Abstract

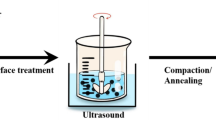

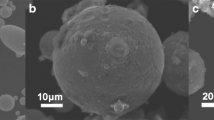

Two silicon resins with excellent thermal stability, JH1123 and JH7102, are used as the insulated agents and binders for the gas-atomized FeSiAl powder, and corresponding magnetic powder cores (MPCs) are fabricated. The insulation capability and application prospects of the two silicon resins are evaluated by comparing the magnetic properties of the coated powder and MPCs. The scanning electron microscopy, energy dispersive X-ray spectroscopy and Fourier transform infrared spectroscopy results show that uniform insulation layers are both formed on the powder surfaces. JH1123 has stronger binding ability, and the JH1123-coated powder exhibits severe agglomeration, with d50 (average particle size) approximately twice that of the JH7102-coated powder. Both as-prepared MPCs exhibit outstanding soft magnetic properties. Wherein, the permeability of FeSiAl@JH1123 is up to 74.0, which is 35.5% higher than that of FeSiAl@JH7102 because JH1123 can further improve the density of the MPCs. As for FeSiAl@JH7102, it has better direct current bias and lower core loss of 716.9 mW cm−3 at 20 mT and 1000 kHz due to its lower coercivity and greater anti-magnetic saturation ability. A comprehensive comparison shows that FeSiAl@JH1123 is suitable for medium and high frequency applications, while FeSiAl@JH7102 is more suitable for high frequency applications. This indicates that the use of JH1123 and JH7102 silicon resins for binding and insulated coating not only simplifies the preparation process of MPCs, but also enables the controlled production of MPCs for different applications.

Similar content being viewed by others

References

B. Yang, X. Li, R. Guo, R. Yu, Mater. Des. 121 (2017) 272–279.

C.B. Huang, T.C. Liu, X.Y. Wang, C.W. Lu, D.R. Li, Z.C. Lu, J. Iron Steel Res. Int. 22 (2015) 67–71.

J.M. Silveyra, E. Ferrara, D.L. Huber, T.C. Monson, Science 362 (2018) 6413.

G. Zhang, G. Shi, W. Yuan, Y. Liu, Ceram. Int. 47 (2021) 8795–8802.

H. Shokrollahi, K. Janghorban, J. Mater. Process. Technol. 189 (2007) 1–12.

O. Gutfleisch, M.A. Willard, E. Brück, C.H. Chen, S.G. Sankar, J.P. Liu, Adv. Mater. 23 (2011) 821–842.

J.Q. Liu, Y.N. Dong, P. Wang, H. Zhao, J. Pang, X.Y. Li, J.Q. Zhang, J. Iron Steel Res. Int. 30 (2023) 1142–1155.

K.J. Sunday, M.L. Taheri, Met. Powder Rep. 72 (2017) 425–429.

W. Li, H. Cai, Y. Kang, Y. Ying, J. Yu, J. Zheng, L. Qiao, Y. Jiang, S. Che, Acta Mater. 167 (2019) 267–274.

Z.H. Liu, Y.Q. Dong, X.C. Liu, H. Lu, Y. Wu, H.J. Zhang, A.N. He, J.W. Li, X.M. Wang, J. Alloy. Compd. 885 (2021) 160924.

P. Wang, J. Liu, Y. Dong, Z. Zhu, J. Pang, J. Zhang, J. Mater. Res. Technol. 23 (2023) 730–743.

X. Zhong, Y. Liu, J. Li, Y. Wang, J. Magn. Magn. Mater. 324 (2012) 2631–2636.

W. Li, W. Li, J. Wu, X. Han, Y. Ying, J. Yu, J. Zheng, L. Qiao, J. Li, S. Che, Mater. Sci. Eng. B 291 (2023) 116387.

C.B. Huang, T.C. Liu, X.Y. Wang, C.W. Lu, D.R. Li, Z.C. Lu, J. Iron Steel Res. Int. 21 (2014) 348–351.

