Abstract

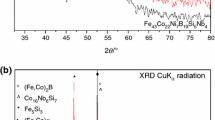

Three types of Fe-based metallic glass alloys with nominal compositions of Fe74.5B5Si2C4P10Cr2Mo2Mn0.5(#A1), Fe73.5B5Si3C4P10Cr2Mo2Mn0.5(#A2), and Fe72.5B6Si3C4P10Cr2Mo2Mn0.5(#A3) are developed using commercial pure raw materials in the forms of ribbon, rod, and powder. The structural and thermal properties are investigated by X-ray diffractometer (XRD) and differential scanning calorimetry (DSC), respectively. The alloy #A1 displays complete crystallinity in powder form while dispersion of crystallites in amorphous matrix found in ribbon and rod. The replacement of Fe by Si in #A1 causes complete amorphous structure for all forms of alloy #A2 and ribbon and rods of alloy #A3. More B atoms in alloy #A3 enhance glass transition and crystallization temperatures than alloys #A1 and #A2. The additional B and Si atoms in #A2 and #A3 influence the lowering of saturation magnetization compared to alloy #A1. However, the alloy #A3 possess the lowest coercivity, sustaining its good magnetic softness even after post-annealing at 770 K. The optimized composition in alloy #A3 is found with high amorphous-forming ability and good sphericity in powders, which would be beneficial for improving the alloy performance at further processing like additive manufacturing.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

A. El-Refaie, M. Osama, High specific power electrical machines: a system perspective. CES Trans. Electr. Mach. Syst. 3, 88–93 (2019). https://doi.org/10.30941/CESTEMS.2019.00012

J.M. Park, J.H. Na, D.H. Kim, K.B. Kim, N. Mattern, U. Kühn, J. Eckert, Medium range ordering and its effect on plasticity of Fe–Mn–B–Y–Nb bulk metallic glass. Phil. Mag. 90, 2619–2633 (2010). https://doi.org/10.1080/14786431003662556

M. Stoica, K. Hajlaoui, A. LeMoulec, A.R. Yavari, New Ternary Febased bulk metallic glass with high boron content. Phil.Mag. Lett. 86, 267–275 (2006). https://doi.org/10.1080/09500830600696344

Y. Wu, H.X. Li, Z.B. Jiao, J.E. Gao, Z.P. Lu, Size effects on the compressive deformation behaviour of a brittle Fe-based bulk metallic glass. Phil. Mag. Lett. 90, 403–412 (2010). https://doi.org/10.1080/09500831003705344

Y. Liu, Y. Yi, W. Shao, Y. Shao, Microstructure and magnetic properties of soft magnetic powder cores of amorphous and nanocrystalline alloys. J. Mag. Magn. Mater. 330, 119–133 (2013). https://doi.org/10.1016/j.jmmm.2012.10.043

V.V. Popov, M.L. Grilli, A. Koptyug, L. Jaworska, A. Katz-Demyanetz, D. Klobčar, S. Goel, Powder bed fusion additive manufacturing using critical raw materials: a review. Materials. 14, 909 (2021). https://doi.org/10.3390/ma14040909

J.C. Kim, H.J. Ryu, J.S. Kim, B.K. Kim, Y.J. Kim, H.J. Kim, Synthesis and densification of Cu added Fe-based BMG composite powders by gas atomization and electrical Explosion of wire. J. Alloys Comp. 483, 28–31 (2009). https://doi.org/10.1016/j.jallcom.2008.08.109

Y. Shi, W. Lu, W. Sun, S. Zhang, B. Yang, J. Wang, Impact of gas pressure on particle feature in Fe-based amorphous alloy powders via gas atomization: Simulation and experiment. J. Mater. Sci. Tech. 105, 203–213 (2022). https://doi.org/10.1016/j.jmst.2021.06.075

I. Otsuka, K. Wada, Y. Maeta, T. Kadomura, M. Yagi, Magnetic properties of Fe-Based amorphous powders with high-saturation induction produced by Spinning Water atomization process (SWAP). IEEE Trans. Magn. 44, 3891–3894 (2008). https://doi.org/10.1109/TMAG.2008.2002249

J. Liu, Y. Dong, Z. Zhu, J.H. Pang, P. Wang, J. Zhang, Fe-based amorphous magnetic powder cores with low core loss fabricated by Novel gas–water combined atomization powders. Materials 15, 6296 (2022). https://doi.org/10.3390/ma15186296

