Abstract

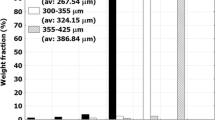

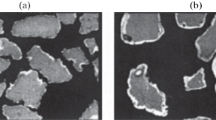

Agglomeration and defluidisation processes in fluidised-bed reactors due to ash melting are a real difficulty encountered when gasifying feedstock with high ash content. This work aims to investigate the influence of agglomeration on the hydrodynamic behaviour of a bubbling fluidised-bed reactor. The identification of the main parameters involved in agglomeration and defluidisation and the study of their influence on these processes are carried out inside both a laboratory fluidised-bed operating at high temperature (700–1000 °C) and a cold-flow fluidised-bed at ambient temperature. Results are then compared to a gasification test performed in a pilot-scale facility (800 °C). Results show that hydrodynamic disturbances and defluidisation are the result of agglomerates segregation. Once formed, the agglomerates tend to segregate at the bottom of the bed causing the formation and the build-up of a fixed bed crossed by multiple channels. In addition, the hydrodynamic behaviour is highly sensitive to the in-bed liquid amount. Complete defluidisation was seen to occur for very low liquid amount (few vol%). Based on these results, a simplified modelling approach is given in order to predict the operating time before the complete defluidisation of the reactor.

Similar content being viewed by others

References

Bartels, M., Lin, W., Nijenhuis, J., Kapteijn, F., Van Ommen, J.R.: Agglomeration in fluidized beds at high temperatures: mechanisms, detection and prevention. Prog. Energy Combust. Sci. 34, 633–666 (2008)

Visser, H.J., Van Lith, S.C., Kiel, J.H.: Biomass ash-bed material interactions leading to agglomeration in FBC. J. Energy Resour. Technol. 130, 011801 (2008)

Öhman, M., Pommer, L., Nordin, A.: Bed agglomeration characteristics and mechanisms during gasification and combustion of biomass fuels. Energy. Fuels. 19, 1742–1748 (2005)

Fryda, L.E., Panopoulos, K.D., Kakaras, E.: Agglomeration in fluidised bed gasification of biomass. Powder Technol. 181, 307–320 (2008)

Chaivatamaset, P., Sricharoon, P., Tia, S., Bilitewski, B.: A prediction of defluidization time in biomass fired fluidized bed combustion. Appl. Therm. Eng. 50, 722–731 (2013)

Khadilkar, A., Rozelle, P.L., Pisupati, S.V.: Models of agglomerate growth in fluidized bed reactors: critical review, status and applications. Powder Technol. 264, 216–228 (2014)

Vassilev, S.V., Baxter, D., Andersen, L.K., Vassileva, C.G.: An overview of the composition and application of biomass ash: Part 1. Phase–mineral and chemical composition and classification. Fuel. 105, 40–76 (2013)

Melchior, T., Bläsing, M., Günther, P., Müller, M.: Surface tension of coal ash slags under reducing conditions at elevated pressures. Fuel. 90, 280–287 (2011)

Shartsis, L., Spinner, S.: Surface tension of molten alkali silicates. J. Res. Natl. Bur. Stand. 46, 385–390 (1951)

Vargas, S., Frandsen, F.J., Dam-Johansen, K.: Rheological properties of high-temperature melts of coal ashes and other silicates. Prog. Energy Combust. Sci. 27, 237–429 (2001)

Eustathopoulos, N., Nicholas, M.G., Drevet, B.: Wettability At High Temperatures, Elsevier, Oxford (1999)

Kaknics, J., Defoort, F., Richard, A., Veron, E., Poirier, J.: Inorganic phase transformation in Miscanthus ash. Energy & Fuels. 29, 6433–6442 (2015)

Gatternig, B., Karl, J.: Development of Novel Modelling Approaches for Agglomeration Prediction. Proceeding at the 21st Biomass Conference and Exhibition, Copenhagen (2013)

Seville, J.P.K., Willett, C.D., Knight, P.C.: Interparticle forces in fluidisation: a review. Powder Technol. 113, 261–268 (2000)

Visser, H.J.: Biomass Ash-Bed Material Interactions Leading to Agglomeration in Fluidzed Bed Combustion and Gasification. Proceeding at the Developments in Thermochemical Conversion Conference, Tyrol (2000)

Galindo, D.G.: The reduction of the agglomeration in FBC based on novel bed materials: improvement of combustion efficiency and proposal of new materials. Proceeding at the 15th Sustainable Energy Marie Curie Research Conference (2005)

Hernández, J., Soria-Verdugo, A., Villa Briongos, J., Santana, D.: Fluidized bed with a rotating distributor operated under defluidization conditions. Chem. Eng. J. 195–196, 198–207 (2012)

