Abstract

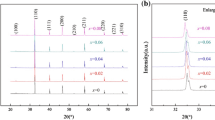

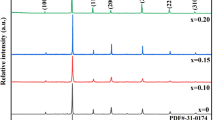

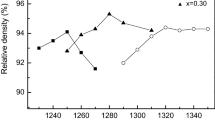

The Ba[(Zr0.2Ti0.8)1−xCex]O3 ceramics were fabricated by liquid phase coating method and the impacts of cerium addition into the barium zirconate titanate matrix on their microstructure and dielectric properties were investigated. According to the XRD analysis, the Ba[(Zr0.2Ti0.8)1−xCex]O3 ceramics retain a cubic perovskite structure without secondary phases. The SEM images indicate that the average grain size and gain size distribution of Ba[(Zr0.2Ti0.8)1−xCex]O3 ceramics can be adjusted by the cerium content. And the minimum average grain size of 4.38 μm is obtained in Ba[(Zr0.2Ti0.8)0.92Ce0.08]O3 ceramic. Local deformation of the perovskite unit cells induced by the substitution of Ce3+ and Ce4+ for B-site host ions results in the reduction of the dielectric maximum temperature Tm as x increases. The room temperature dielectric constant and maximum dielectric constant decrease initially and then increase with the increase of x. The frequency dispersion of dielectric constant and the diffuseness of phase transition are found in the Ba(Zr0.2Ti0.8)O3 matrix after cerium doping. And the temperature stability of permittivity is optimized dramatically by moderate cerium addition in Ba[(Zr0.2Ti0.8)1−xCex]O3 ceramics, making these dielectrics promising for multilayer ceramic capacitor applications.

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

L. Dong, D.S. Stone, R.S. Lakes, J. Appl. Phys. 111, 084107 (2012)

O.M. Hemeda, B.I. Salem, H. Abdelfatah, G. Abdelsatar, M. Shihab, Phys. B Condens. Matter 574, 411680 (2019)

X.G. Tang, K.-H. Chew, H.L.W. Chan, Acta Mater. 52, 5177 (2004)

T. Maiti, R. Guo, A.S. Bhalla, J. Am. Ceram. Soc. 91, 1769 (2008)

K.K. Bajpai, K. Sreenivas, O.P. Thakur, A.R. James, A.K. Shukla, Ceram. Int. 43, 1963 (2017)

C. Ostos, L. Mestres, M.L. Martınez, J.E. Sarrion, A. Garcıa, R. Albareda, Perez, Solid State Sci. 11, 1016 (2009)

C. Wei, F. Chunlin, G. Jiacheng, D. Xiaoling, J. Mater. Sci: Mater. Electron 21, 317 (2010)

X. Chou, J. Zhai, H. Jiang, X. Yao, J. Appl. Phys. 102, 084106 (2007)

S.B. Reddy, K.P. Rao, M.R. Rao, J. Alloys Compd. 509, 1266 (2011)

Y. Wang, B. Cui, L. Zhang, Z. Hu, Y. Wang, Ceram. Int. 40, 11681 (2014)

C. Zhang, Z. Zhou, Z. Tang, D. Ballo, C. Wang, G. Jian, J. Alloys Compd. 889, 161622 (2021)

C. Zhang, F. Chen, X. Zhong, Z. Ling, Z. Tang, G. Jian, J. Mater. Sci: Mater. Electron 29, 16730 (2018)

P.A. Jha, A.K. Jha, Ceram. Int. 40, 5209 (2014)

P.A. Jha, A.K. Jha, J. Alloys Compd. 513, 580 (2012)

T. Maiti, R. Guo, A.S. Bhalla, Appl. Phys. Lett. 90, 182901 (2007)

N. Chakrabarti, H.S. Maiti, J. Mater. Chem. 6, 1169 (1996)

N. Binhayeeniyi, P. Sukvisut, C. Thanachayanont, S. Muensit, Mater. Lett. 64, 305 (2010)

B.W. Lee, S.-B. Cho, J. Eur. Ceram. Soc. 25, 2009 (2005)

S.B. Reddy, K.P. Rao, M.S.R. Rao, Scr. Mater. 57, 591 (2007)

S. Yasmm, S. Choudhury, M.A. Hakim, A.H. Bhuiyan, M.J. Rahman, J. Mater. Sci. Technol. 27, 759 (2011)

Z. Zhao, X. Liang, T. Zhang, K. Hu, S. Li, Y. Zhang, J. Eur. Ceram. Soc. 40, 712 (2020)

Y. Pu, M. Yao, H. Liu, T. Frömling, J. Eur. Ceram. Soc. 36, 2461 (2016)

M.H. Yan, G.T. Miao, G.J. Bai, P. Li, J.G. Hao, W. Li, C.M. Wang, G.R. Li, P. Fu, J. Alloys Compd. 937, 168453 (2023)

J.N.O. Amu-Darko, C. Zhang, S. Hussain, E. Issaka, S.L. Otoo, M.F. Agyemang, E.C. Okoroafor, Mater. Chem. Phys. 287, 126328 (2022)

Funding

This work is supported by the Enterprise-University-Research Institute Cooperation Foundation of Jiangsu Province of China (No. BY2022965).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by ZW, YC and CW. The first draft of the manuscript was written by CZ and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that there are no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, Z., Cao, Y., Zhang, C. et al. Structure and enhanced dielectric temperature stability of Ba[(Zr0.2Ti0.8)1−xCex]O3 ceramics prepared by liquid phase coating method. J Mater Sci: Mater Electron 34, 1437 (2023). https://doi.org/10.1007/s10854-023-10879-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10879-9