Abstract

Herein, PVA: PVP@Ni(OAc)2 nanocomposite spin-coated thin films have been fabricated as a barrier modifier interlayer in a metal/polymer/semiconductor configuration for light detection applications. The nanostructure, as well as the surface roughness profile of the deposited thin films, have been inspected using a high-resolution transmission electron microscope (HR-TEM) and field emission scan electron microscope (FE-SEM). The obtained results showed nanoplatelet architecture films with smooth surfaces of average roughness of ~ 7.08 nm. The optical absorption, reflection, and transmission spectra have been analyzed and the value of the fabricated film’s energy gap has been confirmed with several analytical approaches. Furthermore, the DC electrical properties of Ag/Si (n-type and p-type), as well as Ag/polymer nanocomposite/Si (n-type and p-type), have been investigated under dark conditions. The microelectronic properties have been estimated using thermionic emission, Norde’s, and Cheung-Cheung’s models. Besides, the mechanistic details of charge transport have been explored under forward and reverse bias conditions. The photoresponsive features of the designed Ag/ PVA/PVP@Ni(OAc)2 /p-Si junction have been evaluated under different illumination intensities. The current device achieved superior photodetection capability with high responsivity, detectivity, and fast switching behavior.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The power of electronics always lies in the asymmetry arising on the interface surfaces, which gives rise to functionalities that deviate from linearity, such as rectification of current, thermoelectric power, gain, photovoltage, and lasing. Therefore, it was a challenge to control the electrical functionality of any junction except by understanding and manipulating the chemical and electronic properties of the utilized semiconductor [1, 2]. However, the electrochemical changes on the interfaces of the heterojunction are the main reason for the formation of a potential difference, which enhances the transfer of charge carriers between the two interface surfaces of the junction [2]. Undisputedly, metal/semiconductor (MS) contact (i.e., Schottky contact) is one of the most important electronic components, which has proven over decades their efficiency in many important applications such as UHF and VHF detectors [3, 4], solar cells [5], and photodetectors [6, 7]. The precise controllability of charges transport via the developed Schottky barrier height, SBH, was the main reason for the Schottky configuration preference [8]. This has distinguished the Schottky diode with lower junction capacitance, high current, and fast switching. Unfortunately, Schottky diodes are limited by their low reverse voltage ratings and their relatively high reverse leakage current that increases significantly with an increase in temperature yielding thermal instability of the junction performance [9, 10]. It is worth noting that because of unsaturated dangling bonds, as well as structural, and chemical defects on the surface of the semiconductor, electronic states may have emerged on the interface [1, 2, 8].

Believing in the vital role of interface properties in controlling almost all the characteristics of the designed junction (e.g., rectification ratio, ideality factor, series resistance, reverse saturation current, barrier height, shunt resistance, interface states density, barrier homogeneity, response to light, and temperature, etc.), pioneering contributions have manifested for interface engineering [11,12,13,14]. Manipulation of the interface between semiconductor and metal by involving interlayer affects significantly various aspects of the interface electrostatics such as electrical and chemical passivation of surface, adjusting the energy levels alignment, and charge rearrangement between metal and semiconductor. Besides acting as a tunneling barrier as well as a diffusion barrier to block surface oxidation and react with structural defects and dangling bonds minimizing the chemical imperfections and protecting the surface from oxidation [3, 8,9,10].

Indeed, the performance of the designed metal/interlayer/semiconductor (MIS) strongly depends on the properties of the interlayer (e.g., doping concentration, dielectric constant, refractive index, optical transparency, energy gap) and its thickness [15,16,17]. Many molecular organic and inorganic interlayers have been extensively investigated rather than the traditional SiO2 and SnO2, like high-k metal oxides and polymers giving rise to metal/oxide/semiconductor (MOS) and metal/polymer/semiconductor (MPS) architectures, respectively. Despite the stability of SiO2 as a passivation layer, it is unable to passivate all the surface dangling bonds of the semiconductor, in addition to the high price of its preparation. Although many metal oxides have shown strong successes in limiting the reverse leakage current of the Schottky diode, achieving high stability and high response speed for high frequencies, they need sophisticated deposition techniques which require high costs of fabrication [3, 12, 14,15,16,17,18,19]. This increased the preference for the use of organic materials, especially polymers, because of their availability and ease of preparation (e.g., dip coating, spin coating, and electrospinning), in addition to their high dielectric constant, and their tailorable properties either via controlling preparation conditions or doping.

Regarding the organic passivation interlaying, many studies have been performed to improve the device parameters by employing different types of organic materials such as resins [20, 21], human serum albumin [22], organic dyes [23,24,25], and reduced graphene oxide [26]. All this apart from exploiting the physiochemical properties of polymers, of which many types have been exploited, for example, polyvinyl pyrrolidone (PVP [27,28,29,30,31,32,33,34], polyvinyl alcohol (PVA) [35,36,37,38,39,40], polyaniline (PANI) [41], poly(3,4-ethylene dioxythiophene) polystyrene sulfonate (PEDOT: PSS) [42], poly(3-hexylthiophene-2,5-diyl) (P3HT) [43], phenyl-C61-butyric acid methyl ester (PCBM) [44], polyvinyl chloride PVC) [45, 46], chitosan [47], 2-(4-fluorophenyl)-2-oxoethyl-2-methylprop-2-enoate (PFPAMA) [48], and poly(N-substituted pyrrole) (PNoMPhPPy) [49]. Among all these polymers, PVA: PVP blend has been chosen to be the passivating interlayer material in the present study owing to their low toxicity, good film forming, high water solubility, flexibility, and good adhesiveness to different types of substrates [27,28,29, 35]. Additionally, the combination of the high dielectric strength of PVA (~ 41,000 kV/mm), and the moderate electrical conductivity of PVP may result in an outstanding blend of controllable properties.

Thereby, following our previous study on the optimization of the PVA: PVP blend ratio and then enhancing its optical and optoelectronic properties via incorporation of nickel (II) acetate Ni(OAc)2 into the polymeric matrix yielding a (40: 60) wt.% optimized blend ratio with 28.6 wt.% of Ni(OAc)2 as optimum doping concertation in the prepared nanocomposite [50]. Here, this systematically optimized nanocomposite will be exploited in a thin film form for passivating and controlling the SBH of the silver/silicon (MS) junction. Subsequently, the designed junction can be utilized in efficient light-sensing applications. The present study also provides microstructural and optical investigations on the fabricated thin films.

2 Experimental work

2.1 Materials and preparation of nanocomposite thin films

The current study utilized two types of polymers; polyvinyl alcohol (PVA) with a molecular weight of 125,000 g/mol purchased from Rasayan Laboratories in India, and polyvinyl pyrrolidone (PVP) K30 with a molecular weight of 30,000 g/mol purchased from MP Biomedicals, LLC in France. Meanwhile, nickel (II) acetate tetrahydrate, Ni(OCOCH3)2.4H2O, with a molecular weight of 248.84 g/mol was purchased from Sigma-Aldrich Co. To prepare the nanocomposite, PVA: PVP@ Ni(OAc)2 solution, 0.4 g of PVA, and 0.6 g of PVP were dissolved in 10 mL of bi-distilled water under vigorous magnetic stirring at 60 ºC for 8 h until attaining colorless, homogenous, and transparent PVA-PVP blend solution. Then, 0.4 g of Ni(OAc)2 salt was added to the pre-prepared polymer solution and left to stir for 5 h at 60 ºC at room temperature to ensure complete solubility and homogeneity of the mixed salt in the PVA-PVP polymer solution. The resulting solution has been left at room temperature for about 48 h till becomes bubble-free. Chemically, PVA and PVP are bonded by hydrogen bonding, and during the addition of Ni(OAc)2 to PVA/PVP blend to form PVA: PVP@ Ni(OAc)2 solution, nickel can be bonded electrostatically with the oxygen of PVP or with the hydrogen of PVA. Besides, the positively charged Ni ions that are generated during replacing the C and/or N atoms of the PVA/PVP blend may attract the negatively charged OH group in the polymeric backbone [50].

