Abstract

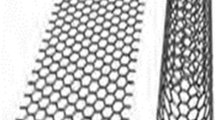

A new method has been evolved to synthesize multi wall carbon nano tubes (MWCNTs) by using rapid thermal process furnace. Nichrome and nickel catalysts are deposited on silicon substrates by electron beam evaporation technique. Acetylene and argon gases are used, in the synthesis of MWCNTs, as precursor and carrier gas respectively, at a temperature of 750 °C for 30 min. To analyze the MWCNTs, synthesized in the present study, they are subjected to various characterizations namely Raman spectroscopy, Field Emission Scanning Electron Microscopy (FESEM), Energy Dispersive X-ray Analysis (EDXA) and High Resolution Transmission Electron Microscopy (HRTEM). FESEM images revealed that carbon nanotubes have diameter ranging from 25 to 75 nm and HRTEM showed that these nanotubes have up to 80 number of walls. Nichrome is the preferred catalyst in terms of yield and growth uniformity of MWCNTs, based on the FESEM and EDXA.

Similar content being viewed by others

Data availability

The authors comply to the Research Data Policy and Data Availability Statements.

References

S. Iijima, Nature 354, 56–58 (1991). https://doi.org/10.1038/354056a0

S. Iijima, T. Ichihashi, Nature 363, 603–605 (1993). https://doi.org/10.1038/363603a0

M. Dresselhaus, G. Dresselhaus, J. Electroceram. 1, 273–286 (1997). https://doi.org/10.1023/A:1009935827658

R. Ramasubramaniam, J. Chen, H. Liu Crossmark, Appl. Phys. Lett. 83, 2928–2930 (2003). https://doi.org/10.1063/1.1616976

M.S. Dresselhaus, G. Dresselhaus, J.C. Charlier, E. Hernandez, Philos. Trans. Math. Phys. Eng. Sci. 362, 2065–2098 (2004). https://doi.org/10.1098/rsta.2004.1430

J. Hone, M.C. Llaguno, M.J. Biercuk, A.T. Johnson, B. Batlogg, Z. Benes, J.E. Fischer, Appl. Phys. A 74, 339–343 (2002). https://doi.org/10.1007/s003390201277

M. Ahlskog, P. Hakonen, M. Paalanen, L. Roschier, R. Tarkiainen, J. Low Temp. Phys. 124, 335–352 (2001). https://doi.org/10.1023/A:1017550607311

E.T. Thostenson, T.W. Chou, J. Phys. D Appl. Phys. (2002). https://doi.org/10.1088/0022-3727/35/16/103

F. Ye, Z. Ge, Y. Ding, J. Yang, Particuology. 15, 56–60 (2014). https://doi.org/10.1016/j.partic.2013.05.001

R. Andrews, D. Jacques, D. Qian, T. Rantell, Acc. Chem. Res. 35, 1008–1017 (2002). https://doi.org/10.1021/ar010151m

R.H. Baughman, A.A. Zakhidov, W.A. de Heer, Science 297, 787–792 (2002). https://doi.org/10.1126/science.1060928

T. Guo, P. Nikolaev, A.G. Rinzler, D. Tomanek, D.T. Colbert, R.E. Smalley, J. Phys. Chem. 99, 10694–10697 (1995). https://doi.org/10.1021/j100027a002

J. Chrzanowska, J. Hoffman, A. Małolepszy, M. Mazurkiewicz, T.A. Kowalewski, Z. Szymanski , L. Stobinski, Phys. Status Solidi B 8, 1860–1867 (2015). https://doi.org/10.1002/pssb.201451614

T. Yanase, T. Miura, T. Shiratori, M. Weng, T. Nagahama, T. Shimada, C J. Carbon Res. 5, 46 (2019). https://doi.org/10.3390/c5030046

Y. Yang, H. Zhang, Y. Yan, Comp. B 160, 369–383 (2019). https://doi.org/10.1016/j.compositesb.2018.12.100

C. Liu, H. Cheng, Mater. Today. 16, 19–28 (2013). https://doi.org/10.1016/j.mattod.2013.01.019

J. Kong, N.R. Franklin, C. Zhou, M.G. Chapline, S. Peng, K. Cho, H. Dai, Science 287, 622–625 (2000). https://doi.org/10.1126/science.287.5453.622

C.J. Lee, J. Park, J.A. Yu, Chem. Phys. Lett. 360, 250–255 (2002). https://doi.org/10.1016/S0009-2614(02)00831-X

C.H. Kiang, J. Chem. Phys. 113, 4763–4766 (2000). https://doi.org/10.1063/1.1287850

A.N. Andriotis, M. Menon, G. Froudakis, Phys. Rev. Lett. 85, 3193–3196 (2000). https://doi.org/10.1103/PhysRevLett.85.3193

J. Sengupta, C. Jacob, J. Nanoparticle Res. 12, 457–465 (2010). https://doi.org/10.48550/arXiv.1908.00391

X. Yan, Y. Wu, B. Wang, Q. Zhang, R. Zheng, X. Wu, G. Cheng, Appl. Surf. Sci. 450, 38–45 (2018). https://doi.org/10.1016/j.apsusc.2018.04.114

P.M. Ajayan, Chem. Rev. 99, 1787–1800 (1999). https://doi.org/10.1021/cr970102g

A.C. Ferrari, J. Robertson, Philos. Trans. Math. Phys. Eng. Sci. 362, 2477–2512 (2000). https://doi.org/10.1098/rsta.2004.1452

L.G. Cançado, A. Jorio, E.H. Martins Ferreira, F. Stavale, C.A. Achete, R.B. Capaz, M.V.O. Moutinho, A. Lombardo, T.S. Kulmala, A.C. Ferrari, Nano Lett. 11, 3190–3196 (2004). https://doi.org/10.1021/nl201432g

E. Mansfield, A. Kar, S.A. Hooker, Anal. Bioanal Chem. 396, 1071–1077 (2010). https://doi.org/10.1007/s00216-009-3319-2

A.C. Dillon, M. Yudasaka, M.S. Dresselhaus, J. Nanosci. Nanotech. 4, 691–703 (2004). https://doi.org/10.1166/jnn.2004.116

N. Sano, S. Yamamoto, H. Tamon, Chem. Eng. J. 242, 278–284 (2014). https://doi.org/10.1016/j.cej.2013.12.073

Acknowledgements

Authors are thankful to Deputy Director, OSA-LEOS and Director, LEOS for their support and encouragement.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed equally to the study (concept, design, materials preparation, data collection and analysis). The manuscript was written by Sakshi Nigavekar and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interest

The authors have no relevant financial or non-financial interests to disclose.

Ethical approval

The authors compliance with ethical standards as per the journal policy.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nigavekar, S., Das, D., Madhumalathi, G.R. et al. Synthesis of multi-walled carbon nanotubes on nichrome and nickel by using rapid thermal processing furnace. J Mater Sci: Mater Electron 35, 714 (2024). https://doi.org/10.1007/s10854-024-12467-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12467-x