Abstract

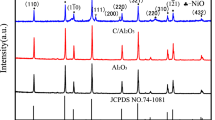

In this work, Sn-0.7Cu-WO3 nanomodified solders were electrodeposited from an aqueous acidic plating bath containing various fractions of WO3 nanoparticles (0.1, 0.25, 0.5 wt%) NPs for mini-light emitting diodes (mini-LEDs) packaging. The produced nanomodified solders were characterized for their morphology, microhardness, melting point, and electrical resistivity. Further, the nanomodified solder bumps were used to mount a 1608 mini-LED chip/ENIG (Electroless Nickel Immersion Gold) pad by reflowing at 240 °C in the air. High-temperature aging was done at 125 °C for 144, 256, and 400 h and joint shear tests were performed to examine the interfacial properties and growth kinetics of the soldered mini-LED/Sn-0.7Cu-WO3/ENIG joints. The results indicated the formation of (Ni,Cu)3Sn4 intermetallic compounds (IMCs) across the solder/ ENIG pad joint. The thickness of the IMC layer decreases showing the maximum rate of decrease when the composition is Sn-0.7Cu-0.25WO3. It was concluded that the optimal set of microstructure, melting point, electrical resistivity, and joint shear reliability could be achieved when the nanomodified solder is reinforced with 0.25 wt.% WO3 NPs into Sn-0.7Cu matrix and thus it can be a potential contestant for the upcoming applications in mini-LED packaging.

Similar content being viewed by others

Data availability

The data used in this work is confidential and cannot be shared at this time.

References

H. Nishida, J. Jpn. Inst. Electron. Packag. 22, 596–606 (2019)

A. Sharma, Y.J. Jang, J.B. Kim, J.P. Jung, J. Alloy. Compd. 704, 795–803 (2017)

Y. Huang, E.L. Hsiang, M.Y. Deng, S.T. Wu, Light Sci. Appl. 9, 105 (2020)

H.W. Chen, J.H. Lee, B.Y. Lin, S. Chen, S.T. Wu, Light Sci. Appl. 7, 17168 (2018)

Y. Zhang, R. Xu, Q. Kang, X. Zhang, Z.H. Zhang, Micromachines 14(5), 991 (2023)

F. Chen, J. Bian, J. Hu, N. Sun, B. Yang, H. Ling, H. Yu, K. Wang, M. Gai, Y. Ma, Y. Huang, Int. J. Extrem. Manuf. 4, 042005 (2022)

T. Wu, C.W. Sher, Y. Lin, C.F. Lee, S. Liang, Y. Lu, S.W.H. Chen, W. Guo, H.C. Kuo, Z. Chen, Appl. Sci. 8(9), 1557 (2018)

D. Chen, Y.C. Chen, G. Zeng, D.W. Zhang, H. Lu, Research 6, 0047 (2023)

Shenzhen Fitech Co., Ltd. https://en.szfitech.com. Accessed 11 Aug 2023

M. Abtew, G. Selvaduray, Mater. Sci. Eng. R 27, 95–141 (2000)

A. Sharma, B. Ahn, Soldering Surf. Mount Technol. 32(1), 24–32 (2020)

H.Y. Lee, A. Sharma, S.H. Kee, Y.W. Lee, J.T. Moon, J.P. Jung, Electron. Mater. Lett. 10, 997–1004 (2014)

A. Sharma, S. Das, K. Das, Microelectron. Eng. 170, 59–68 (2017)

A. Sharma, S. Kumar, D.H. Jung, J.P. Jung, J. Mater. Sci. Mater. Electron. 28, 8116–8129 (2017)

A. Sharma, S. Das, K. Das, Pulse Electrodeposition of Lead-Free Tin-Based Composites for Microelectronic Packaging, in Electrodeposition of Composite Materials. ed. by A.M.A. Mohamed, T.D. Golden (InTech, Croatia, 2016)

M.B.K. Teja, A. Sharma, S. Das, K. Das, J. Mater. Sci. 57, 8597–8633 (2022)

M.H. Roh, A. Sharma, J.H. Lee, J.P. Jung, Metall. Mater. Trans. A 46, 2051–2062 (2015)