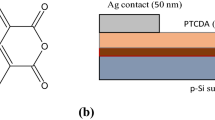

Following, using a micropipette, several droplets of the prepared solutions were dropped on the pre-cleaned quartz and silicon substrates under 1500 rpm spin coating for 60 s for three successive trials and left to dry in a vacuum and under dark conditions. The employed silicon substrates were p-type silicon of < 100 > orientation doped with boron and n-type silicon of < 100 > orientation with no dopant were supported from Sigma-Aldrich Co. Before depositing PVA: PVP@ Ni(OAc)2 solution, the silicon substrates were chemically etched and cleaned to remove surface native contaminations. Two metallic electrodes were patterned using thermal evaporation Edwards coating unit on the upper surface and lower surface of the prepared PVA: PVP@ Ni(OAc)2/p-Si and PVA: PVP@ Ni(OAc)2/n-Si under vacuum 3 × 10–5 mbar. The upper rectifier electrode was silver Ag of thickness 95 nm, and the rear electrode was aluminum Al of thickness 300 nm. Figure 1 shows a schematic diagram for the designed Ag/PVA: PVP@Ni(OAc)2/p-Si/Al MPS junction device with an active area of 0.02 cm2. For highlighting the effective role of the nanocomposite interlayer on the electronic performance of the metal/semiconductor junction, two virgin MS diodes Ag/p-Si/Al and Ag/n-Si/Al have been fabricated without the interlayer and symbolled as D1 and D3, respectively, while the interlayered MPS diodes Ag/PVA: PVP@ Ni(OAc)2/p-Si/Al and Ag/PVA: PVP@ Ni(OAc)2/n-Si/Al have been symbolled as D2 and D4, respectively.

2.2 Characterization techniques

The microstructure of the prepared PVA: PVP@ Ni(OAc)2 thin films has been inspected using the JOEL-JEM-HR-2100 high-resolution transmission electron microscope (HR-TEM). Furthermore, the UV–Vis-NIR absorption, transmission, and reflection of the prepared thin films on quartz substrates were measured spectrophotometrically using a Jasco V-770 spectrophotometer at normal incidence in the photon energy range (0.496–6.53) eV. In addition, the electrical features of the designed diodes have been evaluated in terms of the measured current–voltage relation using a Keithley 6517B electrometer at room temperature in the sweep bias voltage ± 3 V under dark and white light illumination conditions. The utilized illumination source was a 150 W- tungsten halogen lamp and with the help of an IL1400A radiometer/photometer, the intensity of the probed light signals was controlled to be in the range of (20–100) mW/cm2.

3 Results and discussion

3.1 Material characterization

3.1.1 Microstructure of PVA: PVP@Ni(OAc)2 thin films

Figure 2a–c reveals the microstructure of the prepared nanocomposite thin films at different magnifications. It can be observed that the film Ni(OAc)2 has been formed in the form of nanoplatelets uniformly distributed in the PVA: PVP matrix. The distribution of the nanoplatelets size depicted in the inset of Fig. 2a illustrates that the mean value of the nanoplatelets size is about 79 ± 15 nm. The formation of these nanostructured Ni(OAc)2 nanoplatelets may be supported by the interactive impacts of the PVA and PVP matrices. In addition, the halo featureless SAED pattern that is shown in Fig. 2d confirms the dominance of the amorphous nature of the prepared nanocomposite film.

3.1.2 Morphology and surface roughness of PVA: PVP@Ni(OAc)2 thin films

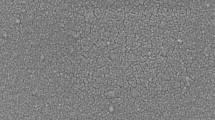

On the other hand, it would be unreasonable not to inspect the surface morphology of the deposited interlayer, since it is well known that the interlayer film’s roughness has many consequences on the performance of the designed MPS device. Therefore, the surface topography of the prepared PVA: PVP@Ni(OAc)2 thin film has been inspected as visualized in the FE-SEM micrograph shown in Fig. 3a. The observed nanoplatelets in the HR-TEM micrographs are also detected in the FE-SEM images. The micrograph reveals the smoothness and homogeneity of the surface. Additionally, the 3D FE-SEM micrograph reveals the roughness profile of the spin-coated nanocomposite film is declared in Fig. 3b. It can be observed that the film’s surface is relatively smooth with an average roughness of about 7.08 ± 2.3 nm. However, these nanoplatelets may occupy a vertical position relative to the film’s plane, which has caused them to appear clearly in some areas, resulting in a relatively high roughness.

3.1.3 Optical properties of PVA: PVP@Ni(OAc)2 thin films

The UV–Vis-NIR transmittance, reflectance, and absorbance spectra of the spin-coated PVA: PVP@Ni(OAc)2 thin films are displayed as a function of photon energy as shown in Fig. 4a–c, respectively. The prepared films exhibited high NIR and visible transparency with a notable weak absorption peak at about 3.1 eV (400 nm) which is related according to the spin–orbit coupling to the electronic triplet–triplet d-d transitions 3A2g(f) → 3T2g(p) of Ni(OAc)2 complex [50,51,52]. Meanwhile, in the UV region, the transparency drops sharply at a fundamental edge yielding null transmittance consistently with a wide sharp absorption band which is centered at 5.49 eV. The onset of the absorption, i.e., the fundamental absorption edge and its wavelength is determined by the band-gap of the PVA: PVP@Ni(OAc)2 composite film. The optical absorption in the UV range is usually attributed to the interaction of light with the bound electrons in the polymer composite. It is also noticed that the reflectance of the prepared film is weak overall in the spectral range as shown in Fig. 4b. This is an efficient result in increasing the light-harvesting capability of the device for more efficient optoelectronic performance especially when exploiting this film as an interlayer photosensitive device.

The absorption coefficient as a function of energy, α (E) of the prepared nanocomposite film of thickness, d, has been calculated using the following relation [53]:

Figure 4d depicts the photon energy dependence of the calculated absorption coefficient. A clear wide intense band absorption band has been observed and resolved into three components at 5.39 eV which corresponds to the electronic transition π → π* transition of syndiotactic PVA [54]. The resolved absorption peaks at 5.58 and 6.17 eV are related to the n → π* and n → σ* transitions of C = O and C = C groups of PVP [55].

It is worth noting that accurate determination of the energy gap of the interlayer in the MPS junction has a pivotal role in how it interacts with the light incident on it in terms of absorption and scattering and about the energetic alignment of its molecular orbitals (i.e., HOMO and LUMO) relative to the Fermi energy of the metal and the valence band and conduction band of the semiconductor. Accordingly, various methods and approaches have been used to determine the energy gap of the prepared nanocomposite films:

-

(a)

The first derivative of transmittance, and reflectance with respect to the wavelength approach:

It is anticipated that the derivative of transmittance, dT/dλ, and reflectance, dR/dλ, with respect to wavelength will diverge and tend to infinity and will have peaks near λg = hc/Eg, as revealed in Fig. 5a following the present relation [53, 56, 57]:

The observed peak of energy E2 is related to the fundamental energy gap and the second E1 is related to the sub-bandgap developed owing to the incorporation of Ni(OAc)2 in the electronic structure of the PVA: PVP matrix.

-

(b)

The first derivative of transmittance, and reflectance with respect to the energy approach:

Considering the dependence of the absorption coefficient α(E) on the photon energy, E, follows the following relation [53]:

where C is a constant, and nr(E) is the energy-dependent refractive index. Meanwhile, the transmittance of such a film of thickness, d, can be represented as follows [53]:

It can be shown that when the incident photon energy approaches the energy gap, the derivative of reflectance dR/dE remains finite at energies near Eg. This occurs because a band tail prevents singularity-type behavior from occurring. On the other hand, the derivative of transmittance dT/dE exhibits a spike toward negative infinity as illustrated in the following equation [53]:

Likewise, as depicted in Fig. 5b it is shown that when absorption tails are present, they attenuate the divergence and create distinct peaks around the gap energy. Hence, two clear transition energies are constituents with the aforementioned energies related to the fundamental and intermediate transition energy gap.

