Abstract

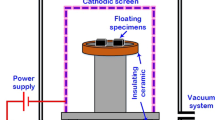

In the present study, the effect of treatment with Ar thermal plasma on the compositional, morphological, and field emission properties of Tin (Sn) has been investigated. For this purpose, Sn has been treated for different exposure times ranging from 2.5 to 20 min at a constant Ar flow rate of 10 L/min. X-ray Diffraction (XRD) analysis identifies no new phase formation. However, the crystallite size of plasma treated Sn goes on increasing upto 15 min and then decreases for treatment time of 20 min. Whereas, vice versa is true for dislocation line density. The anomalous trends are observed for stress and strain measurements of plasma treated Sn. Scanning Electron Microscopy (SEM) analysis of thermal plasma treated Sn reveals the formation of ridges, cones, droplets, cavities, voids and pores at different treatment times. The work function varies from 4.38 to 5.05 eV for different treatment times. The Field Emission (FE) parameters such as maximum current density (Jmax), turn on field (Eo) and field enhancement factor (β) are enhanced and come out to be in the range of 564 nA/cm2 to 2522 nA/cm2, 4 V/µm to 11 V/µm and 2600 to 4520 respectively. The density of surface structures, field enhancement factor (β), turn on field (Eo) and maximum current density (Jmax) are correlated with work function of thermal plasma treated Sn. The structured surfaces of Sn are highly beneficial for various applications like FE-SEM as well as LCD displays.

Similar content being viewed by others

Data availability

Data will be available on reasonable request of editor.

References

T. Feng, J. Zhang, Q. Li, X. Wang, K. Yu, S. Zou, Physica E: Low-Dimens Syst. Nanostruct. 36, 28 (2007). https://doi.org/10.1016/j.physe.2006.07.034

Z.-H. Yang, C.-H. Ho, S. Lee, Appl. Surf. Sci. 349, 609 (2015). https://doi.org/10.1016/j.apsusc.2015.05.055

M. Šíra, D. Trunec, P. Stahel, V. Buršíková, Z. Navrátil, J Buršík, J. Phys. D 38, 621 (2005). https://doi.org/10.1088/0022-3727/38/4/015

D.H. Shin, C.U. Bang, J.H. Kim et al., IEEE Trans. Plasma Sci. 34, 1241 (2006). https://doi.org/10.1109/TPS.2006.876486

O. Goossens, E. Dekempeneer, D. Vangeneugden, R. Van de Leest, C Leys, Surf. Coat. Technol. 142, 474 (2001). https://doi.org/10.1016/S0257-8972(01)01140-9

E.P. Stuckert, E.R. Fisher, Sens. Actuators B: Chemical 208, 379 (2015). https://doi.org/10.1016/j.snb.2014.11.049

G.N. Fursey, Appl. Surf. Sci. 215, 113 (2003). https://doi.org/10.1016/S0169-4332(03)00315-5

E.J. Radauscher, K.H. Gilchrist, S.T.D. Dona et al., IEEE Trans. Electron. Devices. 63, 3753 (2016). https://doi.org/10.1109/TED.2016.2593905

M. Akram, S. Bashir, S.A. Jalil, M.S. Rafique, A. Hayat, K. Mahmood, Mater. Res. Express. 5, 025029 (2018). https://doi.org/10.1088/2053-1591/aaa8ac

J. Li, S. Yao, F. Xiao, SN Amirkhanian, Int. J. Pavement Eng. 23, 651 (2022). https://doi.org/10.1080/10298436.2020.1765242

A. Kaleem, S. Bashir, M. Akram et al., Appl. Phys. A 128, 1 (2022). https://doi.org/10.1007/s00339-022-05789-2

L. Kotte, G. Mäder, J. Roch, S. Kaskel, Contrib. Plasma Phys. 58, 327 (2018). https://doi.org/10.1002/ctpp.201700084

D. Hwangbo, S. Kajita, N. Ohno, D. Sinelnikov, IEEE Trans. Plasma Sci. 45, 2080 (2017). https://doi.org/10.1109/TPS.2017.2679211

H.-Y. Hsu, J.-S. Yen, C.-Y. Lin et al., Appl. Sci. 13, 2531 (2023). https://doi.org/10.3390/app13042531

M. Anitha, N. Anitha, I. Kulandaisamy, L. Amalraj, J. Solgel Sci. Technol. 86, 580 (2018). https://doi.org/10.1007/s10971-018-4673-3

