Abstract

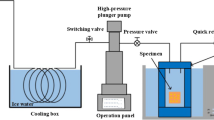

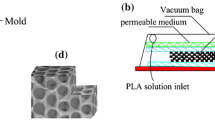

Various techniques have been reported in the literature for the fabrication of biodegradable scaffolds; but, it is very difficult to obtain in the same structure macro, micro and nanostructural characteristics. In this work we developed a supercritical freeze extraction process (SFEP) for the formation of poly(l-lactic acid) (PLLA) scaffolds, that combines the advantages of thermally induced phase separation with those of supercritical drying. We processed solutions in chloroform of two PLLA molecular weights and at different polymer concentrations ranging between 5 and 20 % w/w. Supercritical drying was performed at 35 °Cand pressures ranging between 100 and 250 bar. 3-D scaffolds characterized by high porosity (between 88 and 97.5 %), with coexisting micro and nanometric morphology were obtained. Structures generated were characterized by pores ranging between 10 and 30 μm and with a wrinkled nanostructure of about 200 nm, superimposed on the internal pore surface, that could be useful for biomedical applications. A solvent residue lower than 5 ppm was also measured.

Similar content being viewed by others

References

Langer R, Vacanti JP. Tissue engineering. Science. 1993;260:920–6.

Fuchs JR, Nasseri BA, Vacanti JP. Tissue engineering: a 21st century solution to surgical reconstruction. Annu Thorac Surg. 2001;72:577–91.

Ma PX. Scaffold for tissue fabrication. Mater Today. 2004;7(5):30–40.

Cao Y, Croll TI, Cooper-White JJ, O’ Connor AJ, Stevens GW. Production and surface modification of polylactide-based polymeric scaffolds for soft-tissue engineering. Biopolym Methods Tissue Eng. 2004;238:87–111.

Butler DL, Goldstein SA, Guilak F. Functional tissue engineering: the role of biomechanics. J Biomech Eng. 2000;122(6):570–5.

Thomson R, Wake MC, Yaszemski MJ, Mikos AG. Biodegradable polymer scaffolds to regenerate organs. Adv Polym Sci. 1995;122:245–74.

Mikos AG, Bao Y, Cima LG, Ingber DE, Vacanti JP, Langer R. Preparation of poly(glycolic acid) bonded fiber structures for cell attachment and transplantation. J Biomed Mater Res. 1993;27(2):183–9.

Lin HR, Kuo CJ, Yang CY, Shaw SY, Wu YJ. Preparation of macroporous biodegradable PLGA scaffolds for cell attachment with the use of mixed salts as porogen additives. J Biomed Mater Res. 2002;63(3):271–9.

Nam YS, Park TG. Porous biodegradable polymeric scaffolds prepared by thermally induced phase separation. J Biomed Mater Res. 1999;47:8–17.

Ho H, Ponticiello MS, Leong KW. Fabrication of controlled release biodegradable foams by phase separation. Tissue Eng. 1995;1:15–28.

Schugens C, Maquet V, Grandfils C, Jerome R, Teyssie P. Polylactide macroporous biodegradable implants for cell transplantation. 1. Preparation of macroporous polylactide supports by solid–liquid phase separation. Polymer. 1996;37:1027–38.

Schugens C, Maquet V, Grandfils C, Jerome R, Teyssie P. Polylactide macroporous biodegradable implants for cell transplantation. II. Preparation of polylactide foams by liquid–liquid phase separation. J Biomed Mater Res. 1996;30:449–61.

Hua FJ, Kim GE, Lee JD, Son Y, Lee DS. Macroporous poly(l-lactide) scaffold 1. Preparation of a macroporous scaffold by liquid–liquid phase separation of a PLLA–dioxane–water system. J Biomed Mater Res. 2002;63:161–7.

Kim SS, Lloyd DR. Thermodynamics of polymer/diluent systems for thermally induced phase separation: 3. Liquid–liquid phase separation system. Polymer. 1992;33(5):1047–57.

Hua FJ, Park TG, Lee DS. A facile preparation of highly interconnected macroporous PLGA scaffolds by liquid–liquid phase separation of PLGA–dioxane–water ternary system. Polymer. 2003;44(6):1911–20.

