Abstract

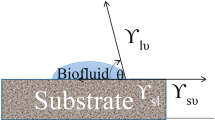

Intervertebral implants should be designed with low load requirements, high friction coefficient and low elastic modulus in order to avoid the stress shielding effect on bone. Furthermore, the presence of a highly interconnected porous structure allows stimulating bone in-growth and enhancing implant-bone fixation. The aim of this study was to obtain bioactive porous titanium implants with highly interconnected pores with a total porosity of approximately 57 %. Porous Titanium implants were produced by powder sintering route using the space holder technique with a binder phase and were then evaluated in an in vivo study. The size of the interconnection diameter between the macropores was about 210 μm in order to guarantee bone in-growth through osteblastic cell penetration. Surface roughness and mechanical properties were analyzed. Stiffness was reduced as a result of the powder sintering technique which allowed the formation of a porous network. Compression and fatigue tests exhibited suitable properties in order to guarantee a proper compromise between mechanical properties and pore interconnectivity. Bioactivity treatment effect in novel sintered porous titanium materials was studied by thermo-chemical treatments and were compared with the same material that had undergone different bioactive treatments. Bioactive thermo-chemical treatment was confirmed by the presence of sodium titanates on the surface of the implants as well as inside the porous network. Raman spectroscopy results suggested that the identified titanate structures would enhance in vivo apatite formation by promoting ion exchange for the apatite formation process. In vivo results demonstrated that the bioactive titanium achieved over 75 % tissue colonization compared to the 40 % value for the untreated titanium.

Similar content being viewed by others

References

McGree TD, Graves AM, Twende WS, Niederauer GG. A biologically active ceramic material with enduring strength. In: Wise DLeditors. Encyclopaedic handbook of biomaterials and bioengineering, part B: applications vol. 1. New York: Marcel Dekker; 1995.

Ginebra MP, Driessens FCM, Planell JA. Effect of the particle size on the micro and nanostructural features of calcium phosphate cement: a kinetic analysis. Biomaterials. 2004;25:3453–62.

Gresser JD, Lewanndrowski KU, Trantolo DJ, Wise DL. Soluble calcium salts in bioresorbable bone grafts. In: Wise DLeditors Biomaterials engineering and devices: human applications. Totowa: Humana; 2000.

Navarro M, Ginebra MP, Planell JA, Zeppetelli S, Ambrosio L. Development and cell response of a new biodegradable composite scaffold for guided bone regeneration. J Mater Sci Mater Med. 2004;15:417–20.

Chen Y, Feng B, Zhu Y, Weng J, Wang J, Lu X. Fabrication of porous titanium implants with biomechanical compatibility. Mater Lett. 2009;63(30):2659–61.

Imwinkelried T. Mechanical properties of open pore titanium foam. J Biomed Mater Res Part A. 2007;81(4):964–70.

Oh I-H, Nomura N, Hanada S. Microstructures and mechanical properties of porous titanium compacts prepared by powder sintering. Mater Trans. 2002;43(3):443–46.

Oonishi H, Yamamoto M, Ishimaru H, Tsuji E, Kushitani S, Aono M, et al. The effect of hydroxyapatite coating on bone growth into porous titanium alloy implants. J Bone Joint Surg Br Vol. 1989;71(2):213–16.

Ryan GE, Pandit AS, Apatsidis DP. Porous titanium scaffolds fabricated using a rapid prototyping and powder metallurgy technique. Biomaterials. 2008;29(27):3625–35.

Spoerke ED, Murray NG, Li H, Brinson LC, Dunand DC, Stupp SI. A bioactive titanium foam scaffold for bone repair. Acta Biomater. 2005;1(5):523–33.

Vasconcellos LMR, Oliveira MV, Graça MLA, Vasconcellos LGO, Carvalho YR, Cairo CAA. Porous titanium scaffolds produced by powder metallurgy for biomedical applications. Mater Res. 2008;11(3):275–80.

Kokubo T, Mijyaji F, Kim HM. Spontaneous formation of bonelike apatite layer on chemically treated titanium metals. J Am Ceram Soc. 1996;79:1127–29.

Kokubo T, Takadama H. How useful is SBF in predicting in vivo bone bioactivity. Biomaterials. 2006;27:2907–15.

Kokubo T, Yamaguchi S. Novel bioactive titanate layers formed on Ti metal and its alloys by chemical treatments. Materials. 2010;3:48–3.

Chem MF, Yang XJ, Hu RX, Cui ZD, Man HC. Bioactive NiTi shape memory alloy used as bone bonding implants. Mat Sci Eng. C 2004;24:497–502.

