Abstract

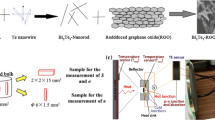

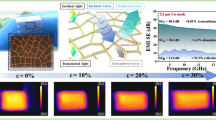

Highly reliable resistor pastes are essential for the development of the electronics industry. However, in recent years, the prices of precious metals used in resistor pastes have continued to rise. Therefore, the development of low-cost and high-performance resistor pastes holds significant practical significance. In this study, we synthesized compositions and morphologies of molybdenum-based materials, namely MoS2, MoC/Mo2C, and MoO3, as the main functional fillers using simple and cost-effective methods such as hydrothermal and thermal decomposition. These molybdenum-based materials were combined with raw materials such as glass powder and organic binders to prepare various molybdenum-based resistor pastes and thick film resistors. The feasibility of preparing high-performance resistor pastes using three-dimensional molybdenum-based materials was systematically investigated. The results showed that compared to MoS2 and MoC/Mo2C, MoO3 exhibited uniform particle size and good thermal stability. The thick film resistor pastes fabricated using MoO3 as a filler formed uniform and defect-free conductive film layers. Moreover, the resistance values of these thick film resistors could be controlled within a wide range (10 Ω to 100 kΩ). Therefore, this simple and cost-effective fabrication process using MoO3 as a functional filler holds greater application potential and value in resistor pastes.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Q. Jiang, J.H. Li, A. Li, D.D. Zhou, H.D. Zeng, Surface hydroxyl modification for silicate-stabilized low-melting glassy tellurite adhesive enabling low resistance of silver conductive paste. J. Non-Cryst Solids. 598, 121959 (2022)

C. Travis, Mallett, Aging in commercial thick- and thin-film resistors: survey and uncertainty analysis. IEEE Trans. Instrum. Meas. 68, 90–4204 (2019)

H.F. Lee, C.Y. Chan, C.S. Tang, Embedding capacitors and resistors into printed circuit boards using a sequential lamination technique. J. Mater. Process. Tech. 207, 72–88 (2008)

Y.T. Wang, A.O. Watanabe, N. Ogura, P.M. Raj, R. Tummala, Sintered nanocopper paste for high-performance 3D heterogeneous package integration. J. Electron. Mater. 49, 6737–6745 (2020)

W. Atse Louwen, van R.S. Sark, A.Ã. Faaij, A cost roadmap for silicon heterojunction solar cells. Sol. Energy Mater. Sol. Cells. 147, 295–314 (2016)

M. Kanwal, N. Shahzad, M.A. Tariq, M.I. Shahzad, Effectively transparent electrical contacts for thermally sensitive solar cells. Sol. Energy Mater. Sol. Cells. 224, 110 (2021)

X.P. Wang, M.J. Zhang, L.W. Zhang, J.C. Xu, X.Q. Xiao, X.S. Zhang, Inkjet-printed flexible sensors, from function materials, manufacture process, and applications perspective. Mater. Today Commun. 31, 103263 (2022)

Z.X. Cai, X.Y. Li, Q.W. Hu, X.Y. Zeng, Fabrication of microheater by laser micro cladding electronic past. Mater. Sci. Eng. B 157, 15–19 (2009)

D. Lan, Y. Wang, Y.Y. Wang, X.F. Zhu, H.F. Li, X.M. Guo, J.N. Ren, Z.H. Guo, G.L. Wu, Impact mechanisms of aggregation state regulation strategies on the microwave absorption properties of flexible polyaniline. J. Colloid Interface Sci. 651, 494–503 (2023)

Y.L. Wu, D. Lan, J.W. Ren, S.J. Zhang, A mini review of MOFs derived multifunctional absorbents: from perspective of components regulation. Mater. Today Phys. 36, 101178 (2023)

Z. Jia, D. Lan, M. Chang, Y. Han, G. Wu, Heterogeneous interfaces and 3D foam structures synergize to build superior electromagnetic wave absorbers. Mater. Today Phys. 37, 101215 (2023)

T. Noriya Izu, W. Itoh, I. Shin, N. Matsubara, Murayama, Evaluation of response characteristics of resistive oxygen sensors using Ce0.9Zr0.1O2 thick film by pressure modulation method. Sens. Actuators B Chem. 130, 466–469 (2008)

M.D. Mahanubhav, L.A. Patil, Studies on gas sensing performance of CuO-modified CdIn2O4 thick film resistors. Sens. Actuators B Chem. 128, 186–192 (2007)

P. Mariya, S.K. Aleksandrova, Andreev, Design methodology and technological flow of screen-printed thick-film sensors. IEEE Sens. J. 22, 10126–10136 (2022)

Y.C. Li, G.Y. Gan, Y.K. Huang, X.L. Yu, J.H. Cheng, C.B. Liu, Ag-NPs/MWCNT composite-modified silver-epoxy paste with improved thermal conductivity. RSC Adv. 9, 20663–20669 (2019)

M.G. Busana, M. Prudenziati, J. Hormadaly, Microstructure development and electrical properties of RuO2-based lead-free thick film resistors. J. Mater. Sci. Mater. Electron. 17, 951–962 (2006)

X.C. Guan, M. Wen, H. Li, J.P. Ou, The influence of firing procedures on strain sensitivity of thick-film resistors. Ceram. Int. 45, 6836–6841 (2019)

A. Konrad Kiełbasiński, M. Młożniak, J. Hrovat, D. Holc, Belavič, Investigation on electrical and microstructural properties of thick film lead-free resistor series under various firing conditions. J. Mater. Sci. Mater. Electron. 21, 1099–1105 (2010)