-

(c)

The logarithmic derivative approach:

Referring to the Tauc method, the photon energy dependence of the absorption coefficient is given by [53, 58]:

The natural logarithmic for both sides will yield:

By differentiating Eq. (7) with respect to photon energy E:

Therefore, the plot of d[ln(αE)]/dE versus photon energy, E, will result in the appearance of a particular peak which is related to the energy gap as illustrated in Fig. 5c. In addition, the type of the electronic transition can be estimated employing Eq. (7), by plotting the relation between ln(αE) vs ln(E-Eg), where m equals the slope of the linear fit as observed in Fig. 5d. The obtained value of m was about 0.49 (~ 0.5) leading to a direct transition.

3.2 Device characterization

3.2.1 Electronic properties of Ag/PVA: PVP@Ni(OAc)2/Si/Al MPS junction

Current–voltage (I-V) measurements under forward and reverse bias voltages are considered a powerful approach for exploring the electronic anatomy of the designed Schottky diode and providing information about the diode’s characteristics such as its barrier height, ΦB, ideality factor, n, rectification ratio, RR, and reverse saturation current, Is. Figure 6a and b illustrate the effective role of the spin-coated nanocomposite interlayer film of PVA: PVP@Ni(OAc)2 on the performance of both Ag/p-Si and Ag/n-Si, respectively. Customary semilogarithmic I-V relations of the Schottky diode under ± 3 V sweep voltage range are demonstrated. The deviation of the current performance from the linearity in the high voltage region is ascribed to the role of the series resistance, Rs [59]. It can be observed that the insertion of the PVA: PVP@Ni(OAc)2 interlayer suppressed the reverse dark current significantly by ~ 78% at -3 V and enhanced the forward current of the Ag/p-Si by ~ 30% at + 3V. Meanwhile, both forward and reverse currents of the Ag/n-Si have been suppressed upon inserting the polymeric nanocomposite interlayer, especially in the high bias regions > ± 1 V. Furthermore, the (I-V) curves clearly show that the fabricated devices possess remarkable rectifying properties, especially when p-type Si is utilized, as it is demonstrated when calculating the rectifying ratio, RR, as depicted in Fig. 7.

3.2.2 Microelectronic parameters using the TE model

Following the assumptions of Thermionic emission theory (TE) of Richardson and Dushman, the microelectronic parameters of the fabricated MS and MPS Schottky diodes (SDs) that govern the flow of current through the device can be estimated via fitting the low bias forward bias (I-V) data at (V ≥ 3kBT/q) by TE relation, where the voltage-dependent diode’s current can be expressed as a function of temperature, T, as follows [10, 36]:

where Is is the saturation current, q is the electron charge, VD = (V-IRs) is the diode voltage drop, V is the applied voltage, Rs is the series resistance, kB is Boltzmann constant, and n is the ideality factor which is a parameter that quantifies how closely a diode adheres to ideal behavior. The ideality factor can be determined by analyzing the slope of the linear part of the lnI-V plot, using the following relationship [10, 36]:

Besides, the reverse saturation current which refers to the current that flows across a diode in the absence of an applied voltage, due to the thermal generation of minority carriers, can be extracted from the intercept of the linear part of the lnI-V plot at zero bias and can be given by [10, 36]:

where A is the device’s effective area, A* is the effective Richardson constant and ΦB0 is the zero-bias barrier height. Table 1 displays the calculated values for the electrical parameters Is, n, and ΦB0, Rs, utilizing p-type Si and n-type Si for both MS and MPS structures. The nonideality of MS and MPS devices in the case of p-Si (i.e., n > one) may be attributed to several factors including series resistance (Rs), heterogeneous barriers, tunneling current, the presence of interlayers, and the density of surface states [36, 39, 42, 59]. Meanwhile, in the case of n-Si, the fabricated devices almost exhibit ideal behavior with n ~ 1. The ideality deviation of MPS (p-Si) rather than other MPS of (n-Si) may be ascribed to the large Fermi level pinning in the case of p-Si rather than n-Si which affects the charge accumulation in the depletion region causing a recombination of charge carriers yielding a nonideal behavior. For p-type Si with an added polymeric interlayer, both the barrier height and ideality factor are observed to decrease. A decrease in the depletion region, caused by doping and leading to an increase in the density of charge carriers and an increase in surface states between the interfacial polymeric layer and semiconductor., is primarily responsible for the reduction observed in the ideality factor and barrier height [60,61,62]. The reason why MPS-type structures exhibit a higher ΦB0 compared to MS structures utilizing n-Si can be attributed to an increase in negative charges at the interface. These negative charges are likely generated by electron traps that are localized at the semiconductor interlayer [63, 64].

Besides, owing to the effectiveness of both parasitic series resistance, Rs, and shunt resistance, Rsh, on the electrical performance of the fabricated device, it was crucial to estimate their values. A diode with a high series resistance will experience a decrease in direct current, deteriorating its efficiency. Conversely, a diode with a high shunt resistance will experience a decrease in leakage current, increasing rectification [65]. The estimated values of both Rs and Rsh from the maximum and minimum values of junction resistance, Rj, under reverse and forward biasing cases, respectively, have been listed in Table 1. As observed both Rs and Rsh have been increased by incorporating the (Ni(OAc)2) interlayer at the Ag/Si interface.

3.2.3 Microelectronic parameters using modified Norde’s model

The modified Norde method is also a widely used approach for measuring the barrier height, ΦB0, and the series resistance, Rs, of metal-polymer-semiconductor (MPS) structures which can be proposed as [37, 42, 66]:

where F(V) is defined as the derivative of the current–voltage (I-V) curve of the Schottky barrier diode, β = q/kBT, and the parameter γ is an integer without units, and it must be selected such that it is greater than the ideality factor n. In the Norde method, the values of ΦB0 and Rs are obtained using Eqs. (13a) and (13b), respectively.

where F(Vmin) is the minimum value of the F(V)-V plot which is obtained by plotting F(V) versus voltage (V) as depicted in Fig. 8a and b for p-Si, and n-Si, respectively, while Vmin and Imin are the corresponding voltage and current values, respectively. The obtained values of Rs and ΦB0 are recorded in Table 1. The little observed differences between the estimated barrier height values from TE and modified Norde’s method may be ascribed to the voltage dependence nature of barrier height, while the significant discrepancy in series resistance values is attributed to the difference of the utilized biasing region, where Norde is applied for the whole forward bias region, while TE is applied in the linear low forward bias region only [20, 37, 67].

3.2.4 Microelectronic parameters using the Cheung–Cheung model

The Cheung and Cheung functions can be utilized as an alternative approach to determine values for Rs, n, and ΦB0. These parameters can be calculated by applying the following relationships [65, 68]:

The curves for dV/dln(I)–I and H(I)–I for MS and MPS are presented in Fig. 9, revealing the behavior of p-type Si in (a) and (c), and n-type Si in (b) and (d). The values for Rs and n were derived from the slope and intercept, respectively, of the dV/d(lnI)-I plot using Eq. (14a) for the given structures. Likewise, the values for Rs and ΦB0 were obtained from the slope and intercept, respectively, of the H(I)-I plot using Eq. (14a). These experimental values have been compiled and are presented in Table 1. As shown, there is a significant variance in the aforementioned parameters, highlighting the fact that their values are shaped not only by surface states, Nss, and the interfacial layer but also by the voltage applied [69].

3.2.5 Conduction mechanism under forward bias

The mechanistic approach at which the charge carriers transport depends on the bias whether it is forward or reverse. Under forward biasing, the conduction mechanism of charge carriers within the designed devices has been evaluated via the double logarithmic relation of the current–voltage relation shown in Fig. 10a and b. As observed, each diode possesses several linear regions of different slope values yielding different conduction mechanisms. The slope of the low bias region (VF < 0.2 V) in all the fabricated diodes ~ 1 ensures the dominance of the ohmic conduction mechanism, where net current arises from the thermally generated electron–hole (e–h) pairs regardless of the charge injection contribution. Meanwhile, in the second region (0.2 V < VF < 1.1 V) the linear I-V relation has been converted to the power law of slope ~ 1.93 and 2.82 for Ag/p-Si (D1) and Ag/n-Si (D3), respectively. This gives rise to single dominating trap SCLC and trap charge limited current (TCLC) of exponential distribution of trap states for D1 and D3, respectively. The space charge limited current mechanism depends on the trapping and accumulation of the injected charge carriers at the junction, hence upon varying the applied bias the electric field profile charges and thereafter changes the drifting component accumulated charges [70,71,72]. These trapping states may arise from intrinsic microstructure disorder and defects or due to interfacing imperfections. In the case of D1, at region (1.1 V < VF < 3 V) the slope ~ 2.52 indicates that all the existing traps have been filled and now the conduction mechanism is a trap-free SCLC. The low slope ~ 0.13 of D3 at region (VF > 2.5 V) is ascribed to the limited software of the employed electrometer. Upon inserting the nanocomposite film as an interlayer, the density of interface trapping states has been increased yielding continuous exponential trapping states assist SCLC over the whole bias range as observed from the estimated slopes 1.40 and 1.45 for D2 and D4, respectively [27, 28, 73]. Besides, it is well known that charge carriers in polymer nanocomposites prefer to transport via hoping between the localized trap states, thereby the charges hop between the localized trap states that are developed by the doping process or by structural defects [38].