Tu C, Cai Q, Yang J, Wan Y, Bei J, Wang S. The fabrication and characterization of poly(lactic acid) scaffolds for tissue engineering by improved solid–liquid phase separation. Polym Adv Technol. 2003;14(8):565–73.

Caputo G, De Marco I, Reverchon E. Silica aerogel–metal composites produced by supercritical adsorption. J Supercrit Fluids. 2010;54:243–9.

Caputo G, Liparoti S, Adami R, Reverchon E. Use of supercritical CO2 and N2 as dissolved gases for the atomization of ethanol and water. Ind Eng Chem Res. 2012;51:11803–8.

Reverchon E, Cardea S. Production of controlled polymeric foams by supercritical CO2. J Supercrit Fluids. 2007;40:144–52.

De Marco I, Cardea S, Reverchon E. Polymer micronization using batch supercritical anti solvent process. Chem Eng Trans. 2013;32:2185–90.

Reverchon E, Cardea S. Supercritical fluids in 3-D tissue engineering. J Supercrit Fluids. 2012;69:97–107.

Cardea S, Gugliuzza A, Schiavo Rappo E, Aceto M, Drioli E, Reverchon E. Generation of PEEK-WC membranes by supercritical fluids. Desalination. 2006;200:58–60.

Duarte ARC, Mano JF, Reis RL. Preparation of starch-based scaffolds for tissue engineering by supercritical immersion precipitation. J Supercrit Fluids. 2009;49:279–85.

Mooney DJ, Baldwin DF, Suh NP, Vacanti JP, Langer R. Novel approach to fabricate porous sponges of (d,l-lactic-co-glycolic acid) without the use of organic solvents. Biomaterials. 1996;17:1417–22.

Harris LD, Kim BS, Mooney DJ. Open pore biodegradable matrices formed with gas foaming. J Biomed Mater Res. 1998;42:396–402.

Reverchon E, Cardea S, Rapuano C. A new supercritical fluid based process to produce scaffolds for tissue replacement. J Supercrit Fluids. 2008;45:365–73.

Reverchon E, Pisanti P, Cardea S. Nanostructured PLLA-hydroxyapatite scaffolds produced by a supercritical assisted technique. Ind Eng Chem. Res. 2009;48:5310–6.

Pisanti P, Yeatts AB, Cardea S, Fisher JP, Reverchon E. Tubular perfusion system culture of human mesenchymal stem cells on poly-l-lactic acid scaffolds produced using a supercritical carbon dioxide-assisted process. J Biomed Mater Res—Part A. 2012;100A:2563–72.

Cardea S, Baldino L, De Marco I, Pisanti P, Reverchon E. Supercritical gel drying of polymeric hydrogels for tissue engineering applications. Chem Eng Trans. 2013;32:1123–8.

Levit N, Tepper G. Supercritical CO2-assisted electrospinning. J Supercrit Fluids. 2004;31:329–33.

Brunner G. Applications of supercritical fluids. Annu Rev Chem Biomol Eng. 2010;1:321–42.

Van de Witte P, Dijkstra PJ, Van den Berg JWA, Feijen J. Phase separation processes in polymer solutions in relation to membrane formation. J Membr Sci. 1996;21:1–31.

Reverchon E, Cardea S. PVDF-HFP membranes formation by supercritical CO2 processing: elucidation of formation mechanisms. Ind Eng Chem Res. 2006;45:8939–45.

Reverchon E, Schiavo Rappo E, Cardea S. A flexible supercritical CO2 assisted process for poly(methyl methacrylate) structures formation. Polym Eng Sci. 2006;46:188–97.

Reverchon E, Cardea S. Formation of cellulose acetate membranes using a supercritical fluid assisted process. J Membr Sci. 2004;240:187–95.

Reverchon E, Cardea S. Formation of polysulfone membranes by supercritical CO2. J Supercrit Fluids. 2005;35:140–6.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cardea, S., Baldino, L., Pisanti, P. et al. 3-D PLLA scaffolds formation by a supercritical freeze extraction assisted process. J Mater Sci: Mater Med 25, 355–362 (2014). https://doi.org/10.1007/s10856-013-5069-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-013-5069-0