Abstract

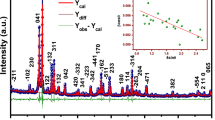

Transparent MgAl2O4 spinel ceramic parts were fabricated by the slip casting process and densified to > 99% of theoretical density (TD) through air sintering at 1650 °C. Further, the residual porosity in the sintered samples was eliminated by placing the samples in a hot isostatic press (HIP) and applying a temperature of 1800 °C temperature with an argon pressure of 195 MPa to achieve near theoretical optical transmission. Samples under sintered & HIP conditions were comparatively evaluated for their properties by XRD, SEM, dielectric, AC impedance spectroscopy and AC conductivity studies. Sintered and HIP samples showed XRD patterns corresponding to phase pure MgAl2O4 spinel. However, a substantial increase in average grain size from 3 to 47 µm is observed through Fe-SEM as a result of HIP parameters. Dielectric properties measured with frequency and temperature showed an exponential decrease in the dielectric constant (ε′) and impedance real part (Z′) with increasing frequency (30@1 MHz for sintered and 38@1 MHz HIPed samples) and a significant increase in the AC conductivity with an increase in frequency from 6.2 × 10−9 − 1.8 × 10−6 S/cm and 4.9 × 10−9 − 2.02 × 10−6 S/cm for sintered and HIP samples respectively. The impedance imaginary part (Z″) increased with frequency and showed a peak value and subsequently falls with a frequency indicating relaxation behavior. Nyquist plots were drawn from impedance measurements on sintered and HIP samples and the resultant spectra were analyzed. The depressed semi-circular arcs from the complex impedance result reveal the total conduction in the material might be due to the combination of grain boundaries and bulk grains. The grain boundary is less resistive than MgAl2O4 bulk grains because of the dynamic features of the grains. An equivalent circuit model containing a series combination of R||CPE and R||C is well-fitted with the semi-circular arcs revealing a non-Debye type relaxation mechanism. Activation energy calculated from the Arrhenius plots (0.21 eV for sintered and 0.25 eV for HIPed sample) indicates the conduction by the mechanism of hopping due to oxygen vacancies by the process of thermal activation. The responses in the dielectric and AC conductivity studies suggest MgAl2O4 spinel as a candidate material for high-frequency dielectric applications and also in the high-temperature broad frequency range optical devices.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

F. Yang, Y. Lai, Y. Zeng, Q. Zhang, J. Han, X. Zhong, H. Su, Ceram. Int. 47, 22522 (2021)

H. Chen, X. Fu, Q. An, B. Tang, S. Zhang, H. Yang, Y. Long, M. Harfouche, H. Wang, Y. Li, Sci. Rep. 7, 14120 (2017)

K.P. Surendran, P.V. Biumon, P. Mohanan, M.T. Sebastian, Appl. Phys. A 81, 823 (2005)

X. Yang, Y. Lai, Y. Zeng, F. Yang, F. Huang, B. Li, F. Wang, C. Wu, H. Su, J. Alloys Compd. 898, 162905 (2022)

H. Chen, Z. Zhang, Z. Xiong, B. Tang, Y. Yuan, S. Zhang, J. Am. Ceram. Soc. 100, 4058 (2017)

C.M. Kanamadi, B.K. Das, C.W. Kim, D.I. Kang, H.G. Cha, E.S. Ji, A.P. Jadhav, B.E. Juna, J.H. Jeonga, B.C. Choi, B.K. Chougulec, Y.S. Kang, Mater. Chem. Phys. 116, 6 (2009)