3.2.6 Conduction mechanism under reverse bias

The charge transport mechanism under the reverse bias of the designed MS and MPS can be interpreted in the light of Schottky or Pool–Frenkel emission mechanisms. Schottky emission is an electrode-limited mechanism that results when the electron overcomes the interfacial barrier after gaining enough thermal energy to be injected from/to the metal to/from the conduction band p-Si/n-Si passing by the dielectric layer. The lowering of potential barrier height at the metal/dielectric interface arises from the image force effect [70, 71]. Accordingly, the voltage dependence of the reverse current in terms of Schottky emission is given by [70, 71]:

where εi and εo are the electric permittivities of insulating material and free space, respectively, while E is the electric field.

In contrast, Poole–Frenkel is a bulk-limited mechanism that depends mainly on the electrical properties of the dielectric itself. Poole–Frenkel involves the thermal emission of the trapped charge carriers (de-trapping) from the localized trapping states into the conduction band owing to the lowering of the coulombic energy barrier by the effect of the local electric field within the depletion region. Hence, the Poole–Frenkel current can be expressed as follows [70, 71, 74]:

where μ is the electronic drift mobility, ΦT is the trap barrier, and NC is the conduction band density of states. Thereby, the relation between V 1/2 and lnIR has been plotted for all the fabricated MPS diodes as revealed in Fig. 11a and b. Depending on the estimated slopes of the illustrated linear fitting, the obtained values of the lowering factor for D2 were about 7.69 × 10–5 eV. m1/2.V1/2 and 2.84 × 10–5 eV. m1/2.V1/2 for the low and high bias regions, while the obtained values of the lowering factor for D4 were about 1.27 × 10–4 eV. m1/2.V1/2 and 4.94 × 10–5 eV. m1/2.V1/2 for the low and high bias regions, respectively. Theoretically, the estimated values of Poole–Frenkel and Schottky lowering factor (\(= \sqrt {q^{3} /\eta \pi \varepsilon_{i} \varepsilon_{o} }\), η = 1 and 4 for SC and PF, respectively) are about 3.65 × 10–5 eV. m1/2.V1/2 and 1.82 × 10–5 eV. m1/2.V1/2, respectively. These findings suggest the dominance of the Schottky emission mechanism in the low bias region (0.85 < VR < 0) V for p-Si and (0.80 < VR < 0) V for n-Si MPS devices, respectively. In addition to the dominance of the Poole–Frenkel mechanism in the high bias region (3.00 < VR < 0.85) V for p-Si and (3.00 < VR < 0.80) V for n-Si MPS devices, respectively. The discrepancy between the calculated and experimental values of lowering factors may arise from the small width of the depletion region in PVA: PVP@(NiOAc)2 film or because of the phonon-assisted tunneling mechanism of charges through the energy barrier [74, 75].

3.2.7 Interface states density

To strengthen the significant role of the interlayered PVA: PVP@(NiOAc)2 film on the performance of the fabricated MPS, the energetic interface states density profile with respect to the top of valance band and the minimum of conduction band for p-Si and n-Si devices, respectively, should be estimated. Hence, according to the variation of effective barrier height with respect to voltage, dΦe/dV, with ideality factor as a function of voltage, n (V) [75,76,77,78,79]:

The effective barrier height, Φe, can be deduced from the estimated zero-bias barrier height, ΦB, as follows [75,76,77,78,79]:

Considering the high thickness of the embedded interlayer of thickness, d, the interface states density, Nss, can be expressed as follows [75,76,77,78,79]:

The energetic position of the interface states density with respect to the top valance band, Ess–Ev, or with respect to the bottom of the conduction band, EC–Ess, for p-Si and n-Si based devices, respectively, can be expressed as follows [75,76,77,78,79]:

Therefore, the energetic profiles of the estimated interface states density of the fabricated junctions have been plotted as shown in Fig. 12a and b. It can be observed that the insertion of nanocomposite film increased the interface states density significantly for both types of diodes. Furthermore, the energetic position of the interface states has been shortened. Since it can be noticed that after inserting the nanocomposite thin film into the Ag/p-Si/Al device, the distribution of interface states density has been limited to Ess–Ev in the range (0.50–0.66) eV, while regarding the n-Si device, the distribution of interface states density has been limited to Ev–Ess in the range (0.54–0.63) eV. It can be also observed that the insertion of the nanocomposite polymer film increased the density of interface states, especially in the energetic positions near the top of the valance band and bottom of the conduction band for p-Si and n-Si, respectively, while as far as the interface state, as their density descends. This also explains the increment of the series resistance upon inserting the polymeric nanocomposite films.

3.3 Light detection properties of Ag/PVA: PVP@Ni(OAc)2/p-Si/Al MPS junction

Based on the obtained results and the observed behavior of our fabricated Ag/PVA: PVP@Ni(OAc)2/p-Si/Al junction such as its high rectification ratio, and quasi-voltage independence of the reverse current behavior suggesting the good passivation of the silicon surface, it can be considered as a promising candidate for light detection applications surface.

3.3.1 Current–voltage relation under illumination

After that, the response of the prepared junction to the change in the intensity of the incident light from a halogen lamp source at room temperature was examined, as shown in Fig. 13. When the device is illuminated, its behavior can change due to photo-excitations, which generates charge carriers in the deep depletion region. These charge carriers can tunnel through the interfacial layer between the Ag electrode and the p-Si, resulting in a slight increase in forward currents compared to dark current [39], as depicted in Fig. 13. When a reverse bias voltage is applied, the depletion region of a device increases, which results in a larger photosensitive area. This, in turn, leads to the formation of more electron–hole pairs, thereby increasing the photoconductivity of the device [20, 44]. Consequently, the number of charge carriers generated is directly proportional to the intensity of the incident light, leading to an increase in the reverse bias current as shown in Fig. 13. The device under consideration exhibits exceptional sensitivity to light and delivers a consistent output in response to varying light intensities. This noteworthy attribute renders it invaluable in optoelectronic applications, particularly in the design of photodiodes and photodetectors.

In the quest to enhance the efficiency of MPS devices, various approaches have been implemented. These include fine-tuning the interfacial characteristics between the polymer and semiconductor layers, incorporating interfacial layers to augment charge separation, and modifying the surface chemistry of the layers to bolster charge transfer. Such strategies are instrumental in improving the effectiveness of charge separation and transport mechanisms, resulting in amplified photocurrent densities and superior overall performance of the device. The phenomenon of photocurrent density, Jphoto, in MPS devices arises from the absorption of photons, which generates electron–hole pairs within the material. An electric field can subsequently separate these pairs of electrons and holes, producing a measurable current [79, 80]. The correlation between photocurrent density, Jphoto, and incident light intensity under reverse bias is shown in Fig. 14a using the following relation [32]:

where Ilight and Idark correspond to the currents with and without illumination, respectively and A is the area exposed to the light.