T.H. Kim, K.K. Jee, B.K. Yoon, D.J. Byun, J.H. Han, High-frequency magnetic properties of soft magnetic cores based on nanocrystalline alloy powder prepared by thermal oxidation. J. Mag. Magn. Mater. 322, 2423–2427 (2010). https://doi.org/10.1016/j.jmmm.2010.02.050

Y. Zhang, Y. Dong, L. Liu, L. Chang, B. Zhou, Q. Chi, X. Wang, High filling alumina/epoxy nanocomposite as coating layer for Fe-based amorphous powder cores with enhanced magnetic performance. J. Mater. Sci. 30, 1486–1487 (2019). https://doi.org/10.1007/s10854-019-01858-0

J. Huang, L. Jiao, Y. Yang, Y. Dong, Y. Zhang, L. Chang, M. Gong, J. Li, A. He, X. Wang, Fe-6.5 wt%Si powder cores with low core loss by optimizing particle size distribution. Metals 10, 1699 (2020). https://doi.org/10.3390/met10121699

Z. Mahbooba, L. Thorsson, M. Unosson, P. Skoglund, H. West, T. Horn, C. Rock, E. Vogli, O. Harrysson, Appl. Mater. Today 11, 264–269 (2018). https://doi.org/10.1016/j.apmt.2018.02.011

M.G. Ozden, N.A. Morley, Laser Additive Manufacturing of Fe-Based magnetic amorphous alloys. Magnetochemistry. 7, 20 (2021). https://doi.org/10.3390/magnetochemistry7020020

D. Ouyang, W. Xing, N. Li, Y. Li, L. Liu, Structural evolutions in 3D-printed Fe-based metallic glass fabricated by selective laser melting. Addit. Manuf. 23, 246–252 (2018). https://doi.org/10.1016/j.addma.2018.08.020

N. Lamichhane, L. Sethuraman, A. Dalagan, H. Wang, J. Keller, M.P. Paranthama, Additive manufacturing of soft magnets for electrical machines—a review. Mater. Today Phys. 15, 100255 (2020). https://doi.org/10.1016/j.mtphys.2020.100255

C. Suryanarayana, A. Inoue, Int. Mater. Rev. 58, 131–166 (2013). https://doi.org/10.1179/1743280412Y.0000000007. Iron-based bulk metallic glasses

B. Shen, M. Akiba, A. Inoue, Effects of Si and Mo additions on glass-forming in bulk glassy alloys with high saturation magnetization. Phys. Rev. B 73, 104204 (2006). https://doi.org/10.1103/PhysRevB.73.104204

B. Shen, A. Inoue, Effect of Ga addition on the glass-forming ability of Fe-based bulk glassy alloy. J. Mater. Sci. Lett. 22, 857 (2003)

F. Li, B. Shen, A. Makino, A. Inoue, Excellent soft-magnetic properties of (Fe,Co)–Mo–(P,C,B,Si) bulk glassy alloys with ductile deformation behavior. App. Phy. Lett. 91, 234101 (2007). https://doi.org/10.1063/1.2820608

H.X. Li, J.E. Gao, Z.B. Jiao, Y. Wu, Z.P. Lu, Glass-forming ability enhanced by proper additions of oxygen in a Fe-based bulk metallic glass. Appl. Phys. Lett. 56, 1035 (2009). https://doi.org/10.1063/1.3248186

Y. Fu, B. Shen, H. Kimura, A. Makino, A. Inoue, Enhanced glass-forming ability of FeCoBSiNb bulk glassy alloys prepared using commercial raw materials through the optimization of nb content. J. Appl. Phys. 107, 09A315 (2010). https://doi.org/10.1063/1.3350898

H.X. Li, Z.C. Lu, S.L. Wang, Y. Wu, Z.P. Lu, Fe-based bulk metallic glasses: glass formation, fabrication, properties and applications. Prog. Mater. Sci. 103, 235–318 (2019). https://doi.org/10.1016/j.pmatsci.2019.01.003

Y. Jiang, S. Jia, S. Chen, X. Li, L. Wang, X. Han, Theoretical prediction and experimental validation of the Glass-Forming ability and magnetic properties of Fe-Si-B Metallic glasses from Atomic structures. Materials. 15, 3149 (2022). https://doi.org/10.3390/ma15093149