Z. Li, Z. Li, H. Yang, H. Li, X. Liu, J. Electron. Mater. 51 (2022) 2142–2155.

H. Li, H. Yang, Z. Li, Z. Li, X. Liu, J. Electron. Mater. 51 (2022) 3418–3429.

H. Lu, Y. Dong, X. Liu, Z. Liu, Y. Ma, Y. Wu, A. He, J. Li, X. Wang, J. Mater. Sci. 33 (2022) 10131–10141.

H. Lu, Y. Dong, X. Liu, Z. Liu, Y. Wu, H. Zhang, A. He, J. Li, X. Wang, Polymers 13 (2021) 1350.

J. Liu, Y. Dong, P. Wang, Z. Zhu, J. Pang, X. Li, J. Zhang, J. Non-Cryst. Solids 605 (2023) 122166.

B.V. Neamţu, M. Pszola, A. Opriş, F. Popa, T.F. Marinca, I. Chicinaş, Ceram. Int. 47 (2021) 1865–1874.

X. Yi, Q. Li, Y. Peng, Y. Zhao, S. Zhu, J. Supercond. Nov. Magn. 34 (2021) 2957–2968.

Z.Q. Zhu, J.Q. Liu, H. Zhao, J. Pang, P. Wang, J.Q. Zhang, Materials 16 (2023) 1270.

D. Liu, S. Gao, Y. Zhang, S. Yu, F. Wang, Ceram. Int. 45 (2019) 21804–21809.

P.P. Singh, G. Nath, Waste Biomass Valorization 13 (2022) 2905–2916.

R. Rehman, I. Manzoor, L. Mitu, Bull. Chem. Soc. Eth. 32 (2018) 213.

M. Tajabadi, I. Rahmani, S.M. Mirkazemi, H.G. Orimi, Adv. Powder Technol. 33 (2021) 103366.

Z.Y. Wu, L. Kang, X.W. Liao, H. Kong, H.C. Wang, R. Wang, Ceram. Int. 49 (2023) 19870–19878.

J. Wang, X.A. Fan, Z. Wu, G. Li, J. Solid State Chem. 231 (2015) 152–158.

J. Liu, Y. Dong, Z. Zhu, H. Zhao, J. Pang, P. Wang, J. Zhang, Materials 15 (2022) 6296.

R.D. Shull, J. Iron Steel Res. Int. 14 (2007) No. 4, 69–74.

P. Wang, Z.Q. Zhu, J.Q. Liu, C.F. Wang, J. Pang, J.Q. Zhang, J. Alloy. Compd. 962 (2023) 171095.

H.J. Woo, J.H. Ahn, C.P. Kim, D.H. Choi, S. Kim, B.W. Lee, J. Non-Cryst. Solids 577 (2022) 121309.

S. Wu, Y. Dong, X. Li, M. Gong, R. Zhao, W. Gao, H. Wu, A. He, J. Li, X. Wang, X. Liu, Ceram. Int. 48 (2022) 22237–22245.

P. Wang, J.Q. Liu, Y.N. Dong, H. Zhao, J. Pang, J. Zhang, J. Non-Cryst. Solids 602 (2023) 122082.

T. Zhao, C. Chen, X. Wu, C. Zhang, A.A. Volinsky, J. Hao, J. Alloy. Compd. 857 (2021) 157991.

G. Bertotti, IEEE Trans. Magn. 24 (1988) 621–630.

L. Ďáková, J. Füzer, S. Dobák, P. Kollár, Y. Osadchuk, M. Strečková, M. Fáberová, R. Bureš, P. Kurek, M. Vojtko, IEEE Trans. Magn. 54 (2018) 1–6.

K.Y. Huang, Y.Q. Dong, M. Liu, J.H. Ren, S.H. Lu, Z.K. Zhao, C.T. Chang, X.M. Wang, J. Iron Steel Res. Int. 25 (2018) 624–629.

J.G. Yeo, D.H. Kim, Y.J. Choi, B.W. Lee, J. Electron. Mater. 48 (2019) 6018–6023.

J. Lei, J. Zheng, H. Zheng, L. Qiao, Y. Ying, W. Cai, W. Li, J. Yu, M. Lin, S. Che, J. Magn. Magn. Mater. 472 (2019) 7–13.

C. Xia, Y. Peng, X. Yi, Z. Yao, Y. Zhu, G. Hu, J. Non-Cryst. Solids 559 (2021) 120673.

Acknowledgements

This work was financially supported by the Key R&D Program of Shandong Province, China (Grant No. 2022CXGC020308).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Jq., Zhu, Zq., Wang, P. et al. Effects of two silicone resin coatings on performance of FeSiAl magnetic powder cores. J. Iron Steel Res. Int. 31, 1279–1288 (2024). https://doi.org/10.1007/s42243-023-01105-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-01105-1