The remarkable stability of the reverse photocurrent density as shown in the figure, coupled with its noticeable rise in response to increasing light intensity, highlights the immense potential of this architecture in various optoelectronic applications. To gain insights into the photoconductivity mechanism, which is largely influenced by the interfacial layer, it is imperative to analyze the effect of trapping states in the materials constituting the photodetector on the dominant recombination mechanism. In this regard, plotting a graph of photocurrent density (lnJphoto) against light intensity (lnP), as depicted in Fig. 14b, can be extremely helpful. The relationship between these two parameters can be described by the following equation [81]:

where C is a constant and ζ is the exponent coefficient and indicative of the densities of uninvaded trap levels at lower concentrations and can be derived from the linear slope of the ln(Jphoto) vs ln(P) curve. As shown in the figure, Jphoto increases with increasing P which can be explained by the formation of electron–hole pairs. Upon analysis of the slope, the determined γ value was observed to exceed unity, which is indicative of a reduced density of unoccupied trap levels that are exponentially distributed which controls the recombination mechanism [82, 83].

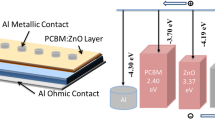

The band diagram of an MPS-structured device is essential for understanding its electronic properties, such as carrier transport and photovoltaic behavior which is depicted in Fig. 15. This interfacial layer serves as a barrier that prevents the injection of charge carriers from Ag into the semiconductor. The height of this barrier is influenced by the work function of the metal and the alignment of the energy bands at the interfaces between Ag, Ni(OAc)2, and P-Si layers. When it comes to injecting holes from the Ag into a p-Si layer, the height of the barrier must be less than the difference in energy between the Fermi level of the metal and the highest energy level in the valence band of the p-Si layer. To inject photo-generated holes into the p-Si layer in optoelectronic devices, two mechanisms can be used: direct tunneling through the polymer or carrier transport through interface states. The effectiveness of hole injection is dependent on the energy distribution of the photo-generated holes and the density of interface states [8, 84]. The presence of more interface states can facilitate hole injection by creating additional routes for carrier transport. Moreover, the narrower energy distribution of the photo-generated holes can enhance the injection efficiency by minimizing carrier scattering and recombination. Thus, optimizing the interface state density and energy distribution of photo-generated holes is critical for efficient hole injection in p-Si-based optoelectronic devices [85, 86].

When the MPS device is illuminated, photo-generated electrons (e−) and holes (h+) can be injected into the p-Si layer. The injection of these carriers depends on their concentration, mobility, and band alignment at the p-Si/insulator interface. Because p-Si has a higher concentration of holes, it is anticipated that the injection of photo-generated electrons into the p-Si will be more significant than the injection of holes. This is due to the electrons being injected into a lower concentration of carriers, allowing for more efficient transport and less recombination. On the other hand, the injection of photo-generated holes into the p-Si may be impeded by their lower mobility compared to electrons, as well as the potential barrier at the p-Si/insulator interface. This potential barrier can prevent the holes from reaching the p-Si layer and cause them to accumulate at the interface, resulting in carrier recombination. As a result, the injection of photo-generated electrons from an illuminated p-Si layer is generally expected to be higher than the injection of photo-generated holes into the p-Si layer. Nevertheless, the exact injection efficiency of these carriers will depend on various factors, such as the doping level of the p-Si, the thickness of the interfacial layer, and the intensity and wavelength of the incident light [10].

3.3.2 Photodetection parameters of the light detector

The photodetector plays an extremely crucial function as the eyes of a photoelectric system. Most photodetectors are devices that convert the absorbed light energy and generate electrical signals, that can be further processed or stored. Therefore, there will naturally be some parameters that characterize this conversion process. These parameters can be considered as quality indicators of a photodetector for particular applications. These parameters include responsivity, R, as a measure of the output signal produced by the detector in response to the incident light, detectivity, D*, which characterizes its ability to detect a weak optical signal, linear dynamic range, LDR, is defined by the response of the detector to produce a linear output signal over a range of input optical powers, signal-to-noise ratio, SNR, represent the ratio of the detector’s output signal to the level of noise present in the signal, noise equivalent power, NEP, define the minimum detectable power of the detector, and noise current, IN, as the current that flows through a photodetector due to random fluctuations in the detector’s internal properties, such as thermal noise, shot noise, and flicker noise. The preceding characteristic parameters of the photodetector and their corresponding values can be expressed and determined using the following relations, respectively [39, 87]:

The relationship between reverse biasing voltages at various illumination intensities and the parameters R, D*, LDR, SNR, NEP, and IN is presented in Fig. 16a–f. By measuring these parameters, researchers and engineers can determine the suitability of different light detectors for specific applications, as well as optimize their performance to achieve reliable and accurate measurements. Table 2 illustrates the superiority of the present MPS device relative to other many organic/Si devices.

3.3.3 Temporal On–Off switching behavior

The On–Off switching behavior is characterized by a rapid surge in current upon illumination, followed by a gradual decay once the light source is turned off. The decay can be attributed to the slow recombination of charge carriers within the semiconductor layer, resulting in a gradual decrease in current. The temporal On–Off switching behavior is highly advantageous for optoelectronic applications as it enables the detection of short-duration light pulses and the capacity to regulate the device’s response time. Moreover, the switching behavior can be modulated by adjusting the properties of the MPS layers, such as the doping concentration and thickness, or by altering the illumination conditions [88]. To study the response time of the photodetector to incident light signals, the temporal On–Off switching characteristics of the prepared Ag/PVA: PVP@ Ni(OAc)2/p-Si/Al device were studied as shown in Fig. 17 at a bias voltage of − 3 V, a frequency of 0.05 Hz, and choppered square light signals with different intensities. Based on the obtained results, it can be concluded that the photodetector exhibited a rapid, steady, and consistent On–Off switching response at all levels of illumination. To evaluate the operational speed of the fabricated photodetector in response to a light signal, it is necessary to calculate the rise time (trise) and decay time (tdecay). Table 2 illustrates that as the light intensity increases from 20 to 100 mW/cm2, the estimated rise time decreases from 621 to 76.4 ms, and the decay time decreases from 140 to 77.1 ms. This information reveals that the photodetector’s response time improves as the light intensity increases. This is an essential characteristic for optoelectronic devices that require a fast response time, such as in optical communication and sensing applications. According to the presented data, it can be observed that at illumination intensities below 60 mW/cm2, the rise time is longer than the decay time. This discrepancy can be attributed to the limited number of photogenerated carriers that may be trapped by the trapping levels, which could be a result of the defects present in the Ni(OAc)2 interlayer. On the other hand, at higher intensities (≥ 60 mW/cm2), the rise time is shorter than the decay time. This could be attributed to the dependence of the decay time on the discharge of junction capacitance and electron–hole recombination, while the rise time depends on the occupation of trap levels. Due to the larger effective mass and lower mobility of holes compared to electrons, the decay time takes longer than the rise time [39]. Therefore, the observed phenomenon can be explained by the difference in carrier mobility and the presence of trapping levels in the Ni(OAc)2 interlayer.

4 Conclusions

Thin films based on PVA: PVP@Ni(OAc)2 nanostructured composite have been successfully prepared on quartz and silicon substrates. On the scale of the structural investigations, the prepared films showed a relatively smooth surface with nanoplatelet structures and an amorphous SAED pattern. The optical measurements declared sufficient high UV and visible light absorption and several approaches have confirmed the values of energy gaps. Meanwhile, the insertion of the prepared nanocomposite film in an MPS-structured device achieved a remarkable improvement of the junction characteristics based on the estimated parameters from TE, Norde’s, and Cheung-Cheung’s models. The conduction mechanisms of the designed junction under forward and reverse bias have been conclusively interpreted in detail. For light detection applicability, the fabricated Ag/ PVA: PVP@Ni(OAc)2/p-Si showed superior sensitivity for light intensity variations and fast response for variation of the illumination state between On and Off. Comparatively, the present device achieved high photodetection performance relative to other organic/Si heterojunction photodetectors which increases its potentiality for applications. Futuristically, the photoconductivity of the designed interlayer may be improved by incorporating graphene quantum dots for the matrix which will be performed in our future work.

Data availability

All data generated or analyzed during this study are included in this published article.

References

H. Kroemer, Nobel lecture: quasi electric fields and band offsets: teaching electrons new tricks. Rev. Mod. Phys. 73, 783–793 (2001)

A. Vilan, D. Cahen, Chemical modification of semiconductor surfaces for molecular electronics. Chem. Rev. 117, 4624–4666 (2017)

A. Chasin, S. Steudel, F. Vanaverbke, K. Myny, M. Nag, T.H. Ke, S. Schols, G. Gielen, J. Genoe, P. Heremans (2012) UHF IGZO Schottky diode, IEEE, International Electron Devices Meeting, San Francisco, pp. 12.4.1–12.4.4.