S. Shanmugan, D. Mutharasu, Radiat. Phys. Chem. 81, 201 (2012). https://doi.org/10.1016/j.radphyschem.2011.09.016

B. Illés, A. Skwarek, J. Ratajczak, K. Dušek, D Bušek, J. Alloys Compd. 785, 774 (2019). https://doi.org/10.1016/j.jallcom.2019.01.247

Å. Haryński, D. Czylkowski, B. Hrycak et al., Appl. Surf. Sci. 615, 156472 (2023). https://doi.org/10.1016/j.apsusc.2023.156472

M. Yang, T. Yi, F. Zheng et al., J. Nucl. Mater. 575, 154210 (2023). https://doi.org/10.1016/j.jnucmat.2022.154210

A. Belkind, S Gershman (2008) Vacuum Coating Technol. Nov., 46

S. Chander, M. Dhaka, Thin Solid Films. 625, 131 (2017). https://doi.org/10.1016/j.tsf.2017.01.052

S. Chander, A. Purohit, S. Patel, M. Dhaka, Physica E: Low-Dimens. Syst. Nanostruct. 89, 29 (2017). https://doi.org/10.1016/j.physe.2017.02.002

L.K. Singh, A. Bhadauria, S. Jana, T. Laha, Acta Metall. Sin. (2018). https://doi.org/10.1007/s40195-018-0795-4

S. Sahoo, S. Singh, Ceram. Int. 43, 15561 (2017). https://doi.org/10.1016/j.ceramint.2017.08.108

M. Aftab, M.Z. Butt, D. Ali, M.U. Tanveer, A. Hussnain, Proc. Pak. Acad. Sci. Phys. Comput. Sci. 57, 51 (2020)

N. Ali, S. Bashir, A.M. Alshehri, N. Begum, Materials. 14, 3671 (2021). https://doi.org/10.3390/ma14133671

B.H. Toby, Powder Diffr. 21, 67 (2006). https://doi.org/10.1154/1.2179804

R. Amir, S. Bashir, M. Akram et al., Radia. Effects Defects Solids (2022). https://doi.org/10.1080/10420150.2022.2073882

F. Poitrasson, F.-X. d’Abzac, J. Anal. At. Spectrom. 32, 1075 (2017). https://doi.org/10.1039/C7JA00084G

H. Ahmad, S. Bashir, A. Hayat, K. Mahmood, A. Batool, F. Hussain, IEEE Trans. Plasma Sci. 48, 4191 (2020). https://doi.org/10.1109/TPS.2020.3035882

A. Dawood, S. Bashir, N.A. Chishti, M.A. Khan, A. Hayat, Laser Part. Beams. 36, 261 (2018). https://doi.org/10.1017/S0263034618000137

Y. Pauleau, Materials Surface Processing by Directed Energy Techniques (Elsevier, Amsterdam, 2006)

N. Ali, S. Bashir, A.M. Alshehri, N. Begum, Coatings. 12, 1193 (2022). https://doi.org/10.3390/coatings12081193

N. Ali, S. Bashir, M.S. Rafique et al., Chin. Phys. B 26, 015204 (2017). https://doi.org/10.1088/1674-1056/26/1/015204

H. Itagaki, K. Hanada, S. Hirose, Jpn. J. Appl. Phys. 59, SJJG01 (2020). https://doi.org/10.35848/1347-4065/ab8282

H. Husin, T. Asnawi, A. Firdaus, H. Husaini, I. Ibrahim, F. Hasfita, (2018) IOP Conference Series: Materials Science and Engineering, IOP Publishing

S. Ahmad, S. Bashir, M. Akram et al., Surface Interface Anal. (2022). https://doi.org/10.1002/sia.7169

M.A. Ali, S. Bashir, M. Akram et al., Nuclear instruments and methods. Phys. Res. Sect. B: Beam Interact. Mater. Atoms. 423, 7 (2018). https://doi.org/10.1016/j.nimb.2018.03.004

J. Saghaei, A.M. Brewer, W. Jiang, S.M. Russell, P.L. Burn, A Pivrikas, Thin Solid Films. 718, 138475 (2021). https://doi.org/10.1016/j.tsf.2020.138475

I. Baikie, P. Smith, D. Porterfield, P. Estrup, Rev. Sci. Instrum. 70, 1842 (1999). https://doi.org/10.1063/1.1149678

K.H. Lee, H.W. Jang, K.-B. Kim, Y.-H. Tak, J.-L. Lee, J. Appl. Phys. 95, 586 (2004). https://doi.org/10.1063/1.1633351

D. Lu, A. Ogino, B. Liang, J. Liu, M. Nagatsu, Jpn. J. Appl. Phys. 48, 090206 (2009). Doi:DOI. https://doi.org/10.1143/JJAP.48.090206