P. Sarkar, R.K. Roy, A.K. Panda, A. Mitra, Optimization of process parameters for developing FeCoSiB amorphous microwires through in-rotating-water quenching technique. Appl. Phys. A 111, 575–580 (2013). https://doi.org/10.1007/s00339-012-7260-4

E.J. Lavernia, T.S. Srivatsan, The rapid solidification processing of materials: science, principles, technology, advances, and applications. J. Mat. Sci. 45, 287–325 (2010). https://doi.org/10.1007/s10853-009-3995-5

A. Inoue, B.L. Shen, C.T. Chang, Fe- and co-based bulk glassy alloys with ultrahigh strength of over 4000 MPa. Intermetallics 14, 936–944 (2006). https://doi.org/10.1016/j.intermet.2006.01.038

B.S. Patial, N. Thakur, Tripathi,on the variation of activation energy for amorphous–crystallization phase transition in Se–Te–Sn chalcogenide glasses using iso-conversional analysis. Phase Trans. 90, 1101–1111 (2017). https://doi.org/10.1080/01411594.2017.1318442

B.S. Patial, N. Thakur, S.K. Tripathi, Crystallization study of sn additive Se–Te chalcogenide alloys. J. Therm. Anal. Calorim. 106, 845–852 (2011). https://doi.org/10.1007/s10973-011-1579-5

H.E. Kissinger, Reaction kinetics in differential thermal analysis. Anal. Chem. 29, 1702–1706 (1957). https://doi.org/10.1021/ac60131a045

D. Turnbull, Under what conditions can a glass be formed. Contemp. Phys. 10, 473–488 (1969). https://doi.org/10.1080/00107516908204405

Z.P. Lu, C.T. Liu, A new glass-forming ability criterion for bulk metallic glass. Acta Mater. 50, 3501–3512 (2002). https://doi.org/10.1016/S1359-6454(02)00166-0

B.S. Patial, Calorimetry to Understand Structural Relaxation in Chalcogenide Glasses, in Applications of Calorimetry. ed. by J.L. Rivera-Armenta, C.G. Flores-Hernández (Intech Open, London, 1973), p.307. https://doi.org/10.5772/intechopen.104418

Y.G. Nam, B. Koo, M.S. Chang, S. Yang, J. Yu, Y.H. Park, Jeong, elective laser melting vitrification of amorphous soft magnetic alloys with help of double-scanning-induced compositional homogeneity. Mater. Lett. 261, 127068 (2020). https://doi.org/10.1016/j.matlet.2019.127068

H. Chen, B. Dong, S. Zhou, X. Li, J. Qin, Structural, magnetic, and electronic properties of Fe82Si4B10P4 metallic glass. Sci. Rep. 8, 5680 (2018). https://doi.org/10.1038/s41598-018-23952-9

R.M. Bozorth, Ferromagnetism (Wiley-IEEE Press, Piscataway, 1978), pp.423–430

K. Narita, H. Fukunaga, J. Yamasaki, Effect of metalloid content on Curie temperature and magnetic moment of amorphous Fe–Si–B alloys. Jpn. J. Appl. Phys. 16, 2063–2064 (1977)

S. Yue, H. Zhang, R. Cheng, A. Wang, Y. Dong, A. He, H. Ni, C.T. Liu, Magnetic and thermal stabilities of FeSiB eutectic amorphous alloys: compositional effects. J. Alloys Comp. 776, 833–838 (2019). https://doi.org/10.1016/j.jallcom.2018.10.331

D. Goll et al., Additive manufacturing of soft magnetic materials and components. Addit. Manuf. 27, 428–439 (2019). https://doi.org/10.1016/j.addma.2019.02.021

Acknowledgements

Authors are thankful to Director, CSIR-NML, Jamshedpur, for giving permission for this publication. CSIR-NML in-house project (OLP0398) is highly acknowledged for financial support of this investigation.

Funding

This work was supported by CSIR-NML in-house project (OLP0398).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by RKR, PM, GKB, KGK, and AKP. The first draft of the manuscript was written by RKR and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Roy, R.K., Murugaiyan, P., Bansal, G.K. et al. Structural and magnetic behaviors of Fe-based glassy alloys prepared by industrial raw materials and different processing routes. J Mater Sci: Mater Electron 34, 2218 (2023). https://doi.org/10.1007/s10854-023-11650-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11650-w