Abstract

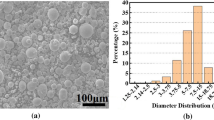

Gas-atomized FeSiAl powder was coated with the same concentration of epoxy resin, sodium silicate (NS), silicone resin and aluminum dihydrogen phosphate and the corresponding magnetic powder cores (MPCs) were prepared, and the performance superiority of the NS coating was proved by the related performance characterization and theoretical calculations. Among the four insulating coatings, the average insulation layer thickness of NS was the thinnest (only 0.57 μm), and the density of the FeSiAl@NS was also the largest (6.56 g cm−3), indicating that the FeSiAl@NS contained the least amount of nonferromagnetic phase and was easy to reach magnetic saturation. Although the DC bias performance deteriorated, the FeSiAl@NS also exhibited the highest permeability (70.5 at 100 kHz). The loss test results showed that the core loss of the FeSiAl@NS under 100 kHz and 0.05 T was 137.2 mW cm−3, only 20% of that of other MPCs. In order to analyze the loss profile, loss separation was conducted, and it was found that the FeSiAl@NS had remarkably low hysteresis loss. Compared to other insulators, the NS coatings not only effectively improve the comprehensive performance of MPCs, but also has a wide annealing process window. The FeSiAl@NS prepared in this study has high permeability and low core loss, and exhibits industrial application potential in the field of medium and high-frequency electronics and electricity due to the simple process.

Similar content being viewed by others

Data availability

All relevant data are within the manuscript and its Additional files.

References

M. Hasiak, M. Miglierini, M. Lukiewski, J. Kaleta, Microstructure, magnetic properties, and applications of Co-rich HITPERM-type amorphous alloys. IEEE Trans. Magn. 48, 1665–1668 (2012). https://doi.org/10.1109/TMAG.2011.2172590

Y.N. Dong, J.Q. Liu, P. Wang, H. Z, X.Y. J. P, J.Q. Li, Zhang, Study of bulk amorphous and nanocrystalline alloys fabricated by high-sphericity Fe84Si7B5C2Cr2 amorphous powders at different spark-plasma-sintering temperatures. Materials 15, 1106 (2022). https://doi.org/10.3390/ma15031106

H. Shokrollahi, K. Janghorban, Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 189, 1–15 (2007). https://doi.org/10.1016/j.jmatprotec.2007.02.034

J.Q. Liu, Z.Q. Zhu, P. Wang, Y.F. Li, J. Pang, J.Q. Zhang, Effects of two silicone resin coatings on performance of FeSiAl magnetic powder cores. J. Iron Steel Res. Int. (2023). https://doi.org/10.1007/s42243-023-01105-1

Y.B. Kim, D.H. Jang, H.K. Seok, K.Y. Kim, Fabrication of Fe–Si–B based amorphous powder cores by cold pressing and their magnetic properties. Mater. Sci. Eng. A 449, 389–393 (2007). https://doi.org/10.1016/j.msea.2006.02.394

P. Wang, J.Q. Liu, Y.N. Dong, Z.Z. Zhu, J. Pang, J.Q. Zhang, Breakup process modeling and production of FeSiAl magnetic powders by close-coupled gas atomization. J. Mater. Res. Technol. 23, 730–743 (2023). https://doi.org/10.1016/j.jmrt.2022.12.169

D. Liu, C. Wu, M. Yan, Investigation on sol–gel Al2O3 and hybrid phosphate-alumina insulation coatings for FeSiAl soft magnetic composites. J. Mater. Sci. 50, 6559–6566 (2015). https://doi.org/10.1007/s10853-015-9189-4

X. Zhong, Y. Liu, J. Li, Y. Wang, Structure and magnetic properties of FeSiAl-based soft magnetic composite with AlN and Al2O3, insulating layer prepared by selective nitridation and oxidation. J. Magn. Magn. Mater. 324, 2631–2636 (2012). https://doi.org/10.1016/j.jmmm.2012.03.026

M. Lauda, J. Füzer, P. Kollár, Magnetic properties and loss separation in FeSi/MnZnFe2O4 soft magnetic composites. J. Magn. Magn. Mater. 411, 12–17 (2016). https://doi.org/10.1016/j.jmmm.2016.03.051

