Abstract

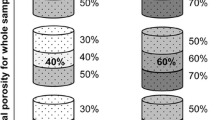

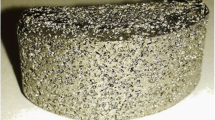

A porous implant material with adequate pore structure and the appropriate mechanical properties for bone ingrowth has long been sought. This article presents details of the development, characterization and in vivo evaluations of powder metallurgy-processed titanium samples exhibiting a dense core with an integrated porous surface for biomedical applications. A space-holder method was applied to investigate the effects of different percentages and particle sizes of the urea on bone neoformation in 30 rabbits. The samples were previously characterized using scanning electron microscopy and mechanical testing. After 8 and 12 weeks of implantation, bone ingrowth was histologically and histometrically analyzed and push-out testing was performed. This study demonstrated that the association of a dense core integrated with the greatest number of interconnected pores of the smallest size is a promising biomaterial for bone tissue engineering. This sample exhibits appropriate mechanical properties combined with increased bone ingrowth, providing enhanced resistance to displacement.

Similar content being viewed by others

References

Pilliar RM. Powder metal-made orthopedic implants with porous surface for fixation by tissue ingrowth. Clin Orthop Relat Res. 1983;176:42–51.

Kuboki Y, Takita H, Kobayashi D, Tsuruga E, Inoue M, Murata M, Nagai N, Dohi Y, Ohgushi H. BMP-induced osteogenesis on the surface of hydroxyapatite with geometrically feasible ad nonfeasible structures: topology of osteogenesis. J Biomed Mater Res. 1998;39:190–9.

Nugroho AW, Leadbeater G, Davies IJ. Processing of a prorous titanium alloy from elemental powders using a solid state isothermal foaming technique. J Mater Sci: Mater Med. 2010;21:3103–7.

Li JP, Habibovic P, Doel MVD, Wilson CE, Wijn JR, Blitterswijk CA, Groot K. Bone ingrowth in porous titanium implants produced by 3D fiber deposition. Biomaterials. 2007;28:2810–20.

Mendonça G, Mendonça DB, Aragão FJ, Cooper FL. Advancing dental implant surface technology—From mícron- to nanotopography. Biomaterials. 2008;29:3822–35.

Thelen S, Barthelat F, Brinson LC. Mechanics considerations for microporous titanium as an orthopedic implant material. J Biomed Mater Res. 2004;69A:601–10.

Vasconcellos LMR, Oliveira MV, Graça MLA, Vasconcellos LGO, Cairo CAA, Carvalho YR. Porous titanium scaffolds produced by powder metallurgy for biomedical applications. Mater Res. 2008;11:275–80.

Bari E, Lefebvre LP, Hacking SA. Direct visualization and quantification of bone growth into porous titanium implants using micro computed tomography. J Mater Sci: Mater Med. 2011;22:1321–32.

Vasconcellos LMR, Oliveira MV, Graça MLA, Vasconcellos LGO, Cairo CAA, Carvalho YR. Design of dental implants, influence on the osteogenesis and fixation. J Mater Sci: Mater Med. 2008;19:2851–7.

Wazen RM, Lefevre LP, Baril E, Nanci A. Initial evaluation of bone ingrowth into a novel porous titanium coating. J Biomed Mater Res Part B: Appl Biomater. 2010;94:64–71.

Ryan G, Pandit A, Apatsidis DP. Fabrication methods of porous metals for use in orthopaedic applications. Biomaterials. 2006;27:2651–70.

An YB, Lee WH. Synthesis of porous titanium implants by environmental-electro-discharge-sintering process. Mat Chem Phys. 2006;95:242–7.

Deporter DA, Watson PA, Pilliar RM, Melcher AH, Winslow J, Howley TP, Hansel P, Maniatopoulos C, Rodriguez A, Abdulla D, et al. A histological assessment of the initial healing response adjacent to porous-surfaced, titanium alloy dental implants in dogs. J Dent Res. 1986;65:1064–70.