A. Sharma, D.H. Jung, M.H. Roh, J.P. Jung, Electron. Mater. Lett. 12, 856–863 (2016)

X. Liu, M. Huang, C.M.L. Wu, L. Wang, J. Mater. Sci. Mater. Electron. 21, 1046–1054 (2010)

L.C. Tsao, S.Y. Chang, Mater. Des. 31, 990–993 (2010)

A. Sharma, S. Bhattacharya, S. Das, K. Das, Metall. Mater. Trans. A 44, 5587–5601 (2013)

A. Sharma, B.G. Baek, J.P. Jung, Mater. Des. 87, 370–379 (2015)

D.H. Jung, A. Sharma, J.P. Jung, J. Alloys Compd. 743, 300–313 (2018)

A. Sharma, S. Bhattacharya, S. Das, H.J. Fecht, K. Das, J. Alloys Compd. 574, 609–616 (2013)

Y.S. Shin, S. Lee, S. Yoo, C.W. Lee, Mechanical and Microstructural Properties of SiC-Mixed Sn-Bi Composite Solder Bumps by Electroplating, in European Microelectronics and Packaging Conference, Rimini, Italy. (IEEE, New York, 2009), pp.1–4

J.W. Park, J.Y. Eom, H. Kwon, Electrochem. Commun. 11(3), 596–598 (2009)

E.K. Choi, K.Y. Lee, T.S. Oh, J. Phys. Chem. Solids 69, 1403–1406 (2008)

A. Sharma, K. Das, S. Das, J. Electron. Mater. 46, 5855–5865 (2017)

S. Bhattacharya, A. Sharma, S. Das, K. Das, Metall. Mater. Trans. A 47A, 1292 (2016)

N. Guglielmi, J. Electrochem. Soc. 119(8), 1009–1012 (1972)

W. Tang, Y. Hu, S. Huang, Metal. Mater. Int. 18, 177–183 (2012)

T. Siewert, S. Liu, D. R. Smith, J. C. Madeni, Database for Solder Properties with Emphasis on New Lead-free Solders, Properties of Lead-Free Solders Release 4.0, NIST and Colorado School of Mines, 2002

A.F. Mayadas, M. Shatzkes, Phys. Rev. B 1(4), 1382–1389 (1970)

S.Y. Chang, C.F. Chen, S.J. Lin, T.Z. Kattamis, Acta Mater. 51, 6191–6302 (2003)

P. Babaghorbani, S.M.L. Nai, M. Gupta, J. Alloy. Compd. 478, 458–461 (2009)

A. Sharma, A.K. Srivastava, K. Lee, B. Ahn, Met. Mater. Int. 25, 1027–1038 (2019)

A. Sharma, A.K. Srivastava, B. Ahn, Mater. Res. Express 6(5), 056520 (2019)

J. Shen, Y.C. Chan, Microelectron. Reliab. 49, 223–234 (2009)

A. Sharma, A.K. Srivastava, B. Ahn, Metall. Mater. Trans. A 50, 5384–5394 (2019)

B. Sharma, M. Kumar, V. Kumar, A. Sharma, ACS Appl. Nano Mater. 5(9), 13626–13636 (2022)

S.M.L. Nai, J. Wei, M. Gupta, Thin Solid Films 504(1–2), 401–404 (2006)

Y. Tang, G.Y. Li, Y.C. Pan, Mater. Design 55, 574–582 (2014)

Funding

This paper was supported by the Korea Institute for Advancement of Technology (KIAT) and a grant funded by the Korean Government (MOTIE) (P0018010, 2024).

Author information

Authors and Affiliations

Contributions

Conceptualization: AS, Methodology: GAL; Formal analysis and investigation: JPJ, Writing—original draft preparation: GAL, AS; Writing—review and editing: AS, JPJ; Funding acquisition: JPJ; Resources: AS, JPJ, Supervision: AS.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, G.A., Sharma, A. & Jung, J.P. Electrochemical deposition of Sn-0.7Cu alloy modified with nano-WO3 for high-density mini-LED packaging. J Mater Sci: Mater Electron 35, 953 (2024). https://doi.org/10.1007/s10854-024-12606-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12606-4