P. Wang, J.Q. Liu, Y.N. Dong, H. Zhao, J. Pang, J.Q. Zhang, Industrial-scale fabrication of amorphous magnetic powder cores with excellent high-frequency magnetic properties: optimization for kinds and content of insulating agents. J. Non Cryst. Solids. 602, 122082 (2023). https://doi.org/10.1016/j.jnoncrysol.2022.122082

Z.G. Luo, B. Feng, D.Y. Chen, Z.J. Yang, S.W. Jiang, J. Wang, Z.Y. Wu, G.Q. Li, Y.W. Li, X.A. Fan, Preparation and magnetic performance optimization of FeSiAl/Al2O3-MnO-Al2O3 soft magnetic composites with particle size adjustment. J. Mater. Sci. Mater. Electron. 33, 850–860 (2022). https://doi.org/10.1007/s10854-021-07355-7

T.C. Zhao, C.G. Chen, X.J. Wu, C.Z. Zhang, A.A. Volinsky, J.J. Hao, FeSiBCrC amorphous magnetic powder fabricated by gas-water combined atomization. J. Alloys Compd. 857, 157991 (2021). https://doi.org/10.1016/j.jallcom.2020.157991

H.X. Li, H. Yang, Z.Z. Li, Z. Li, X.G. Liu, Multifunctional FeSiAl soft magnetic composites with inorganic–organic hybrid insulating layers for high mechanical strength, low core loss and comprehensive anti-corrosion. J. Electron. Mater. 51, 3418–3429 (2022). https://doi.org/10.1007/s11664-022-09602-x

H. Lu, Y.Q. Dong, X.C. Liu, Z.H. Liu, Y. Ma, Y. Wu, A.N. He, J.W. Li, X.M. Wang, Enhanced magnetic properties of FeSiAl soft magnetic composites prepared by utilizing phosphate: PSA as insulating layer. J. Mater. Sci. Mater. Electron. 33, 10131–10141 (2022). https://doi.org/10.1007/s10854-022-08003-4

H. Lu, Y.Q. Dong, X.C. Liu, Z.H. Liu, Y. Wu, H.J. Zhang, A.N. He, J.W. Li, X.M. Wang, Enhanced magnetic properties of FeSiAl Soft magnetic composites prepared by utilizing PSA as Resin Insulating Layer. Polymers. 13, 1350 (2021). https://doi.org/10.3390/polym13091350

J.H. Wang, S.Q. Song, H.B. Sun, G.H. Hang, Z.L. Xue, C. Wang, W.H. Chen, D.C. Chen, Insulation layer design for soft magnetic composites by synthetically comparing their magnetic properties and coating process parameters. J. Magn. Magn. Mater. 519, 167496 (2021). https://doi.org/10.1016/j.jmmm.2020.167496

B. Zhou, Y.Q. Dong, Q. Chi, Y.Q. Zhang, L. Chang, M.J. Gong, J.J. Huang, Y. Pan, X.M. Wang, Fe-based amorphous soft magnetic composites with SiO2 insulation coatings: a study on coatings thickness, microstructure and magnetic properties. Ceram. Int. 46, 13449–13459 (2020). https://doi.org/10.1016/j.ceramint.2020.02.128

W.C. Li, Z.J. Wang, Y. Y, J. Yu, J.W. Zheng, L. Qiao, S.L. Che, In-situ formation of Fe3O4 and ZrO2 coated Fe-based soft magnetic composites by hydrothermal method. Ceram. Int. 45, 3864–3870 (2019). https://doi.org/10.1016/j.ceramint.2018.11.058

S.D. Wu, Y.Q. Dong, X.B. Li, M.J. Gong, R.L. Zhao, W. Gao, H. Wu, A.N. He, J.W. Li, X.M. Wang, X.C. Liu, Microstructure and magnetic properties of FeSiCr soft magnetic powder cores with a MgO insulating layer prepared by the sol–gel method. Ceram. Int. 48, 22278–22286 (2022). https://doi.org/10.1016/j.ceramint.2022.04.227

B. Meng, J. Hou, F. Ning, B. Yang, B. Zhou, R. Yu, Low-loss and high-induction Fe-based soft magnetic composites coated with magnetic insulating layers. J. Magn. Magn. Mater. 492, 165651 (2019). https://doi.org/10.1016/j.jmmm.2019.165651

Z. Li, Z.Z. Li, H. Yang, H.X. Li, X.G. Liu, Soft magnetic properties of gas-atomized FeSiAl microparticles with a triple phosphoric acid-sodium silicate–silicone resin insulation treatment. J. Electron. Mater. 51, 2142–2155 (2022). https://doi.org/10.1007/s11664-022-09441-w