Deporter DA, Watson PA, Pilliar RM, Pharoah M, Smith DC, Chipman M, Locker D, Rydall A. A prospective clinical study in humans of an endosseous dental implant partially covered with a powder-sintered porous coating: 3- to 4-year results. Int J Oral Maxillofac Implants. 1996;11:87–95.

Pilliar RM, Deporter DA, Watson PA, Todescan R. The endopore implant-enhanced osseointegration with a sintered porous-surfaced design. Oral Health. 1998;7:61–4.

Pilliar RM. Overview of surface variability of metallic endosseous dental implants: textured and porous surface-structured designs. Implant Dent. 1998;7:305–14.

Oliveira MV, Pereira LC, Cairo CAA. Porous structure characterization in titanium coating for surgical implants. Mater Res. 2002;5:269–73.

Brentel AS, Vasconcellos LMR, Oliveira MV, Graça MLA, Vasconcellos LGO, Cairo CAA, Carvalho YR. Histomorphometric analysis of pure titanium implants with porous surface versus rough surface. J Appl Oral Sci. 2006;14:213–8.

Faria PEP, Carvalho AL, Felipucci DNB, Wen C, Sennerby L, Salata LA. Bone formation following implantation of titanium sponge rods into humeral osteotomies in dogs: a histological and histometrical study. Clin Implant Dent Relat Res. 2010;12:72–9.

Vasconcellos LMR, Leite DO, Nascimento FO, Vasconcellos LGO, Graça MLA, Carvalho YR, Cairo CAA. Porous titanium for biomedical applications: an experimental study on rabbits. Braz Oral Res. 2010;15:407–12.

Vasconcellos LMR, Leite DO, Oliveira FN, Carvalho YR, Cairo CAA. Evaluation of bone ingrowth into porous titanium implant: histomorphometric analysis in rabbits. Braz Oral Res. 2010;24:399–405.

Bottino MC, Coelho PG, Henriques VAR, Higa OZ, Bressiani AHA, Bressiani JC. Processing, characterization, and in vitro/in vivo evaluations of powder metallurgy processed Ti-13Nb-13Zr alloys. J Biomed Mater Res. 2009;88A:689–96.

Barrabés M, Sevilla P, Planell JA, Gil FJ. Mechanical properties of nickel-titanium foams for reconstructive orthopaedics. Mater Sci Eng C. 2008;28:23–8.

Torres FG, Nazhat SN, Sheikh SH, Fadzullah MD, Maquet V, Boccaccini AR. Mechanical properties and bioactivity of porous PLGA/TiO2 nanoparticle-filled composites for tissue engineering scaffolds. Compos Sci Technol. 2007;67:1139–47.

Dewidar MM, Yoon HC, Lim JK. Mechanical properties of metals for biomedical applications using powder metallurgy process. Met Mater Int. 2006;12:193–206.

Consolaro A, Carvalho RS, Francischone EC Jr, Consolaro MFMO. Saucerization of osseointegrated implants and planning of orthodontic clinical cases simultaneous. Dent Press J Orthod. 2010;15(3):19–30.

Li JP, Li SH, Van Blitterwijk CA, De Groot K. Cancellous bone from porous Ti6Al4V by multiple coating technique. J Mater Sci: Mat Med. 2006;17:179–85.

Otsuki B, Takemoto M, Fujibayashi S, Neo M, Kokubo T, Nakamura T. Pore throat size and connectivity determine bone and tissue ingrowth into porous implants: three-dimensional micro-CT based structural analyses of porous bioactive titanium implants. Biomaterials. 2006;27:5892–900.

Acknowledgment

This study was supported by research grant 2005/03709-4, awarded by the State of São Paulo Research (FAPESP), Brazil.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vasconcellos, L.M.R., Oliveira, F.N., Leite, D.O. et al. Novel production method of porous surface Ti samples for biomedical application. J Mater Sci: Mater Med 23, 357–364 (2012). https://doi.org/10.1007/s10856-011-4515-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-011-4515-0