Takadama H, Kim HM, Kokubo T, Nakamura T. TEM-EDX study of mechanism of bonelike apatite formation on bioactive titanium metal in simulated body fluid. J Biomed Mater Res. 2001;57:441–48.

Fernández-Fairén M, Murcia A, Iglesias R, Sevilla P, Manero JM, Gil FJ. Analysis of tantalum implants used for avascular necrosis of the femoral head: a review of five retrieved specimens. J Appl Biomater Funct Mater. 2012;10(1):29–36.

Goldstein SA. The mechanical properties of trabecular bone: dependence of anatomic location and function. J Biomech. 1987;20:1055–61.

Sevilla P, Aparicio C, Planell JA, Gil FJ. Comparison of the mechanical properties between tantalum and nickel–titanium foams impllant materials for bone ingrowth applications”. J Alloys Compd. 2007;439:67–73.

Karageorgiou V, Kaplan D. Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials. 2005;26:5474–91.

Habibovic P, Gbureck U, Doillon DJ, van Blitterswijk C, Barralet JE. Osteoconduction and osteoinduction of low—temperature 3D printed bioceramic implants. Biomaterials. 2008;29:944–53.

Zardiackas LD, Parsell DE, Dillon LD, Mitchell DW, Nunnery LA, Poggie R. Structure, metallurgy, and mechanical properties of a porous tantalum foam. J Biomed Mater Res. 2001;58:180–87.

Schoettle T, Standard S, Lanford G, Abram S, Robertson D, Robie B. Successful use of a modern porous tantalum (trabecular metal TM) device for cervical interbody fusion: results from a prospective, randomized Multi-Center Clinical Study. In: Proceedings of the Annual Meeting of CSRS, San Diego, 2005 (poster 11).

Li JP, Li SH, Van Blitterswijk CA. A novel porous Ti6Al4V: characterization and cell attachment. J Biomed Mater Res A. 2005;73(2):223–33.

Gil FJ, Libenson C, Planell JA. Differences in the pseudoelasticity behaviour of Nickel–Titanium orthodontic wires”. J Mater Sci Mater Med. 1993;4:281–84.

Gil FJ, Manero JM, Planell JA. Relevant aspects in the clinical applications of NiTi shape memory alloys. J Mater Sci Mater Med. 1996;7:403–06.

Bobyn JD, Stackpool DJ, Hacking SA, Tanzer M, Krygier JJ. Characteristics of bone ingrowth and interface mechanics of a new porous tantalum biomaterial. J Bone Joint Surg (Br). 1999;81B:907–14.

Ayers RA, Bateman TA, Simske SJ. Porous NiTi and a material for bone engineering, basic properties. In: Hocine Yahia L’ editor. Shape memory implants. New York: Springer; 2000.

Levine BR, Sporer S, Poggie RA, Della Valle CJ, Jacobs JJ. Experimental and clinical performance of porous tantalum in orthopedic surgery. Biomaterials 2006;27:4671–81.

Wigfield C, Robertson J, Gill S, Nelson R. Clinical experience with porous tantalum cervical interbody implants in a prospective randomized controlled trial. Br J Neurosurg. 2003;17:418–25.

Collier DP, Mayor MB, Chae JC. Macroscopic and microscopic evidence of prosthetic fixation with porous-coated materials. Clin Orthop. 1998;3:249–62.

Cook SD, Barrack RL, Thomas KA, Haddad RJ. Quantitative analysis of tissue growth into human porous total hip components. J Arthroplasty. 1989;3:249–62.

Cook SD, Barrack RL, Thomas KA, Haddad RJ. Tissue growth into porous primary and revision femoral stems. J. Arthroplasty. 1991;6(Supp):37–46.

Gibson LJ, Ashby MF. Cellular solids. Cambridge University Press. Cambridge. (1997).

Hernández R, Polizu S, Turenne S, Yahia L’H. Characteristics of porous nickel–titanium alloys for medical applications. Bio Med Mater Eng. 2002;12:37–45.

Acknowledgments

This work was supported by CICYT Spanish project MAT-2015-67183-R (MINECO/DEFDER,UE) and the Andorra and Catalan Government for CTP grants.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests

Rights and permissions

About this article

Cite this article

Caparrós, C., Ortiz-Hernandez, M., Molmeneu, M. et al. Bioactive macroporous titanium implants highly interconnected. J Mater Sci: Mater Med 27, 151 (2016). https://doi.org/10.1007/s10856-016-5764-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-016-5764-8