H.P. Wei, H.Y. Yu, Y. Feng, Y.F. Wang, J.Y. He, Z.W. Liu, High permeability and low core loss nanocrystalline soft magnetic composites based on FeSiBNbCu@ Fe3O4 powders prepared by HNO3 oxidation. Mater. Chem. Phys. 263, 124427 (2021). https://doi.org/10.1016/j.matchemphys.2021.124427

D. Liu, C. Wu, M. Yan, J. Wang, Correlating the microstructure, growth mechanism and magnetic properties of FeSiAl soft magnetic composites fabricated via HNO3 oxidation. Acta Mater. 146, 294 (2018). https://doi.org/10.1016/j.actamat.2018.01.001

E.Y. Kang, Y.H. Chung, M.R. Ok, H.K. Baik, Research on the surface oxidation procedure of Fe-base metallic glass during wet oxidation treatment. Mater. Sci. Eng. A 449, 159–164 (2007). https://doi.org/10.1016/j.msea.2006.02.311

J.Q. Liu, Y.N. Dong, P. Wang, H. Zhao, J. Pang, X.Y. Li, J.Q. Zhang, Simulation and experiment investigations on fabrication of Fe-based amorphous powders by a novel atomization process equipped with assisted gas nozzles. J. Iron Steel Res. Int. 30, 1142–1155 (2023). https://doi.org/10.1007/s42243-022-00855-8

B.V. Neamţu, M. Pszola, A. Opriş, F. Popa, T.F. Marinca, I. Chicinaş, Influence of fibres diameter on the AC and DC magnetic characteristics of Fe/Fe3O4 fibres based soft magnetic composites. Ceram. Int. 47, 1865–1874 (2021). https://doi.org/10.1016/j.ceramint.2020.09.015

H.I. Hsiang, L.F. Fang, K.T. Ho, Minor yttrium nitrate addition effect on FeSiCr alloy powder core electromagnetic properties. J. Magn. Magn. Mater. 444, 1–6 (2017). https://doi.org/10.1016/j.jmmm.2017.07.099

H. Zhang, X. Zhu, X.B. Zhang, W. Liu, H.L. Su, Z.Q. Zou, J.Z. Wang, Great reduction in pressure by particle grading for Fe–Si–Al SMCs with good low-frequency magnetic properties. J. Magn. Magn. Mater. 555, 169325 (2022). https://doi.org/10.1016/j.jmmm.2022.169325

X.W. Yi, Q.B. Li, Y.D. Peng, Y.F. Zhao, S.Z. Zhu, Effect of processing condition on microstructure and properties of FeSiAl powder coated with metal oxides by using a NaOH solution. J. Supercond Novel Magn. 34, 2957 (2021). https://doi.org/10.1007/s10948-021-05977-w

D. Neena, K.B. Garg, P.A. Alvi, D. Kumar, K.S. Jerath, M. Abu-Samak, S. Dalelaa, Study of band structure properties of pnictide LaO1–xFxFeAs (x = 0, 0.2) superconducting compound. J. Supercond Novel Magn. 27, 1967–1972 (2014). https://doi.org/10.1007/s10948-014-2539-7

R.M. Mohamed, M.W. Kadi, A.A. Ismail, A facile synthesis of mesoporous α-Fe2O3/TiO2 nanocomposites for hydrogen evolution under visible light. Ceram. Int. 46, 15604–15612 (2020). https://doi.org/10.1016/j.ceramint.2020.03.107

Y.X. Jia, S.L. Zhu, Z.L. Liu, L. Yang, M.L. Shen, F.H. Wang, Effects of oxygen incorporation in low expansion ni + CrAlYN nanocomposite coatings on the oxidation behavior. Corros. Sci. 167, 108550 (2020). https://doi.org/10.1016/j.corsci.2020.108550

Z.G. Luo, X.A. Fan, W.T. Hu, F. Luo, J. Wang, Z.Y. Wu, X. Liu, G.Q. Li, Y.W. Li, Formation mechanism and enhanced magnetic properties of Fe–Si/Fe2SiO4 soft magnetic composites transformed from Fe-6.5 wt%Si/α-Fe2O3 core-shell composites. J. Alloys Compd. 817, 152803 (2020). https://doi.org/10.1016/j.jallcom.2019.152803