Gómez-Hernández, J., Serrano, D., Soria-Verdugo, A., Sánchez-Delgado, S.: Agglomeration detection by pressure fluctuation analysis during Cynara cardunculus L. gasification in a fluidized bed. Chem. Eng. J. 284, 640–649 (2016)

Lin, W., Dam-Johansen, K.: Sintering in biofuel and coal-biofuel fired FBC. Final report to EC Joule III, Department of Chemical Engineering, Technical University of Denmark (1997)

Lin, W., Dam-Johansen, K., Frandsen, F.: Agglomeration in bio-fuel fired fluidized bed combustors. Chem. Eng. J. 96, 171–185 (2003)

Mettanant, V., Basu, P., Butler, J.: Agglomeration of biomass fired fluidized bed gasifier and combustor. Can. J. Chem. Eng. 87, 656–684 (2009)

Kunii, D., Levenspiel, O.: Fluidization Engineering (Second Edition). Butterworth-Heinemann, Boston (1991)

Olofsson, G., Ye, Z., Bjerle, I., ersson, A.: Bed agglomeration problems in fluidized-bed biomass combustion. Ind. Eng. Chem. Res. 41, 2888–2894 (2002)

Seville, J.P.K., Clift, R.: The effect of thin liquid layers on fluidisation characteristics. Powder Technol. 37, 117–129 (1984)

Williams, A.R.: Sticky fluidized beds. Ph. D. Thesis, Cambridge Univ. (1989)

McLaughlin, L.J., Rhodes, M.J.: Prediction of fluidized bed behaviour in the presence of liquid bridges. Powder Technol. 114, 213–223 (2001)

Makkawi, Y.T., Wright, P.C.: Tomographic analysis of dry and semi-wet bed fluidization: the effect of small liquid loading and particle size on the bubbling behaviour. Chem. Eng. Sci. 59, 201–222 (2004)

Gluckman, M.J., Yerushalmi, J., Squires, A.M.: Defluidization characteristics of sticky or agglomerating beds. Fluidization Technol., 395–420 (1976)

Balland, M.: Biomass gasification in fluidized-bed: Phenomenological investigation of agglomeration due to ash melting. PhD Thesis, Univ. Orléans (2016)

Bale, C.W., Bélisle, E., Chartrand, P., Decterov, S.A., Eriksson, G., Hack, K., Jung, I.H., Kang, Y.B., Melançon, J., Pelton, A.D., Robelin, C., Petersen, S.: FactSage thermochemical software and databases : recent developments. Calphad 33, 295–311 (2009)

Michel, R., Kaknics, J., De Bilbao, E., Poirier, J.: The mechanism of agglomeration of the refractory materials in a fluidized-bed reactor. Ceram. Int. 42, 2570–2581 (2016)

Valin, S., Bedel, L., Guillaudeau, J., Thiery, S., Ravel, S.: CO2 as a substitute of steam or inert transport gas in a fluidised bed for biomass gasification. Fuel. 177, 288–295 (2016)

Kaknics, J., Michel, R., Richard, A., Poirier, J.: High-temperature interactions between molten Miscanthus ashes and bed materials in a fluidized-bed gasifier. Energy & Fuels. 29, 1785–1792 (2015)

Grimm, A., Skoglund, N., Boström, D., Öhman, M.: Bed agglomeration characteristics in fluidized quartz bed combustion of phosphorus-rich biomass fuels. Energy Fuels 25, 937–947(2011)

Zevenhoven-Onderwater, M., Backman, R., Skrifvars, B.-J., Hupa, M., Liliendahl, T., Rosén, C., Sjöström, K., Engvall, K., Hallgren, A.: The ash chemistry in fluidised bed gasification of biomass fuels - Part II: ash behaviour prediction versus bench scale agglomeration tests. Fuel. 80, 1503–1512 (2001)

Balland, M., Froment, K., Valin, S., Ratel, G., Roussely, J., Michel, R., Poirier, J., Kara, Y., Galnares, A.: Biomass Ash Fluidized-Bed Agglomeration: Hydrodynamic Investigations Using High Temperature and Cold Flow Lab-Scale Reactors. Proceeding at the 22nd International Conference on Fluidized Bed Conversion, Turku (2015)

Acknowledgements

This PhD work was funded by the French Alternative Energies and Atomic Energy Commission (CEA) and ENGIE. The work was performed as part of the GAYA project (partially funded by the French Environment and Energy Management Agency (ADEME)). Wheat straw feedstock comes from the AMAZON project and the INVERTO project (both partially funded by the French National Research Agency (ANR)).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balland, M., Froment, K., Ratel, G. et al. Biomass Ash Fluidised-Bed Agglomeration: Hydrodynamic Investigations. Waste Biomass Valor 8, 2823–2841 (2017). https://doi.org/10.1007/s12649-017-9853-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-9853-9