R. Trevisoli, H.P. da Paz, V.S. da Silva, R.T. Doria, I.R.S. Casella, C.E. Capovilla, Modeling Schottky diode rectifiers considering the reverse conduction for RF wireless power transfer. IEEE Trans Circ. Syst. II: Express Briefs 69(3), 1732–1736 (2022)

X. Kong, L. Zhang, B. Liu, H. Gao, Y. Zhang, H. Yan, X. Song, Graphene/Si Schottky solar cells: a review of recent advances and prospects. RSC Adv. 9, 863–877 (2019)

E.A. Kerimov, Study of photodetectors with Schottky barriers based on the IrSi–Si contact. Russ. Microelectron. 52, 32–34 (2023)

P. Ji, S. Yang, Y. Wang, K. Li, Y. Wang, H. Suo, Y.T. Woldu, X. Wang, F. Wang, L. Zhang, Z. Jiang, High-performance photodetector based on an interface engineering-assisted graphene/silicon Schottky junction. Microsyst. Nanoeng. 8, 9 (2022)

R.T. Tung, The physics and chemistry of the Schottky barrier height. Appl. Phys. Rev. 1, 011304 (2014)

N.A. Al-Ahmadi, Metal oxide semiconductor-based Schottky diodes: a review of recent advances. Mater. Res. Express 7, 032001 (2020)

S.M. Sze, Physics of semiconductor devices, 2nd edn. (Willey, New York, 1981)

C.-M. Kang, K.H. Shin, C. Lee, High-frequency organic rectifiers through interface engineering. MRS Commun 7, 1–15 (2017)

M. Labed, J.Y. Min, J.Y. Hong, Y.-K. Jung, S. Kyoung, K.W. Kim, K. Heo, H. Kim, K. Choi, N. Sengouga, Y.S. Rim, Interface engineering of β-Ga2O3 MOS-type Schottky barrier diode using an ultrathin HfO2 interlayer. Surf. Interfaces 33, 102267 (2022)

X. Ma, Y. Dai, L. Yu, B. Huang, Interface Schottky barrier engineering via strain in metal–semiconductor composites. Nanoscale 8, 1352–1359 (2016)

C.V. Prasad, J.H. Park, J.Y. Min, W. Song, M. Labed, Y. Jung, S. Kyoung, S. Kim, N. Sengouga, Y.S. Rim, Interface engineering of p-type quaternary metal oxide semiconductor interlayer-embedded β-Ga2O3 Schottky barrier diode. Mater. Today Phys. 30, 100932 (2023)

B. Arslan, S.O. Tan, İ Orak, H.U. Tecimer, Comparative study of the effect of different interlayer thicknesses on frequency dependent electric modulus and conductivity in Au/ n-Si structures. Thin Solid Films 738, 138968 (2021)

L. Zhao, H. Liu, X. Wang, Y. Wang, S. Wang, Electrical properties and interfacial issues of HfO2/Ge MIS capacitors characterized by the thickness of La2O3 interlayer. Nanomaterials 9, 697 (2019)

X. Yang, Y. Gu, M.A. Migliorato, Y. Zhang, Impact of insulator layer thickness on the performance of metal–MgO–ZnO tunneling diodes. Nano Res. 9(5), 1290–1299 (2016)

S.E. Ali, A.R. Wassel, A.M. El-Mahalawy, Novel BixLa1-xMnyCo1-yO3 nanocrystalline perovskite based MIS Schottky UV photodetector device. Mater. Res. Bull. 161, 112154 (2023)

A. Cherif, S. Alotaibi, H. Saghrouni, L. Beji, Improvement of physical properties of MOS devices based on rare earth oxides. AIP Adv. 13, 025042 (2023)

E. Daş, U. Incekara, Ş Aydŏgan, A comparative study on electrical characteristics of Ni/n-Si and Ni/p-Si Schottky diodes with Pinus Sylvestris Resin interfacial layer in dark and under illumination at room temperature. Opt. Mater. 119, 111380 (2021)

F. Yıldırım, M. Yilmaz, U. Incekara, Ş Aydŏgan, On the investigation of the electro-optical sensor potential of Boswellia serrata resin. Opt. Mater. 117, 111154 (2021)

Z. Orhan, M. Yilmaz, Ş Aydoğan, M. Taskin, U. Incekar, Improving light-sensing behavior of Cu/n-Si photodiode with human Serum albumin: microelectronic and dielectric characterization. Optik—Int. J for Light Electron Optics 241, 167069 (2021)

M.S. Salem, A.R. Wassel, M. Fedawy, A. Shaker, A.H. Al-Bagawia, A. Alanazi, A.M. El-Mahalawy, Elucidation the effectiveness of acridine orange as light-harvesting layer for photosensing applications: structural, spectroscopic and electrical investigations. Opt. Mater. 133, 112928 (2022)

M.S. Salem, A.R. Wassel, M. Fedawy, A. Shaker, A.H. Al-Bagawia, G.M. Aleid, A.M. El-Mahalawy, Integration of biocompatible Coomassie brilliant blue dye on silicon in organic/inorganic heterojunction for photodetection applications. J. Phys. Chem. Solids 169, 110890 (2022)

F. Yıldırım, Z. Orhan, Ş Aydoğan, UV–Visible photovoltaic detector based on biomaterial-inorganic semiconductor in the propolis/n-Si heterojunction configuration. Mater. Res. Bull. 159, 112113 (2023)

E. Daş, Z. Orhan, Ş Aydoğan, B. Güzeldir, Fabrication and characterization of Al/n-Si/Al schottky diode with rGO interfacial layer obtained by using spin coating method. Mater. Today: Proc. 46, 6899–6903 (2021)

A. Tataroglu, A.B. Ulusan, Ş Altındal, Y.A. Kalandaragh, A compare study on electrical properties of MS diodes with and without CoFe2O4-PVP interlayer. J. Inorg. Organomet. Polym. Mater. 31, 1668–1675 (2021)

A. Tataroğlu, Ş Altındal, Y.A. Kalandaragh, Comparison of electrical properties of MS and MPS type diode in respect of (In2O3-PVP) interlayer. Physica B 576, 411733 (2020)

S. Alptekin, A. Tataroğlu, Ş Altındal, Dielectric, modulus and conductivity studies of Au/PVP/n-Si (MPS) structure in the wide range of frequency and voltage at room temperature. J. Mater. Sci. Mater. Electron. 30, 6853–6859 (2019)

A. Tataroğlu, Ş Altındal, Y.A. Kalandaragh, Electrical and photoresponse properties of CoSO4-PVP interlayer based MPS diodes. J. Mater. Sci. Mater. Electron. 31, 11665–11672 (2020)

M. Ulusoy, Ş Altındal, P. Durmuş, S. Özçelik, Y.A. Kalandaragh, Frequency and voltage-dependent electrical parameters, interface traps, and series resistance profile of Au/(NiS:PVP)/n-Si structures. Mater Sci.: Mater Electron 32, 13693–13707 (2021)

S. Khalili, H.M. Chenari, F. Yıldırım, Z. Orhan, Ş Aydoğan, Highly sensitive, self-powered photodetector based on reduced graphene oxide- polyvinyl pyrrolidone fibers (Fs)/p-Si heterojunction. J. Alloys Compd. 889, 161647 (2021)

A.S. Namini, M.S. Asl, G.P. Givi, S.A. Delbari, J. Farazin, Ş Altındal, Y.A. Kalandaragh, On the electrical characteristics of Al/p-Si diodes with and without (PVP: Sn-TeO2) interlayer using current–voltage (I–V) measurements. Appl. Phys. A 126, 935 (2020)

A.B. Ulusan, A. Tataroglu, Ş Altındal, Y.A. Kalandaragh, Photoresponse characteristics of Au/(CoFe2O4-PVP)/n-Si/Au (MPS) diode. J. Mater. Sci. Mater. Electron. 32, 5732–15739 (2021)

