet Polym 29, 1738–1745 (2019). https://doi.org/10.1007/s10904-019-01135-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-019-01135-x