Z.L. Zhang, Z.J. Jin, J. Guo, The effect of the interface reaction mode on chemical mechanical polishing. CIRP J. Manufact. Sci. Technol. 31, 539–547 (2020). https://doi.org/10.1016/j.cirpj.2020.08.005

Z.G. Wang, X.T. Zu, X. Xiang, J. Lian, L.M. Wang, Preparation and characterization of polymer/inorganic nanoparticle composites through electron irradiation. J. Mater. Sci. 41, 1973–1978 (2006). https://doi.org/10.1007/s10853-006-1120-6

N. Zhang, T. Bao, Y. Gao, X.L. Xu, S.C. Wang, Growth of MOF@COF on corncob as effective adsorbent for enhancing adsorption of sulfonamides and its mechanism. Appl. Surf. Sci. 580, 152285 (2022). https://doi.org/10.1016/j.apsusc.2021.152285

X. Yu, H.J. Qi, Z.H. Huang, B. Zhang, S.X. Liu, Preparation and characterization of spherical β-cyclodextrin/urea–formaldehyde microcapsules modified by nano-titanium oxide. RSC Adv. 7, 7857–7863 (2017). https://doi.org/10.1039/C6RA27895G

X. Geng, Z.H. Li, Y.L. Hu, H.F. Liu, Y.Q. Sun, H.M. Meng, Y.W. Wang, L.B. Qu, Y.H. Lin, One-pot green synthesis of ultrabright N-Doped fluorescent silicon nanoparticles for cellular imaging by using ethylenediaminetetraacetic acid disodium salt as an effective reductant. ACS Appl. Mater. Interfaces 10, 27979–27986 (2018). https://doi.org/10.1021/acsami.8b09242

A. Jaiswal, S. Pal, A. Kumar, R. Prakash, Metal free triad from red phosphorous, reduced graphene oxide and graphitic carbon nitride (red P-rGO-g-C3N4) as robust electro-catalysts for hydrogen evolution reaction. Electrochim. Acta. 338, 135851 (2020). https://doi.org/10.1016/j.electacta.2020.135851

Z. Luo, X.A. Fan, W. Hu, F. Luo, G. Li, Y. Li, X. Liu, J. Wang, Controllable SiO2 insulating layer and magnetic properties for intergranular insulating Fe-6.5wt.%Si/SiO2 composites. Adv. Powder Technol. 30, 538–543 (2019). https://doi.org/10.1016/j.apt.2018.12.004

J.W. Zheng, D.N. Zheng, L. Qiao, Y. Ying, Y.P. Tang, W. Cai, W.C. Li, J. Yu, J. Li, S.L. Che, High permeability and low core loss Fe-based soft magnetic composites with co-ba composite ferrite insulation layer obtained by sol–gel method. J. Alloys Compd. 893, 162107 (2022). https://doi.org/10.1016/j.jallcom.2021.162107

Y.P. Wang, R.T. Hao, J. Guo, X.M. Li, S.L. Fang, H.M. Liu, S.H. Sun, Effect of mg doping on Cu2ZnSnS4 solar cells prepared by DMF-based solution method. Opt. Mater. 117, 111211 (2021). https://doi.org/10.1016/j.optmat.2021.111211

H.L. Li, C.X. Fei, D. Yang, C. Tan, Z.Y. Chen, J. Wang, G.X. Wang, H.Y. Fan, H. Yao, C.Y. Wang, H. Chong, Synthesis of carbon nitride quantum dots and biocompatibility evaluation using C. elegans as a model organism. Mater. Today Commun. 25, 101383 (2020). https://doi.org/10.1016/j.mtcomm.2020.101383

J.M. Cen, P.K. Shen, Y.F. Zeng, Ru doping NiCoP hetero-nanowires with modulated electronic structure for efficient overall water splitting. J. Colloid Interface Sci. 610, 213–220 (2022). https://doi.org/10.1016/j.jcis.2021.12.028

G.L. Wu, L. Li, M. Sun, Y. Wang, F. Luo, Q.L. Zhang, R. Liu, Z.J. Chen, J.H. Yao, Microstructural evolution and biological properties of PEO coating on SLM-prepared NiTi alloy. Surf. Coat. Technol. 452, 129065 (2023). https://doi.org/10.1016/j.surfcoat.2022.129065