S. Demirezen, S.A. Yerişkin, A detailed comparative study on electrical and photovoltaic characteristics of Al/p-Si photodiodes with coumarin-doped PVA interfacial layer: the effect of doping concentration. Polym. Bull. 77, 49–71 (2020)

E.E. Baydilli, S.O. Tan, H.U. Tecimer, Ş Altındal, Detection of current transport mechanisms for graphene-doped-PVA interlayered metal/semiconductor structures. Physica B 598, 412457 (2020)

O. Çiçek, H.U. Tecimer, S.O. Tan, H. Tecimer, Ş Altındal, İ Uslu, Evaluation of electrical and photovoltaic behaviours as comparative of Au/n-GaAs (MS) diodes with and without pure and graphene (Gr)-doped polyvinyl alcohol (PVA) interfacial layer under dark and illuminated conditions. Compos. B Eng. 98, 260–268 (2016)

A.M. El-Mahalawy, M. Abd-El Salam, Fabrication and photoresponse characteristics of high rectification photodetector based on methyl violet nanoparticles-PVA/p-Si heterojunction for optoelectronic applications. Appl. Phys. A 126, 393 (2020)

A.M. Nawar, A.M. El-Mahalawy, Heterostructure device based on brilliant green nanoparticles–PVA/p-Si interface for analog–digital converting dual-functional sensor applications. J. Mater. Sci. Mater. Electron. 31, 3256–3273 (2020)

H. Tecimer, T. Tunç, Ş Altındal, Investigation of photovoltaic effect on electric and dielectric properties of Au/n-Si Schottky barrier diodes with nickel (Ni)–zinc (Zn) doped organic interface layer. J. Mater. Sci. Mater. Electron. 29, 3790–3799 (2018)

Ş Aydoğan, M. Sağlam, A. Türüt, On the barrier inhomogeneities of polyaniline/p-Si/Al structure at low temperature. Appl. Surf. Sci. 250, 43–49 (2005)

A.R. Deniz, A.İ Tas, Z. Çaldıran, Ü. Incekara, M. Biber Aydŏgan, A. Türüt, Effects of PEDOT:PSS and crystal violet interface layers on current-voltage performance of Schottky barrier diodes as a function of temperature and variation of diode capacitance with frequency. Curr. Appl. Phys. 39, 173–182 (2022)

E. Yükseltürk, M. Çotuk, M.M. Bülbül, Ş Altındal, S. Zeyrek, On the profile of temperature dependent main electrical parameters in Al/P3HT/p-Si (MPS) structures at low temperatures. Mater. Today: Proc. 18, 1852–1860 (2019)

S. Demirezen, H.G. Çetinkaya, M. Kara, F. Yakuphanoğlu, Ş Altındal, Synthesis, electrical and photo-sensing characteristics of the Al/(PCBM/NiO:ZnO)/p-Si nanocomposite structures. Sens. Actuators A: Phys. 317, 112449 (2021)

Ş Karata, Ş Altındal, M. Ulusoy, Y.A. Kalandaragh, S. Özçelik, Temperature dependence of electrical characteristics and interface state densities of Au/n-type Si structures with SnS doped PVC interface. Phys. Scr. 97, 095816 (2022)

M. Ulusoy, Ş Altındal, Y.A. Kalandaragh, S. Özçelik, Z.M. Kalar, The electrical characteristic of an MIS structure with biocompatible minerals doped (Brushite+Monetite: PVC) interface layer. Microelectron. Eng. 258, 111768 (2022)

H. Kacus, Ş Aydoğan, U. Incekara, M. Yilmaz, M. Biber, On thermal and optical sensor applications of chitosan molecule in the Co/Chitosan/p-Si hybrid heterojunction design. J. Mater. Sci. Mater. Electron. 32, 6586–6597 (2021)

R.O. Ocaya, I. Erol, A.G. Al-Sehemi, A. Dere, A.A. Al-Ghamdi, F. Yakuphanoğlu, ZnO-doped PFPAMA: a novel transparent conducting polymer for fast photodiodes. J. Mater. Sci. Mater. Electron. 33, 24803–24818 (2022)

Ş Altındal, A.F. Özdemir, Ş Aydoğan, A. Türut, Discrepancies in barrier heights obtained from current–voltage (IV) and capacitance–voltage (CV) of Au/PNoMPhPPy/n-GaAs structures in wide range of temperature. J. Mater. Sci. Mater. Electron. 33, 12210–12223 (2022)

A.M. El-Mahalawy, M.M. Abdrabou, S.A. Mansour, F.M. Ali, Appreciably optimization of PVA/PVP nanocomposite blend for enhanced optoelectronics properties and multifunctional applications. Physica B 650, 414586 (2023)

P.A. Narayana, A. Mehra, P. Venkateswarlu, Electronic absorption spectrum of nickel acetate tetrahydrate. Can. J. Phys. 46, 1705–1709 (1968)

J.L. Rao, G.L. Narendra, S.V.J. Lakshman, Optical absorption spectra of cobalt(II) and nickel ions in lead acetate glasses. Polyhedron 9(12), 1475–1477 (1990)

A. Faramawy, H. Elsayed, C. Scian, G. Mattei, Structural, optical, magnetic and electrical properties of sputtered ZnO and ZnO: Fe thin films: the role of deposition power. Ceramics 5, 1128–1153 (2022)

M. Behera, An intensive study on the optical, rheological, and electrokinetic properties of polyvinyl alcohol-capped nanogold. Int Nano Lett. 5, 161–169 (2015)

R.M. Ahmed, Optical properties and structure of cobalt chloride doped PVA and its blend with PVP. Int. J. Mod. Phys. B 28(5), 1450036 (2014)

M. Isik, N. Gasanly, Analysis of optical constants and temperature-dependent absorption edge of GaS0.75Se0.25 layered crystals. Mater. Res. Bull. 90, 280–284 (2017)

M. Isik, N. Gasanly, Composition-tuned band gap energy and refractive index in GaSxSe1-x layered mixed crystals. Mater. Chem. Phys. 190, 74–78 (2017)

J. Tauc, A. Menth, States in the gap. J. Non-Cryst. Solids 8, 569–585 (1972)

M.A.M. Ahmed, W.E. Meyer, J.M. Nel, Investigation of the structural and temperature-dependent electrical properties of MZnO (M = Ce and Sm) Schottky diode devices fabricated using the sol–gel spin-coating technique. J. Mater. Sci. Mater. Electron. 34, 1312 (2023)

S. Alialy, H. Tecimer, H. Uslu, Ş Altındal, A comparative study on electrical characteristics of Au/N-Si Schottky diodes, with and without Bi-doped PVA interfacial layer in dark and under illumination at room temperature. Nanomed. Nanotechnol. 4, 1000167–1000173 (2013)

A.B. Uluşan, A. Tataroğlu, Y.A. Kalandaragh, M. Koşal, Double-exponential current-voltage (I–V) and negative capacitance(NC) behavior of Al/(CdSe-PVA)/p-Si/Al (MPS) structure. J. Mater. Sci. Mater. Electron. 30, 9572–9581 (2019)

Ç.Ş Güçlü, E. Erbilen Tanrıkulu, A. Dere, Ş Altındal, Y. Azizian-Kalandaragh, A comparison of electrical characteristics of the Au/n-Si Schottky diodes with (ZnCdS:GO(1:1) and (ZnCdS:GO(1:05) doped PVP interlayer using current–voltage (I–V) and impedance–voltage (Z–V) measurements. J. Mater. Sci. Mater. Electron. 34, 1909 (2023)

N. Baraz, İ Yücedağ, A. Demir, G. Ersöz, Ş Altındal, M. Kandaz, Controlling the electrical characteristics of Au/n-Si structure with and without (biphenyl-CoPc) and (OHSubs-ZnPc) interfacial layers at room temperature. Polm. Adv. Technol. 28(8), 952–957 (2017)

E. Arslan, S. Bütün, Y. Şafak, H. Uslu, I. Taşcıoğlu, Ş Altındal, E. Özbay, Electrical characterization of MS and MIS structures on AlGaN/AlN/GaN heterostructures. Microelectron. Reliab. 51, 370–375 (2011)

