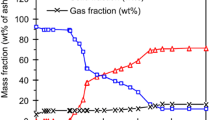

A study has been made of the hydrodynamic characteristics of the transition of a multicomponent bed consisting of coal sludge and straw pellets to a fluidized state. It has been shown that increase in the fraction of large particles (pellets) in the bed leads to a decrease in its relative height and in the amplitude of pulsations of the pressure difference in it; this contributes to the rise in the degree of conversion of chemical reations occurring in the bed. The possibility of assessing the minimum fluidization velocity of a multicomponent bed from the dependence of the standard deviation of a pulsation of the pressure difference in it on the velocity of air blown though the bed has been proved.

Similar content being viewed by others

References

The Handbook of Biomass Combustion and Co-Firing, Earthscan, London (2008).

J. Werther, Potentials of biomass cocombustion in coal fi red boilers, Proc. 19th Int. Conf. on Fluidized Bed Combustion, Xi′an, China, May 2009.

S. Y. Li, H. P. Teng, W. H. Jiao, L. L. Shang, and Q. G. Lu, Characterization of combustion and emission of several kind of herbaceous biomass pellets in a circulating fluidized bed combuster, Proc. 20th Int. Conf. on Fluidized Bed Combustion, Xi′an, China, May 2009, pp. 1309–1315.

Vesna Barisic, Edgardo Coda Zabetta, and Juha Sarkki, Prediction of agglomeration, fouling, and corrosion tendency of fuels in CFB co-combustion, Proc. 20th Int. Conf. on Fluidized Bed Combustion, Xi′an, China, May 2009, pp. 416–421.

H. Li, X. Liu, R. Legros, X. T. Bi, C. J. Lim, and S. Sokhansanj, Pelletization of torrefied sawdust and properties of torrefied pellets, Appl. Energy, 93, 680–685 (2012).

W.-H. Chen, J. Peng, and X. T. Bi, A state-of-the-art review of biomass torrefaction and densifi cation and applications, Renew. Sustain. Energy Rev., 44, 847–866 (2015).

M. A. Sukiran, F. Abnisa, W. M. A. Wan Daud, N. Abu Bakar, and S. K. Loh, A review of torrefaction of oil palm solid wastes for biofuel production, Energy Convers. Manage., 149, 101–120 (2017).

D. Chen, A. Gao, K. Cen, J. Zhang, X. Cao, and Z. Ma, Investigation of biomass torrefaction based on three major components: hemicellulose, cellulose, and lignin, Energy Convers. Manage., 169, 228–237 (2018).

D. Chen, Y. Li, M. Deng, J. Wang, M. Chen, B. Yan, et al., Effect of torrefaction pretreatment and catalytic pyrolysis on the pyrolysis poly-generation of pine wood, Bioresour. Technol., 214, 615–622 (2016).

D. Chen, J. Mei, H. Li, Y. Li, M. Lu, T. Ma, et al., Combined pretreatment with torrefaction and washing using torrefaction liquid products to yield upgraded biomass and pyrolysis products, Bioresour. Technol., 228, 62–68 (2017).

R. Isemin, A. Mikhalev, D. Klimov, P. Grammelis, N. Margaritis, D.-S. Kourkoumpas, and V. Zaichenko, Torrefaction and combustion of pellets made of a mixture of coal sludge and straw, Fuel, 210, 859–865 (2017).

P. Brachi, R. Chirone, F. Miccio, M. Miccio, and G. Ruoppolo, Valorization of orange peel residues via fluidized bed torrefaction: Comparison between different bed materials, Proc. 23th Int. Conf. on Fluidized Bed Conversion, Seoul, Korea (2018), pp. 977–987.

P. Brachi, R. Chirone, F. Miccio, M. Miccio, and G. Ruoppolo, Fluidized bed torrefaction of industrial tomato peels, Proc. 22th Int. Conf. on Fluidized Bed Conversion, 2015, pp. 438–447.

P. Brachi, F. Miccio, M. Miccio, and G. Ruoppolo, Torrefaction of tomato peel residues in a fl uidized bed of inert particles and a fi xed-bed reactor, Energy Fuels, 30, 4858–4868 (2016).

Z. Wang, H. Lia, C. J. Lim, and J. R. Grace, Oxidative torrefaction of spruce-pine-fi r sawdust in a slot-rectangular spouted bed reactor, Energy Convers. Manage., 174, 276–287 (2018).

Z. Wang, C. J. Lim, J. R. Grace, H. Li, and M. R. Parise, Effects of temperature and particle size on biomass torrefaction in a slot rectangular spouted bed reactor, Bioresour. Technol., 144, 281–288 (2017).

M. Martínez, I. Fonts, J. Abrego, J. Ceamanos, and G. Gea, Sewage sludge torrefaction in a fluidized bed reactor, Chem. Eng. J., 222, 534–545 (2013).

E. A. Pitsukha, Yu. A. Teplitskii, and É. K. Buchilko, Characteristic features of fluidization of bidisperse beds in suffusion conditions, J. Eng. Phys. Thermophys., 90, No. 6, 1379–1385 (2017).

Yu. A. Teplitskii and V. I. Kovenskii, Velocity of full fluidization of a bed of polydisperse granular materials, J. Eng. Phys. Thermophys., 82, No. 2, 291–295 (2009).

M. Puncochar, J. Drahos, J. Cermak, and K. Selucky, Evaluation of minimum fluidizing velocity in gas fluidized bed from pressure fluctuations, Chem. Eng. Commun., 35, 81–87 (1985).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Inzhenerno-Fizicheskii Zhurnal, Vol. 93, No. 3, pp. 773–779, May–June, 2020.

Rights and permissions

About this article

Cite this article

Is’yomin, R.L., Kuz’min, S.N., Mikhalyov, A.V. et al. Fluidization of a Multicomponent Bed in a Reactor for Co-Torrefaction of Waste Coal and Biomass. J Eng Phys Thermophy 93, 750–756 (2020). https://doi.org/10.1007/s10891-020-02175-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10891-020-02175-8