S. Nakahara, E.A. Périgo, Y. Pittini-Yamada, Y. de Hazan, T. Graule, Electric insulation of a FeSiBC soft magnetic amorphous powder by a wet chemical method: identification of the oxide layer and its thickness control. Acta Mater. 58, 5695–5703 (2010). https://doi.org/10.1016/j.actamat.2010.06.044

J.W. Luo, X.T. Liu, M.P. Ma, J.K. Tang, F.R. Huang, Dendritic poly (silylene arylacetylene) resins based on 1, 3, 5-triethynylbenzene. Eur. Polym. J. 129, 109628 (2020). https://doi.org/10.1016/j.eurpolymj.2020.109628

C. Zhang, W. Zhang, W.H. Yuan, K. Peng, Preparation and magnetic properties of core–shell structured Fe-Si/Fe3O4 composites via in-situ reaction method. J. Magn. Magn. Mater. 531, 167955 (2021). https://doi.org/10.1016/j.jmmm.2021.167955

J.Q. Liu, Y.N. Dong, Z.Z. Zhu, H. Zhao, J. Pang, P. Wang, J.Q. Zhang, Fe-based amorphous magnetic powder cores with low core loss fabricated by novel gas–water combined atomization powders. Materials 15, 6296 (2022). https://doi.org/10.3390/ma15186296

J.Q. Liu, Y.N. Dong, P. Wang, Z.Z. Zhu, J. Pang, X.Y. Li, J.Q. Zhang, Improved high-frequency magnetic properties of FeSiBCCr amorphous soft magnetic composites by adding carbonyl iron powders. J. Non Cryst. Solids. 605, 122166 (2023). https://doi.org/10.1016/j.jnoncrysol.2023.122166

Q. Chi, L. Chang, Y.Q. Dong, Y.Q. Zhang, B. Zhou, C.Z. Zhang, Y. Pan, Q. Li, J.W. Li, A.N. He, X.M. Wang, Enhanced high frequency properties of FeSiBPC amorphous soft magnetic powder cores with novel insulating layer. Adv. Powder Technol. 32, 1602–1610 (2021). https://doi.org/10.1016/j.apt.2021.03.017

H.C. Yu, S.X. Zhou, G.Q. Zhang, B.S. Dong, L.B. Meng, Z.Z. Li, Y.Q. Dong, X. Cao, The phosphating effect on the properties of FeSiCr alloy powder. J. Magn. Magn. Mater. 552, 168741–168748 (2022). https://doi.org/10.1016/j.jmmm.2021.168741

T. Li, Y.Q. Dong, L. Liu, M. Liu, X.Z. Shi, X. Dong, Q.Y. Rong, Novel Fe-based nanocrystalline powder cores with high performance prepared by using industrial materials. Intermetallics. 102, 101–105 (2018). https://doi.org/10.1016/j.intermet.2018.09.001

Y. Zhang, P. Sharma, A. Makino, Production and properties of soft magnetic cores made from Fe-Rich FeSiBPCu powders. IEEE Trans. Magn. 51, 1–4 (2015). https://doi.org/10.1109/TMAG.2014.2359003

Y. Zhang, P. Sharma, A. Makino, Fe-rich Fe–Si–B–P–Cu powder cores for high-frequency power electronic applications. IEEE Trans. Magn. 50, 1–4 (2014). https://doi.org/10.1109/TMAG.2014.2316543

W.W. Guan, X.Y. Shi, T.T. Xu, K. Wan, B.W. Zhang, W. Liu, H.L. Su, Z.Q. Zou, Y.W. Du, Synthesis of well-insulated Fe–Si–Al soft magnetic composites via a silane-assisted organic/inorganic composites coating route. J. Phys. Chem. Solids 150:109841 ((2021)(2021)

Funding

This work was financially supported by Key R&D Program of Shandong Province, China (Grant No. 2022CXGC020308).

Author information

Authors and Affiliations

Contributions

PW: Conceptualization, Data curation, Formal analysis, Investigation, Writing—original draft. JL: Investigation, Methodology, Writing—review & editing. ZZ: Project administration. JP: Supervision, Funding acquisition. JZ: Resources, Writing—review & editing.

Corresponding authors

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, P., Liu, J., Zhu, Z. et al. Sodium silicate coatings for improving soft magnetic properties of FeSiAl powder cores with industrial compatibility. J Mater Sci: Mater Electron 35, 425 (2024). https://doi.org/10.1007/s10854-024-12212-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12212-4