Y.A. Kalandaragh, J. Farazin, Ş Altindal, M.S. Asl, G.P. Givi, S.A. Delbari, A.S. Namini, Electrical and dielectric properties of Al/(PVP: Zn-TeO2)/p-Si heterojunction structures using current–voltage (I–V) and impedance-frequency (Z–f) measurements. Appl. Phys. A 126, 635 (2020)

H. Norde, A modified forward I-V plot for Schottky diodes with high series resistance. J. Appl. Phys. 7(50), 5052 (1979)

E. Erdogan, M. Yilmaz, S. Aydogan, U. Incekara, H. Kacus, Modification of barrier diode with cationic dye for high power applications. Optik 232, 166598 (2021)

S.K. Cheung, N.W. Cheung, Extraction of Schottky diode parameters from forward current-volatge characteristics. Appl. Phys. Lett. 49(2), 85–87 (1986)

Ç. Bilkan, S. Zeyrek, S.E. Şan, Ş Altındal, A compare of electrical characteristics in Al/p-Si (MS) and Al/C20H12/p-Si (MPS) type diodes using current–voltage (I–V) and capacitance–voltage (C–V) measurements. Mater. Sci. Semicond. Proces. 32, 137–144 (2015)

F.-C. Chiu, Review on conduction mechanisms in dielectric films. Adv. Mater. Sci. Eng. (2014). https://doi.org/10.1155/2014/578168

Y. C. Li, and S. C. Tjong, Nonlinear current–voltage characteristics in polymer nanocomposites in a properties and applications of polymer nanocomposites. Woodhead Publishing series in composites science and engineering (2010), pp 862–890. https://doi.org/10.1533/9780857090249.4.862

S. Eymur, N. Kaya, N. Tuğluoğlu, Observation of space charge limited current in Schottky diodes with V2O5 interfacial layer prepared by radio frequency magnetron sputtering. J. Adv. Appl. Sci. 1(1), 24–31 (2022)

N.A. Roslan, A. Supangat, S. Sagadevan, Investigation of charge transport properties in VTP: PC71BM organic Schottky diode. Electronics 11, 3777 (2022)

P. Pipinys, V. Lapeika, Analysis of reverse-bias leakage current mechanisms in metal/GaN Schottky diodes. Adv. Condens. Matter Phys. (2010). https://doi.org/10.1155/2010/526929

A.M. Nawar, M. Abd-Elsalam, A.M. El-Mahalawy, M.M. El-Nahass, Analyzed electrical performance and induced interface passivation of fabricated Al/NTCDA/p-Si MIS–Schottky heterojunction. Appl. Phys. A 126, 113 (2020)

I. Hussain, M.Y. Soomro, N. Bano, O. Nur, M. Willander, Systematic study of interface trap and barrier inhomogeneities using I-V-T characteristics of Au/ZnO nanorods Schottky diode. J. Appl. Phys. 113, 234509–234515 (2013)

B. Boyarbay, H. Çetin, A. Uygun, E. Ayyildiz, Electrical characterization and fabrication of organic/inorganic semiconductor heterojunctions. Appl. Phys. A 103, 89–96 (2011)

A. Ugur, A.G. Imer, Y.S. Ocak, Electrical and photoelectrical characterization of an organic–inorganic heterojunction based on quinolone yellow dye. Mat. Sci. Semicond. Proc. 39, 569–574 (2015)

F.M. Amin, A.R. Wassel, A.M. El-Mahalawy, Fabrication of organic-inorganic hybrid device for optoelectronic applications: charge carriers dynamics and photoresponse assessment. Synt. Met. 292, 117210 (2023)

H. Guo, H.-Y. Niu, W.-J. Wang, Y. Wu, T. Xiong, Y.-R. Chen, C.-Q. Su, C.-G. Niu, Schottky barrier height mediated Ti3C2 MXene based heterostructure for rapid photocatalytic water disinfection: antibacterial efficiency and reaction mechanism. Sep. Purif. Technol. 312, 123412 (2023)

S. Zeiske, W. Li, P. Meredith, A. Armin, O.J. Sandberg, Light intensity dependence of the photocurrent in organic photovoltaic devices. Cell Rep. Phys. Sci. 3, 101096 (2022)

M. Soylu, A.A. Al-Ghamdi, W.A. Farooq, F. Yakuphanoglu, Correlations for coumarin additive on the electrical and photocatalytic activity of TiO2 modified by thiourea. Microelectron. Eng. 154, 26–37 (2016)

R.O. Ocaya, A.G. Al-Sehemi, A. Al-Ghamdi, F. El-Tantawy, F. Yakuphanoglu, Organic semiconductor photosensors. J. Alloys Compd. 702, 520–530 (2017)

A. Barkhordari, H.R. Mashayekhi, P. Amiri, Ş Altındal, Y.A. Kalandaragh, Role of graphene nanoparticles on the electrophysical processes in PVP and PVP:ZnTiO3 polymer layers at Schottky diode (SD). Semicond. Sci. Technol. 38, 075002 (2023)

D.J. Friedman, J.J. Cuomo, Photoconductive properties of silicon. IEEE Trans. Electron Devices 22, 805–814 (1975)

L. Colace, G. Masini, G. Assanto, Analysis of hole injection in metal/insulator/p-silicon photodiodes. J. Appl. Phys. 95, 5816–5821 (2004)

Z. Bielecki, K. Achtenberg, M. Kopytko, J. Mikołajczyk, J. Wojtas, A. Rogalski, Review of photodetectors characterization methods. Bull. Pol. Acad. Sci. Tech. Sci. 70(2), e140534 (2022)

X. Wang, C. Sun, F. Xie, Y. Zhang, On-off switching behavior in optoelectronic devices based on semiconductors. J. Appl. Phys. 126, 051102 (2019)

İ Dökme, T. Tunç, İ Uslu, Ş Altındal, The Au/polyvinyl alcohol (Co, Zn-doped)/n-type silicon Schottky barrier devices. Synth. Met. 161, 474–480 (2011)

M. Bednorz, G.J. Matt, E.D. Głowacki, T. Fromherz, C.J. Brabec, M.C. Scharber, H. Sitter, N.S. Sariciftci, Silicon/organic hybrid heterojunction infrared photodetector operating in the telecom regime. Org. Electron. 14, 1344–1350 (2013)

R. Marnadu, J. Chandrasekaran, S. Maruthamuthu, V. Balasubramani, P. Vivek, R. Suresh, Ultra-high photoresponse with superiorly sensitive metal insulator- semiconductor (MIS) structured diodes for UV photodetector application. Appl. Surf. Sci. 480, 308–322 (2019)

M. Gökçen, T. Tunç, Ş Altındal, İ Uslu, Electrical and photocurrent characteristics of Au/PVA (Co-doped)/n-Si photoconductive diodes. Mater. Sci. Eng. B 177, 416–420 (2012)

A.B. Ulusan, A. Tataroglu, Ş Altındal, Y.A. Kalandaragh, Photoresponse properties of Au/(CoFe2O4-PVP)/n-Si/Au (MPS) diode. J. Mater. Sci. Mater. Electron. 32, 15732–15739 (2021)

A.M. Nawar, Fast processed crystalline methyl violet-6B thin films for optimizing the light-harvesting characteristics of Ag/methyl violet 6B/p-Si/Al solar cells. Appl. Phys. A 125, 210–228 (2019)

H. Abdel-Khalek, E. Shalaan, M.-E. Salam, A.M. El-Mahalawy, Effect of illumination intensity on the characteristics of Cu(acac)2/n- Si photodiode. Synth. Metals 245, 223–236 (2018)

H.A. El-Khalek, M.A. Salam, F.M. Amin, Fabrication and characterization of dual-band organic/inorganic photodetector for optoelectronic applications. Curr. Appl. Phys. 19, 629–638 (2019)

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Material preparation, data collection, and analysis were performed by AME, MMA, SAM, and FMA. The first draft of the manuscript was written by AME, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

El-Mahalawy, A.M., Abdrabou, M.M., Mansour, S.A. et al. Mechanistic exploration of charge transport and photosensitivity of metal/polymer/semiconductor (MPS) junction for sensitive light detection applications. J Mater Sci: Mater Electron 34, 2313 (2023). https://doi.org/10.1007/s10854-023-11680-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11680-4