M. Akram, S. Bashir, S.A. Jalil, M.S. Rafique, A. Hayat, K. Mahmood, Appl. Phys. A 124, 1 (2018). https://doi.org/10.1007/s00339-018-1612-7

C.-T. Hsieh, J.-M. Ting, Chem. Phys. Lett. 413, 84 (2005). https://doi.org/10.1016/j.cplett.2005.07.050

M. Shakerzadeh, N. Xu, M. Bosman et al., Carbon. 49, 1018 (2011). https://doi.org/10.1016/j.carbon.2010.11.010

S. Kajita, N. Ohno, Y. Hirahata, M. Hiramatsu, Fusion Eng. Des. 88, 2842 (2013). https://doi.org/10.1016/j.fusengdes.2013.05.014

C. Li, Y. Yang, X. Sun et al., Nanotechnology. 18, 135604 (2007). https://doi.org/10.1088/0957-4484/18/13/135604

M. Ojima, S. Hiwatashi, H. Araki, A. Fujii, M. Ozaki, K. Yoshino, Appl. Phys. Lett. 88, 053103 (2006). https://doi.org/10.1063/1.2170436

A.V. Arkhipov, P.G. Gabdullin, N.M. Gnuchev, S.N. Davydov, S.I. Krel, B.A. Loginov, St. Petersburg Polytech. Univers. J. Phys. Math. 1, 47 (2015). https://doi.org/10.1016/j.spjpm.2015.03.011

S. Bhattacharjee, R. Sarkar, P. Chattopadhyay et al., Appl. Phys. A 128, 501 (2022). https://doi.org/10.1007/s00339-022-05638-2

S.N. Sami, L. Diaz, M. Sanati, R. Joshi, J. Appl. Phys. (2020). https://doi.org/10.1063/5.0031568

J. Lin, X. Dai, X. Liang et al., Adv. Funct. Mater. 30, 1907265 (2020). https://doi.org/10.1002/adfm.201907265

N. Lang, W Kohn, Phys. Rev. B 3, 1215 (1971). https://doi.org/10.1103/PhysRevB.3.1215

A. Haque, S. Karmakar, R.K. Trivedi, B. Chakraborty, R. Droopad, ACS Omega (2023). https://doi.org/10.1021/acsomega.2c07576

J.-H. Wang, T.-H. Yang, W.-W. Wu, L.-J. Chen, C.-H. Chen, C.-J. Chu, Nanotechnology. 17, 719 (2006). https://doi.org/10.1088/0957-4484/17/3/017

J. Xu, K. Yu, Z. Zhu, Phys. E: Low-Dimen. Syst. Nanostruct. 42, 1451 (2010). https://doi.org/10.1016/j.physe.2009.11.115

J. Majumdar, S. Bhattacharjee, Front. Phys. 9, 310 (2021). https://doi.org/10.3389/fphy.2021.674928

A.K. Singh, J. Kumar, J. Appl. Phys. (2013). https://doi.org/10.1063/1.4790323

R. Gupta, R. Chauhan, S. Chakarvarti et al., J. Mater. Sci.: Mater. Electron. 29, 19013 (2018). https://doi.org/10.1007/s10854-018-0027-8

M.M.H. Raza, M. Sadiq, M. Zulfequar, S. Husain, J Ali, J. Phys. Chem. Solids. 178, 111309 (2023). https://doi.org/10.1016/j.jpcs.2023.111309

M.M.H. Raza, M. Sadiq, M. Zulfequar, S. Husain, J Ali, Diam. Relat. Mater. 132, 109627 (2023). https://doi.org/10.1016/j.diamond.2022.109627

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

SMKS: The work is actually MPhil research work of Syed Muhammad Kamran Shabbir who performed whole experiment and wrote paper. SB: SB is supervisor of Syed Muhammad Kamran Shabbir who planned and designed this whole research work of this manuscript and contributed a lot. MA: MA is co-supervisor of this research work. She helped a lot for field emission measurements. MSR: Helped to designing and fabricate Thermal plasma set-up. KM: Helped for successful experimental set-up. SN and SR: Both helped to perform work function measurements. SA, MAA, MH, MAM and MS: They are collaborators for experimental set-ups of thermal plasma and field emission.

Corresponding author

Ethics declarations

Conflict of interest

There is no competing interest for any authors.

Ethical approval

All Ethical Standards are strictly compliance.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shabbir, S.M.K., Bashir, S., Akram, M. et al. Thermal plasma treatment of tin for the enhancement of field emission properties. J Mater Sci: Mater Electron 34, 2244 (2023). https://doi.org/10.1007/s10854-023-11564-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11564-7