H. Li, H.-Y. Wei, Y. Cui, R.-L. Sang, J.-L. Bu, Y.-N. Wei, J. Lin, J.H. Zhao, J. Ceram. Soc. Jpn. 125, 100 (2017)

A. Benkhelif, M. Kolli, Waste Biomass Valorization. 13, 2637 (2022)

K. Maca, M. Trunec, R. Chmelik, Ceram. Silik. 51, 94 (2007)

A. Rothman, S. Kalabukhov, N. Sverdlov, M.P. Dariel, N. Frage, Int. J. Appl. Ceram. Technol. 11, 146 (2014)

Z. Shi, Q. Zhao, B. Guo, T. Ji, H. Wang, Mater. Des. 193, 108858 (2020)

N.I. Radishevskaya, A.Y. Nazarova, O.V. Lvov, N.G. Kasatsky, V.D. Kitler, IOP J. Phys. Conf. Series. 1214, 012019 (2019)

M. O’Horo, A. Frisillo, W. White, J. Phys. Chem. Solids. 34, 23 (1973)

H. Cynn, S.K. Sharma, T.F. Cooney, M. Nicol, Phys. Rev. B 45, 500 (1992)

M.J. Iqbal, S. Farooq, Mater. Sci. Eng. B 136, 140 (2007)

E.A. Kozlovskaya, M.O. Senina, D.O. Lemeshev, Mater. Sci. Eng. 971, 032008 (2020)

R. Ianoş, R. Lazău, Mater. Chem. Phys. 115, 645 (2009)

O. Padmaraj, M. Venkateswarlu, N. Satyanarayana, Ceram. Int. 41, 3178 (2015)

H. Shahbazi, H. Shokrollahi, A. Alhaji, J. Alloys Compd. 712, 732 (2017)

S. Xuan, X. Wang, Y. Tian, J. Hao, Int. J. Appl. Ceram. Technol. 18, 1205 (2021)

B.K. Bammannavar, L.R. Naik, B.K. Chougule, J. Appl. Phys. 104, 0641231 (2008)

A.V. Ul’yanova, M.O. Senina, D.O. Lemeshev, Russ J. Inorg. Chem. 66, 1245 (2021)

R.J. Braton, J. Am. Ceram. Soc. 54, 141 (1971)

J. Ahmad, M.Q. Awan, M.E. Mazhar, M.N. Ashiq, Phys. B 406, 254 (2011)

S. Sanjabi, A. Obeydavi, J. Alloys Compd. 645, 535 (2015)

A.A. El-Amir, S. Li, M. Abdelgawad, E.M. Ewais, J. Korean Ceram. Soc. 58, 574 (2021)

K. Izumi, T. Mizukowa, E. Hanamura, J. Appl. Phys. 102, 053109 (2007)

S.M. Hosseini, Phys. Status Solidi B 245, 2800 (2008)

X. Suu, X. Jiang, Y. Shan, X. Han, J. Xu, J. Li, Ceram. Int. 48, 17471 (2022)

P. Ramavath, P. Biswas, K. Rajeswari, M.B. Suresh, R. Johnson, G. Padmanabhama, C.S. Kumbhar, T.K. Chongdar, N.M. Gokhale, Ceram. Int. 40, 5575 (2014)

P. Biswas, S. Manivannan, Y.S. Rao, R. Johnson, Mater. Chem. Phys. 252, 123372 (2020)

M.K. Naskar, M. Chatterjee, J. Am. Ceram. Soc. 88, 38 (2005)

M. Saleem, D. Varshney, J. Alloys Compd. 708, 397 (2017)

S.S. Ata-Allah, M.K. Fayek, Phys. Status Solidi A 175, 725 (1999)

W.A. Yager, Phys. 7, 434 (1936)

C.G. Koops, Phys. Rev. 83, 121 (1951)

Funding

The authors declare that no funds, grants or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by MBS, PB, BPS, RJ. The first draft of the manuscript was written by MBS, PB and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Suresh, M.B., Biswas, P., Saha, B.P. et al. Fabrication of optically transparent MgAl2O4 polycrystalline ceramics and evaluation of high temperature dielectric, impedance spectroscopy & AC conductivity. J Mater Sci: Mater Electron 34, 1877 (2023). https://doi.org/10.1007/s10854-023-11315-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11315-8