Abstract

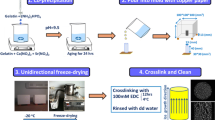

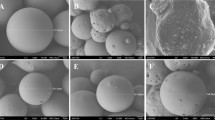

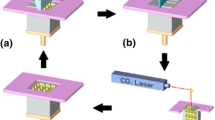

Recently, several methods have been reported for fabricating tailored amorphous multi porosity bioscaffolds for bone regeneration and tissue engineering. In particular, the melt-quench-heat-etch method appears attractive for making large and/or complex shape structures or fibers for flexible products. However, often the macropore size has been limited to <100 μm. In this paper we report an improved method for fabricating nano-macroporous soda lime phosphosilicate glass using sucrose as a macropore former. The composite compact consisting of soda lime phosphosilicate glass and sucrose powders is pressed in a die at room temperature. 3D interconnected macroporous structure is formed first by dissolving the sucrose part in water at room temperature, and then sintering the compact at temperatures above the glass transition temperature. Thus, interconnected macropores with controlled size (≥100 microns) are formed readily. The sintering heat-treatment also induces nanoscale phase separation, which is then exploited for introducing nanoscale porosity. For the latter goal, the sample is leached in HCl under optimized conditions to yield desired nano-macroporous glass for bone scaffold or other applications.

Similar content being viewed by others

References

Komatsu DE, Warden SJ. The control of fracture healing and its therapeutic targeting: improving upon nature. J Cellu Biochem. 2010;109(2):302–11.

Dominici M, Rasini V, Bussolari R, Chen X, Hofmann TJ, Spano C, Bernabei D, Veronesi E, Bertoni F, Paolucci P, Conte P, Horwitz EM. Restoration and reversible expansion of the osteoblastic hematopoietic stem cell niche after marrow radioablation. Blood. 2009;114(11):2333–43.

Chen Y, Alman BA. Wnt pathway, an essential role in bone regeneration. J Cellu Biochem. 2008;106(3):353–62.

Kokubu T, Nobuzou M, Masahiro K, Masaya T. Healing process of fracture. Clin Calcium. 2003;13(10):1243–9.

Chowdhury S, Thomas V, Dean D, Catledge SA, Vohra YK. Nanoindentation on porous bioceramic scaffolds for bone tissue engineering. J Nanosci Nanotech. 2005;5(11):1816–20.

Yu X, Cai S, Guohua X, Zhou W, Wang D. Low temperature fabrication of high strength porous calcium phosphate and the evaluation of the osteoconductivity. J Mater Sci Mater Med. 2009;20(10):2025–34.

Li X, Li D, Lu B, Wang C. Fabrication of bioceramic scaffolds with pre-designed internal architecture by gel casting and indirect stereolithography techniques. J Porous Mater. 2008;15(6):667–71.

Hench LL, Wilson J. An introduction to bioceramics. Adv Ceram. 1993;1:1–24.

Zhang Y, Zhang M. Three-dimensional macroporous calcium phosphate bioceramics with nested chitosan sponges for load-bearing bone implants. J Biomed Mater Res. 2002;61(1):1–8.

Zhao J, Guo LY, Yang XB, Weng J. Preparation of bioactive porous HA/PCL composite scaffolds. Appl Surf Sci. 2008;255(5):2942–6.

Zhang H, Ye XJ, Li JS. Preparation and biocompatibility evaluation of apatite/wollastonitederived porous bioactive glass ceramic scaffolds. Biomed Mater. 2009;4(4):1–7.

Neo M, Kotani S, Fujita Y, Nakamura T, Yamamuro T, Bando Y, Ohtsuki C, Kokubo T. Differences in ceramic-bone interface between surface-active ceramics and resorbable ceramics: a study by scanning and transmission electron microscopy. J Biomed Mater Res. 1992;26(2):255–67.

Tang PF, Li G, Wang JF, Zheng QJ, Wang Y. Development, characterization, and validation of porous carbonated hydroxyapatite bone cement. J Biomed Mater Res Part B. 2009;90B(2):886–93.

Hench LL. Bioceramics. J Am Ceram Soc. 1998;81(7):1705–28.

Marques AC, Almeida RM, Thiema A, Wang S, Falk M, Jain H. Sol–gel derived glass scaffold with high pore interconnectivity and enhanced bioactivity. J Mater Res. 2009;24:3495–502.

Pereira MM, Jones JR, Orefice RL, Hench LL. Preparation of bioactive glass-polyvinyl alcohol hybrid foams by the sol–gel method. J Mater Sci Mater Med. 2005;16(11):1045–50.

Marques AC, Jain H, Almeida RM. Sol–gel derived nano/macroporous monolithic scaffolds. Eur J Glass Sci Tech. 2007;48:65–8.

Moawad HM, Jain H. Fabrication of nano–macro porous soda-lime phosphosilicate bioactive glass by the melt-quench method. Ceramic engineering and science proceeding, 28 (9, Developments in Porous, Biological and Geopolymer Ceramics) 2008;183–195.

Brentrup GJ, Moawad HM, Santos LF, Almedia RM, Jain H. Structure of Na2O–CaO–P2O5–SiO2 glass–ceramics with multimodal porosity. J Am Ceram Soc. 2009;92(1):249–52.

Acknowledgment

This work was initiated and continued as an international collaboration with support from National Science Foundation via International Materials Institute for New Functionality in Glass (DMR-0844014) and Materials World Network (DMR-0602975) programs.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moawad, H.M., Jain, H. Fabrication of nano-macroporous glass–ceramic bioscaffold with a water soluble pore former. J Mater Sci: Mater Med 23, 307–314 (2012). https://doi.org/10.1007/s10856-011-4466-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-011-4466-5