X. He, Q. Chen, X.D. Xiong, X. Zhang, Z.J. Nan, Microstructure analysis of thick film platinum resistance paste during sintering. Precious Met. 28, 28–31 (2007)

A. Kshirsagar, S. Rane, U. Mulik, D. Amalnerkar, Microstructure and electrical performance of eco-friendly thick film resistor compositions fired at different firing conditions. Mater. Chem. Phys. 101, 492–498 (2007)

Y.C. Lu, R. Peng, Y.X. Li, F.Y. Li, L. Shi, D.M. Chen, Q.Y. Wen, Q.H. Yang, C.T. Yang, Improved Nb–substituted La0.5Sr0.5CoO3 ceramics as new and low–cost functional materials for thick–film resistors. Ceram. Int. 48, 19174–19179 (2022)

Y.C. Lu, R. Peng, Y.X. Li, F.Y. Li, Y.J. Zhang, D.M. Chen, Q.Y. Wen, Q.H. Yang, Evaluation of Zn-substituted La0.5Sr0.5CoO3 ceramics as functional materials for thick-film resistors. J. Am. Ceram. Soc. 105, 2744–2753 (2021)

N. Astapov, A.I. Matulyak, Reaction synthesis for producing MoSi2-based coatings. Russ. Metall. 2022, 1569–1577 (2022)

J. Pang, J. Huang, Q. Li, Xie, Preparation of Fe3Si-based thick film resistor paste and study on resistance characteristics. Chin. J. Electron Devices 41, 565–571 (2018)

L.X. L.Chang, X.Z. Sun, B. Wang, Ca, Applied research of nickel paste in thick-film humidity sensitive resistor. J. Transducer Technol. 23, 29–30 (2004)

J. Jiri Hlina, M. Reboun, T. Simonovsky, M. Syrovy, A. Janda, Hamacek, Study of new nitrogen–fireable copper–nickel thick film paste formulation compatible with thick printed copper. Materials 15, 1372 (2022)

A. Tomasz Matusiak, L. Dabrowski, Golonka, Electrical properties of graphite-glass thick-film resistor. Circuit World. 47, 138–154 (2021)

B. Tabernig, N. Reheis, Joining of molybdenum and its application. Int. J. Refract. Met. Hard Mater. 28, 728–733 (2010)

J.J. Li, Q.Q. Zhu, J.H. Zhu, Y.H. Cheng, Z.R. Jia, F. Lu, C. Wang, L. Wu, Inimitable 3D pyrolytic branched hollow architecture with multi-scale conductive network for microwave absorption. J. Mater. Sci. Technol. 173, 170–180 (2024)

L.Y. Yu, Q.Q. Zhu, Z.Q. Guo, Y.H. Cheng, Z.R. Jia, G.L. Wu, Unique electromagnetic wave absorber for three-dimensional framework engineering with copious heterostructures. J. Mater. Sci. Technol. 170, 129–139 (2024)

J.H. Perepezko, The hotter the engine, the better. Science. 326, 1068–1069 (2009)

J. Fan, M. Lu, H. Cheng et al., Effect of alloying elements Ti, Zr on the property and microstructure of molybdenum. Int. J. Refract. Met. Hard Mater. 27, 78–82 (2009)

M.S. El-Genk, J.M. Tournier, A review of refractory metal alloys and mechanically alloyed-oxide dispersion strengthened steels for space nuclear power systems. J. Nucl. Mater. 340, 93–112 (2005)

M.S. Dahiya, A. Agarwal, S. Khasa, Dielectric characterization VO2+ doped CaCl2•CaO•B2O3 glasses. Mater. Lett. 176, 241–243 (2016)

Q. Sun, W.C. Yang, Y.H. Liu, Y.F. Li, M.Y. Li, Microstructure and mechanical properties of tempered glass joint bonded with Bi–B–Zn low melting glass. J. Mater. Process. Tech. 271, 404–412 (2019)

A. Kusy, Chains of conducting particles that determine the resistivity of thick resistive films. Thin Solid Films. 43, 243–250 (1977)

S. Zhang, X.H. Liu, C.Y. Jia, Z.S. Sun, H.W. Jiang, Z.R. Jia, G.L. Wu, Integration of multiple Heterointerfaces in a hierarchical 0D@2D@1D structure for lightweight, flexible, and hydrophobic multifunctional electromagnetic protective fabrics. Nano-Micro. Lett. 15, 204 (2023)

Y.L. Pan, Q.Q. Zhu, J.H. Zhu, Y.H. Cheng, B.W. Yu, Z.R. Jia, G.L. Wu, Macroscopic electromagnetic synergy network-enhanced N-doped Ni/C gigahertz microwave absorber with regulable microtopography. Nano Res. 16, 10666–10677 (2023)

Funding

This work was financially supported by State Grid Corporation of China’s Headquarters Technology Project“Research on Energy Efficiency Measurement and Loss Reduction Technology for UHV DC Transmission Systems Based on Digital Twins” (5700-202122200 A-0-000).

Author information

Authors and Affiliations

Contributions

DL: related literature, designed experiment and writing—original draft preparation. JY: Data curation. XZ and CY: Formal analysis. LD and YL: Conceptualization.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

The authors declare that they have compliance with ethical standards.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, D., Yu, J., Zheng, X. et al. Exploration of tunable, low-depletion novel resistor paste system based on molybdenum-based functional phase modulation. J Mater Sci: Mater Electron 34, 1957 (2023). https://doi.org/10.1007/s10854-023-11278-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11278-w